Choosing the right propeller can have a decisive effect on the performance of your boat regarding speed, balance, and fuel efficiency. The most controversial comparisons in the boating world are the differences between 3-blade and 4-blade propellers. Depending on the type of boat, its intended purpose, and the performance goals, each option comes with its own set of merits. Through a technical and detailed discussion, this article will analyze the differences between these two types of propellers with respect to their influence on speed, fuel economy, maneuverability, and overall efficiency. Regardless of whether you are a leisure boater or a performance fanatic, it is of paramount importance to grasp these subtleties in order to make an educated decision that will not only unlock but also maximize your boat’s full capacity.

Introduction to Propellers

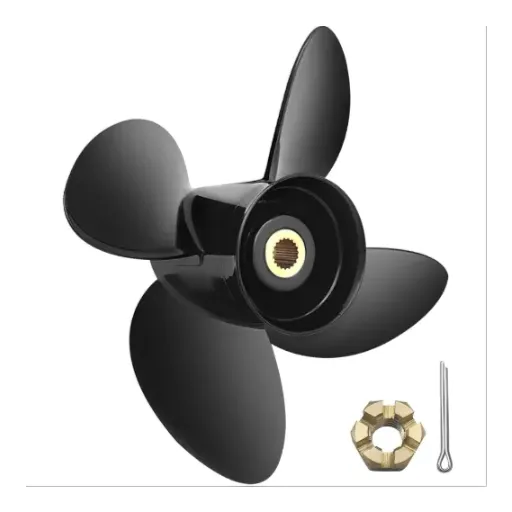

Overview of 3-Blade vs 4-Blade Propellers

3-Blade Propellers: 3-blade propellers are known for their great top speed skills. They cause less drag thanks to their narrow blades and are therefore the best choice for the applications aiming at speed and performance. Moreover, these propellers are the ones that consume the least fuel at high speeds due to the lower water resistance that they create and the engine’s greater efficiency. On the other hand, they might lose some of their handling power at low speeds or when precision is required.

4-Blade Propellers: Four-blade propellers, however, are quite different— they are more focused on control, stability, and smoothness of operation. Their thrust and balance are particularly increased in rough water or with heavy loads, by the extra blade. The configuration gives them a much better locking in the water, which means they will be less hard to turn and will have a better speed thanks to it even at lower speeds. What’s more, 4-blade propellers are very useful in towing, be it water sports or hauling heavy equipment. Although they usually make the maximum speed a little less than that of 3-blade ones, their reliability and adaptability make them a choice of many in the marine recreation and utility domains.

Which propeller to choose between the 3-blade and the 4-blade should depend on the primary application of the vessel. For speed lovers or applications needing maximum velocity, the 3-blade propeller is usually preferred. A 4-blade propeller, on the other hand, if the operator is looking for precision, load handling or better control under different circumstances, offer the most beneficial option. In the end, analyzing the needs of the propulsion system along with the factors like hull design, engine power, and environmental conditions can provide the best combination of performance and efficiency.

Importance of Choosing the Right Propeller

Choosing the right propeller is absolutely crucial to the whole mechanism of the vessel getting the best performance, being the most fuel-efficient, and being the safest. The propeller creates the engine’s work in the best way and thus, the engine is not stressed and the power output is maximized. This is part of the main propulsion system that operates very effectively and efficiently, thus speeding up, maneuverability, and load capacity become the results of the right choice of propeller.

There are mainly the vessel’s purpose, the engine power, and the hull design that the propeller choice is dependent on. A propeller that is used for high-speed performance, for instance, will easily lose its control and efficiency when working with heavy loads or boats in rough waters. On the other hand, a propeller that is perfect for control and stability will not reach the maximum speed but will provide better handling and less power consumption with changing conditions.

💡 Expert Tip: The prompt and comprehensive analysis of the operational needs as well as the environmental factors is the only way to go in terms of making a well-informed choice. It is, therefore, highly recommended to consult the performance charts, the manufacturer’s guidelines, and the certified marine professionals to get the propeller specifications that exactly match the boat’s needs. This not only guarantees long-term efficiency but also decreases the costs of maintenance while improving the overall safety and reliability during the operation.

Trends in Propeller Design for 2025

The propeller design trends for 2025 and onward are all about better materials, hydrodynamic performance, and the environment. One of the major advances is that composite materials are being used more that are strong and light at the same time. Composite propellers benefit not only from fuel savings but also from their resistance to corrosion which results in lower maintenance costs throughout the lifespan of the ship. All these innovations are in accordance with the industry’s efficiency and eco-friendly goals.

The integration of computational fluid dynamics (CFD) into the design process has become another major trend. Engineers can use CFD to optimize blade geometry through simulations so that energy efficiency and noise levels are both improved. This technology allows manufacturers to create designs depending on the specific operating conditions prevailing and thus, performance will be at its best in various vessel types. In addition, wake-adaptive and self-tuning propeller technologies are becoming more and more popular since they offer improved efficiencies in changing conditions which are often met in both commercial and recreational marine operations.

But the biggest and most important factor of propeller design is still sustainability. As a result of stricter global emissions regulations, the industry is moving toward a greener energy future by integrating hybrid or fully electric systems, and thus producing propellers that will not have any problem working with them. Also, the practice of biomimetic designs inspired by nature, such as whale fins or fish tails, is likely to lead to propulsion systems that are both eco-friendlier and more efficient. All these advancements in technology are making it possible for the marine industry to ride the modern times while keeping the environment clean.

Performance Differences

Acceleration: 3-Blade vs 4-Blade

When it comes to the choice between 4-blade and 3-blade propellers, the former are faster for the same power and for the same speed they have smaller drag while the latter give better speed with less power and suposse greater drag.

| Aspect | 3-Blade | 4-Blade |

|---|---|---|

| Acceleration | Moderate | Better |

| Planing | Slower | Quicker |

| Top Speed | Higher | Lower |

| Control | Moderate | Superior |

| Drag | Lower | Higher |

Handling and Maneuverability Insights

To compare the handling and maneuverability of 3-blade and 4-blade propellers it is necessary to analyze their distinct performance attributes of different kinds in each case and then suggest the best one according to the operational requirements. Usually, the 3-blade propellers are associated with a lower drag, which means that the propellers can make the boat move easier through water and also they can be more efficient in high-speed water. Though this design leads to the loss of some accuracy in low-speed driving taking into consideration the specific operations of the watercraft which need the controlled spacing navigation or during docking operation this way the decision must be made very carefully.

On the other hand, the 4-blade propellers provide better control and stability especially at lower speeds. The increased blade surface area is the main reason for the consistent thrust that is generated and the cavitation that is reduced, hence the superior handling. The vapor bubbles created by cavitation that changes the pressure can be a drag on both performance and handling while the 4-blade design manages to alleviate this problem better than its rival. Also, 4-blade propellers are more effective in keeping course stability during rough water conditions, thus they are more often the choice for vessels that operate in such environments.

🎯 Bottom Line: In conclusion, the choice between 3-blade and 4-blade propellers should be matched to the specific handling characteristics of the vessel and its working environment. While high-speed applications usually take advantage of the drag reduction and efficiency of a 3-blade propeller the situations that require precise control, good hold at low speeds, or harsh weather may prefer a 4-blade setup. Moreover, the combination of advanced materials and dynamic balancing in modern propeller technology further develops these characteristics and that is one of the reasons for the safer and more efficient watercraft performance across different use cases.

Fuel Efficiency Considerations

Fuel Consumption Analysis

The fuel consumption of the boat depended directly on different factors such as the ship’s design, engine efficiency, propeller configuration, and working conditions. It was necessary to consider the relationship between engine RPM and fuel usage for optimal performance. Usually, higher RPMs mean more fuel consumed, whereas the slowest efficient cruising speed means less waste and better mileage.

The latest progress in marine engineering has paved the way for the installation of fuel monitoring systems which are capable of giving real-time information on consumption rates. These systems are the fists of operators to adjust performance through tiny changes in speed and load management. For example, it has been found that under standard conditions maintaining optimum cruising speeds and proper trim settings fuel saving can be as high as 15-20%. Also, new hull coatings and regular maintenance of propulsion systems have been used as one of the ways to reduce resistance and simultaneously improve fuel economy.

Therefore, by employing detailed analytics and sophisticated technologies, shipowners can not only reduce their operational costs but also be a part of the eco-friendly practices that the maritime industry is gradually adopting.

Impact of Operating Conditions on Efficiency

The performance of ships is greatly determined by the operating conditions. A range of factors have a direct impact on the fuel consumption, performance, and efficiency of the operation. The following are the five major factors:

- Load Distribution and Weight Management: With improper load distribution, resistance and power consumption of hull would increase. For instance, if the vessel is not distributed well for its cargo, it will lose 10% of the fuel consumption efficiency due to the reduced hydrodynamic efficiency in the case where the cruising speed is the same for the ships under equal conditions.

- Weather and Sea State: Wind, waves, and ocean currents are a few of the environmental factors that affect vessel efficiency a lot. Depending on the situation, bad weather may push the fuel consumption up to 15-30% based on the resistance from the waves and the need for more propulsion.

- Engine Performance and Maintenance: A poor-quality engine or one that is not properly maintained will use a lot of fuel and also emit more greenhouse gases. Operating an engine badly can waste up to 25% of the fuel, pointing to the necessity of frequent checks and following the service schedule suggested by the manufacturer.

- Hull Condition and Fouling: The presence of marine life on a vessel’s hull may lead to a 20% increase in drag thus greatly affecting the vessel’s speed and fuel efficiency. The smooth operation and performance of a vessel depend on its regular application of anti-fouling coatings and the periodic underwater cleaning.

- Speed and Route Optimization: Shipping at speeds that are not optimal or taking the wrong routes can greatly increase the consumption of fuel. For instance, vessels that are running faster than their design speed are consuming more energy more than exponentially due to the resistance caused by the waves, while the longer and energy-consuming routes may also contribute to the pre-determined travel times and thus the costs. Proper planning in voyage using GPS and weather data can save up to 10-15% of the fuel consumption.

Advanced monitoring systems and proactive operational strategies will help maritime operators reduce their environmental footprint significantly and improve their efficiency as a result of addressing these factors.

Cavitation Effects on Fuel Usage

Cavitation is the process that takes place when vapor bubbles are formed and then collapsed around a ship’s propeller due to changing pressure. This very event is not only responsible for the gradual destruction of propellers but also attracts the ship’s fuel inefficiently. the energy that could have been used to push the ship forward is lost in cavitation; therefore, the fuel is consumed more. Below are five effects nicely detailed that cavitation has on fuel usage:

- Propeller Efficiency Reduction: Cavitation acts as a barrier to the proper flow of water around the blades of the propeller, thus decreasing giving push and forcing the engine to work more, so it burns more fuel.

- Vibration and Noise: The burst of vapor bubbles produces a lot of vibrations and noise that can cause poor performance of machines and more wearing of propulsion systems, thus indirectly increasing fuel consumption over time.

- Hull Resistance Increase: The poor-water condition all around caused by cavitation might heavily flow against the hull, thus increasing drag forces. This resistance increase means the engine has to produce more power and hence more fuel usage.

- Erosion and Maintenance Requirements: Cavitation causes pitting damage on propellers; thus, erosion is inevitable. This leads to more frequent repairs or replacements, indirectly affecting the operational efficiency and cost since poorly maintained propellers often lead to higher fuel demands.

- Ineffective Energy Conversion: The energy spent on bubble formation during cavitation is just a waste, leading to an overall reduction in the efficiency of the power used for the propulsive force. This makes the ship consume more energy to reach and keep the desired speeds.

Through advanced propellers designs, regular maintenance, and operational adjustments (e.g., optimizing speed and depth) to minimize cavitation effects, operators can achieve energy efficiency and significantly lower fuel consumption.

Maintenance Considerations

Expected Wear Patterns of 3-Blade and 4-Blade Propellers

The technical aspect of the discussion concerning the wear patterns of 3-blade and 4-blade propellers indicates that these are closely related to their geometry, operating conditions, and the material of the blades. In general, 3-blade propellers experience more stress on single blades because the load is not as well distributed among them as in 4-blade propellers, and thus wear is not only concentrated but also rather uneven, often taking place mainly on leading edges and tips—areas which are most involved with water flow, cavitation regions, and debris.

On the other hand, with their one extra blade, 4-blade propellers are more likely to distribute loads—both mechanical and hydrodynamic—pretty evenly. One of the major benefits of this trait is the reduction of stress on each blade, which further leads to wear that is more or less uniform. Nevertheless, the enlarged area that comes with the extra blade also means that they are more susceptible to biofouling or impact damage during operations in environments where propellers are heavily deployed. The smoother operation of 4-blade designs often negates these problems in terms of providing the necessary stability and efficiency for the vessels that require high levels of reliability in propulsion.

⚙️ Summary: In short, I would say that the expected wear on 3-blade propellers often shows up as spots of localized and very pronounced stress on single blades, particularly in situations of high-speed operation or when the water is dirty with debris. For 4-blade, even though the wear is more even, the operators should be on the lookout for issues such as biofouling and gradual loss of efficiency when the maintenance intervals are not strictly adhered to. The wear and tear and the life span of both types of propellers can be managed and prolonged by good maintenance schedule, periodic material evaluations, and taking environmental factors into account.

Susceptibility to Damage: What to Watch For

Propeller systems, because of the nature of their operation and the associated stresses, are always prone to damage from various sources. Among the different types of damage, cavitation is the most frequent; it occurs due to the vaporization and subsequent collapse of bubbles at the surface of the propeller. If cavitation is not controlled, it can result in pitting, surface erosion, and even loss of strength of the structure with time. Besides, the issue of impact damage is very prominent and such damage occurs when the propeller contacts submerged objects, or gets entangled with marine debris, or if navigation in shallow waters is unexpectedly done. Impact can take forms such as blade deformation, loss of balance, and decline in thrust production.

Corrosion is a continual danger no matter the situation, but it is hard to bear in the case of naval operations where a significant factor is the galvanic corrosion among different metals used in the construction of the propeller. Staying along with the potential for biofouling, which is a very serious phenomenon in marine applications where it increases the resistance and lowers the performance of the machines, these factors put a strong case for active monitoring of the materials to catch wear and tear early on. The stress fractures represent yet another type of damage and they often appear as a result of the propeller operating under extreme mechanical load which subsequently causes the tiny cracks to be amplified with the repeated damage.

Non-destructive testing (NDT) methods that involve regular monitoring like dye penetration tests and ultrasonics can unearth the early signs of damage development. Besides that, the collaboration of improvements in computational fluid dynamics (CFD) and the development of extremely durable materials like composite alloys has reduced the vulnerability to damage by not only improving hydrodynamic efficiency but also lowering the stress concentrations throughout the propeller. The confronting of these perils with the help of modern tools and strict maintenance practices will always be of the utmost importance when it comes to the reliability and longevity of marine propellers in harsh environments.

Cleaning and Upkeep for Optimal Performance

Proper cleaning and upkeep procedures not only prevent but also prolong the efficiency and lifespan of marine propellers, particularly in high-performance and corrosive environments. Inspections done regularly let us know when marine biofouling, corrosion, or cavitation damage appears first. Cleaning techniques that are very advanced, like high-pressure water jets or eco-friendly abrasive cleaning systems, are used to do away with biofouling and debris but keeping the propeller’s surface finish intact.

Applying antifouling coatings is another maintenance activity that has to be done, because these coatings that are specifically developed for this purpose do not let the marine organisms that could cause drag and decrease hydrodynamic efficiency grow on the propeller. The implementation of cathodic protection systems such as sacrificial anodes or impressed current systems can also get rid of electrochemical corrosion for the propellers working in the saltwater environment. The use of measurement tools like hydrodynamic performance analyzers and ultrasonic thickness gauges allows for thorough monitoring of the structural integrity, thus enabling predictive maintenance strategies which shorten the duration of unplanned downtimes.

The combination of a strict cleaning schedule and the use of inspection technologies guarantee that the propeller is always ready for operation, while at the same time, supporting the compliance with ecological and performance standards in challenging marine operations.

Innovations in Propeller Technology for 2025

Sharrow Propeller Technology

Sharrow propeller technology is a remarkable step forward in the field of marine propulsion systems, giving a very effective and creative method to the working of the vessel. In contrast with the regular propellers, Sharrow propeller which has its own patented looping blade design is able to eliminate cavitation and turbulence to a great extant resulting in quiet and very efficient operation. The new design was able to cut the energy going to waste to such an extent that it turned out to be cheaper to have a marine operation commercial sector to get involved in this as a way of fueling their operations and being eco-friendly. The preliminary findings suggest that vessels outfitted with Sharrow propellers may realize up to a 30% decrease in fuel usage during specific operational periods.

Key Benefits of Sharrow Propellers:

- Up to 30% reduction in fuel consumption

- Enhanced thrust and control in rough sea conditions

- Minimized vibrations and noise

- Ideal for luxury yachts, military vessels, and passenger ferries

- Supports IMO 2030 and IMO 2050 decarbonization targets

The Sharrow propeller not only reduces fuel consumption, but also increases thrust and control making it easier to move and steer even in rough sea conditions thus providing good marine environment control. Thus blade design enables the hydrodynamic forces to be controlled evenly with the minimum of vibrations and noises produced. This technology could be considered as the most suitable one for not only shipping industries but also luxury yachts, military vessels, and passenger ferries, where both efficiency and passenger comfort are of utmost concern. The tests that have been done in the lab and by the sea have continuously validated the propeller’s capability of delivering excellent performance through diverse speed and load states.

The far-reaching effects of Sharrow propeller technology go beyond the marine industry and into the domain of environmental protection and compliance with increasingly stringent shipping regulations. These propellers not only help reduce the carbon footprint of the ships but also contribute to the global effort of achieving the IMO 2030 and IMO 2050 decarbonization targets. Ships outfitted with these devices may effectively be said to be operating in an age of green marine, wherein measures of efficiency or reliability are not at stake. Moreover, another round of R&D is going to be conducted that will probably lead to the refinement of this technology further as well as the adoption of advanced materials and manufacturing methodologies that will further improve the reliability and the ease of maintenance. The operators who are looking to innovate and to ensure their vessels will be “future-proofed” can put their trust in Sharrow propeller technology that is based on cutting-edge engineering principles and real-world performance data.

Electric Propulsion Compatibility

The unification of electric propulsion systems with Sharrow propeller technology is a huge step forward in the field of marine engineering. Electric propulsion systems, which are gaining popularity due to their efficiency, reduced emissions, and operational flexibility, are basically powered by electric motors. Sharrow propellers are a great match for these systems as they deliver thrust to the power of the electric motor and, at the same time, improve the hydrodynamic efficiency. The combination even gets more pronounced as these systems have synergistic effects when integrated that along with electric propulsion maximizes the energy usage and minimizes the operational costs, thereby, being in the league of a sustainable approach and a future-oriented solution for the maritime industry.

The main advantage of mixing Sharrow propeller technology with electric propulsion lies in the cutting down of energy wastage. Electric propulsion systems often depend on changing speed control to get the best out of the motor, and the special design of Sharrow propellers guarantees consistent and effective performance over different speeds. This acceptance lightens the load on the propulsion system, cuts down on vibrations, and even allows the ship to perform better overall, and in fact, much better in the roughest sea conditions. Furthermore, the silent operation of Sharrow propellers is in line with the natural noise suppression of electric motors hence, the overall operation profile of the vessel will be quieter and more environmentally friendly.

Tests on field have provided proof that boats with Sharrow propellers and electric propulsion systems consume less fuel (when hybrid systems are deployed), have longer battery life, and better maneuverability in comparison to the traditional setups. Such advantages can be crucial in activities where energy efficiency is the top priority like ferry systems, research vessels, and luxury yachts. It is not only that shipbuilders and operators are becoming compliant with the constantly tightening environmental regulations, but they are also positioned to advantageously compete in the rapidly changing market scenario by the use of these innovations.

Anti-Fouling Coatings and Foldable Designs

Modern maritime engineering heavily relies on anti-fouling coatings that help to biofoul, the attaching of microorganisms, algae, and other marine life to a ship’s hull. Biofouling tremendously boosts hydrodynamic resistance, which means that more fuel is consumed, and operational expenses are increased. Cutting-edge anti-fouling coatings are using both biocidal and non-biocidal methods such as copper-based compounds, silicone polymers, or foul-release coatings to greatly reduce the adhesion of organisms. The latest innovations are all about non-toxic and environmentally safe coatings that conform to worldwide regulations like the International Maritime Organization’s (IMO) bans on harmful substances, thus making the industry more sustainable in the long run.

Foldable designs, on the contrary, are the most modern and advanced architectural style of naval construction. These types of structures are specifically made to get the most out of the vessels’ functionality, especially in places where saving room is absolutely necessary, like in the case of modular ferries or small research boats. The addition of collapsible structures—be it in the form of hull extensions, foldable railings, or even retractable cargo platforms—will pave the way for the creation of vessels that are easily adaptable to different environmental conditions. By this, the shipping industry will not only gain more versatile ships but will also be able to tackle the issues of docking and storage in a more efficient way since there will be less need for these ports or transport systems to have open space ready.

The combination of the use of the latest anti-fouling coatings and foldable designs results in better ship performance, lessened environmental impact, and increased operational efficiency. This method of applying dual technology brings shipbuilders and operators a step closer to the creation of solutions that are both competitively priced and are greatly in demand for being sustainable and flexible. These technological developments indicate the permanent change towards eco-friendly and versatile marine solutions, thereby guaranteeing the existence of the sector which is more and more influenced by technological and environmental hurdles.

References

-

Investigation of the NACA 4-(5)(08)-03 and NACA 4-(10)(08)-03 Two-Blade Propellers

This study provides insights into the performance of different propeller designs, including blade configurations, at high forward speeds. -

Performance and Optimum Design Analysis/Computation for Propeller-Type Wind Turbines

This research discusses the theoretical and practical aspects of propeller blade design, including performance optimization. -

NREL Advanced Research Turbine (ART) Aerodynamic Design of ART-2B Rotor Blades

This paper explores aerodynamic designs and performance characteristics of rotor blades, which can be applied to propeller analysis. - Click here to read more.

Frequently Asked Questions (FAQ)

A: The differences in performance characteristics are the main things to note when comparing a 3 blade and a four blade propeller. A three-blade propeller usually will give you a faster top speed because of its streamlined shape and smaller blade surface area, whereas a four-blade propeller will deliver better acceleration and thus the ability to trust on the water, together making it very useful for lifting heavier boats and improving general performance.

A: The 4-blade prop is preferred in wakeboarding propeller application as its acceleration abilities are superior andits the rides controlled even better. The extra blade not only creates larger wake but also allows for more torque to be generated which is critical factor in the efficient caretaking of wakeboarders.

A: The number of blades a propeller has can play a huge role in both the horsepower demanded and the performance delivered. A 3-blade propeller tends to be more tolerant to horsepower consumption at the same RPM and can plage faster, while a 4-blade propeller, on the other hand, gives you the benefit of stability and the nice side effect of lower fuel consumption but with the disadvantage of not being able to reach the very high speeds in a single run.

A: A 3-blade prop will be the best choice if you are mainly interested in speed. A 4-blade prop, on the other hand, would help any way you want if quickness and maneuverability are important especially if you are going to be a heavy loader.

A: A 4-blade prop does indeed enhance the maneuverability of boats when they have to cross rough waters because of providing better grip and steadiness. Vibration dampening is another helpful factor in a propeller with an additional blade and hence, the ride becomes smoother; thus, making it more approachable for difficult water conditions.

A: Indeed, 3 blade and 4 blade props can differ a lot in fuel consumption. A 3-blade prop can promise a higher maximum speed but only up to a certain point; beyond that, a 4-blade prop and its less throttling ability win on fuel economy which can be beneficial for long trips.

A: When compared purely on acceleration grounds, a 4-blade prop generally takes the lead over a 3-blade one. The presence of an extra blade gives rise to more thrust which means not only faster hole shots but also better acceleration that comes most in handy when starting from a standstill or in the case of towing.

A: In general, more maintenance will not be required for four bladed props as compared to three bladed ones. Still, the propeller’s design and materials may influence maintenance needs. Both must be regularly checked for damage/ wear to ensure best performance.

A: Blade area plays a huge role in deciding between a 3-blade prop versus a 4-blade one especially concerning performance and efficiency. The case of the 3-blade prop is such that it will lose blade area, this translates into higher speeds but the 4-blade prop side of the story is that it will with all the blade area it has (more so than the 3-blade prop) yield better acceleration and gain even more of stability especially in the difficult conditions.

Final Thoughts

Choosing between a 3-blade and 4-blade propeller ultimately depends on your specific boating needs, vessel type, and operating conditions. Whether you prioritize speed, control, fuel efficiency, or versatility, understanding these key differences will help you make an informed decision that maximizes your boat’s performance and enhances your overall boating experience.