The very hull of enjoying a day on the water side depends on the correct selection of a propeller for your Mercury outboard motor, and the stakes will be higher in 2025. Whether you are an avid boater or a commercial angler, choosing a 4-blade stainless-steel prop should primarily focus on efficiency, durability, and control on the water —the trifecta. This guide will cover all the primary considerations, innovations, and expert advice available, so you can select exactly what suits your boating needs. From grasping the latest tow prop technology to balancing prop selection with engine specifications, everything you will want to know to enhance your boating ventures is tied in! Get set to unleash your Mercury outboard motor’s full potency throughout 2025 and far beyond!

Understanding Mercury Outboard Motors

Overview of Mercury Outboard Models

As it remains at the forefront of marine innovation, Mercury outboards are manufactured in a wide variety to suit the specific needs of customers; for instance, some are suitable for recreational boating, while others are designed for commercial settings. Main series include: FourStroke, Verado, Pro XS, and SeaPro. Each of these series imparts the very attributes of performance, dependability, and fuel efficiency.

Mercury FourStroke Series

Known for its reliability and economy, the FourStroke series prioritizes smooth operation and low emissions. These outboards come in horsepower ranges, from small and portable ones starting at 2.5 HP to those exceeding 150 HP, which are quite powerful and designed for the casual boater requiring versatility and reliability.

Mercury Verado Series

The Verado series sets the benchmark for premium power with advanced engineering and rugged durability. With power ranging up to 600 HP, this series is designed for high-performance applications, including cruising and offshore fishing. Features include adaptive speed control and noise-reduction technologies.

Mercury Pro XS Series

It is the name in speed and acceleration, very popular among competitive anglers and speed lovers. Pro XS outboards are offered in mid-size models, ranging from 115 HP to heavy-duty configurations exceeding 300 HP, and provide outstanding torque and fuel efficiency optimized for demanding applications.

Mercury SeaPro Series

Pure originated for commercial and heavy-duty purposes; SeaPro is designed for rugged use. Increased corrosion resistance and specialized components ensure a long service life, making these outboards a reliable choice for any operator in a demanding marine environment.

New control technologies have been installed in each model to enable the boat operator to achieve maximum efficiency, noise reduction, and improved performance, including Digital Throttle & Shift, Active Trim, and advanced fuel-injection systems. Your Mercury outboard motor is equipped for maintenance in both shallow inland waters and deep offshore conditions.

Key Features of Mercury Engines

Mercury engines have now become synonymous with advanced technology, world-class production, and performance-based design. Here are the key features that keep them atop the list:

Digital Throttle & Shift (DTS)

The DTS system by Mercury provides smooth and precise control, enhancing the operator experience with effortless shifting and throttle response. The technology carries noise and vibrations while guaranteeing reliability in all conditions.

Active Trim System

The Active Trim automatically adjusts the trim of the engine according to speed, which is great for fuel efficiency and top performance. Such an intelligent system will ensure that the ride is smooth, mostly for inexperienced operators. Hence, it provides much value in terms of usability.

Advanced Fuel Injection Technology

An advanced fuel injection system in every Mercury outboard achieves better combustion by utilizing less fuel while emitting fewer pollutants, thus ensuring longer engine life and stronger torque and acceleration.

Corrosion Resistance

Mercury’s engines are constructed from solid, marine-grade materials and feature advanced corrosion-resistant finishes. This way, they are ready to withstand intense marine environments in full performance reliability.

High-Horsepower Options for Varied Needs

Mercury’s product lineup comprises numerous horsepower options for any application, from light-duty recreation to commercial, heavy-duty use. The flexibility allows the user to pinpoint and design-fit exactly what his operations require.

Precision Engine Build

Each Mercury engine is meticulously built to precise performance specifications, incorporating rigorous testing and quality control procedures throughout the process. This meticulous building process ensures the delivery of power to an expected standard, along with reliability for years to come.

Integrated SmartCraft Technology

The integration of the SmartCraft system provides real-time engine monitoring and diagnostics, offering users critical insight into operational parameters such as fuel consumption, speed, and tilt position. The technology eases maintenance and allows one to maintain peak performance.

These features, in combination, make Mercury engines the favorite among ardent mariners and professionals, offering innovative and reliable, long-standing performance.

Performance Expectations with Different Propellers

Understanding the effects of specific designs on propeller performance is crucial when selecting the right one for your Mercury engine. The size, pitch, and material of the propeller can significantly impact speed, acceleration, fuel efficiency, and handling. For instance, a higher-pitch propeller tends to perform better at maintaining high top speeds and would thus be of value to racers or sporting enthusiasts. Another example is a low-pitch propeller, which is best suited for situations that require thrust and quick acceleration, such as towing or moving heavy loads.

One might argue that material is yet another variable; stainless steel propellers maintain the highest rating for durability and performance consistency in harsher environments, whereas aluminum options are cheaper and lighter, suitable only for recreational boats. Further refinement arises with the blade count; three-blade configurations provide better speed and efficiency, while a fourth blade is added to the design for more comfortable handling and control at lower speeds.

There is an urgent need to test and fine-tune the engine RPMs and fuel efficiency to achieve the optimal balance between power and economy. Assessing your individual requirements for various boating activities in consideration of environmental factors should enable you to find a propeller that matches your performance expectations and ensures the best experience whenever you go out on the water.

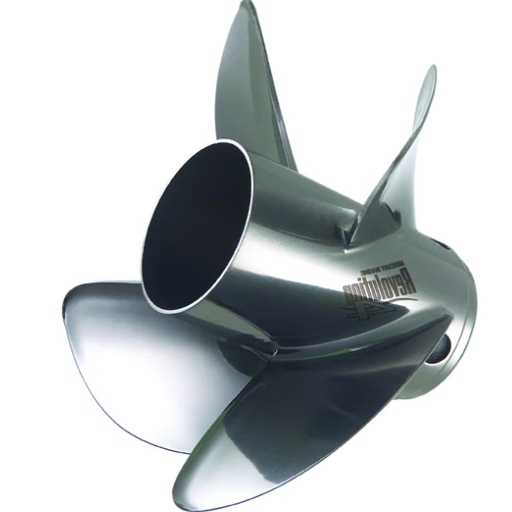

Benefits of 4 Blade Stainless Propellers

The Performance and Speed

These 4-blade stainless steel propellers provide optimized performance and speed, offering unmatched versatility for numerous boating applications. Because the blade area has increased, the thrust has increased as well, improving acceleration and steady cruising. With chopping waves, it maintains grip, reduces slippage, and allows for sharp turning from brief maneuvers. In other words, four-bladed propellers also enable boats to achieve the most fuel-efficient speed in the mid-range, which is quite helpful when robots need to cover long distances or participate in water sports. With these features, the propellers are designed for enthusiasts who expect reliable, sturdy, consistent, and efficient performance on the water.

Durability and Corrosion Resistance

Whatever the nature of the marine environment, durability and corrosion resistance should be guaranteed for any apparatus, of which the propeller is a particularly vital one. Nowadays, 4-blade propellers are primarily made from high-tech materials such as stainless steel and aluminum alloy, offering better resistance to chafing and exposure to harsh conditions. Typically, steel finds favour in saltwater applications wherein corrosion is chiefly yet temporally caused by salt-laden air and water. Likewise, an aluminum alloy is lightweight and inexpensive, but it provides sufficient anticorrosive protection when coated or anodized properly.

Industry Insight

To enhance their life, many propellers are given a special coating to protect them against rust or marine growth, such as shell voidance or barnacle adhesion. These coating systems would increase the working life of the propeller and, consequently, maintain its efficiency by ensuring smooth surfaces for water flow through the blades. Industry sources have recently reported that a propeller with these protective coatings can exhibit up to 30 percent more resistance to corrosion than an untreated alternative.

Beyond that, the propellers require minimal maintenance due to high construction durability, which saves users’ time and effort. Many manufacturers now offer design features such as streamlined hub construction and reinforced blade edges to avoid damage from debris or to slight impacts. These new changes ensure longer operational periods without compromising functionality, providing boat owners who value reliability and longevity with some respite. Combined with new technologies for improved durability and corrosion resistance, today´s 4-blade propellers represent a great value, mainly when used in the long run or in heavy-duty applications in various water environments.

Comparing Analysis: 3 Blade vs. 4 Blade

When choosing between a 3-blade and a 4-blade, knowledge of their distinctive characteristics can lead to an improvement in efficiency and performance. The three-blade propellers are normally preferred because they achieve a higher top speed and are extremely efficient when operating under light or moderate loads. In contrast to other alternatives that emphasize speed for recreational boating or applications, they safely ensure higher speeds. Having a lesser surface area with 3-blades reduces drag, enhancing fuel efficiency and overall responsiveness. They are also lighter and less costly in most cases, and are thus found to be an excellent compromise between performance and price.

3-Blade Propellers

- Higher top speed capability

- Better fuel efficiency

- Lighter weight

- Lower cost

- Ideal for recreational boating

4-Blade Propellers

- Better stability and control

- Superior load-carrying capacity

- Improved acceleration

- Less noise and vibration

- Excellent for towing and water sports

Conversely, 4-blade propellers excel where stability, load-carrying capacity, and handling precision are paramount. Their extra blade provides the thrust and grip on the water, translating into more acceleration with smooth operation even in the roughest waters. This configuration is welcome whenever the heaviest of loads come under constant maneuvering, which could be larger boats and watersports. Additionally, these propellers produce less noise and vibration than their 3-blade counterparts, resulting in a more pleasant travel experience.

One technical consideration is the performance of a vessel under different conditions. While 3-blade props would be the best choice for attaining high speed in open waters, 4-blade props are preferred for towing, cruising, and maintaining relatively steady power when hard turns or rough weather come up. Given the various materials and engineering expertise, the efficiency and reliability of both have improved significantly, allowing a boat owner to fine-tune their option to suit a particular use case. The decision comes down to what is paramount in its operation: speed, stability, efficiency, or versatility.

Choosing the Right Propeller for Your Needs

Considerations: HP and Boat Type

The HP and boat type are two crucial considerations when selecting a propeller and assigning it to a vessel to optimize performance, efficiency, and handling. Horsepower relates to how much power your engine can produce, so a mismatch with the propeller can either underperform or over-strain the engine. Usually, a boat having an engine of high HP requires propellers designed to hold top speed and great thrust, i.e., with maybe high diameters or low pitch angles. For instance, speedboats are fitted with stainless steel props designed for fast acceleration and excellent efficiency at high RPM.

Key Matching Principles

- High HP Engines: Require stainless steel props with specific diameter and pitch configurations for optimal speed and thrust

- Fishing/Pontoon Boats: Need propellers that prioritize torque and stability over pure speed

- Shallow Water Operations: Benefit from weedless or cupped blade designs

- Heavy Loading Conditions: Require specific propeller geometries to optimize efficiency

Again, the type of boat defines its operational requirements and expectations for performance. Larger boats, such as those for fishing or pontoon use, require propellers that prioritize torque and stability over speed. Aluminum propellers with a medium pitch angle would be well-suited for these types of boats, providing an extra margin of fine handling in varying water conditions. Furthermore, in cases where the boat will be operating in shallower water or under heavier loading conditions, a specific design of propeller may be preferred, such as weedless or cupped blades, to optimize efficiency and reduce drag.

By balancing the horsepower of your engine versus what your boat is meant to be doing, you set a true balance for power output versus fuel consumption and can reward you for increased durability and reliability on the water.

Matching Propeller Size to Performance Goals

Selecting the right propeller size is paramount for your boat to reach peak performance and efficiency. The propeller has two main features that determine its size: diameter and pitch, both of which have a direct implication on how your boat navigates across the water. Diameter is the terminology used for the width of the circular sweep carried out by the blades. Typically, larger diameters are suitable for heavier boats that demand more thrust. Pitch, meanwhile, describes the distance a propeller moves forward during a full rotation and is highly associated with speed and efficiency.

Lower Pitch Benefits

- Better acceleration

- Increased pull pressure

- Ideal for towing

- Suitable for heavy currents

Higher Pitch Benefits

- Higher top speeds

- Better fuel efficiency at cruising

- Ideal for lightweight boats

- Perfect for high-speed scenarios

To give an example, the lower the pitch, the more acceleration and pull pressure can be exerted for towing or for held navigation under heavy currents. On the other hand, a higher pitch will give more speed; lightweight boats or high-speed scenarios are most fitting for this. Industry studies confirm that even slight changes in pitch or diameter can significantly impact fuel efficiency, engine RPM, and overall handling of the boat. Proper matching of these dimensions also prevents undesired strain on the engine, thereby prolonging its life and reducing maintenance costs.

Advanced testing, along with data-driven tools, would now permit the boat operator to fine-tune propeller dimensions according to load, hull design, and typical cruising conditions. For instance, propellers with a combination of moderate pitch and diameter tend to provide optimal fuel economy for the amateur leisure boater. Achieving better performance, reduced wear and tear, and a more enjoyable boating experience are possible by adjusting the propeller to meet your goals.

Impact of Weight and Load on Propeller Selection

Weight and load play hugely important roles when choosing the right propeller to provide the best performance for the boat. When a vessel carries weight from passengers, equipment, or excess fuel, the load created by the weight on the hull further adds to resistance and also affects the engine’s ability to reach its maximum RPM range. A heavier load typically requires a propeller with a smaller pitch, allowing the engine to continue operating efficiently while generating effective thrust.

Load Considerations

On the other hand, lighter boats tend to benefit from having higher-pitch propellers installed to harness speed and fuel efficiency. The distribution of weight evenly on the vessel affects its balance and performance; uneven loading can cause instability and inefficient propulsion. According to the manufacturer’s recommended RPM range, it is best to fine-tune testing under actual load conditions. Having your propeller tailored to specific weight/load configurations ensures that fuel efficiency is maximized while minimizing engine stress, which ultimately leads to increased engine lifespan and smoother boating experiences.

Top 4 Blade Stainless Propeller Options

Quicksilver Q4 Stainless Steel Propeller Review

Product Overview

The Quicksilver Q4 stainless steel propeller is designed for the heavier and high-powered boat category, catering to the needs of speed enthusiasts and those concerned with exceptional durability. Made from high-grade stainless steel, the Q4 offers corrosion resistance and sturdiness for extended usage, making it a worthwhile investment for the harsh marine environment.

The quad-blade design propeller enables a faster rate of acceleration, improved midrange performance, and dependable handling in rough water conditions. Thus, the extra blade also means less slipping, and the vessel has a tighter grip, even when executing aggressive turns. Another unique advantage is the wide pitch range, which allows for adjustment to meet specific engine requirements and loads. Suitably, it is best for bigger boats. At slow speeds, however, the operation of this propeller is steadier, making it ideal for towing activities, such as water skiing or wakeboarding.

Performance Highlights

- Faster acceleration and improved midrange performance

- Reduced slipping with tighter grip during turns

- Wide pitch range for various engine requirements

- Steady operation at low speeds

- Ideal for towing activities like water skiing

These performance tests demonstrate that Quicksilver Q4 is a fuel saver across a wide range of RPMs, while maintaining power. Robustly engineered means reduced strain on the engine, thereby prolonging motor life and ensuring consistent dependability when put to stress. Quicksilver Q4 remains a highly popular and recognized name among boaters seeking to combine supreme performance with durability.

Performance Insight of Bravo Series Propellers

Bravo Series propellers are famous for their exceptional performance, versatility, and advanced engineering. Hence, their applications at high speed levels are found in powerboats and outboard-engine systems that require strong thrust and superior handling capabilities. One of the Bravo Series’ distinguishing features is its stainless steel, precision-cast construction, which provides long service and resistance to extreme marine conditions.

Key Performance Features

Performance evaluations highlighted the Bravo Series’ ability to increase top speeds while maintaining equilibrium, even in turbulent waters. Their blade setup ensures minimal cavitation; hence, the ride feels smooth, and the boat is more fuel-efficient. Other than that, the series comes with options for pitch settings, allowing boaters to tune performance to suit different load or speed requirements.

Other than that, good control at low speeds will come in handy when used in docking or going through tight areas. Further assisted by superior ventilation features that improve acceleration while reducing propeller slip, the Bravo series propellers are a great choice for watersport enthusiasts and other boaters with a performance-oriented approach. These all-purpose propellers offer a perfect blend of durability, power, and precise handling, making them suitable for various marine applications.

Comparative Data on Leading Brands

When observing top performers in the field of propellers, several brands stand out for their uniqueness and innovation. The following comparative review pertains to specific features and performance criteria that separate front-runners in the industry:

| Brand | Material | Performance Strengths | Target Applications |

|---|---|---|---|

| Bravo Series | Stainless Steel | Superior acceleration, reduced prop slip, and excellent low-speed control | Watersports, performance boating |

| Mercury Enertia | Proprietary X7 Alloy | Enhanced fuel efficiency, smooth mid-range planning, and exceptional top-end speed | High-speed boating, offshore fishing |

| Yamaha Reliance | Stainless Steel | High-strength durability, optimized ventilation for excellent grip | Recreational and moderate commercial uses |

| Solas Amita | Aluminum or Stainless Steel | Versatile pitch range, competitive price, and good all-around performance | General boating, entry-level applications |

| PowerTech OFX | Precision-cast Stainless Steel | Rugged durability for heavy loads, superior thrust in challenging conditions | Workboats, heavy-duty marine projects |

Each brand applies engineering methodology to support a target boat need: speed, efficiency, or strength. The Bravo Series, for instance, stands out for its performance versatility; Mercury Enertia is optimized for fuel economy and speed; Yamaha Reliance is built to last yet offers features suitable for leisure and light commercial work; Solas Amita offers cheaper applications for more generic uses, gaining popularity among new boat owners; while PowerTech targets heavy-duty applications where reliability and strength in extreme conditions are key.

This comparison illustrates the alignment of product strengths with niche demands, enabling users to select the propeller solution that best suits their boating priorities.

Installation and Maintenance Tips

Proper Installation Techniques for Optimal Performance

I start by preparing all the necessary tools and ensuring cleanliness and organization of the work area. If the right size and pitch of the propeller for my particular boat are not applied, it will seriously affect performance and efficiency. I gently fit the propeller hub onto the engine shaft, being very careful to check the manufacturer’s prescribed specification for compatibility. Then, I inspect the shaft for any debris or damage and apply a thin coating of marine grease to prevent corrosion and to facilitate easier removal later on.

Installation Steps:

- Align the propeller with the keyway on the shaft, ensuring a snug fit without applying any force

- Tighten the propeller nut to the recommended torque using a torque wrench to prevent over-tightening and damage to the threads

- Install a lock, such as a cotter pin or lock washer, ensuring it sits firmly in place to prevent the propeller from turning off

- Test for smooth rotation by turning the propeller by hand, checking for wobbling or resistance

- Perform other maintenance tasks, such as checking for fishing line wraps around the shaft or signs of wear

A well-installed propeller, combined with regular maintenance, ensures that my boat runs efficiently and reliably on the water.

Routine Maintenance for Longevity

The routine maintenance I provide for the boat is the most critical factor in judging its efficiency. My usual checks involve inspecting the propeller for fishing lines and debris wrapped around the shaft. If these are not removed in time, they could cause harm over time. Then I check for dents, cracks, or other visible defects of the propeller itself. If some slight damage is caused, the boat will not perform well and will burn extra fuel. After assessing the damage, the component gets repaired or replaced.

The next step is to apply greasy materials to the propeller shaft as frequently as possible to prevent corrosion, particularly after operating in saltwater. Corrosion can cause the propeller to become jammed or even damage the shaft. Additionally, I remove my propeller at the end of every season to inspect the shaft and seals closely. This helps catch any hidden problems and keeps everything in tip-top shape.

The final step involves observing the general alignment and balance of the propeller. A correctly balanced propeller will operate smoothly and exert minimal strain on the engine. By carrying out these simple but necessary maintenance checks regularly, I maximize the working life of my equipment and ensure that it performs as needed when I take the boat out onto the water.

Signs of Wear and When to Replace Your Propeller

Throughout the years, I have come to identify some of the telltale signs that suggest it’s time to replace a propeller. One of the easiest signs is visible wear and damage to the blades. Such damage could include cracks, chips, or bent blades. These not only hinder operation but also place undue stress on the engine, possibly leading to costly repairs. At the sight of any significant physical damage, I immediately go to have the propeller either repaired or replaced.

Warning Signs to Watch For:

- Visible cracks, chips, or bent blades

- Power reduction or difficulty reaching appropriate speed

- Diminished fuel efficiency

- Unusual vibration during operation

- Changes in boat handling characteristics

The next thing to observe is a power reduction; for instance, the boat may have difficulty reaching the appropriate speed, experience diminished fuel efficiency, or vibrate unusually during operation. All of these are often attributed to problems with balance or alignment that occur over time due to gradual wear and tear. I remain vigilant for any signs of change in my boat’s handling, as those slight changes can provide an early warning that the propeller is not performing correctly.

Lastly, there is the age of my propeller and the way in which I use it. Even though I might not be able to see any damage right away, constant use in the hardest conditions, such as in shallow water or where more debris floats about, would wear it down faster. I just go ahead and replace any prop that has gone through the turf for a few years, or one that has been faced with extreme wear, so I won’t have to worry about sudden failure when out on the water. Keeping an eye out for these signs and indications keeps my boat running in tip-top shape and safe for another great day of boating.

Reference Sources

-

How to Choose the Right Mercury Outboard Propeller – VIF Prop

Discusses the benefits of 4-blade propellers, including better thrust and control, especially at lower speeds or when towing. -

How to Choose the Right Mercury Outboard Propeller – VIF Marine

Explains how to select the best propeller based on engine horsepower, boat type, and specific needs. -

Picking a 4 Blade Prop – The Hull Truth

Provides insights into selecting a 4-blade prop, including size recommendations and performance considerations. - View for more details.

Frequently Asked Questions (FAQs)

What is the advantage of using a 4-blade stainless propeller on a Mercury outboard?

The 4-blade stainless steel propeller offers improved lift and acceleration, making it suitable for all types of boat conditions. It has gained popularity due to its holeshot performance, which means that acceleration from a standstill is quicker under heavy loads. It is also more durable than aluminum, resisting corrosion and damage better. This propeller is designed for high RPMs and thus performs more efficiently. Matched with Mercury outboards, the stainless prop could offer an even smoother ride while saving some fuel. In summary, the 4-blade propeller is an ideal design for those seeking to enhance the performance of their boat.

How to choose the right pitch for my stainless steel prop?

Selecting the correct pitch for your stainless steel propeller is crucial for achieving optimal performance from your boat. Between the pitch and how fast your boat will run and accelerate, the higher the pitch, the greater the top speed, but the less acceleration. Conversely, with a lower pitch, you may have a good holeshot and acceleration, but less top speed. Depending on your boat’s weight and motor horsepower, as well as its intended use for cruising or water sports, you should consider all of these criteria. Alongside this, one can also ask for further insight from the Mercury dealer, ranging from propellers to engine-related advice, as suggestions will be concrete to their setup. Besides, the PVS® (Performance Vent System) can help adjust the prop for performance, depending on individual needs. There need not be much compromise between pitch and engine; when both are complementing each other, that is when you get the best out of something.

What are the benefits of QuickSilver Q4 stainless boat propellers?

QuickSilver Q4 stainless steel propellers feature a design that enhances performance and adds to the durability for Mercury outboards. These propellers are made from finer stainless steel to resist corrosion and wear over long-term usage. The Q4 design is one of the latest geometries developed to promote fuel efficiency and increase speed, thus useful for leisure or competition. Q4 propellers are designed to match perfectly with Mercury outboard motors to enhance performance at different RPMs. Many gondoliers noticed improved handling and responsiveness with QuickSilver Q4 props, thus making them a choice for any serious boater. If you’re thinking of upgrading, the Q4 stainless propeller should be taken into serious consideration.

Does a stainless steel propeller improve fuel consumption in my Mercury outboard?

Indeed, a stainless prop can significantly aid in increasing fuel efficiency for your Mercury outboard. Stainless steel propellers are designed to achieve optimal performance with lower drag compared to aluminum types, allowing for improved power transfer from the motor to the water. If pitched and sized correctly, these props will enable the engine to adjust its RPM to the most efficient range within which the motor can operate. Furthermore, the presence of stainless props allows the product to have an increased lifespan, reducing the need for replacements and, consequently, saving fuel and maintenance costs in the long run. Many boaters report significant increases in fuel consumption after switching to their steel props, making this a worthwhile investment. From a practical point of view, a dealer would be the best source for recommendations on finding the right fit.

What maintenance does a stainless steel prop require?

Maintaining stainless steel propellers is vital for their optimal performance and longevity. Regular checks for dings, dents, or signs of wear should be made, especially after extended outings or when navigating through rough terrain. Occasional cleaning is needed to remove marine growth or debris that could affect performance. Applying protective coatings or anti-fouling paints helps the propellers against corrosion. If you discover significant damage to the propeller, it is best to have it fixed or replaced by an authorized dealer or professional. A well-maintained stainless steel propeller performs well and dramatically improves the overall operation of your Mercury outboard motor.

What is the influence of a stainless steel propeller on boat handling?

Under most conditions, boat handling can be significantly enhanced by using stainless steel propellers. The rigid nature of stainless steel enables effective control and responsiveness, especially during high-speed maneuvers or when negotiating tight turns. A lift and stability factor is added by four blades of the stainless prop, which improves handling in choppy waters. Moreover, the precision of construction endows these props with much smoother transitions, whereas aluminum ones tend to cavitate and slip. Many boaters have reported that they thoroughly enjoy the controlled experience with stainless steel props on the water. To achieve optimal handling performance, it is essential to select the correct size and pitch for the Mercury outboard kit.