The world of boating technology stands on the precipice of major revolutionary advances, and 2025 seems destined to become a landmark calendar year for innovations in boat propellers engineered specifically for Mercury outboard motors. Rising faster and faster, combined with demands for efficiency, sturdiness, and speed, is the propeller design itself being pushed to new vistas, so to speak, to meet changing expectations of boaters. This article delves deeper into the innovative changes that are affecting performance and upending the entire boating experience. From materials and hydrodynamic design to improved fuel efficiency and greener technologies, we will explore how these innovations provide an advantage to both recreational and professional boaters. Whether they are looking to push the boundaries of performance or work on sustainability, all of these insights should unlock some inherent potential in their Mercury outboard motors. Stay tuned as we unravel the trends that shape the future of high-performance boating.

Understanding Mercury Outboard Motors and Their Propeller Needs

Brief Mercury Outboards Engines

Mercury outboard engines establish their name in the boating community through modern technology, reliability, and unmatched performance. Offering versatility to cater to practically every need, adventure, or technical application, these engines come with features such as direct fuel injection to enhance fuel efficiency and reduce emissions, along with precision-built components that ensure smooth and powerful performance on water.

Key Features: One of the key factors that established Mercury as an eco-friendly brand is its massive effort toward lighter-engine design and efficient fuel economy, thereby offering its customers the luxury of an extended cruise with minimal environmental impact. Additionally, Mercury outboards typically feature digital control and monitoring systems that provide real-time performance data and integrate seamlessly with navigation systems. Such intelligent systems provide boaters with all the controls they can think of, thereby ensuring safety while also enhancing the boating experience.

Engines vary in models, ranging from the small and portable types ideal for small crafts to high-horsepower ones that offer breathtaking speed and performance. With strong engineering and consistent innovation, Mercury outboard engines remain among the top choices for those seeking quality, durability, and versatility in marine performance.

Propeller Necessity in Outboard Performance

Performance, efficiency, and feel when operating an outboard motor are heavily dependent on propellers. A propeller acts as a link between a motor’s power output and a ship’s movement. Hence, the various factors like design, material, and pitch of a propeller control speed, acceleration, and fuel consumption:

Design Considerations:

- Three-blade propellers: Typically used for higher speeds and good top-end performance, making them a favorite among recreational boating enthusiasts.

- Four-blade or five-blade propellers: Offer the benefits of smooth operation and excellent thrust control—the best combination for towing, watersports, or running in rough water.

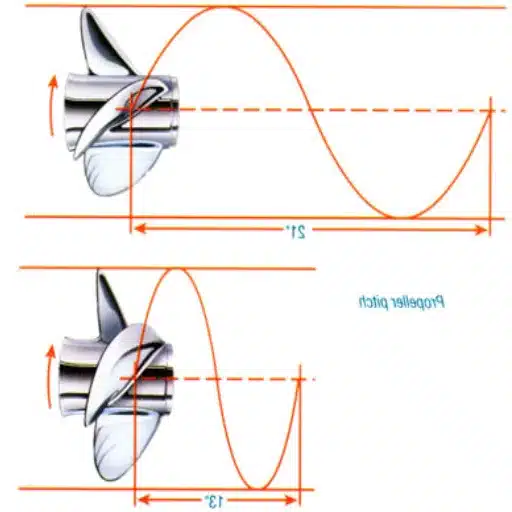

Propeller pitch, theoretically, the distance a propeller would move in one revolution if there were no resistance from the water, is another crucial factor. Hence, a small pitch accentuates acceleration, but the drawback lies in its limited top speed capacity. On the other hand, a large pitch provides for a higher top speed, making it more demanding for an engine to develop peak performance. Thus, selecting such an optimal balance on which the engine operates without being overloaded will surely enhance durability with fuel economy.

| Material | Characteristics | Best For |

|---|---|---|

| Aluminum | Light, relatively inexpensive, performs well in calm water conditions | Recreational boating, freshwater use |

| Stainless Steel | Greater durability and performance in harsh conditions, heavy loads, saltwater environments | Professional use, saltwater, high-performance applications |

Technology has brought some innovations into the world of propellers, including variable-pitch propellers and new anti-cavitation designs that reduce drag while maximizing thrust behind the outboard. Together with advanced engineering, the designs ensure a smooth ride, comfortable handling, and extended lifespan.

Understanding the relationship between these aspects when selecting a propeller is essential for the full output of an outboard engine. It enables the boater to modify their configurations depending on application, from high-speed racing to relaxed fishing, thereby increasing both fun and competence.

Types of Mercury Propellers Available

Mercury Marine propellers suit a large variety of boaters’ applications, each optimized for performance on its own. These vary from aluminum to stainless steel, depending on the durability required and the amount they can afford to pay for it. Here is a breakdown of these main categories:

Aluminum Propellers

Aluminum propellers are lightweight, inexpensive, and best suited for casual or recreational boating. They offer the user a reasonable price and are primarily suitable for smaller boats or engines. Modern designs utilize a highly efficient blade geometry that enhances acceleration and efficiency, leveraging materials principles to ensure durability for use in freshwater.

Stainless Steel Propellers

Stainless steel propellers are most suitable for high-power performance applications or harsher environments, such as saltwater boating, due to their strength against deformation. They also offer higher top speeds and improved fuel economy, thanks to their rigid structure, which optimizes accuracy and further reduces flexing. Although stainless steel propellers come at a higher price, their lifespan and performance justify the cost.

Performance Series Propellers

Designed for the speed enthusiast, this series focuses on boosting maximum top speed and acceleration. They are sophisticatedly designed, featuring high rake angles and special blade shapes, which are perfect for high-speed racing boats and watersports. Models such as Fury and Tempest are often commended for efficiency and nimbleness.

Four-Blade Propellers

These four-blade propellers prioritize smooth handling, quick planing, and excellent rough-water performance. Although popular among offshore and fishing enthusiasts, they are ideal for those seeking more grip and control, as well as lower-speed maneuverability. They also maintain their pace during momentary load shifts.

Dual-Prop Systems

Mercury’s dual-prop systems, such as the Bravo Three series, utilize counter-rotating propellers to enhance finer controls and thrust. Such setups excel in situations where large vessels are involved or heavy towing is done since they provide much-needed stability and downforce against cavitation under harsh working conditions.

Eco-Friendly Propellers

With increasing pressure on the environment, Mercury has introduced an eco-friendly option for propellers, designed to provide fuel efficiency and a positive overall impact on the environment. From pitch to blade area, these propellers enable engine efficiency improvements that, in themselves, result in cleaner boating experiences.

Quality Assurance: Each Mercury propeller is subjected to stringent tests to ensure it meets the manufacturers’ high standards for performance and durability. Factors to consider when selecting a propeller include boat type, engine specifications, and intended use. Understanding these options will enhance the potential for both novice and professional boaters to achieve the performance they want while remaining reliable on the water.

Popular Mercury Propeller Options for 2025

Aluminum vs. Stainless Steel Propellers

When deciding which choice of propellers is suitable for finer adjustment to the combinations of characteristics proper to theirs, the boater must equip himself with some knowledge. Aluminum propellers are a conventional choice for recreational boats due to their low cost and lightweight nature. They work well given standard conditions and can provide a cheaper alternative to those who want to ply the waters at moderate speed. Aluminum, however, is less durable than stainless steel and can bend or be damaged when handled in rough circumstances.

Aluminum Propellers – Pros & Cons

Advantages:

- Low cost and lightweight

- Good for standard conditions

- Ideal for moderate speeds

- Perfect for recreational boats

Disadvantages:

- Less durable than stainless steel

- Can bend in rough circumstances

- Limited performance in harsh conditions

Stainless Steel Propellers – Pros & Cons

Advantages:

- Higher performance and longer life

- Resistance to impact and wear

- Better fuel economy

- Higher top-end speed

Disadvantages:

- More expensive initially

- Heavier than aluminum

In contrast, with a focus on higher performance and longer life, stainless steel propellers are designed. They are ruggedly constructed to offer higher resistance against impact and wear, making them a better choice for high-horsepower applications or in rough-water conditions. Additionally, stainless steel propellers are more efficient, which, in turn, offers better fuel economy and a higher top-end speed. While stainless steel propellers are more expensive initially, they are worth it in the long term, offering reliability and performance, which are more critical to the frequent or professional boater.

Recommended Applications:

- Aluminum propellers: Great for small engines on smaller boats such as pontoon boats, small fishing boats, and PWCs. This provides a truly balanced match between performance and price for the casual user.

- Stainless steel propellers: Ideal in applications where precision and power are paramount, such as offshore fishing, racing, or any high-performance motoring. They keep their shape even when subjected to high stress, thus delivering solid performance with a little bit of grit in challenging situations.

Well, the choice between aluminum and stainless steel propellers depends on the specific needs, available means, and operating conditions. Choosing one over the other, and its proper application, can maximize your boat’s performance, fuel economy, and longevity, enabling an easy glide and a smooth time on the water.

Highlights on Enertia and Fury Propellers

Inertia and Fury propellers are truly the embodiment of design and performance and hence are a favorite among those who seek speed, efficiency, and precision for their motorboat. In simple words, both models are designed with the latest engineering technology to give you, boaters, a choice to pick the one that best suits your style of driving and performance.

Enertia Propellers

Enertia propellers are built with mercury-proprietary X7 alloy, providing the most significant strength while offering special properties that allow blades to be thinner and more efficient in design. This ensures that acceleration and top speed are achieved without compromising on structural integrity.

Key Features:

- Mercury-proprietary X7 alloy construction

- Thinner, more efficient blade design

- Excellent fuel efficiency

- Superior control and maneuverability

- Ideal for long-distance cruising

Fury Propellers

Fury propellers are built to cater to fast boating and tournament anglers who want speed and accuracy. Such a huge prop serves explosive holeshots for rapid takeoffs, thanks to its large blade surfaces and carefully calculated pitch angles.

Key Features:

- Explosive holeshots for rapid takeoffs

- Large blade surfaces

- Carefully calculated pitch angles

- Strong construction for heavy loads

- Perfect for competitive anglers

The Enertia propeller type excels in fuel efficiency, making it an ideal choice for boats that require steady performance during long-distance cruising or watersports activities. The smaller range of engine RPM changes allows better adjustment to varying conditions, giving superior control and maneuverability.

Its lift qualities at both bow and stern complement speeding potential, notably on heavy bass boats. Thanks to its strong construction, unreasonable loads cannot compromise the performance of the Fury, thus enabling competitive anglers to reach their destinations quickly and in a well-timed manner.

Both propeller choices work wonders in enhancing the boating experience by catering to individual needs. Whether it is fuel efficiency, quick acceleration, or enhanced top speed that you want, the Enertia and Fury prop draft selections will give you a reliable boost that you will feel on the water.

Comparative analysis of the Spitfire and Enertia Eco models

The two models, Spitfire and Enertia Eco, cater to boaters who demand efficiency, versatility, and top performance over-the-water experiences. Yet, each conforms differently to the individual’s will and wishes.

| Comparison Factor | Spitfire | Enertia Eco |

|---|---|---|

| Design & Structure | Four-blade design for smaller boats and mid-range engines, enhances acceleration and handling | Advanced X7 Alloy (30% stronger than stainless steel), thinner blades for reduced drag |

| Performance Focus | Quick acceleration and hole shots (15% faster to plane than traditional three-blade) | Fuel efficiency (10% better fuel economy at medium to high speeds) |

| Best Applications | Water sports, fishing, shallow/inland waters, recreational boating | Deep-sea fishing, cruising, long-distance trips, eco-conscious boating |

| Durability | Durable for lighter applications, may require more maintenance in heavy/saltwater use | Superior corrosion resistance, excellent for offshore and saltwater applications |

| Target User | Water sports enthusiasts, fishing anglers seeking quick responsiveness | Eco-conscious boaters, long-distance cruisers, fuel-efficiency focused users |

Conclusion: Overarching, choosing between the Spitfire and Enertia Eco is a matter of personal preference. The former offers a taste of agility and speed suited to smaller crafts, whereas the Enertia Eco combines performance efficiency and eco-friendliness for larger, fuel-conscious tours. The two are keepers of innovative design, representing the performance tailored for taste and demands in boating.

Trends in Boat Propeller Technology for Enhanced Performance

Innovation Driving the New Generation of Propellers

Advancements in technology are opening up new avenues for performance, efficiency, and sustainability in marine propellers. One such advancement is the use of composites. Lightweight yet sturdy, these materials further improve fuel efficiency by reducing the overall weight of the vessel, and they also offer superior corrosion resistance compared to standard metal alloys. They acquire more years of service under challenging marine weather conditions. At the same time, some manufacturers are employing 3D printing capabilities in other ways; propellers with complicated geometry can be produced, especially when customized to a hull’s geometry and its operational requirements. The precision manufacturing thus imparts the optimized speed and drag reduction.

🔬 Advanced Composites

- Lightweight yet sturdy materials

- Superior corrosion resistance

- Extended service life

- Improved fuel efficiency

🖨️ 3D Printing Technology

- Complex geometry production

- Customized hull optimization

- Precision manufacturing

- Optimized speed and drag reduction

📊 Smart Sensors

- Real-time performance data

- Engine load monitoring

- RPM tracking

- Hydrodynamic flow analysis

🌿 Eco-Friendly Design

- Sustainable coating materials

- Reduced marine biofouling

- Energy-efficient designs

- Minimal emissions optimization

Another vital evolution is facilitated by the pluralization of smart sensors integrated in the propeller systems. Sensors, therefore, provide real-time data on performance, including engine load, RPM, and hydrodynamic flow. Operators can then adjust their vessels for optimum efficiency. At the same time, hydrodynamic simulation software is being improved so that engineers can utilize testing and refinement in the digital arena, minimizing the trial-and-error approach as much as possible in the physical prototyping phase.

Lastly, sustainability remains committed to the propeller design, utilizing eco-friendly coating materials that significantly reduce marine biofouling and energy-efficient designs optimized for minimal emissions. These green propulsors will align with international efforts aimed at reducing the carbon footprint of the maritime industry, marking a new chapter in innovation for the next generation of propellers.

Impact of Design on Performance and Efficiency

The design of propellers influences efficiency and performance in all aspects of maritime operations. CFD simulations, aided by state-of-the-art materials, enable engineers to formulate blade geometries that maximize hydrodynamic performance. This essentially entails minimizing drag while maximizing thrust. For example, reducing fuel consumption through the optimal pitch, diameter, and skew angle of propellers has been proven to achieve an energy efficiency of approximately 10-15% in some vessels.

⚡ Performance Improvements

Energy Efficiency:

10-15% improvement in fuel consumption through optimal design

Weight Reduction:

Carbon fiber composites maintain strength while reducing weight

Cavitation Prevention:

Vented tips and anti-cavitation designs minimize energy losses

Furthermore, the division of building materials is bringing a revolution with the use of lightweight materials such as carbon fiber composites. They reduce the weight of the propeller structures while maintaining strength and durability, hence improving propulsion efficiency. These developments, along with innovations such as vented tips and anti-cavitation designs, minimize energy losses and sustain structural integrity by preventing wear caused by vibration induced by cavitation.

Modern designs in propulsion gears must be intelligent and data-driven to meet the rapidly evolving requirements of performance, safety, and environmental concerns in the increasingly competitive and dynamic maritime sector. Mechanically, these improvements lower operational costs; therefore, they also support the increasingly strict environmental regulations evolving globally.

Data-Driven Propeller Performance Perspectives

Computational modeling and analysis have modernized the strategies for analyzing propeller performance; therefore, they are also used today for optimization purposes. By utilizing data science, engineers can more effectively analyze thrust efficiency, cavitation patterns, and noise emission values. Of particular interest are CFD simulations, which help assess water flow dynamics around propeller blades and give detailed insights into areas of potential energy loss or turbulence.

📈 Data Analytics Applications

- CFD Simulations: Assess water flow dynamics and identify energy loss areas

- Real-time Monitoring: Sensor data provides insights on load changes and wear conditions

- Predictive Maintenance: Historical performance data enables proactive maintenance scheduling

- Performance Optimization: Continuous data analysis improves operational efficiency

Hence, real-time sensor data coming from different vessels enriches the opportunities to monitor and adapt performance parameters. Load changes, wear conditions, and operational efficiency-related information can be conveyed through these sensors for stakeholders to inform their decisions on maintenance and design. This type of sensor information, when combined with data on previous performance, can help develop predictive maintenance schedules that reduce downtime and operational costs.

Working together, these data-driven methods ensure the design of propellers that are successful and in line with environmental criteria, while balancing the dual goals of the maritime industry: efficiency versus sustainability. Advanced analytics are soon pushing the envelope in propeller engineering, while fine-tuning how vessels operate within an increasingly competitive market.

Factors Affecting Mercury Propeller Selection

Understanding Pitch and Diameter

Pitch and diameter play crucial roles in determining how a mercury propeller performs. The pitch indicates the distance the propeller would theoretically move forward in one full rotation, assuming zero slippage. Hence, a high pitch offers high speeds that may affect acceleration and are suited for high-speed vessels. A low pitch, however, is beneficial for thrust and acceleration, making it ideal for accelerating heavy loads or cruising at low speeds.

⚡ High Pitch

- Advantage: Higher top speeds

- Best for: High-speed vessels

- Trade-off: May affect acceleration

- Application: Racing, high-performance boats

🚀 Low Pitch

- Advantage: Better thrust and acceleration

- Best for: Heavy loads, low-speed cruising

- Trade-off: Lower top speeds

- Application: Fishing boats, heavy cargo

The diameter is the total width covered by the circular path of the propeller blades. The larger the diameter, the more thrust it generates, and thus benefits vessels that require the power to overcome water resistance. On the contrary, smaller diameters would increase velocity by lessening drag. Pitch versus diameter should be balanced so that the propulsion system is in constant proportion to the vessel’s weight, engine output, and purpose.

🎯 Application Examples

Recreational Boat (20ft, 2,500 lbs):

High-pitch, smaller diameter, three-blade propeller for maximum speed

Cruiser (35ft, heavy load):

Lower pitch, larger diameter, four or five-blade propeller for handling weight

For instance, a lighter recreational boat equipped with a high-performance engine would benefit from a propeller with a higher pitch and lower diameter to emphasize speed. Conversely, a large, hard-working fishing boat would require a lower pitch in propeller diameter to generate the necessary torque and pulling power. If all these factors are taken into account, along with their intricate relationship, boat owners can further enhance their operational efficiency toward specific performance goals.

Evaluating Boat Size and Weight Considerations

Boat size and weight are of prime importance, which significantly influences propeller considerations for optimal performance. Bigger and heavier boats require larger diameter and smaller pitch propellers to generate sufficient thrust for adequate gliding and handling loads. Smaller and lighter boats require smaller diameter and higher pitch propellers for increased speed with reduced drag.

| Boat Category | Weight Range | Recommended Propeller | Primary Focus |

|---|---|---|---|

| Small Recreational | Up to 2,500 lbs | High-pitch, 3-blade, smaller diameter | Top speed |

| Medium Cruiser | 2,500 – 8,000 lbs | Balanced pitch, 4-blade | Performance & handling |

| Large Vessel | 8,000+ lbs | Lower pitch, 4-5 blade, larger diameter | Thrust & load handling |

For instance, a 20-foot recreational boat that weighs 2,500 pounds may be best suited for a high-revolution-per-minute, three-blade propeller for top speed. However, the 35-foot cruiser requires a four-blade or even a five-blade propeller that will provide a larger surface area and enhance the performance of the added weight.

Being conversant in the relationship between weight and water resistance is essential. The heavier the vessel, the more water it displaces, and the propeller is obliged to wrestle up against a larger resistance to keep on steadily accelerating without taxing the engine. Selecting the proper propeller according to the boat’s weight class enhances performance, prolongs engine longevity, and ultimately saves fuel.

Price vs. Performance: Finding the Right Balance

Deciding on the perfect propeller for your boat entails balancing price and performance. Typically, high-priced propellers contain special features for enhanced durability, superior materials, and advanced engineering optimizations to work with utmost efficiency; however, this is beyond what many people can afford. On the contrary, a less expensive propeller might be ideally suited for lighter use or typical applications. In contrast, one that requires specialized use or long-lasting performance may find it inadequate.

💰 Cost-Benefit Analysis Framework

Budget-Friendly Options

- Aluminum propellers

- Standard engineering

- Good for casual/recreational use

- Lower upfront investment

- May require more frequent replacement

Premium Performance

- Stainless steel construction

- Advanced engineering features

- Superior durability and strength

- Long-term fuel savings

- Higher initial cost, better ROI

One crucial aspect to consider is the choice of materials. Stainless steel propellers are positioned at the upper end of the price scale. Still, they also offer greater durability and strength compared to aluminum propellers, which are cheaper alternatives but cannot withstand corrosion as well. The workmanship of the blades can be the very essence of the propeller’s performance. A propeller featuring finely engineered pitch and blade count may potentially yield fuel savings and smoother acceleration, thereby offsetting higher upfront costs with sustained savings over time.

💡 Smart Investment Strategy: Based on the needs of being on the water, such as speed, load, and average conditions in the waters, one should be able to gauge the performance one really needs. Evaluating the cost of a particular investment against its term and use renders the proposition worthwhile, as it meets expectations and serves dependably without incurring unwarranted expenses.

Choosing the Right Dealer for Mercury Propellers

Key Considerations When Selecting a Dealer

For Mercury propellers, I typically advise my clients to visit dealers with a well-established reputation and proven expertise in marine products. These are dealers certified by Mercury to ensure that the vendor offers genuine products and is provided with information on the latest propeller models and updates. Having a quick check on testimonials and online reviews can give some perspective on the vendor’s reliability and quality of service. My attention is also drawn to their expert advice, which is specific to my needs, particularly regarding the best propeller choice for me.

🏆 Reputation & Certification

- Mercury-certified dealers

- Established reputation

- Proven marine expertise

- Genuine product guarantee

- Latest model information

🛠️ After-Sales Support

- Installation assistance

- Maintenance support

- Warranty claim processing

- Technical troubleshooting

- Knowledgeable support team

📦 Inventory & Availability

- Sufficient stock levels

- Quick product availability

- Minimal waiting times

- Wide product selection

- Emergency replacements

💼 Pricing & Policies

- Fair, competitive pricing

- Clear return policies

- Customer-friendly exchanges

- Transparent warranty terms

- No hidden costs

Other factors I keep in consideration include after-sales support. An excellent distributor never simply sells an item; it supports the customer with installing or maintaining the item or filing a warranty claim should the need arise. Having a support team with in-depth knowledge of the subject can save me time and trouble over the course of a few months if I start to encounter technical issues. I also prefer to work with a distributor who has sufficient stock on hand, so I can select the products I want without having to wait for a long time.

Lastly, I’d like to review the pricing and return policies in place. While price is not a significant factor in selecting a better-quality propeller, I check dealer prices to ensure I am being charged fairly for my purchase. If their return or exchange policies are clear and customer-friendly, that gives me confidence to purchase the product, knowing I will be able to address any fit or performance issues should they arise. With these considerations in mind, I can select a dealer that matches my boating needs and ensures a smooth and rewarding purchasing experience.

Benefits of Working with Authorized Mercury Dealers

These authorized Mercury dealers enhance consumer confidence in their purchase of quality, genuine articles. The dealers sell genuine Mercury parts and accessories that will enhance and maintain the optimal performance of my craft. I can rest assured that the products produced with the highest manufacturing standards in mind will work perfectly with my engine. When I want to maximize the efficient and safe functioning of my boating experience, this concept of reliability is valuable to me.

🎯 Key Advantages of Authorized Dealers

✅ Product Authenticity

- 100% genuine Mercury products

- Factory-specified performance

- Optimal engine compatibility

- Highest manufacturing standards

🧠 Professional Expertise

- Comprehensive product knowledge

- Tailored recommendations

- Technical compatibility guidance

- Performance optimization advice

🛡️ Warranty & Support

- Full warranty coverage

- Streamlined claim process

- Ongoing customer support

- Service scheduling assistance

Having authorities at your side provides an additional benefit of having professional expertise readily available. They are well-qualified, competent, and knowledgeable about the entire range of Mercury products, enabling them to offer advice and recommendations tailored to my needs. Whether it’s replacement parts, upgrades, or maintenance solutions, the best decisions will be prioritized based on quality and compatibility. Their knowledge helps me save time and spare me from making incompatible choices that would cost me heavily in performance and quality.

Additionally, buying from authorized Mercury dealers often earns you warranty coverage and after-sales support that you would not get from unauthorized sources. Dedicated to ensuring customer satisfaction, these dealers make the entire experience of buying and owning a Mercury engine a smooth and worry-free process. I can always count on support in warranty claims, scheduling service, and helping answer questions about my boat’s running system. That peace of mind is probably the single most precious thing one can gain from choosing an authorized Mercury dealer.

Studies of Successful Propeller Upgrades

Initially, I found myself overwhelmed by the myriad choices in my effort to find an upgraded propeller for my boat. Yet, working with an authorized Mercury dealer made it all so much easier and quicker. They guided my choice in selecting the perfect propeller to match the boat’s engine, size, and typical usage. They considered goal-related factors such as performance, fuel economy, and handling, and wanted me to have a stainless-steel propeller that lasts and pushes better. In effect, I wasted my time and probably money because their advice was exactly what I needed, and I didn’t need to explore any other options.

📈 Upgrade Results

Performance

Increased acceleration and top speed

Efficiency

Improved fuel consumption on long trips

Support

Ongoing dealer assistance and fine-tuning

Indeed, that was a good story patronized. Immediate and impressive are just some of the adjectives I can use in describing the effect of installing a better propeller in my boat—improvements in horsepower translate to increased acceleration and top speed. At the same time, I noticed good diesel consumption from my readings, which, of course, means it was lower in operational cost during long trips. Connecting good performance to their support for further purposes, that was the dealer’s guarantee, which stated that they would assist in ensuring the propeller was fit for my purpose. Whether it was going through fine-tuning with me or helping with follow-up questions after installation, they were always there proactively.

This really affirmed to me the importance of working with professionals who genuinely understand the details of boat performance. Not only did I achieve my desired results, but I also gained a great deal of satisfaction from this upgrade, which was backed by expert advice and high-quality materials. An investment well bestowed on a better boating life and confidence on the waters.

Reference Sources

-

How to Choose the Right Mercury Outboard Propeller: The Ultimate 2025 Guide – A comprehensive guide to selecting the best Mercury outboard propellers in 2025.

-

Mercury Racing launches new Altitude Propeller at 2025 Miami International Boat Show – Details on the new Altitude propeller designed for high-performance outboard-powered hulls.

-

Mercury Racing Altitude Propellers – Insights into the Altitude propellers launched at the 2025 Miami International Boat Show for outboards with 300-500hp.

-

Sharrow Marine Unveils Highly-Anticipated Sharrow MX-A – Introduction of Sharrow Marine’s first aluminum propeller, expanding patented technology to new markets.

-

Boat Propellers by Mercury Marine – Overview of Mercury’s innovative propeller technology and premium materials.

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What are the advantages of fitting a Mercury prop on my outboard?

Using a Mercury propeller for your outboard motor assures that the performance and compatibility potentials are fully exploited. Mercury props are precision-engineered to enhance speed and handling, and they are tested to factory specifications that match the motor, thereby improving throttle response and efficiency. Additionally, a more suitable selection should help reduce fuel consumption, which would be particularly beneficial on long-distance trips. The latest designs, such as the Enertia and Fury, have improved blade shapes to facilitate smoother working and enhanced performance. It is your assurance of quality and reliability if you adopt a Mercury-branded prop.

🔧 What is the correct prop for my Mercury outboard motor?

The appropriate propellers for a Mercury outboard depend on its horsepower, size, and intended application. Let’s start by checking your motor’s specifications and the diameters and pitches it can accommodate. The diameter and pitch must match the boat design for optimal performance. A local dealer or a Mercury outboard technician might also help you with expert advice. Considering popular models like Bravo Series or Enertia Eco could lead you in the right direction to a prop that suits your requirements. Trying out different props may help you find an optimal fit for the exact boating conditions.

⚖️ What would be the difference between aluminum and stainless steel Mercury props?

Aluminum and stainless steel Mercury propellers have fundamental differences in terms of construction and performance characteristics. Aluminum propellers are lighter and less expensive, making them ideal for recreational boating. They perform well in normal conditions but may not be able to handle very high speeds or rugged conditions as well as stainless steel. In contrast, stainless steel propellers, such as the Bravo One, offer better durability, speed, and handling. These are for performance applications and are not prone to deformation. Ultimately, boating hours and the budget will decide the option one might consider between aluminum and stainless steel.

🔧 What are some tips for keeping my Mercury outboard prop in good shape?

Maintaining your Mercury outboard prop means a longer life for its optimal performance. Check the prop regularly for any damage, such as nicks or dents, which could be detrimental to speed or handling. It is recommended to clean the prop after every use, especially when it comes into contact with saltwater, to prevent corrosion. Inspect the hub and replace it if it shows signs of material loss. Lubricating the prop shaft will promote easy fitting and removal. In case you are not sure how to maintain your prop, contact your dealer or technician for detailed advice on your prop model.

🏆 Which Mercury propellers top the list of best-selling models?

Some of the most preferred models from Mercury propeller manufacturers were the Enertia series, the Fury series, and the Bravo series. The Enertia prop is considered one of the more efficient models, allowing for smooth performance across various boat-building applications. The Fury model is sought after primarily by the performance trade for its aggressive design, from which one can expect increased acceleration and excellent handling. Then there’s the Bravo Three, known for its patented dual-prop design, which improves grip and maneuverability. All of these models have been emulated to deliver the worthy experience of cruising or water sports.

📐 What is the pitch of a Mercury prop in relation to performance?

The pitch of the Mercury propeller is crucial for boat performance, including speed and acceleration. The higher the pitch, the higher the speed; however, acceleration may be curtailed, making it unsuitable for quick acceleration. Lower pitch gives preference to acceleration but constrains the speed. Pitching needs to be suited to your motor power and to your style of boating. For example, if water sports are your thing, go for a low pitch! Always consider obtaining adequate information from Mercury or your dealer to ensure a correct pitch for your setup.