Innovation is the lifeblood of the maritime industry, and 2025 is expected to be a crucial year for boat propeller manufacturers. Technological advancements, increasingly restrictive environmental regulations, and heightened awareness of sustainability are prompting propeller manufacturers to revisit traditional designs and methods. This article describes how industry players utilize novel materials, develop eco-friendly solutions, and integrate smart technology to enhance performance and efficiency. Suppose you are an owner, engineer, or simply an enthusiast for boats. In that case, you will want to know the disruptive technologies working to change the future of propeller technology and what they imply for the whole industry.

Overview of the Boat Propeller Industry in 2025

Current Propeller Technology Trends

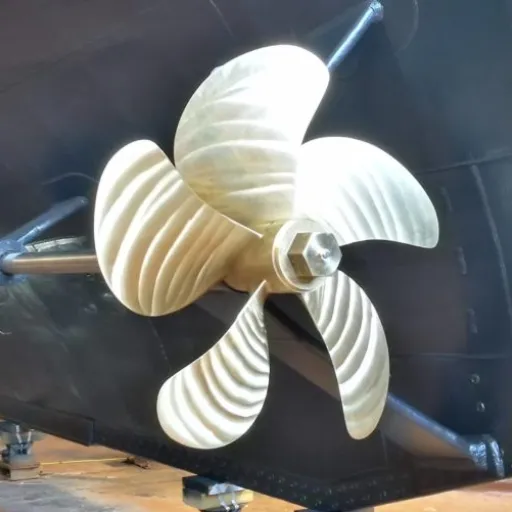

Large-scale changes are occurring in the industry and market due to technological advancements and environmental concerns. One core trend is the development of lightweight, high-performance materials such as carbon fiber-reinforced composites. These composites reduce the overall weight of the vessel, thus enabling it to become more efficient with less drag and greater propulsive force. Traditional metals such as aluminum are now enhanced with advanced coatings to resist corrosion and provide enhanced durability in the most rigorous marine environments.

Another trend worth mentioning is the rise of electric and hybrid propulsion systems. With the increasing demand for sustainable approaches, propellers are being developed that consume less energy while maintaining their operational characteristics. Hydro- and hydrodynamic considerations, combined with advances in CFD, are at the heart of this development, enabling accurate design calculations for specific vessel types and specialized applications. The result would be customized propellers that offer the utmost levels of fuel efficiency and operational performance.

Additionally, the integration of smart technology is reshaping the propeller engineering landscape. Embedded sensors within propellers provide real-time data on performance indicators, such as RPM, torque, and efficiency, to assist the operator in the decision-making process. The smart systems thus provide predictive maintenance, helping to reduce downtime and repair costs.

Lastly, modular propeller systems are gaining ground as a solution to the diverse demands of the marine industry, ranging from pleasure craft to commercial and naval vessels. The modular systems provide more flexibility, allowing for quicker repairs and upgrades, thereby minimizing downtime during operations. All these factors, taken together, mark a watershed period for the industry in terms of embracing innovation for the twin goals of performance and sustainability.

Key Players in the Boat Propeller Market

Many key manufacturers and innovators drive the boat propeller market with their cutting-edge solutions for marine performance and sustainability. A few of the key players are:

| Company | Specialization | Key Features |

|---|---|---|

| Brunswick Corporation | Mercury Marine propeller solutions | Performance-oriented designs engineered for speed, fuel efficiency, and durability in both recreational and commercial marine applications |

| Yamaha Motor Co., Ltd. | Robust and innovative products | High performance propellers that maximize engine output and maneuverability, available in stainless steel and aluminum lines |

| Michigan Wheel Corporation | Custom-designed solutions | Efficient propellers for recreational, industrial and naval applications, emphasizing performance and reducing cavitation |

| Torqeedo GmbH | Electric and hybrid propulsion | Green boating solutions with advanced propeller design technology that reduces carbon footprint |

| Suzuki Motor Corporation | Outboard motor propellers | High-quality propellers offering ease of operation, efficiency, and durability for diverse customer needs |

| Solas Science & Engineering | International propeller solutions | Vast range of propellers for various marine engines, known for high-performance materials and precise engineering |

So many efforts from key market players are responsible for the sustainable technological advancements and improved functionality. Their technological innovations aim to meet today’s market requirements, thereby laying a solid foundation for future growth in the industry. Through consistent investments in research and alliance partnerships, these companies continue to set standards for performance, efficiency, and environmental impact.

Impact of Regulations on Propeller Design

The regulatory framework constitutes an essential factor in directing propeller evolution, especially as industries prioritize profitability, sustainability, safety, and efficiency. Environmental concerns, whether related to inhibiting greenhouse gas emissions or reducing noise pollution, are driving the development of newer and more advanced materials and aerodynamic designs. Compliance with a certain standard, such as that set by the International Maritime Organization (IMO) or the Federal Aviation Administration (FAA), has compelled propeller manufacturers to undertake innovation studies aimed at producing more fuel-efficient and environmentally less-polluting propellers.

The increasing incorporation of lightweight composite materials is one trend that has been identified. These materials not only meet standards in serviceability and performance but also allow considerable reductions in energy consumption. Additionally, noise restrictions have promoted prescribed blade geometries with good cavitation features, allowing for the reduction of acoustic effects without impairing the application.

Building on this, while modern ship propellers are equipped with energy-saving devices such as ducts and fins in response to tightening emission standards, similar demands for efficiency in the aviation sector have driven the development of ultra-quiet propeller systems in line with airport noise control regulations. Hence, manufacturers adapt themselves to these regulatory pressures as a way to ensure compliance while simultaneously branding themselves as leaders in environmentally friendly engineering.

Innovations in Propeller Design and Efficiency

The Size and Shape Evolution

Propeller design has undergone significant improvement in recent years, with a particular focus on its size and shape to achieve maximum efficiency and sustainability. Through matters such as computational modeling and materials science, engineering aims to refine blade geometries so that they attract as much thrust as possible while minimizing drag. Another noticeable trend among designers is the increasing use of larger-diameter propellers fitted with thinner, more aerodynamic blades. These designs tend to increase their lift-to-drag ratios and consume less power, particularly in the newer airplane and marine vessel applications.

In addition, tip techniques, including scimitar-shaped blades and swept tips, also enhance noise reduction without compromising performance. For instance, studies demonstrate that these novel configurations can reduce noise by as much as 20% compared to traditional designs, thereby providing valuable solutions for meeting generally tighter noise regulations. Composite lightweight materials, such as carbon fiber-reinforced polymers, further reduce the weight of the propellers while increasing their strength and corrosion resistance. Thus, these developments will enable manufacturers to develop environmentally viable solutions without compromising operational performance.

Enhancements in Fuel Efficiency due to Design

Innovative advancements in propeller design are significantly enhancing fuel efficiency in twenty-first-century aeronautical and marine applications. Designers have given more aerodynamic blade shapes and angles of attack precedence to minimize drag while attempting to optimize thrust. Computational fluid dynamics (CFD) techniques enable the analysis of air flow, allowing for the examination of various design configurations to determine which one yields the best results with minimal energy input.

Another way to look at this is that employed materials, such as titanium alloys and high-performance composites, have enabled the design of propeller systems that are lighter and, therefore, possibly more efficient. These materials not only lighten the propulsion mechanism but also contribute to the mechanical strength of the system, ensuring reliability over long operational cycles. Manufacturing techniques have advanced significantly, with procedures such as 3D printing supporting fuel efficiency by enabling the manufacture of exquisitely complex, custom designs that were previously impossible through conventional means.

Industry Impact: According to a recent industry study, depending on the specific case, such design improvements may save between 15% and 20% of fuel, proving valuable in both reduced operational costs and a lessened environmental impact. Of course, this development stands as proof for continuous sustainability and efficiency drives across all industries that are dependent on propeller technologies.

Custom Propeller Solutions for Recreational Boats

Understanding the Need for Customization

Custom propeller solutions are essential for recreational boats to ensure optimal performance and user satisfaction. Various sizes and designs exist for recreational vessels; each requires different speed, maneuverability, and fuel efficiency. Commercially available propellers generally do not meet the exact requirements of these boats, resulting in compromised performance and high operational costs.

Whereas a speed-oriented small boat requires further design to suit its propulsion machinery for efficient acceleration, maximum speed, fuel economy, and smooth lateral handling, the larger cruising vessel requires a different design of the propeller. An accommodation greatly means adjusting the shape and geometry of the blades to pitch and diameter so that the propeller matches either the engine’s working arrangement or performance specifications already desired. In the new setting, a materials and computational fluid dynamics-based design approach provides even greater opportunities for optimization to withstand various working conditions while offering the highest efficiency.

Boat owners who embrace customization can achieve better fuel economy, reduced engine strain, and superior overall performance, which elevates recreational boating to a higher level of enjoyment.

Installation Methods for Best Performance

Mount the propeller correctly to ensure it operates at its full potential and to maximize the propeller’s and engine’s lifespan. First, check if the propeller shaft is clean and free from dirt; even the smallest dent can cause imbalance or inefficiencies. Align the propeller onto the shaft carefully, following the manufacturer’s specifications regarding tightness and spacing to avoid issues such as excessive vibration or improper alignment.

Installation Best Practices:

- Use a torque wrench so that the propeller nut is tightened to the specified torque, which depends upon the size of the engine and the type of propeller

- Use a cotter pin or lock washer for additional security, as this resists attempts to loosen the nut during operations

- Apply an anti-corrosion agent to the shaft to protect from rust and wear, particularly important in environments with high salt content

- Conduct a final balance check after installation, as an unbalanced propeller could reduce fuel efficiency and add strain to the engine

Inspection and maintenance of the propeller after installation ensure long life with balanced operation and low maintenance costs over time.

Consumer Feedback Regarding Custom Propeller Solutions

Consumers generally provided a few good points as to why one should opt for a custom propeller tailored to their specific needs. Far greater praise is leveled toward fuel economy; considerations of both price and pollution come into play. The general feeling has been that a custom-made propeller improves vessel performance by reducing drag and balancing thrust, allowing the engines to run smoothly even in unfavorable water conditions.

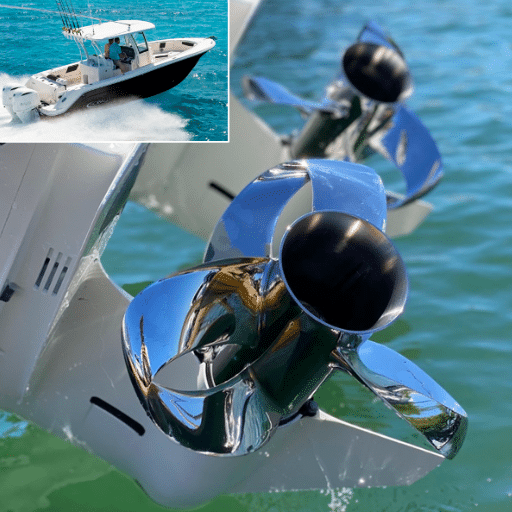

Durability is another feature that appears to be widely discussed by users, especially those working in tough environments filled with saltwater and a lot of debris. Many users stated that custom propellers made from advanced materials, such as stainless steel or certain alloys, tend to last longer than standard ones and therefore do not need to be replaced as frequently. Moreover, through precise engineering and collaboration with manufacturers, boat owners can address their specific operational requirements, which may include having custom propellers designed for speed, handling, or load capacity.

Other appreciated aspects included the accessibility of data and simulations during design, which helped customers make informed decisions about their investments. While the price may be higher than that of an off-the-shelf option at times, most users consider the performance, efficiency, and durability benefits as something that far outweighs the initial cost; hence, custom propeller solutions make a crucial upgrade for any serious maritime enthusiast or professional.

The Role of Wake Performance in Propeller Development

Wake Efficiency Measurement for Different Models

Wake efficiency is crucial for achieving vessel optimization, enabling the effective use of propeller energy to reduce drag and turbulence. To study wake efficiency for different propeller models, engineers investigate the interaction of the wake field with the propeller blades. This includes studying flow patterns around the blades and in thrust distribution, as well as cavitation patterns.

These measurements are now handled more elegantly with CFD simulation technology, yielding very detailed views into the efficiency of various designs. In fact, at lower speeds, blades with a lower area ratio are found to work better, whereas at higher speeds, those with a larger blade area ratio seem to gain more. Developers of skewed and raked blades usually prefer those that reduce noise and vibration, which also influence wake patterns.

Evaluators use these detailed analyses to compare models side by side and select configurations that best suit their vessel in terms of specific performance and operational requirements. Unsurprisingly, this desire for good performance conflicts with the need for durability and lower operational costs in the long term.

Wake and Its Effects on Boat Handling and Performance

Wake configurations significantly impact a boat’s handling and performance, prioritizing safety and efficiency. With the passing of a ship, the wake creates turbulence that can annoy or imperil neighboring vessels, in some instances even harming the structural elements of that vessel. Perhaps periods of discrete wake-induced rolling motions do exist, rendering difficult maneuvers unstable and posing a risk to passenger safety.

Wake management concerns such as hull shape, speed, and load distribution. Flat-bottom hulls tend to create the largest wake, and V-shaped hulls tend to produce a smaller wake, ensuring a smoother journey. Also, keep an eye on your speeds, as higher ones tend to generate larger wakes because of the greater displacement. Regarding other factors that maximize performance, a thorough understanding of hull-draft shaping through computational fluid dynamics (CFD) simulations enables ensuring minimal wake impact while achieving maximum hull speed and control.

Analysis of data obtained from recent maritime field investigations suggests that optimizing boat hull and propulsion reduces wake-induced turbulence and lowers fuel consumption through reduced drag. These discoveries shed light on the need for precision engineering that ensures smoother handling, improved maneuverability, and an eco-friendly approach to mitigate wake impact on the environment and around boats.

Future Trends in Wake Optimization

A wake optimization will evolve under the influence and trends of high technology and varying sustainability ethics. With the advancement in CFD simulations, design engineers can verify hull shapes with higher accuracy, allowing them to concentrate on minimizing drag and wake generation well before any product is submitted for prototype testing. Additionally, AI and machine learning applications in boat design alter the way performance data is interpreted, sometimes proposing adaptive solutions to specific scenarios for actual operations.

Electrification and hybrid propulsion systems are increasingly recognized as major trends that contribute to reduced fuel consumption and environmental degradation. Thus, energy-efficient motors are combined with optimized hull structures to reduce wake turbulence while maximizing operational efficiency. In addition, materials technology represents an equally important sector of progress with lightweight composites and eco-friendly coatings applied to lessen water resistance and promote marine sustainability.

As an additional reference, vessels are now equipped with such systems, allowing operators to adjust speed and propulsion dynamics to account for wake impact. Greater efficiency and compliance with rising regulations aimed at shielding aquatic habitats from undue turbulence and erosion resulting from wakes are achieved through such systems. Collaboration between researchers, shipbuilders, and environmental agencies will go a long way toward further developing such technology to ensure that next-generation vessels retain both high efficiency and environmental considerations.

Brand Comparisons: Leading Propeller Manufacturers

Top Brands and Their Innovations Analyzed

One can summarize this answer by saying that many leading propeller manufacturers have chosen to stand out with innovative designs and technologies that intend to maximize efficiency and minimize environmental impacts. For example, Rolls-Royce pioneered the design and manufacture of highly efficient propeller systems, such as the Promas integrated propeller and rudder system. This design reduces fuel consumption and emissions, making it a sought-after option for shipping companies concerned with environmental sustainability. Similarly, Wärtsilä enhanced efficiency with the EnergoProFin, a cap solution that transforms the way energy loss occurs due to propeller tip vortices. Such developments further enhance performance and meet sustainability goals, which, in today’s maritime industry, are more vital than ever.

Another important player is Schottel; its main development thrust during the rise of azimuth thrusters has been toward those thrusters that offer the utmost quality of maneuvering, along with good fuel efficiency. Their SCHOTTEL EcoPeller stands out for its highly optimized hydrodynamic design and ability to ensure stable operation even under the most demanding conditions. Additionally, MAN Energy Solutions focuses on holistic solutions, providing energy-efficient propeller systems integrated with digital monitoring tools that enhance operational insights. Therefore, each of these companies has developed its methods for addressing the ever-growing demand for proper propeller systems in both economic and ecological spheres.

In effect, the array of innovations contributed by the prominent brands indicates that technological advances lead the path forward of marine propulsion. Working towards reducing environmental impact while simultaneously enhancing fuel efficiency and promoting the sustainable utilization of maritime infrastructure, these brands have been setting new standards for the industry. Their emphasis is on meeting shipping requirements, modern regulatory requirements, and ecological considerations, so that there may be an orderly evolution of the sector.

Consumer Preferences and Brand Loyalty

To me, consumer preferences in the marine industry are mostly impacted by innovative design, sustainability, and practicality. Consumers have recently begun to favor companies with advanced propulsion systems that offer higher performance and address significant environmental concerns related to human activities. The movement toward greater eco-consciousness speaks volumes about the increased expectations placed on brands for their products to align with global sustainability goals, while being compliant with stringent regulatory standards. A brand that stands for green technologies, yet maintains an impeccable record of highest performance, fosters trust with the consumer, making itself more attractive to buyers in today’s world.

From my perspective, brand loyalty can be developed not only by the quality of products but also through the process of fostering ongoing relationships with customers. Companies that focus on customer support after the sale, maintain transparency in their communication, and proactively address others’ problems in some way will have a greater degree of loyal clients. Warranties, training, and scheduled maintenance are all features that contribute to consumer satisfaction and loyalty. A brand that preaches innovation and demonstrates greater foresight in predicting market needs will have a stronger grip on retaining its place in a competitive industry.

What I am trying to say is that environmentally responsible, high-performance brands, along with good customer engagement, protect consumer loyalty in the marine propulsion sector. Customers invest in brands they feel will meet their present needs and prepare them for future demands, ensuring their operations remain efficient and compliant when their situation changes. Thus, it is incumbent upon any manufacturer to meet these conditions in order to achieve long-term success in this ever-changing industry.

Market Share and Competitive Strategies

When dealing with market share and competitive strategies, I keep customer demands at the center and relate them to innovative solutions that meet their needs. Advanced technology, improved performance, and sustainable operations represent the distinguishing features of the product and service offerings in the competitive marine propulsion industry. This ensures that environmental compliance and efficiency are consistently high, a reflection of the fundamental values of reliability, responsibility, and forward-thinking innovation that underpin my strategies. Meeting the needs of customers from this perspective enables me to market my offerings as practical and future-ready concepts.

I also continuously monitor market movements and competitor activities. This uses data-driven insights to locate new openings or, conversely, missing points from my perspective. I maintain strong industry contacts and stay informed about the latest regulatory changes, allowing me to continually refine my approach to stay competitive in a market that is constantly evolving. I put my money on careful planning and scrupulous attention to customers to achieve both short-term gains and long-term market share growth.

Reference Sources

-

7 Innovative Boat Manufacturers Leading Marine Technology in 2025 – Yachting Ventures

Discusses advancements in sustainable propulsion systems and energy-efficient technologies in the marine industry. -

Boat Propellers Market Scenario 2025: Resilience and Innovation – LinkedIn

Highlights how manufacturers are addressing environmental concerns with low-emission, fuel-efficient propellers. -

Loopy High-Efficiency Propellers Accelerate into Production – New Atlas

Focuses on Sharrow Engineering’s innovative looped propellers and their production expansion in 2025. -

Propeller Systems Market Innovations and Projections for 2025 – OpenPR

Explores industry trends in research and development aimed at improving propeller efficiency, reducing noise, and enhancing performance. - View for more details.

Frequently Asked Questions (FAQs)

What are the leading names among the propeller manufacturers?

Within the marine industry, there exist a few leading brands in the manufacturing of boat propellers. Some distinguished names, a list probably incomplete, include Michigan Wheel, Acme, and Solas, all of which produce top-grade propellers. The manufacturers offer designs of different blades, with 4-blade and stainless steel options available to the purchaser, depending on their boating needs. Additionally, Sharrow Marine is making a name for itself by offering designs that optimize fuel efficiency. The choice of a propeller is primarily influenced by concerns about customer support and product quality associated with a given brand.

How does performance depend on propeller design?

The propeller design has a direct impact on the characteristics that govern vessel performance, such as speed, acceleration, and fuel efficiency. With an increase in pitch, the top-end speed can be better achieved, whereas acceleration may be improved with a decrease in pitch. Again, the number of blades is relevant: four-blade propellers, for example, offer increased grip and smoother operation, especially in rough waters. Firms such as Michigan Wheel and Acme employ advanced manufacturing processes to optimize their designs, resulting in a product that fulfills nearly every conceivable boating application. The correct choice of propeller can lead to near-miraculous improvements in a boat’s overall performance.

What materials do the various manufacturers of boat propellers usually use?

Generally, two primary materials — namely, aluminum and stainless steel — are used by propeller manufacturers. Aluminum props are lightweight and cheap, and are popular with recreational boaters. On the other hand, stainless steel propellers are preferred when strength and corrosion resistance are considered, especially in a saltwater environment. Leading manufacturers utilize CNC machining techniques to achieve extremely high precision in stainless steel prop formation. The materials and processes help promote higher performance, longer life, and increased efficiency in the marine propulsion systems. Boat owners need to weigh in on the selection of material that best suits their specific boating requirements and conditions.

What factors should I consider when choosing a prop for my inboard boat?

Choosing the right propeller for your inboard vessel depends on several factors that are crucial to ensure good performance. The diameter and pitch of a propeller are the primary considerations, as these two features determine its speed and torque capabilities. Moreover, the number of blades could affect performance; having more blades might provide a better grip on water. A prop should be chosen based upon the specifications of your engine and what the prop will be used for, leisure cruising or water skiing performances. Top manufacturers, such as Volvo Penta and Acme, provide a wide array of options for inboard applications. Additionally, consider the manufacturer’s reputation for providing good customer service and support.

How do I improve my fuel efficiency with the right marine propeller?

Fuel efficiency can be improved with your watercraft by choosing the appropriate marine propeller. Selecting the right propeller for your engine will enable it to run at low RPMs without affecting speed. It’s essential to select a prop with the correct pitch and diameter, as an improperly chosen one will cavitate and lose efficiency. On the manufacturers and brands side, fuel-efficient designs were introduced by Sharrow Marine through improved hydrodynamics. Maintaining your marine bearings and shaft seals will also help improve the performance and efficiency of the whole system. Consult a propeller expert to determine the propeller that will perform best on your vessel.

What is the manufacturing process involved in making high-grade performance propellers?

A high-performance propeller manufacturing process involves numerous precision techniques to ensure quality and performance. Leading manufacturers typically begin with premium materials, such as stainless steel, and utilize CNC machining to shape the specimens, enabling complex blade designs that smooth water flow and reduce drag. After machining, the props undergo extensive quality checks and testing to ensure they meet industry standards. Furthermore, some manufacturers employ high-tech methods to refine designs for specific boat applications, ensuring that the propellers deliver optimal performance. Understanding the process helps the boater identify the best products for their boats.