When it comes to jet skiing, keeping it in top condition ensures a smooth ride for those out on the water. With time, however, even the best engines may undergo wear and tear, and riders may be forced to decide whether they want to replace the engine or opt for a more suitable alternative. With all the current advances in technical features and a booming tech market, 2025 presents riders with more options than ever before. This article provides an in-depth analysis of the best alternatives to replacing your jet ski engine, examining costs, performance, and durability. If you are an outdoor recreational rider or professional, here are some practical tips that’ll keep the jet ski running perfectly for a reasonable time and money. So, stay tuned as the best alternative is discussed for you to choose, ensuring your excitement on the waves.

Introduction to Jet Ski Engines

Understanding the Importance of Jet Ski Engines

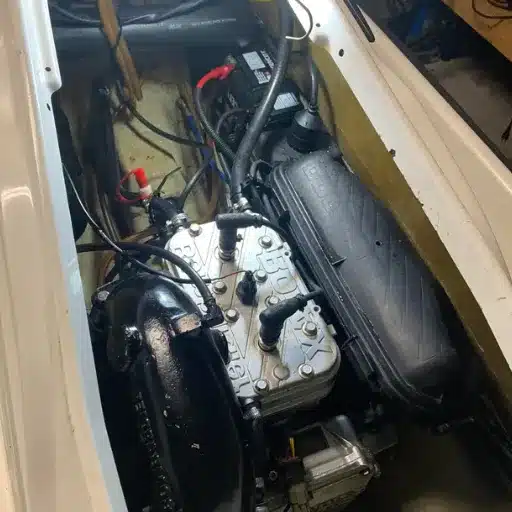

A jet ski engine is the beating heart of these made-for-adrenaline watercraft. This heart drives the exhilaration and adrenaline rush that riders want to experience. It guarantees their optimum speed capacity and maneuvers skills. It may also improve the fuel economy of the jet ski and lengthen its life.

Modern-day jet ski engines incorporate advanced engineering, focusing on maximizing power output while also considering ecological concerns, such as reduced emissions and lower fuel consumption rates. For instance, most manufacturers today are installing four-stroke engines, which are known to be more durable, require less maintenance, and are quieter than their older two-stroke counterparts. This includes good engine care: regular oil changes, proper winterization, and prompt inspections when something doesn’t seem right. Knowing all the above will help owners make informed decisions when it comes to jet ski engine repair, replacement, or upgrade, ensuring that life on the water remains reliable and enjoyable.

Common Issues Leading to Engine Replacement

Jet ski engine replacements are typically necessary due to common problems that, if left unaddressed, would significantly impair performance or lead to engine failure. One such problem is inadequate cooling system maintenance, which can lead to overheating. Overheating causes damage to vital components, such as the cylinder head and pistons, gradually leading to irreparable wear. Another frequent problem is the ingress of water through defective seals or mishandling, which can cause corrosion and internal damage.

Common Engine Problems Include:

- Fuel system failures from clogged injectors to contaminated fuel

- Oil-related problems accelerating wear on moving parts

- Ignition system malfunctions including spark plug issues

- Worn components like crankshaft, bearings, and gaskets

At the same time, fuel system failures can occur in various instances, ranging from clogged injectors to contaminated fuel. These create issues during combustion and unnecessarily stress the engine. On the other hand, oil-related problems may accelerate wear on all moving parts, such as improper lubrication or the use of incompatible oils. In addition, to further reduce engine efficiency and increase strain on it, ignition system malfunctions include problems with spark plugs, incorrect ignition timing, and other similar issues.

Typically, old or heavily used jet skis require the replacement of components that have worn out through use, depending on the extent of wear and tear on the crankshaft, bearings, and gaskets. Preventative maintenance, which includes scheduled inspections and the swift fixing of any minor issues, really assists in keeping the engine running longer between major repairs or even replacements. By understanding common problems, a jet ski owner can identify potential risk factors before they develop, thereby protecting their investment and enhancing their enjoyment of the water.

Overview of Engine Replacement Options

When replacing an engine, the options available will depend on the specific needs, the type of vessel, and the budget. New engines provide an excellent choice, bought directly from the manufacturer. It ensures a new performance, the highest reliability grade, and, in theory, the most recent design available to reduce fuel consumption, lower emissions, and minimize noise. A higher initial investment will be required, but the durability will compensate for it, given that warranty coverage remains.

| Engine Type | Cost | Reliability | Warranty |

|---|---|---|---|

| New OEM Engine | High | Excellent | Full Coverage |

| Rebuilt Engine | Medium | Good | Limited |

| Remanufactured Engine | Medium | Very Good | Good Coverage |

| Used/Secondhand Engine | Low | Variable | Minimal/None |

| Electric/Hybrid Engine | Very High | Good | Manufacturer Dependent |

A further consideration is buying a rebuilt engine. During the rebuilding of an engine, the engine is disassembled, cleaned, worn components are replaced, and the engine is restored to near-new condition. Rebuilds are significantly cheaper than new engines, yet still offer a viable alternative. However, performance and lifespan will depend entirely on the rebuilding process and the parts used.

Essentially, a remanufactured engine is completely rebuilt; elsewhere, it is said that the engine is reassembled to meet one or more performance parameters that exceed those of the original equipment manufacturer (OEM). This alternative is almost certainly warranted and, in fact, subjected to the highest quality control, presenting, instead, a tempting compromise between the new one and the reconditioned one. These kinds appeal to the people who want a stubbornly reliable remanufactured engine at a price well under that of the brand-new replacement.

There is yet another way of looking at them: they are used and or secondhand. Depending on the condition, they can be purchased from junkyards or from the owners of similar vessels, so they may still be in good working order and considered used. The advantages to the buyer are dramatically reduced costs, though there are risks involved in the unknown wear level, not to mention limited or no warranty.

Lastly, modern technology has introduced electric and hybrid engine replacements. These high-end solutions appeal to environmentally conscious boaters, offering lower emissions, quieter operation, and reduced maintenance costs. Please note that this engine option is gaining more acceptance, but factors such as purchase price, battery life, and charging infrastructure should still be considered.

Selecting from these replacement options will enable the boat owner to best match the engine to the vessel’s requirements, performance expectations, and budgetary constraints. Again, some approaches have positive points, while others have drawbacks; hence, it would be wise to carefully consider this for a well-fitting replacement and enhanced enjoyment in boating.

Alternative Options for Jet Ski Engine Replacement

Rebuilding Your Jet Ski Engine

Rebuilding your jet ski engine can be an efficient way to restore the engine. Rebuilding involves disassembling the engine, cleaning its components, replacing worn-out or faulty parts with new ones, and fine-tuning it for optimal performance. The benefit of engine rebuilding is cheapness, so it is usually far less than a complete replacement, especially for older jet ski types for which new stock parts may not be readily available.

Rebuilding Process Steps:

- Complete engine disassembly and inspection

- Thorough cleaning of all components

- Replacement of worn pistons, bearings, and gaskets

- Precision machining of cylinder heads or crankshafts if needed

- Reassembly and fine-tuning for optimal performance

During engine rebuilding, careful consideration is given to replacing pistons, bearings, gaskets, and other parts as warranted by wear. In some cases, precision machining of cylinder heads or crankshafts is also performed, depending on the degree of wear and the requirements for authentic engagement. There is a growing need for an experienced technician to assist with or follow an elaborate rebuilding book, as working with jet ski engines is a job where every detail must be strictly adhered to.

Upgrading with rebuilding presents the opportunity to fit some parts that may improve all aspects of speed, acceleration, and engine life. It also provides the owner with solutions to potentially major problems, such as melting, overheating, or power loss. This is why one must constantly evaluate the overall condition of the engine before deciding to rebuild. Rebuilding cannot be viable when the injury is severe and the engine block itself is compromised.

In Indonesia, the engine rebuild offers a highly tailored approach to enhancing performance and prolonging the life of the jet ski in the water. If they are skilled at it or have access to experienced mechanics, this will be the best solution, offering a good balance of price, performance, and customization.

Aftermarket Engine Swaps: Pros and Cons

When considering an aftermarket engine swap for a jet ski, it is crucial to weigh the pros and cons carefully. With significantly more concerning performance improvements, aftermarket engine swaps present such an opportunity. For greater horsepower, higher fuel efficiency, and state-of-the-art technology, most aftermarket engines typically feature upgraded components, whereas stock engines are not so equipped. For instance, higher torque comes from one engine, while optimized cooling systems come from another, making both highly reliable and enjoyable to ride.

✓ PROS

- Significant performance improvements

- Greater horsepower and fuel efficiency

- State-of-the-art technology features

- Customization to specific needs

- Often more affordable than OEM

- Broader range of choices available

✗ CONS

- Potential compatibility issues

- Increased installation time and labor costs

- May void manufacturer warranty

- Could diminish resale value

- Variable quality and longevity

- Requires extensive research and planning

Another noteworthy benefit is the customization of jet skis to specific needs. Aftermarket options usually offer a broader range of choices, allowing riders to customize their jet skis for speed, long-distance endurance, or cruising with minimal compromise on functionality. Furthermore, aftermarket engines may sometimes be more universally available and cheaper than OEM engine replacements, especially for older or discontinued jet ski models.

Nonetheless, there were a few disadvantages to consider. Aftermarket engines may have compatibility issues, necessitating compromises to fit correctly with the jet ski’s existing components. Such compromises may increase the time and labor costs needed for the swap, and possibly introduce other unforeseen issues. Moreover, choosing an aftermarket engine may void the manufacturer’s warranty and diminish resale value, as some buyers prefer stock setups for peace of mind.

Another downside is reliability, as the quality and longevity of aftermarket engines can vary dramatically depending on the brand and building standards of the aftermarket engines. It is a good idea to conduct extensive research to select manufacturers that minimize these risks. So, while aftermarket engine swaps can breathe new life into your jet ski and enhance its performance, they will also need a great deal of planning and pinpoint execution to ensure you come out with a win!

Use of SBT Engines for Replacement

Jet ski enthusiasts view SBT (Short Block Technologies) engines as a popular and, more importantly, a cost-competitive and reliable replacement option. SBT engines are synonymous with quality and compatibility, striking a beautiful balance between performance and price. All such engines are subjected to stringent remanufacturing standards, whereby each engine must be meticulously inspected, cleaned, and assembled to meet or exceed OEM specifications.

SBT Engine Key Features:

- Available for major brands: Yamaha, Sea-Doo, and Kawasaki

- Comprehensive warranty coverage (typically 2 years)

- Stringent quality control with final testing

- Compression and water jacket integrity checks

- Meet or exceed OEM specifications

Regarding the most significant advantages, an SBT engine is available in various sizes to fit practically every major jet ski brand, including Yamaha, Sea-Doo, and Kawasaki. Besides warranty coverage, users gain assurance of durability and performance for the far future. SBT quality control involves a final stage: the engine is checked for compression, water jacket integrity, and correct operation.

Therefore, if you consider SBT engine installation, you must also factor in the installation costs. It is best to have a trained technician install the engine to avoid problems and maximize performance. This should be followed by continued maintenance and service at intervals recommended by the manufacturer to maintain efficient operation of the engine for years on end. Whether restoration is for recreational jet skiing or competitive, the SBT engines offer the guarantee of a trusted solution, supported by several credible vendors and proven to be reliable.

Comparative Analysis of Popular Engine Alternatives

Kawasaki Jet Ski Engine Alternatives

As for alternatives to Kawasaki jet ski engines, there are specific noteworthy options available to accommodate various needs and preferences, such as performance enhancements or better pricing. Replacement or alternative solutions from Yamaha, Rotax, or aftermarket manufacturers strive for the same level of reliability and durability. For example, Yamaha jet ski engines are worth noting for their smooth power delivery and incomparable build quality, a standard in the PWC industry. Therefore, with their high-performance design and fuel efficiency, Rotax engines meet the needs of those seeking power and agility.

Aftermarket engines are an option for jet ski enthusiasts seeking customization or more affordable alternatives. Many aftermarket manufacturers design engines with upgraded components, providing horsepower upgrades, improved cooling systems, and longer life than the OEM engine. One must ensure that an aftermarket engine is purchased from a reputable manufacturer, as it may compromise reliability.

It is essential to consider how these variants compare to Kawasaki jet ski models, their installation complexity, and the warranty options available to them. Purchasing an engine with lowered emissions and state-of-the-art fuel management technology further enhances eco-friendly efforts while ensuring optimal performance on the water. For jet ski lovers who are conscientious about innovation and long-term returns, these engine box options will ensure balanced performance upgrades while keeping the operating costs.

Honda Aquatrax Engine Options

Engines for Honda Aquatrax watercraft are renowned for their reliability, efficiency, and performance, making them highly favored by jet ski users. They have been equipped with four-stroke engines most of the time, which have a better fuel economy and emit less pollution compared to their traditional two-stroke counterparts. Various Honda Aquatrax engines include the 1,235cc turbocharged motor, which offers a significant amount of power and excellent acceleration, as well as the naturally aspirated 1,198cc unit, which provides a balance of performance and fuel economy.

Honda Aquatrax Engine Specifications:

- 1,235cc Turbocharged: Maximum power and acceleration

- 1,198cc Naturally Aspirated: Balanced performance and fuel economy

- Four-stroke design: Better fuel economy and lower emissions

- Advanced fuel management system: Optimum combustion

- Closed-loop cooling system: Prevents saline intrusion

The key features of Honda Aquatrax engines lie in their advanced fuel management system, which promotes optimum combustion and minimizes fuel consumption. Moreover, these engines operate with a closed-loop cooling method that prevents saline intrusion, thereby increasing the engine’s lifespan and reducing its maintenance requirements. For optimal performance, Honda introduces a lightweight aluminum construction, enhancing speed and handling without compromising durability.

When selecting the right Aquatrax engine, it is essential to choose one based on its intended purpose, whether for recreational or racing use. Models dare to be turbocharged for those high-speed enthusiasts, while natural aspiration will be suitable for those seeking a balance between power and efficiency. Upgrading with Aquatrax engines is highly regarded, as the engine combines innovation with proven longevity to deliver a remarkable water experience.

Performance Comparison: OEM vs Aftermarket Engines

A galaxy of different choices can be thrown into this arena: performance, reliability, price, and the actual variability of the motor. Both options can be viewed as either good or bad in this light. Ultimately, the application should justify the choice; however, once that is decided, the decision may depend on some personal priorities.

| Aspect | OEM Engines | Aftermarket Engines |

|---|---|---|

| Compatibility | Perfect fit without modifications | May require modifications |

| Performance | Consistent, reliable | Often enhanced, customizable |

| Price | Higher initial cost | More affordable options |

| Warranty | Full manufacturer warranty | Variable warranty coverage |

| Quality Control | Stringent standards | Varies by manufacturer |

| Customization | Limited options | Extensive customization |

OEM engines are those specifically designed by the original manufacturer to meet a stringent list of design and performance specifications. These engines are designed for compatibility, where the engine should fit into the watercraft smoothly without any modifications. They have been the benchmark for reliability, consistent performance, and durability over the long term. However, it all depends on your budget, the kind of quality that comes with a price, which may not meet the requirements of those who are more price-sensitive.

Conversely, aftermarket engines afford great latitude in terms of performance upgrades and custom needs. Third-party manufacturers of such engines generally offer gained horsepower, better acceleration, and enhanced fuel efficiency. Such choices are what an enthusiast would be attracted to for performance enhancement. Additionally, prices for aftermarket engines may be on the lower end, making their replacement and upgrade options more affordable. However, one might consider inconsistent quality among different brands and the general need for technical know-how to ascertain correct installation and compatibility.

On another note, the long-term operational costs are significant to consider. OEM engines usually come with a full warranty and reliable servicing options to trim down repair costs as much as possible. However, aftermarket engines, which are often cheaper, may require more maintenance due to varying quality and potential fitment issues.

But in the end, it all depends on the factors on which you base the decision, such as the type of application, constraint of budget, and level of customizations one desires.

Trends in Jet Ski Engine Technology for 2025

Emerging Technologies for Ski Engines

The 2025 advancements in ski engine technology essentially dictate a future where performance, energy efficiency, and a sustainable environment coexist. One prominent trend, then, involves hybrid propulsion systems in which traditional combustion engines are paired with electric motors. It is developing towards one that should use much less fuel and produce fewer carbon emissions, while never having to compromise on power and torque. For instance, these systems are projected to become 25% more fuel-efficient than traditional combustion engines, making them an excellent alternative for those eco-conscious enthusiasts who just love fast rides.

🚀 2025 Technology Innovations:

- Hybrid Propulsion Systems: 25% more fuel-efficient than traditional engines

- Advanced Materials: Enhanced durability with reduced weight

- AI-Based Diagnostics: Predictive maintenance capabilities

- Electric Engines: Zero emissions with near-silent operation

- Solid-State Batteries: Longer range and faster charging

Analysis of variation shows the development in the field of advanced materials whose use is demonstrated in engine engineering. Such materials will enhance the durability of the engine and reduce its overall weight, thereby improving acceleration and maneuverability. Also, the implementation of predictive maintenance through the use of sensors that gather data in real time and AI-based diagnostic systems enables ski owners to keep the engine in check proactively, reducing and even eliminating mechanical failures and, thus, the need for maintenance and repairs; this would give a concomitant increase in service life.

Furthermore, the presence of clean-energy initiatives for promoting electric jet ski engines cannot be discounted. These engines provide users with zero emissions and near-silent propulsion, thereby attracting environmentally sensitive markets and areas with noise regulations. On the other hand, improvements in battery technology, including that of solid-state batteries, appear promising for longer-range capacity and shorter charging times.

Ultimately, these new technologies bring to the forefront an imperative progression toward brighter, cleaner, and more efficient ski engines that fulfill the demands of a fastidious and environmentally aware audience.

Environmental Considerations and Innovations

Since sustainability has become increasingly important in engineering today, major transformations in ski engine design consider it a principal perspective. The major concern from an ecological viewpoint is the reduction of greenhouse gases. Hence, electric-powered ski engines are becoming increasingly popular as a zero-emission alternative to traditional internal combustion engines. These innovations, along with renewables such as solar-assisted charging stations at ski resorts, supply clean energy to recharge the engines.

🌿 Environmental Innovation Areas:

- Zero Emissions: Electric engines eliminate greenhouse gas production

- Noise Reduction: Quieter designs meet environmental regulations

- Clean Materials: Recycled and eco-friendly components

- Water Protection: Prevention of oil leaks and chemical discharge

- Smart Systems: Real-time monitoring for fuel efficiency

Another crucial sector for innovation lies in noise pollution management. Developers are creating quieter engine designs and new, improved sound-absorption materials for the so-called eco-friendly engine concepts, which are intended to meet noise regulations. This heightening of the material technology level has further led to the development of lighter, more durable parts manufactured with the aid of and use of recycled and environmentally friendly materials, resulting in a reduced outlay of resources during their manufacture.

In maintaining water quality and ecosystems, we have clean engine technologies that prevent oil leaks and chemical-drainage discharges. Additionally, intelligent systems embedded in contemporary ski engines track their performance in real-time and maximize fuel efficiency, thereby minimizing resource wastage.

Such developments point to the increasing importance of balancing performance with environmental concern for the eco-conscious customer, as well as the broader global movement against climate change.

Engine Preferences and Trends among Consumers

There is a significant engine preference trend that is driving a strong push toward performance and environmental sustainability. Buyers are increasingly inclined toward hybrid and electric engine systems that reduce emissions and provide long-term savings through improved efficiency. Another trend is the incorporation of various innovative technologies into engines, such as those that provide real-time monitoring and performance adjustments. These new-age features enable users to customize their experiences to suit their individual needs effectively, while maximizing the use of available resources.

Furthermore, engine downsizing has gained significant momentum in design, aiming to produce the same power outputs while achieving a more compact and efficient engine. This approach is attractive to buyers who want cars with low running costs but do not want to compromise on performance qualities. Noise reduction and durability have become essential aspects for many who want engines that provide smooth operation throughout the engine’s life. Lastly, consumer demand reflects an ever-increasing concern for green initiatives, advocating for an engine that does not compromise any of the sustainability goals while retaining good practicality and power.

Case Studies and Real-Life Experiences

User Testimonials on Engine Rebuilds

💬 Customer Testimonial #1

“I’m going to say I wasn’t quite sure what to expect when I finally decided to rebuild my engine; the results far surpassed my expectations. It was a whole new thing for my vehicle to increase the performance and efficiency levels. Almost immediately, I could feel how much smoother the engine’s running was, and I even noticed a decrease in fuel consumption. At the same time, the rebuild procedure can keep quite a bit of change in my pocket, which is a blessing in disguise for me. This decision has been rewarding to me because it now saves time and is practically maintaining the vehicle.”

💬 Customer Testimonial #2

“Rebuilding an engine is what changed my life. Initially, I was concerned about whether it was an expense worth having, but the whole experience was made pleasant by the competent professionals. They went through the entire process with me, explaining all the details and adapting it to fit my needs. Since its rebuild, I have driven thousands of miles with confidence, knowing that my engine runs perfectly, just like it did when it was new. It’s a decision I would highly suggest to any others in such a situation.”

💬 Customer Testimonial #3

“An engine rebuild brought life into my engine in an environmentally friendly manner. I was looking for a solution that would lessen waste and encourage sustainability initiatives, and an engine rebuild fit the bill well. It restored performance on the level I needed while supporting my values by avoiding all the harm a new engine manufacturer and shipping would cause. I am proud that I have taken a path beneficial both for me and the environment.”

Forum Insights on Engine Swaps

From my experience, an engine swap could do wonders to increase engine speed or extend the life of an older car, but ideally, one needs to prepare and carefully consider it. This procedure would entail the removal of an existing engine and the installation of another, whether it is an identical one or a different type. Before making a final choice, you have to check the new engine’s compatibility with your car’s transmission, wiring, and other features. I have noticed that thorough research, including advice from forums and experts, usually goes a long way to making or breaking a project.

📝 Key Forum Insights:

- Thorough compatibility research is essential before starting

- Some swaps are plug-and-play, others require extensive customization

- Professional help may be necessary for complex installations

- DIY swaps can save money but require time, skills, and tools

- Forums provide valuable troubleshooting tips and experiences

Perhaps the greatest lesson learned from the various forum conversations is the importance of selecting the right engine and setting the proper expectations for it. For instance, some swaps are straightforward plug-and-play cases that require few modifications, while others may entail extensive customization, from engine mounts to wiring harnesses. Being aware of both the technical challenges and the costs involved prevents unpleasant surprises down the line.

Moreover, online forums teach us to either seek professional advice or partner with a reliable mechanic where technical expertise becomes daunting. Many enthusiasts emphasize that DIY swaps are cheaper, but time, skills, and tools must be readily available. Therefore, the balance between confident budget limitations and seeking professional help becomes the basis upon which to execute a successful engine swap that improves the vehicle’s performance and reliability. Forums are packed with advice, sharing experiences, and troubleshooting tips to lead you through the process.

Analytical Data on Replacement Engine Performance

Based on my experience with replacement engine performance, there are a few key points that consistently emerge as indicators of success. The first step is to determine the engine’s baseline performance in terms of horsepower, torque, fuel economy, and reliability. When these are compared to the vehicle’s standard engine, it determines whether the conversion actually improves performance. In fact, I have observed that engines equipped with newer fuel injection systems generally tend to perform better in terms of efficiency and power delivery compared to older carbureted systems.

📊 Performance Analysis Framework:

- Baseline Assessment: Measure horsepower, torque, fuel economy, and reliability

- Compatibility Check: Ensure proper tuning and drivetrain integration

- Diagnostic Monitoring: Use live data for optimization

- Long-term Tracking: Monitor durability and maintenance trends

- Preventive Maintenance: Follow recommended service intervals

Another vital aspect to consider when examining compatibility is that even after an engine swap done by the book, incompatibilities in tuning or the drivetrain might bottleneck performance. From personal experience using diagnostic tools that provide live data concerning cylinder pressure, air-fuel ratios, or exhaust gas temperatures, I view such knowledge as being priceless. It allows for using the information to adjust the settings to suit the engine’s output best, while further decreasing wear and tear.

Lastly, and probably most importantly, do not disregard long-term performance trends. Data collected from one or more months of usage reveals useful durability and maintenance traits. I recall instances where improper engine installation led to accelerated component wear, thereby reducing reliability. Early intervention in possible problem areas becomes simpler if properly observed maintenance intervals and running conditions are in place. That is the best way to ensure the newly replaced engine performs according to standard and beyond specific performance measures over time: a thorough and data-informed approach.

Reference Sources

-

Exploring Alternatives to Replacing Your Jet Ski Engine – Captain Propeller: Offers insights into engine overhaul upgrades and advanced maintenance options.

-

Alternative to SBT Engines – Greenhulk Forum: Discusses quality rebuilt engine alternatives and user experiences.

-

The Best Jet Ski Repairs and Upgrades To Do Over Winter – SBT Blog: Highlights repair and upgrade options like replacing worn-out parts and improving performance.

-

What to Do About a 2025 FX Cruiser Jetski – Facebook Group: Shares user experiences and advice on handling jet ski engine issues.

-

What Are the Best Options for Rebuilding a Jet Ski Engine – Kawasaki Jetski Group: Discusses rebuilding options and dealership availability for engine repairs.

- Find more info now.

Frequently Asked Questions (FAQs)

❓ Can I Rebuild My Jet Ski Engine Instead of Replacing It?

This jet ski engine rebuilding can be an alternative to a full replacement. It involves dismantling the engine, inspecting the parts, and replacing any worn components, such as pistons, gaskets, and seals. Rebuilds retain more of the original parts, thereby saving the customer money. It requires some mechanical skills or the know-how of a good mechanic. However, the engine’s performance post-rebuild may not always be restored to its original level, so consider your options carefully.

❓ What Advantages Does a Remanufactured Engine Pose for My Jet Ski?

Buying a remanufactured engine can be a wise choice instead of replacing your jet ski engine entirely. The engines are rebuilt to factory specifications, thereby ensuring performance and reliability. Most remanufactured engines come with a warranty of approximately two years, instilling confidence in potential buyers. These engines are significantly cheaper compared to new engines; thus, they hold a bigger share of popularity among many watercraft enthusiasts. Big names such as Yamaha and Sea-Doo very often offer remanufactured engines for some of their more popular jet ski models.

❓ Are There SBT Engines Available for My Jet Ski Model?

Jet-ski engines with an SBT make are popular choices among potential jet-ski buyers seeking an engine replacement at a lower cost. These machines are designed explicitly for PWC, offering decent performance at an affordable price. Warranty is also an option from SBT — usually lasting two years — which suits some individuals. It should instead consider fitting compatibility with SBTs for its jet ski model, as SBTs are used by Honda, Yamaha, Sea-Doo, and others. Thus, opting for an SBT engine will likely provide you with a reliable power option for your watercraft.

❓ How Do I Maintain My Jet Ski Engine for Longevity?

Jet ski engine maintenance must be taken seriously to ensure the longevity of your engine. Checking your pump, changing water, oil, and fuel filters periodically will maintain performance and keep your jet ski engine from expensive repair bills. Additionally, it is essential to monitor the cooling system closely to ensure the engine operates at its optimal temperature. Preventing issues is always preferable by conducting periodic checks on your electrical system and throttle. Engagement in maintenance issues discussed in fishing gateways or YouTube videos could prove quite helpful.

❓ What Are Some Things I Should Consider When locating a Repair Shop for Jet Ski Engines?

When performing repairs or requiring modifications to your jet ski engine, you want to ensure you’re dealing with an authentic repair shop. Inquire about watercraft repair shops specializing in these engines and services. Their reputation can be checked out through Google reviews or specialized boating forums. For credibility, the repair shop must back its work with warranties and use decent-quality parts, as these can significantly impact your jet ski’s performance and durability. Ask about their experience in repairs with Sea-Doo or Yamaha equipment, just to be sure that they are familiar with your watercraft.

❓ What Are the Signs That My Jet Ski Engine Needs Replacement?

Several signs may indicate a need for a more comprehensive repair than a minor issue with a jet ski engine. A heavy loss of power, excessive smoke, or peculiar noises, such as knocking or grinding, are signs of possible severe internal damage. The engine is also suspect if it has difficulty maintaining idle or exhibits compression losses; these may be indicative of mounting issues or impending replacement. Monitoring performance regularly enables the early detection of these adverse effects. Sometimes, it is beneficial to consult with a mechanic who can thoroughly inspect the issue to determine if a rebuild, remanufactured engine, or complete replacement would be more suitable for the case.