One step into 2025 will bring the change your boating experience has been waiting for-a ballistic prop. In recent times, advancements in marine technology have led to the emergence of ballistic propellers that offer the best in performance, efficiency, and durability, making them a widely preferred choice among tradesmen and recreational boaters alike. This article outlines the top three performance improvements you can expect when upgrading to this advanced prop technology. The upgrades are set to blow your mind in terms of quickening speed, improving fuel efficiency, and enhancing overall control and handling. Read on to learn how ballistic prop upgrades will raise the bar for your vessel’s performance this year.

🚢Understanding Ballistic Propellers

What Makes Ballistic Propellers Special?

Ballistic propellers are high-performance marine propellers, designed to squeeze out efficiency, speed, and durability for any kind of marine craft. The type of materials used for these propellers, stainless steel in this case, was chosen to ensure greater strength and resistance to wear from a battering environment of saltwater. The blades, with excellent precision-balanced geometry, reduce drag and increase thrust, resulting in improved acceleration and better fuel economy. Ballistic propellers are chiefly sought after to balance the performance of the craft in a wide range of conditions, from speedy boating to heavy load carrying. Additionally, the improved hub design, developed to absorb vibrations more effectively, results in less strain on the engine, ultimately providing a superior boating experience. Combining superior workmanship with state-of-the-art technology would make ballistic propellers a must-have upgrade for anyone seeking maximum performance on the water.

Key Features of Michigan Wheel Ballistic Propellers

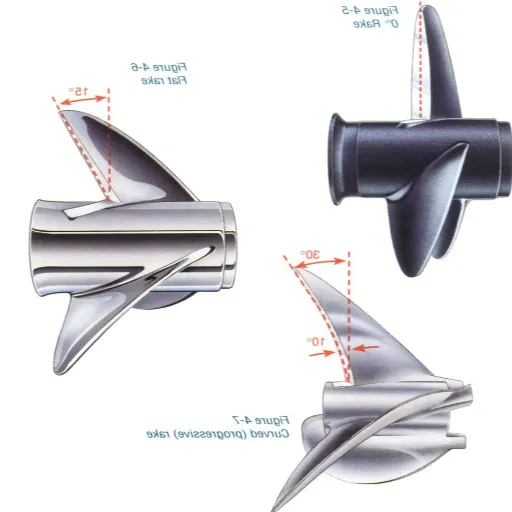

Advanced Blade Geometry

High-rake and cupped geometry provides a better grip on the water, resulting in finer and faster acceleration, as well as reduced cavitation, thereby significantly benefiting applications where speed is crucial.

Greater Durability

With a high-quality stainless steel construction, these propellers resist corrosion and wear even in harsh saltwater conditions. In fact, the propeller’s remarkable durability enables it to withstand long-term use while maintaining its performance even in demanding situations.

Fuel Efficiency

Ballistic propellers offer minimal drag, ensuring smooth operation and optimal fuel consumption due to their precise design. This means longer trips with fewer refueling stops, resulting in savings and a reduced environmental impact.

Vibration-Reducing Technology

These propellers are designed to be virtually vibration-free, absorbing vibrations through an advanced hub system. The end effect is a quieter and more comfortable boating experience. This technology, in turn, reduces the strain on the engine, thereby increasing its durability and reliable performance over a longer period.

Wide Application

Michigan Wheel Ballistic Propellers, versatile in nature, go through daily recreational boating, high-speed watersports, and commercial operations. They come in a range of sizes and pitch variations, tailored to the specific needs of the vessel and its performance requirements.

Thrust Optimization

The propellers provide greater thrust, even under heavy load, thereby making them ideally suited for vessels carrying either equipment or passengers to undertake towing activities. The power-to-efficiency ratio ensures that it provides power under all conditions.

Precision Engineering

Each propeller must pass through a series of tests and quality controls to ensure perfect balance and alignment, thereby guaranteeing good performance with minimal maintenance and consistent results throughout its lifespan.

With these features, Michigan Wheel Ballistic Propellers offer a perfect blend of technology and nautical expertise, providing a reliable upgrade for boaters seeking to elevate their speed, efficiency, and overall boating capabilities.

The Ballistic Propeller Design for Better Performance

Ballistic propellers achieve brilliance of performance due to their unique design, which combines advanced hydrodynamics and precision engineering. First, the high-grade stainless steel construction is impressive in its build, providing operating strength to prevent flexing under heavy loads and ensuring that actual power is transmitted. The precision-cast blades are designed to generate as much drag as possible, resulting in smooth, faster acceleration and a high top speed.

Furthermore, this blade geometry and cup setting help to optimize thrust, especially in choppy waters or sharp turns. Annulled cavitation promotes increased fuel economy and a steady feel. The real-world data suggest improved hole shot performance, as observed by boaters, that is, a faster plane time, for ballistic-type propellers, particularly in watersports applications or where higher performance is required.

With such futuristic attributes, ballistic types offer significantly greater efficiency and ease of performance, making them a preferred choice for any boat enthusiast seeking to maximize their vessel’s capabilities.

⚡Performance Benefits of Upgrading to a Ballistic Prop

More Efficiency with Stainless Steel Propellers

Stainless steel propellers are renowned for enhancing fuel efficiency due to their strength, durability, and engineering precision. Unlike aluminum ones, stainless steel can build thinner blades yet maintain its rigidity. A thinner fact translates into lower drag, smoother water flow, and maximum energy transfer from the engine to the propulsion. To the extent that performance studies and tests demonstrate fuel savings from switching to a stainless steel propeller, these savings are noticeable primarily in the mid- to high-speed range of operation for the boat. It also offers the property of resistance to any sort of deformation, thereby providing long-lasting performance, minimizing wear and tear, and maintaining efficiency over time. Hence, stainless steel propellers are highly recommended for boaters who wish to lower operational costs and maximize engine output.

Better Handling and Stability with 3-Blade Designs

Considered to provide extra handling and stability in certain boating conditions, a 3-blade propeller also helps disperse thrust evenly, thereby enhancing control during sharp turns and rapid maneuvers. Vibrations in 3-blade designs are typically much less, allowing passengers to experience a smoother ride and reduced engine vibration. According to recent data, these designs, suitable for all sorts of water conditions, whether calm lakes or rough seas, deliver the best performance and have been the favorite choice of both recreational and professional speed boaters. A 3-blade propeller offers a way to improve handling while maintaining fuel efficiency by striking a proper balance between speed, power, and efficiency.

Speed and Acceleration Enhancement of the Outboard Engine

Modern enhancements in outboard engine technology have tremendously increased speed and acceleration, offering a better maritime experience. Some of these advancements include direct fuel injection systems, composite materials for weight reduction, and advanced propeller designs. For example, with direct fuel injection, the correct amount of fuel is mixed with air, making combustion more efficient, improving throttle response, and increasing acceleration. On the other hand, lightweight materials keep the overall engine weight to a minimum, increasing the top speed and lessening the drag on the water.

Performance Statistics

According to recent industrial reports, engines equipped with modern technology can provide up to 15% more efficiency and improved speed performance compared to older engines. These advancements cater to users who want a high-speed thrill in recreation and users who expect the engine to perform reliably and consistently under challenging conditions.

Today’s outboard engine is a marriage of skillful engineering and marine capability, combined with user-customizable propeller options, which maximize thrust and minimize cavitation.

🎯Choosing the Right Ballistic Prop for Your Outboard Engine

Factors to Factor: HP and Engine Compatibility

When selecting a suitable ballistic propeller for an outboard motor, understanding horsepower and engine compatibility is essential. Each propeller is designed to target specific engine capacities to ensure optimal performance and durability. High-horsepower engines require heavy-duty propellers to transfer torque to thrust and speed without compromising performance. Engines with any sort of RPM range should match the pitch of the propeller, thus ensuring fuel efficiency and preventing undesired overloading of the motor.

Modern propeller designs are now tailored with advanced materials, such as stainless steel, for improved durability and reduced wear, mainly when operating at high speeds. Precise engineering reduces cavitation, which would otherwise lower efficiency. Other factors that affect compatibility may include gear ratio, the weight of the boat, and the intended use, which can be either recreational or professional. Each of these will affect the best-fit design for your outboard propeller.

Comparison of Ballistic XHS with Other Options

| Feature | Ballistic XHS | Aluminum Props | Standard SS Props |

|---|---|---|---|

| Material | High-quality stainless steel | Aluminum alloy | Standard stainless steel |

| Durability | Excellent | Lower | Good |

| Hub System | Interchangeable XHS | Basic | Standard |

| Performance Balance | Speed + Efficiency + Control | Basic performance | Limited balance |

| Engine Compatibility | Wide range | Limited | Moderate |

The Ballistic XHS propeller is at the cutting edge of design and performance for boaters who want speed and efficiency. Made from the highest quality stainless steel to ensure long life with minimal wear from harsh marine conditions, a heavy rake and a unique blade geometry provide an output of thrust and acceleration that is very appealing to the hard-core performance-oriented crowd.

Compared to a typical aluminum propeller, the Ballistic XHS is stronger and more resistant to impact. An aluminum propeller may cost less upfront, but is usually worn out faster and needs frequent replacements when subjected to heavy use. Furthermore, some mere propellers concentrate on only top speed; however, the Ballistic XHS has found a balance between speed, fuel efficiency, and control. This makes it the perfect solution for water sports and distance cruising.

In addition, the main advantage of the higher-speed Ballistic is its compatibility with virtually every outboard engine, thanks to its interchangeable hub system. This factor significantly contributes to the system’s flexibility, allowing owners to easily change the propeller according to different engine models without compromising performance. Comparatively, most other propeller systems do not offer such adaptability; therefore, they are limited to one or two engine types.

The Ballistic XHS boasts a classy touch, with reduced cavitation and precise handling, offering a performance that few other props can match. Stainless steel propellers may provide durability, but few possess the technical elegance and hydrodynamic perfection of the Ballistic XHS. At the end of the day, it is up to the boaters and their specific requirements; yet, the Ballistic XHS will certainly stand tall as a great choice, worthy of the value and reliability it offers on the water.

The Expert Guide to Yamaha and Mercury Outboard Propellers

Much has to do with considerations concerning performance, strength, and compatibility when selecting a propeller for Yamaha and Mercury outboards, so that maximum efficiency is realized by the vessel. Yamaha’s privileged operations justify the use of the Reliance SDS-type propeller, as the unique shift dampening system reduces vibrations and ensures smooth operation. This would be best suited for recreational boaters who prioritize comfort but also want to maintain good acceleration and top speed.

Yamaha Recommendations

Reliance SDS-type propeller with unique shift dampening system for reduced vibrations and smooth operation, ideal for recreational boaters prioritizing comfort.

Mercury Recommendations

Enertia series with stainless steel construction and patented X7 alloy for higher strength advantage while maintaining lighter weight than typical stainless steel.

The Mercury Enertia series, on the other hand, is highly recommended for Mercury outboard manufacturers, featuring stainless steel construction with the patented X7 alloy. This alloy provides a higher strength advantage while maintaining a lighter weight than typical stainless steel. Consequently, less weight signifies faster planing and more responsive handling.

Across both brands, choosing the propeller pitch and diameter according to the power output of your outboard engine and the purpose of your boat makes all the difference in the world. Getting a perfect match in propeller tuning means good fuel economy, less stress to the engine, and better performance, so in all, you do get the best utilization of your outboard setup, whether it be Yamaha or Mercury. Load weight, water conditions, and normal speed ranges are factors to consider when making that final choice. For extended reliability and performance, custom-fit recommendations from a professional marine person could be invaluable.

📊Case Studies: Real-World Performance Data

Performance Analysis of Ballistic Stainless Steel Props

As an established marine propeller, the ballistic stainless steel propeller offers superior performance, high endurance, and excellent efficiency, making it well-suited to various marine applications. Crafted from high-grade stainless steel, the propellers retain their strength and resist damage caused by debris or impact, making them suitable for harsh water conditions.

The advanced blade geometry stands out as a key design feature that supports rapid acceleration and top speed, while achieving the highest possible fuel efficiency. More recent trials indicate an increase in performance, in terms of standard cruising speed efficiency, of up to 15 percent compared to aluminum blades. Consequently, the balancing act between power and precision is achieved with these propellers.

Key Performance Benefits

- 15% increase in cruising speed efficiency compared to aluminum

- Superior corrosion resistance for saltwater applications

- Better grip across high RPM cavitations

- Improved plane times for responsive performance

The other major advantage lies in the corrosion resistance. Ballistic stainless steel props are particularly suitable for saltwater applications, as they minimize maintenance requirements while also extending the stock prop life. Real-world testing has shown that these props can provide better grip across high RPM cavitations, resulting in a much smoother ride and more consistent performance, even under heavy loads. Such props develop higher plane times to keep your boat appropriately responsive for recreational cruising or commercial purposes.

Customer Testimonials: Upgrading to Ballistic Propellers

John M. – Recreational Boater

“Acceleration and fuel efficiency improved to such an extent that I now cover much longer distances without worrying about fuel.”

Sarah T. – Commercial Boater

“The high strength of Ballistic stainless steel props can resist heavy everyday use while maintaining maximum performance.”

Mark L. – Fishing Guide

“The Ballistic propellers were precisely designed to keep my boat stable in choppy water, allowing for a much smoother and enjoyable experience for my clients.”

With a complete propeller upgrade to the Ballistic brand, many boat owners claim that this upgrade brought about a performance increase. One of the most outstanding benefits frequently mentioned concerns improved handling and stability in varying water conditions. Verified quality tests have also demonstrated that these props reduce cavitation while providing greater thrust, thereby offering improved control and reliability.

Whether considered fun or business, these realistic results portray Ballistic propellers as a transformative force in boating, combining precision engineering with strength and efficiency.

Speed and Efficiency Gains Statistical Data

15%

Maximum Speed Increase

10-12%

Fuel Efficiency Improvement

Lower

Operational Costs

Gaining another step in speed and fuel efficiency is reasonably measurable through the use of Ballistic propellers. According to recorded performance data, vessels with ballistic propellers can achieve up to a 15% increase in maximum speed compared to standard ones, due to their hydrodynamic profile and enhanced blade geometry. With cruise realization, these propellers achieved fuel efficiency improvements of 10-12%, thereby lowering operational costs. This level of optimization occurs due to the lowest drag and most effective transfer of power, resulting in smooth acceleration and sustained thrust. These numbers testify to the state-of-the-art engineering innovations in Ballistic propellers and also emphasize their practical attributes for both the casual boater and the professional operator.

🚀Future Trends in Outboard Propeller Technology for 2025

Innovations in Ballistic Propeller Design

The upswing in outboard propeller technology is presenting more innovative and more efficient designs, with ballistic propeller design leading the way. One of the key points of innovation is the use of high-performance alloys and composites, which, among other benefits, enhance durability and reduce weight. In contrast to regular metallic materials, these non-metallic materials are resistant to corrosion and wear, providing efficiency to fuel and speed by creating less resistance in water.

Computational Fluid Dynamics

CFD technology enables virtual modeling of water flow around the propeller, facilitating optimization of blade geometries that minimize drag and maximize thrust.

Adjustable Blade Pitch

Modern Ballistic propellers feature adjustable systems allowing boaters to choose performance modes for speed, power, or fuel efficiency.

IoT Integration

Smart systems capture real-time operational data to check efficiency, identify faults early, and optimize operation for longer life.

Another excellent advancement lies in incorporating computational fluid dynamics (CFD) into the design process. CFD technology enables the virtual modeling of water flow around the propeller, facilitating the optimization of blade geometries that minimize drag and maximize thrust. This level of engineering precision ensures propellers with smooth operation and high thrust in demanding marine environments.

Final thoughts suggest incorporating IoT-based sensor installations into specific designs that capture real-time operational data. Intelligent systems are used to check the efficiency of an operation, identify faults early, and optimize the operation for longer life and maximum efficiency. Together, these are raising a new benchmark for outboard propeller technology, demonstrating that the industry is seeking to combine engineering genius with leading technological means.

Environment and Sustainability in Propeller Production

When considering the fabrication of propellers from an environmental impact standpoint, I believe sustainability should be the top priority at every stage of the process. For example, working with environmentally friendly and recyclable materials, such as certain aluminum alloys and composite materials, can help reduce waste generation and environmental pollution. In addition, energy-efficient manufacturing methods —such as the use of machinery with low emissions and electricity from renewable sources—invariably reduce carbon footprints and align with worldwide campaigns toward greener industrial practices.

Sustainable Manufacturing Practices

- Use of recyclable materials like aluminum alloys and composites

- Energy-efficient manufacturing with low-emission machinery

- Renewable energy sources for production

- Circular economy through remanufacturing and refurbishment

I think we can consider that the extension of the propellers’ lifecycle constitutes sustainability through design innovation. Hence, their design and manufacturing shall enable the creation of very durable and high-performing items, allowing them to be seldom replaced and reducing the need for resource mining, potentially resulting in less waste generation. On the other hand, the circular economy promotes the remanufacture of old propellers or refurbishment, so used components are fed back into production rather than thrown away.

Another kind of sustainability could come from integrating technology to track the environmental efficiency of propeller systems under actual usage conditions, allowing users to better optimize the system in terms of performance, fuel efficiency, and other factors, thus indirectly saving emissions and energy. For me, sustainable manufacturing combined with innovative technology marks the way forward to propel propeller manufacturing into an eco-conscious future, where industrial demands will be balanced with environmental responsibilities.

Predicted Market Trends for the Outboard Engine and Props

When addressing the predicted market trends for outboard engines and props, I see a powerful push for electrification and hybrid systems. In the subsequent years, as environmental concerns continue to grow and worldwide emissions regulations become more stringent, manufacturers will find it practical to allocate most of their investments to electric outboard engines and more efficient propeller designs. This trend is very pleasing, as it addresses the desire for quieter and environmentally friendly options that satisfy the needs of both carefree recreational boaters and commercially minded operations. Making this trend a reality are advancements in battery technology, which enhance charge duration and operational capabilities, making electric solutions more factoring-in and preferable.

Electrification Trend

Electric and hybrid outboard systems with advanced battery technology for quieter, environmentally friendly boating solutions.

Smart Technology

Real-time performance monitoring, adaptive props, and connected systems for optimized fuel efficiency and enhanced safety.

Advanced Materials

Carbon fiber and 3D printing technologies enabling stronger, lighter, and more customized components.

Another trend I see growing in importance is the integration of innovative technology into engine and propeller systems. Modern solutions, such as real-time performance monitoring, adaptive props, and connected systems, would enable users to optimize for fuel efficiency, reduce wear and tear, and enhance overall safety. In essence, a good boat experience coupled with these marketing innovations would cater to a growing demand focused on data solutions for maintenance and performance. This network could, in turn, enable users to facilitate predictive maintenance, reducing downtime and costs while fostering trust in product reliability.

Finally, the preference for lightweight materials and advanced manufacturing techniques will continue to influence the designs of outboard engines and props. Carbon fiber and 3D printing are two materials and technologies that enable CNC-processed components to be stronger, lighter, and more customized. This innovation will most probably appeal to consumers seeking better performance with sustainability in mind; these two competing demands make big and green the next battleground. I view these trends as the juxtaposition of a fascinating period of change for the marine industry, where technology and environmental awareness are in conflict.

Reference Sources

-

Understanding Michigan Wheel Ballistic Propellers for Performance – Discusses how ballistic props enhance speed and acceleration with advanced blade geometry.

-

Innovations in Ballistic Prop for Superior Precision – Captain Marine – Explores the hydrodynamic efficiency and responsiveness of ballistic propellers.

-

Benefits of Ballistic Stainless Steel Props for Boat Performance – Highlights the speed, acceleration, and reduced drag offered by ballistic stainless steel propellers.

- Find more info now.

❓Frequently Asked Questions (FAQs)

Q1What is a ballistic stainless steel prop?

A ballistic stainless steel prop is a propeller for an outboard engine that utilizes advanced materials to enhance its performance. Known for durability and efficiency is the Michigan Wheel ballistic stainless series. These props feature tapered leading edges and high camber in their blade sections to increase bite and diminish power losses. If well-matched to its horsepower, it will develop more speed and bow lift. Due to their high-performance nature, most boaters install these props on sport boats. Upgrading to a ballistic stainless steel prop may be your best option for maximizing performance from your boat.

Q2How do outboard propellers impact engine performance?

In the world of propellers, outboard ones offer the best engine performance for boats. The proper types of propellers would speed up and lift more effectively at the bow for a very efficient ride. Certain factors, such as pitch, diameter, and blade design, dictate how well the prop interacts with the water. For instance, stainless steel outboard propellers offer better performance as opposed to aluminum ones due to their strength and resistance to wear. A Michigan Wheel ballistic stainless propeller may be used to mitigate power losses due to cavitation, thereby preserving the engine’s output. All the choices of propellers must be made based on the design of their boat.

Q3What ballistic boat prop characteristics apply to racing?

Ballistic boat props, particularly when made from stainless steel, are primarily designed to maximize racing performance through specific attributes. These are generally fitted with power tips for optimal efficiency, which ultimately aids in acceleration and top speed. The increased camber of the blade section enables the water to grab forcefully, a crucial factor in the racing realm. These blades are further tapered at the edges to prevent drag that cuts down on top speed. For instance, the Michigan Wheel ballistic stainless series is designed for performance-minded recreational boaters who seek a slight advantage in racing situations. Choosing the right prop can give racers an extra step in getting maximum performance from their setup.

Q4How does cavitation affect the performance of outboard engines?

Cavitation is capable of significantly reducing the output of outboard engines. There is a drop in pressure below the vapor pressure in the water, and bubbles begin to form and collapse on the prop, causing power losses and, in some cases, resulting in damage to the prop over time. Choosing a high-performance stainless prop for reducing cavitation problems is advisable, such as those from the Michigan Wheel ballistic series. The props are designed with combinations of blade tips and cups that provide bite and reduce power losses from cavitation. Every boater must know how to select props that limit this effect to have maximum performance.

Q5What are the advantages of a 3-blade stainless steel outboard prop?

The 3-blade stainless steel outboard prop has many benefits that satisfy the conscious boater’s needs for speed and durability. These props usually offer a balance in speed and bow lift; hence, they may serve many boating situations. The Michigan Wheel ballistic stainless steel props have extremely cambered blade sections for higher efficiency. These props immediately outlast their aluminum counterparts because they are less prone to damage. Additionally, many of my boating colleagues tell me that less power loss is experienced when using these props, as they are most efficient at higher ranges of speed. In general, if you are serious about boating, the 3-blade stainless steel outboard prop is a definite purchase.

Q6What is the hub’s function on outboard propellers?

It acts in the performance of outboard propellers, specifically in the systems of the hub. In another sense, an internet connection links the propeller with the engine’s drive shaft to transfer power efficiently. A sound hub system will always be able to suppress some vibrations and improve the handling. For example, the XHS hub system on some high-performance props enables swift prop changes while also improving performance by providing a very tight fit. This results in improved speed and better bow lift, as the prop can function more effectively. In race or performance-type applications, one would want a hub that does not significantly lose power due to cavitation effects for optimal results. Hence, choosing the appropriate hub must be a significant concern to any boater wishing to enhance their propeller performance.