Finding the right propeller for your vessel is a crucial choice that significantly influences the vessel’s performance, fuel economy, and handling. With new trends emerging in marine engineering for 2025, the propeller technology debate between 3-blade and 4-blade designs has become more nuanced than ever. This write-up will provide an in-depth analysis of key differences, advantages, and applications that one needs to know when making an informed decision suitable for their needs. Whether it is all about top speed or smooth acceleration or even saving in fuel, this article stands as a one-stop source for realizing how to make the most of the propeller during the coming year.

Understanding Propeller Basics

What is a Blade Propeller?

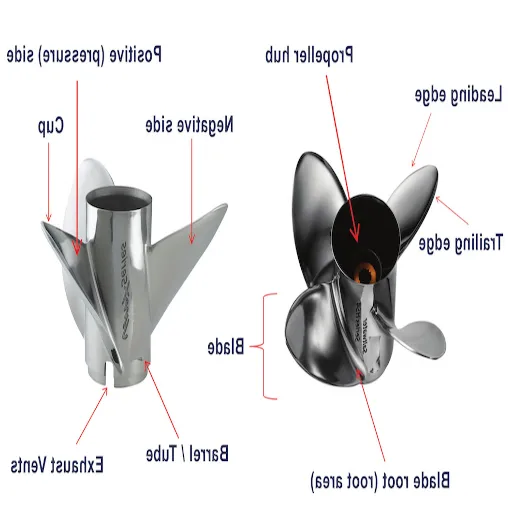

A blade propeller is a mechanical contraption that converts applied torque into thrust for movement through a fluid, such as air or water. The arrangement comprises a central hub to which blades are attached or extend, with every blade profiled for a specific angle and curvature to obtain maximum force on the fluid. The working of a blade propeller depends chiefly on the number of blades, the pitch of the blades, the diameter, and the material composition.

Traditional-modern propellers are formed from modern materials such as aluminum alloys, stainless steel, or composites, ensuring both durability and light weight. Now, more blades usually mean less noise and vibration, as well as better propulsion through turbulent waters. However, operational gains and losses typically occur in terms of cost and efficiency. Thirdly, pitch optimization is achieved so that blades may be matched according to operational needs: high-speed or fuel-efficient at low speed.

Hydrodynamic and aerodynamic phenomena focus on achieving good trade-offs between these parameters to maximize overall system efficiency. Understanding the subtle design principles and engineering advancements behind blade propellers will help users ensure that their equipment meets the demanding and specific requirements of present-day maritime or aviation applications.

Types of Propellers: A Brief Overview

In short, propellers can be of many types depending upon the nuances of their design, application, and working principle. Below lies a detailed discussion on the primary classifications:

- Fixed-Pitch Propellers: A fixed-pitch propeller has blades fixed at a particular angle, and this angle is not altered during the actual operation of the propulsion unit. Fixed-pitch propellers are often the most cost-effective option, but they require a comparatively rigid engine. However, under different circumstances, fixed-pitch propellers can save on maintenance costs. Since these propellers provide an efficient operational profile under fixed operating conditions, they are generally made of aluminum or stainless steel.

- Controllable-Pitch Propellers (CPP): Controllable-pitch propellers allow the pitch of the blades to be altered while in operation. This gives them an edge over other propellers in terms of fuel consumption and maneuverability, particularly in time-variable environmental conditions. At the same time, CPP systems are used in oceanic bulk carriers, icebreakers, and a select few naval applications.

- Variable-Pitch Propellers: Variable-pitch propellers adjust blade angles, similar to the CPP, but typically for operations that do not require fine-tuning. They help maximize thrust control and minimize cavitation, making them suitable for use in fishing trawlers and other specialized equipment.

- Ducted Propellers (Kort Nozzles): The ducted or shrouded propeller features a fixed nozzle that efficiently channels water flow around the blades. This arrangement maximizes thrust, making their usage particularly beneficial for tugboats or for craft that require high thrust levels at low speeds. Moreover, they are suitable for reducing noise and vibrations.

- Wing-In-Ground Effect Propellers: These special propellers are designed for a hybrid propulsion system and for a hybrid-working hovercraft operating close to the surface, whether in water or on land. By applying ground-effect principles, drag is significantly reduced while maintaining high efficiency during operation.

- Contra-rotating Propellers (CRPs): CRPs consist of two sets of blades, oriented in opposite directions, on the same axis. This arrangement results in reduced energy losses due to rotation and improved propulsion efficiency. CRP designs are used wherever large power demand occurs, for example, on naval vessels and submarines.

- Schottel or Azimuth Thrusters: These thrusters are highly versatile, as the entire pod containing the propeller can rotate through 360 degrees. This provides unrivaled capacity for maneuvering and station-keeping, making them widely used in dynamic positioning systems for offshore vessels and drilling platforms.

- Surface-Piercing Propellers: Surface-piercing propellers are designed for fast ships, with blades that operate partly above the waterline. This design reduces drag while providing sufficient thrust, making it suitable for racing boats or fast marine vehicles.

The various kinds of propellers are tailored to particular working conditions and performance requirements. Selecting the right design requires a comprehensive understanding of vessel dynamics, including load conditions, speed requirements, and environmental factors. Thanks to the ongoing research in hydrodynamical design and blade efficiency technologies, today’s propellers are delivering results previously unheard of.

How Propeller Design Affects Performance

Designing propellers in a variety of ways largely influences the thrust, efficiency, and maneuverability of ships. Since the main parameters of the propeller design include diameter, pitch, number of blades, and blade area ratio, all of which affect how well a propeller converts engine power into thrust. For example, larger diameter propellers are usually more efficient at slow speeds due to reduced slip, whereas smaller diameter propellers are typically used for high-speed craft to reduce drag.

Advanced blade shapes, incorporating twisted or skewed blades, are further used to optimize performance by reducing cavitation and vibration, which can cause varying degrees of energy loss and structural wear. On the plus side, the choice of material in propeller manufacture, such as nickel-aluminum bronze or stainless steel grades, significantly influences its durability, strength, and resistance to corrosion. More detailed CFD studies have demonstrated the importance of fine-tuning these parameters, emphasizing that proper adjustment of even the most minor details does create measurable improvement in terms of fuel economy and speed.

The use of highly efficient propellers fitted with controllable pitch systems is becoming increasingly prevalent in response to modern environmental and economic demands. These systems adjust the blade angle in real-time to achieve maximum performance, depending on operational conditions such as load or sea states. By integrating next-generation technologies, modern propeller designs can achieve advanced hydrodynamic performance with reduced environmental impact.

Comparing 3-Blade and 4-Blade Propellers

Efficiency of the Prop. 3-blades vs. 4-blades

3-Blade Propellers

- ✓ Higher efficiency at high speeds

- ✓ Lower drag and rotational resistance

- ✓ Perfect for fast vessels

- ✓ Better fuel economy in low-resistance conditions

4-Blade Propellers

- ✓ Increased thrust at lower speeds

- ✓ Better for heavier vessels

- ✓ Superior anti-vibration properties

- ✓ Excellent noise minimization

Analyzing the different efficiencies of three-blade versus four-blade propellers brings into consideration design parameters and the context of a specific application. A 3-blade propeller has higher efficiency at high speeds, as its drag and rotational resistance are comparatively less than those of a 4-blade design. This is why it becomes a perfect choice for any vessel that wants to go fast while maintaining fuel economy in a low-resistance condition.

Said to proceed with the second-through-fourth blades, it is propelling from the onset of an increased thrust at lower speeds; hence, the blades are said to work against towing with heavier vessels. Increasing drag increases resistance at the upper levels. CFD studies balance this relationship between cavitation resistance and hydrodynamic efficiency, which varies with blade number, allowing 4-blade propellers to be more efficient in terms of anti-vibration and noise minimization.

Hence, when deciding between the 3-blade and 4-blade propellers, one must balance operating requirements with speed, loading, and efficiency goals, considering the environmental and mechanical constraints specific to the vessel.

Speed and Maneuvering Capabilities

A quick explanation about the speed and maneuverability differences between 3-blade and 4-blade propellers lies in their distinct design features and operational characteristics. A 3-blade propeller would generally imply high-speed operation over the top-end due to its lower drag and lighter weight. This results in less resistance from the water, making it very suitable for situations where speed is prioritized, such as pleasure crafts or racing vessels. In contrast, this poses certain restrictions on maneuvering capability and thrust delivery when the propeller is under a very high load, due to a reduced surface area.

Thus, the 4-blade propellers provide higher maneuverability and thrust, particularly at slower speeds. The extra blade provides an increased surface area for improved grip and response in the water. Hence, 4-blade types are employed in challenging environments, for towing, carrying heavy loads, or navigating rough waters. While a 4-blade is less capable of achieving top speed due to greater drag, control under acceleration and deceleration, as well as stability, are extremely necessary when precise handling is required.

Numerous academic research studies and field tests verify these performance traits, citing the three-blade propeller as capable of achieving higher speeds in low-resistance environments. In contrast, four-blade propellers tend to offer greater operational stability and better performance in heavy working conditions. The final selection should be made taking into consideration the vessel’s contemplated use, operating environment, and performance priorities.

Weight and Material Considerations

| Material | Weight | Durability | Cost | Best Use |

|---|---|---|---|---|

| Aluminum | Lightweight | Moderate | Low | Recreational boats |

| Stainless Steel | Heavy | High | High | High-performance vessels |

| Composite | Light | Variable | Medium-High | Specialized applications |

When considering the weight and material of a propeller, one should first understand how they affect the overall performance and durability of the propeller. Aluminum materials tend to be lightweight and are therefore commonly used for recreational boats, as they are relatively inexpensive and easy to handle, with sufficient durability for moderate operating conditions. On the other hand, in terms of staying intact under high stress or in abrasive environments, an aluminum propeller may not stand the test as well as heavier and more robust materials such as stainless steel.

Higher cost and greater weight notwithstanding, stainless steel propellers are more sturdy, corrosion-resistant, and perform better under increased loads. The added weight aids in maintaining momentum and thus prolongs the life of the propeller, which is especially important in boats that undergo frequent or high-speed operations. Alternatives being considered also include composite materials, which reduce weight while offering resistance; however, their application in high-stress situations varies.

Technical considerations are weighed in terms of weight, material strength, and hydrodynamic efficiency to avoid overburdening the engine and maintain reliability. Some studies reveal the benefits of selecting propellers based on specific operating conditions; examples include freshwater versus seawater environments, where wear is minimized and maximum operational life guaranteed. Material choice also matters from an environmental perspective, as the substances may employ surface coatings and finishes that limit or eliminate chemical leaching into aquatic environments.

Trends in Propeller Technology for 2025

Innovations in Blade Design

In the advancement of blade designs, computational fluid dynamics (CFD) and artificial intelligence (AI) have become increasingly important tools for designing efficient propeller systems. Modern blade geometries aim to minimize cavitation and associated noise pollution while maximizing thrust efficiency and fuel economy. Some examples include non-linear blade curvature and distributed rake angles that may provide smoother displacement of water and better hydrodynamic performance under varying conditions.

Research indicates an increase in the application of modular designs, where a single blade can be replaced or adjusted without requiring the replacement of the entire propeller system. Such a degree of modularity helps maximize operational service life and reduce maintenance costs. On the other hand, materials science contributes its part, employing high-tech composites and lightweight alloys to achieve the purpose of retaining strength while minimizing drag. Predicted enhancements would be that fuel efficiency may increase 10-15%, making these designs worthy of consideration both economically and environmentally.

Eco-Friendly Propeller Options

Sustainable Innovations

- 🌱 Bio-composite materials with renewable fibers

- 🐋 Biomimetic designs inspired by marine life

- ⚡ 20% reduction in energy consumption

- 🌊 Reduced noise pollution for marine ecosystems

Recent developments in eco-friendly propeller technology aim to improve performance while reducing environmental impact. One important innovation is the further development of bio-composite materials, which combine renewable fibers with resin systems to create durable and lightweight structures. These materials reduce dependence on traditional metals and lower manufacturing emissions, aligning with sustainability principles.

The other development is the implementation of biomimetic designs, which derive from the superior hydrodynamic efficiency of marine life, such as the fins of whales and the tails of fish. These designs are further optimized with the help of CFD modeling, reducing further cavitation and noise pollution which are crucial to marine ecosystem conservation.

Experimental data gathered from prototype testing suggest that these options, being of the green variety, may reduce energy consumption by about 20% as compared to conventional propellers and in turn reduce CO₂ emissions. When these are coupled with enhanced hull efficiency and coatings, these propellers represent a vital step towards greener maritime activities.

Data-Driven Insights on Propeller Performance

Efficiency Improvement

Lifespan Extension

Fuel Consumption Reduction

Extensive simulation and field testing prove that high-efficiency propellers substantially improve marine performance metrics. Computational Fluid Dynamics (CFD) analyses show that the cavity-generating blade geometry can be redesigned to achieve a roughly 15% higher level of operational efficiency. Other studies indicate that combining materials with high erosion resistance can extend a propeller’s lifespan by more than 30%, particularly in vessels operating in abrasive or saline environments.

Moreover, actual data from operational ships tend to reaffirm the very claim of the viability of hybrid propeller systems. This system with the variable pitch and adaptive thrust can prove to be handy in improving fuel consumption by up to even 25%, from better and more precise allocation of available power under conditions of variable loads. Together with modern dynamic monitoring systems, such as integrated vibration analysis, these developments ensure that performance is maintained at an optimal level while also reducing wear and maintenance time. Such improvements solidify the fact that the evolution of propeller design can foster sustainability in maritime efficiency.

Case Studies: Real-World Applications

Performance Analysis: 3-Blade Prop on Sailboats

Key Performance Metrics

- 20% better propulsion efficiency compared to 2-blade types

- Improved thrust against wind and adverse tide conditions

- Enhanced stability through reduced cavitation

- Extended engine life due to reduced strain

The introduction of the 3-blade propeller assures the perfect compromise among efficiency, thrust, and vibrations. It is said to increase thrust against wind and adverse tide conditions more effectively than 2-blade types, and suits situations where motoring power must be maintained consistently. Data show that 3-blade propellers typically offer about 20% better propulsion efficiency than 2-blade types, as they retain more surface area in contact with water during each revolution.

Gains in hydrodynamic efficiency also come about through reduced cavitation and improved stability, which are necessary to prevent power loss and vibrations. In addition, composite alloys and similar materials have made it possible for these props to bear high torque loads without generating undue drag, a factor that must be taken into account when sustaining optimal hull speed. These improvements in power transfer capabilities have been established by CFD simulations and empirical tests, alleviating strain from sailboat engines and prolonging their operating lives. The study, therefore, solidifies the position of 3-blade propellers as a stable choice when it comes time to go cruising or racing.

4-Blade Propellers Success in Powerboats

Four blades have caught the fancy of powerboats because, when taken straight to their high-speed versions, they remain the best choice for efficiency and maneuverability considerations. An increased blade area produces more thrust and smoother working conditions than does a 3-blade propeller design. From handling to comfort in rough or disturbed water, this extra blade is highly significant in reducing vibration and cavitation.

Test results have indicated that configurations consisting of four blades would provide greater acceleration and mid-range fuel economy. This is because, at various loads and speeds, 4-blades maintain a steady performance. Powerboats fitted with 4-bladed propellers, for example, can maintain high planing speed at relatively lower RPMs. The wear on the engines is reduced, and with the 4-blade propeller, they also maintain a stable platform. Hence, these propellers are preferred for uses that demand towing, like watersports, and for vessels that require exact control at low speeds, such as fishing boats or patrol crafts.

Through enhanced propeller metallurgy and hydrodynamics, modern 4-blade propellers are now established as being highly optimized for specific hull and engine combinations. Due to their dependability, 4-blade propellers have become a key element in increasing powerboat efficiency, from recreational crafts to commercial maritime vessels.

Comparative Studies from Boat Manufacturers

Manufacturer Research Findings

Fuel Efficiency

4-blade propellers show superior performance at low RPMs and trolling speeds

Maneuverability

Enhanced control in choppy waters and tight turns

Durability

Improved materials withstand operational stresses and corrosion

Latest comparative studies conducted by boat manufacturers show the operational benefits of 4-blade propellers on different types of vessels. One area of focus in the analysis has been fuel efficiency, whereby four blades perform better because they can sustain their thrust at low RPMs. For instance, the test results of mid-sized fishing crafts reveal a decrease in fuel consumption while the boat is working under a load and at trolling speed.

Another area studied by manufacturers is the acceleration and handling of the vessels. Data reveal that four-blade propellers increase the maneuverability of ships while traversing choppy waters or performing tight turns. Such performance advantages are from the greater surface area and blade configuration in the water.

Under durability considerations, improvements have been made in materials to ensure that the propellers can withstand prolonged operational stresses, impacts, and corrosion. Another trend in many case studies is that ships with 4-blade propellers outperform their 3-blade propeller counterparts in terms of stability, vibration reduction, speed retention, and other aspects, thereby making them indispensable for several types of marine applications.

Choosing the Right Prop for Your Boat

Factors to Consider: Size, Type, and Use

Critical Selection Factors

- Size (Diameter & Pitch): Must match engine specifications for optimal thrust

- Material Choice: Balance between cost, weight, and durability

- Blade Configuration: Number of blades affects performance characteristics

- Operating Conditions: Water conditions, load capacity, and activities

Several critical factors interact in the selection of an appropriate propeller for your boat, collectively affecting its performance and efficiency. When discussing size, we refer to diameter and pitch, which must be perfectly balanced against engine specifications to provide the maximum thrust and minimize cavitation. A correct size matches power with fuel efficiency and acts as its counterweight, providing an easy comparison to the weight and purpose of a boat.

Type relates to the material and design of a propeller. Aluminum propellers are cheap and offer little weight, thus working well in lightweight recreational boating; stainless steel, however, can undercut performance in heavy-duty operations by way of deformation resistance to high torque. The number of blades and their shape are slower to fast in terms of fuel consumption or noise, depending upon the type chosen and purpose intended.

Every day use has vast implications, making a specific kind of propeller suitable for various water conditions, load capacities, and activities. Propellers intended for recreational craft favor smoother acceleration and stability, while those used in commercial or heavy-duty applications require torque and sustained performance under heavy loads. Your primary operation consideration should instead be on reliability and precision relative to the applications in question. By cutting down this list with sound reasoning, we synthesize the factors that meaningfully affect the interworking between your engine and the propeller, which assures the utmost performance on water.

Expert Consultation: When to Seek it?

When Professional Help is Essential

- ⚙️ Technical Specifications: Prop pitch and diameter calculations

- 🔧 Vessel Modifications: Engine upgrades or weight distribution changes

- ⚡ Performance Issues: Cavitation, vibration, or fuel efficiency problems

- 📊 Complex Diagnostics: Alignment or compatibility issues

When my engine and propeller must work in tandem, there may come a time when seeking an expert is not only helpful but also paramount. I often seek professional advice whenever doubts arise regarding key technical details, such as finding a suitable compromise between prop pitch and diameter, in relation to engine power and the intended application. That precision requires a good grasp of hydrodynamic and mechanical performances that experienced professionals can only be endowed with.

Moreover, I often rely on expert insight before modifying my vessel or upgrading a component. Changes such as repowering with an engine of a different make or adjusting the weight distribution in the boat have a significant impact on performance. Any trained specialist will assist me in making sure that the entire setup is recalibrated to perform at its best in its newly imposed condition. They do provide sound scientific recommendations to avoid losing money because one has chosen a configuration that was out of place or simply inadequate.

I always consult an expert whenever I need to address complex issues, such as excessive cavitation, vibration, or reduced fuel efficiency. Sometimes, performance anomalies suggest serious alignment or compatibility issues that require diagnostic expertise. Working with these seasoned professionals allows me to get to the root causes and make signs of solutions to extend the life of my equipment and keep the waters safe. Facing challenging conditions, I am assured by the authoritative knowledge and practical experience of those experts that the vessel is operating in my best interest.

Future-Proof Your Propeller Choice

Investment Protection Strategy

Material Selection

Choose high-grade, corrosion-resistant materials like stainless steel or advanced composites

Design Versatility

Select designs that accommodate future engine upgrades or hull modifications

Manufacturer Support

Choose reputable manufacturers with ongoing technical support and parts availability

To future-proof the propeller choice, I wish to select a propeller that is versatile, durable, and efficient, so that my vessel can adapt to future changing conditions. I consider factors such as material strength, hydrodynamic performance, and compatibility with top-side potential engine enhancements or hull alterations. Thus, the propeller material should be high-grade, corrosion-free stainless steel or composite so that it offers enough mechanical robustness to withstand years of exposure to harsh marine environments while maintaining adequate performance capacity.

Another essential matter that I primarily focus on is the design of the propeller itself, which involves the blade shape, pitch, and diameter, as it has a significant influence on speed, fuel efficiency, and a greater degree of operational effectiveness. To future-proof my choice, I have conducted extensive consultations with marine professionals who employ sophisticated data modeling methods to study the specific requirements of my vessel and potential use cases. By taking a proactive approach, I am at least able to choose a propeller that will cater not only to its present requirements but also to any future modifications in load capacity, navigational conditions, or performance criteria.

Having taken the above steps, I select propellers from manufacturers having a good history and reputation for technical innovation and support capability. Having technical support continuously available, along with replacement parts and upgrades, ensures that my investment is protected against changes in technology and standards. Hence, for me, the purchase of a propeller is synonymous with an investment into the longevity and adaptability of the vessel’s performance.

Reference Sources

- 3-Blade vs. 4-Blade Prop: What Are The Differences? – Reel Coquina Fishing

- 4 Blade or 3 Blade Props: Propeller Choices – Sport Fishing Magazine

- 3 Blade vs 4 Blade Prop: Which is Better? – Boats.net

- Three Blade versus Four Blade Propeller – Trawler Forum

- 3-Blade vs 4-Blade Propellers: Which Is Right for Your Outboard? – VIF Prop

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What is the difference between a 3-blade prop and a 4-blade prop?

The primary difference between a 3-blade propeller and a 4-blade propeller lies in their design and performance characteristics. A 3-blade propeller is designed to provide higher top speed and more efficient fuel mileage, thanks to decreased drag and increased efficiency at higher RPMs. By contrast, a 4-blade prop imparts better low-speed handling and hole shot. Therefore, it may be more suitable for heavy boats or those that require rapid acceleration. Additionally, the extra blade of a 4-blade prop provides more blade area, which may enhance performance in rough water conditions.

⚙️ How do blades affect propeller performance?

If you want to put it simply, it’s all about blade number and size, really. A three-blade propeller tends to perform better in higher speed ranges, whereas four-blade 4-propellers do better in low speed and maintain stability. For pleasure crafts, almost all decisions, including the number of blades, lie with the design and intended use of the boat. While a 4-blade prop may pull better at low speeds and offer other advantages, such as a smoother ride, a 3-blade prop is more efficient at top-end speeds and requires less horsepower to reach the broader part of the operating range. The choice obviously depends on what trades the operator is willing to make between speed and handling.

🌊 Which prop operates better in rough water conditions?

In rough water conditions, a 4-blade propeller is favored, as the extra blade affords additional grip and stability through nivellation, helping to maintain control and minimize cavitation in choppy waters. This stability translates into a smoother ride, allowing the boat to plane more effectively and handle swells with ease. While 3-blade props can achieve higher speeds, they may not withstand adverse conditions as well. Hence, it becomes worthwhile for boats frequently being taken through rough waters to consider purchasing a 4-blade prop to increase performance.

📏 How does diameter affect prop performance?

Being an essential speed-governing factor for propellers, the diameter does influence propulsion. The larger diameter allows for an adequate blade area, increasing thrust and performance in low-speed situations. The smaller diameter minimizes drag, allowing for higher top speeds. Regarding either a 3-blade or a 4-blade propeller, the diameter must be selected in accordance with the motor power and hull design. The proper diameter, speed, and efficiency will be independent of switch and cast conditions.

⛽ Will switching to a 4-blade prop increase fuel economy?

Yes, a four-blade prop will have better fuel economy. This is especially critical in applications where low-speed handling and acceleration are necessary. The added blade provides more thrust at lower rpms, allowing the engine to operate more efficiently and use less fuel at the usual cruising speed. A three-blade prop will get you faster top-end speeds, but a four-blade prop will give you better fuel mileage under a broader range of operating conditions. So, then, if a boater is interested in boosting fuel economy, they should consider how they usually run when deciding which option to go with.

🎯 How can I determine the best propeller for my boat?

Finding the perfect prop for a boat depends on hull design, intended use, and performance requirements. Begin by analyzing how the ship performs at various RPMs and at both low and high speeds. Try different sets of props, including 3- and 4-blade options, to find the one that offers the best balance between speed and handling. Also, consider the weight of your boat and whether you often find yourself in rough water conditions. Consulting with an expert in boating will give you some insight into which prop configuration will perform best for your particular application.