A boat propeller is what determines the performance, efficiency, and safety of any watercraft. During use, a propeller may lose its optimal efficiency, best abrasion resistance, or reasonable condition due to regular use and environmental factors. Hence, understanding good propeller repair methods is paramount to the curiosity of the boat owner. This 2025 guide delves into the basics to offer advanced insights, practical ideas, and the latest trends in boat propeller maintenance and repair. From addressing minor nicks and bends to safeguarding against significant structural damage and even navigating innovations in propeller technology, this book aims to equip you with the knowledge to ensure your equipment performs well and has its lifespan prolonged. So, prepare yourself to polish your skills and always be ready to take on the water with confidence.

Understanding Boat Propellers

1Boat Propellers Components

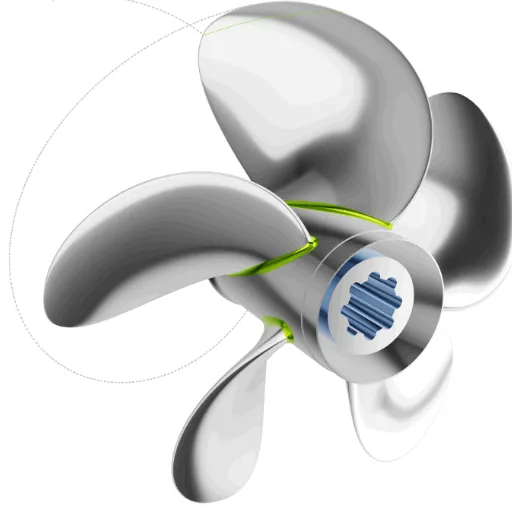

A boat propeller is comprised of several critical components that work in coordination to efficiently transfer engine power into thrust. This thrust type of the vessel is either forward or backward.

Blades

The blades are the most visible part of a propeller and cut through the water to create lift for propulsion. The number, shape, and pitch of the blades significantly contribute to defining the performance, including speed, fuel efficiency, and maneuverability.

Hub

The hub is the central part of the propeller join. It is fitted onto the extension shaft of the propeller, allowing rotations from the engine to be correctly translated. A well-designed hub is also important to keep balance and structural integrity under various operating loads.

Leading and Trailing Edge

The leading edge is at the front of the blade that first comes into contact with water, while the trailing edge is at the back, where the water leaves the blade. Any unusual wear or damage to these edges will result in inefficiency during operation or cavitation.

Cupping

Most modern propellers feature cupping, characterized by a curved lip on the trailing edge of the blades. This helps to provide better grip in water, accelerating the boat, reducing slippage, and making the propeller more efficient at high speeds.

Pitch

The pitch of a propeller indicates the theoretical distance that it will move forward in one full rotation, assuming no slippage occurs. Pitch is usually decisive when it comes to speed and power. High-pitch propellers mean high speed, while low-pitch propellers are for great pull.

Diameter

The diameter is called the overall size of the propeller, determined by measuring the most significant distance across the circle traced by the blade tips during rotation. With larger diameters, more thrust could be exerted on heavy boats, while smaller diameters will be exerted on light, high-speed crafts.

Splines and Bushings

The splines are grooves inside the hub that copy the corresponding ones on the propeller shaft, attaching loosely. The bushings, made from rubber or another resilient material, would absorb vibrations and thereby protect the drivetrain from sudden impacts or strain.

Key Insight: A good understanding of these components and their functional aspects will lead to better maintenance and performance of adjustments, ensuring the boat delivers top performance and reliability on the water.

2Types of Boat Propellers: Aluminum vs. Stainless Steel

Necessary considerations when selecting either aluminum or stainless steel propellers include the mechanical properties, performance characteristics, and intended application of both materials.

🔶 Aluminum Propellers

- ✓ Cost: Inexpensive to produce

- ✓ Weight: Lightweight construction

- ✓ Efficiency: Less strain on engine

- ✓ Fuel: Better fuel efficiency

- ✗ Durability: Easily damaged by debris

⚡ Stainless Steel Propellers

- ✓ Strength: Superior durability

- ✓ Performance: High-torque applications

- ✓ Efficiency: Thinner blades, less drag

- ✓ Longevity: Extended lifetime

- ✗ Cost: Higher upfront investment

Aluminum propellers are widely accepted for being inexpensive to produce and lightweight in construction. The lighter weight puts less strain on the engine, which is beneficial for fuel efficiency, making them a more economical option for most recreational boating needs. Yet, being a soft material, aluminum tends to be readily damaged when it comes in contact with debris or ground impacts. In harsher conditions, it can indeed flex, thereby losing its efficacy at faster speeds.

By contrast, stainless steel propellers are said to remain strong and retain their quality for years. They will never deform in the presence of high torque or greater stress and, therefore, will be ideal for high-performance applications or heavy loads. Far too rigid, stainless steel would ensure that flexing rarely occurs, resulting in power transfer variations and inconsistent performance in high-speed, turbulent waters. To put it simply, stainless steel propellers are more expensive upfront, but their extended lifetime and boost to efficiency can surely pay off in the long run.

Hydrodynamically speaking, stainless steel propellers tend to have thinner blades, which, thanks to the material’s strength, yield overall less drag and better performance. Aluminum propellers with thicker blades may still provide adequate performance within a moderate range of operation. Knowing these differences can enable boat owners to select the propeller material that best suits their specific marine requirements.

3How the Propeller Design Affects Performance

The propeller design is one of the most critical factors affecting the performance, efficiency, and handling of the ship. For example, major factors that affect the translation of engine power into thrust by the propeller include the number of blades, blade shapes, pitch, and diameter.

Number of Blades

One key factor of propeller design is the number of blades. The more the blades, the smoother and less vibratory a propeller is considered to be; such propellers are thereby found in use on larger vessels where comfort is a critical consideration. On the contrary, fewer blades will produce more drag but offer greater efficiency; hence, they are the choice of high-speed watercraft.

Pitch Considerations

Imagine the pitch of a propeller as the distance it theoretically moves ahead in one rotation through water; whatever the pitch, it is associated with speed and power. If one wishes to do something quickly, it will demand energy to maintain the RPM; conversely, if one wants to accelerate quickly, it must do so at the expense of a lower top speed. Choosing the pitch thus becomes of prime importance in making the trade-off between speed and power output.

Blade Profile and Rake

The blade profile and rake also influence the performance. High rake propellers help in recovering from cavitation and deliver improved performance in disturbed or aerated water, whereas low rake propellers are very stable in flat water. Diameter refers to the full width of the circle formed by the rotating blades, which affects the delivery of thrust and hull compatibility. Bigger sizes produce vast amounts of thrust at very low RPMs, making them best suited for big and heavy boats. Smaller sizes, on the other hand, produce thrust at higher RPMs, thereby helping speed in lighter boats.

Modern Innovation: Modern advances in the science of fluid flows and materials engineering further refine these design variables. With the help of computational modeling and high-precision manufacturing, a propeller is designed to match the profile of an individual vessel, thereby enabling it to perform optimally under varying conditions.

Common Types of Damage to Boat Propellers

⚠Identifying Damage in Outboard Propellers

Damage to outboard propellers manifests in different ways, acting as the primary antagonist to the propulsion system’s performance and efficiency. A visual inspection is necessary to identify common problems, such as bent blades, cracks, or chips along the propeller edges.

Bent Blades

Typically causes an imbalance in the hydrodynamic forces, resulting in excessive vibration and poor fuel consumption conditions.

Cracks

Often develop from stress or sudden impacts on submerged objects and further spread upon operation, thus compromising structural integrity.

Pitting/Corrosion

Typical in areas exposed to saltwater, due to the corrosion caused by the electrochemical reaction on the propeller.

Hub Deformation

Wear or deformation of the propeller hub could cause slippage or misalignment of the drive shaft.

These faults frequently manifest themselves through performance variation, often characterized by sudden speed loss, increased engine workload, or erratic RPM fluctuations.

🔬 Advanced Diagnostics

Advanced diagnostic tools, such as vibration analysis and acoustic monitoring, are increasingly being used to detect propeller damage with greater accuracy. These means measure abnormalities that bigger eyes can seldom catch before initiation of preventive maintenance intervention for damage arrest toward the propulsion system. Thus, maintaining a regular maintenance program and developing knowledge of the vessel’s operating conditions are crucial in reducing propeller damage and ensuring optimal performance.

🔍Signs Your Boat Propeller Needs Repair

Early identification of propeller damage will ensure your vessel remains efficient and safe. A standard indicator, in this case, is the significant loss of speed or thrust at usual engine RPMs.

⚠️ Warning Signs Checklist

- 1

Speed/Thrust Loss: Significant loss of speed or thrust at usual engine RPMs - 2

Unusual Vibration: Felt in either the engine or the stern area due to propeller imbalance - 3

Visible Damage: Cracking, nicking, or corrosion that should never go unnoticed - 4

Increased Fuel Consumption: Without corresponding performance improvements - 5

Reduced Top Speed: Boat cannot reach its usual maximum speed

This can occur due to bent blades, chipped edges, or uneven surfaces that disrupt water flow. Meanwhile, another significant warning is the unusual vibration felt in either the engine or the stern area. This typically occurs due to propeller imbalance, which can result from impact damage or material wear.

Visible damage to the propeller, such as cracking, nicking, or corrosion, should never go unnoticed, as aggressive factors may increase such problems into larger structural concerns. Increased fuel consumption without corresponding performance improvements may indicate other issues with the pitch or alignment of the propeller. Lastly, if the boat cannot reach its usual top speed, then the propeller may need repair to restore its ultimate performance or replacement. Such regular inspections and timely interventions on the signs can ensure the reliability and longevity of the propulsion system.

💥Common Causes of Propeller Damage

The direct impact of environmental factors and operational stresses causes typical damage to propellers.

🪨 Impact Damage

It is more common for a propeller to strike a submerged object-a rock, a tree stump, or even debris-while navigating the shallow or uncharted waters. Even the slightest impact can cause nicks, bends, or cracks in the blades, thereby impairing performance.

🌊 Corrosion

Long-term exposure to corrosive elements such as saltwater is another common cause of damage. The degradation of metals, especially when maintenance and coating are withheld, is accelerated.

💨 Cavitation

The formation of vapor bubbles under pressure through cavitation lowers the pressure on the opposing surface of the propeller. Upon collapse, this violent erosion of the metal surface causes pitting and a reduction in efficiency over time.

⚙️ Installation Issues

Further damage comes from improper installation of the propeller or having it set off-centre through its mountings, as vibrations and stress increase on the blades and hub. Additionally, installing the wrong pitch for the engine and vessel can result in undue wear and strain on the propeller.

Finally, wear and tear from regular operation, combined with high levels of engine torque, only serve to aggravate these microfractures or other minor imperfections, which, over time, eventually enlarge to inflict severe damage if left unattended. It is imperative to identify these damage offenders and inspect and maintain the propeller regularly to ensure its longevity and optimal operation.

Boat Propeller Repair Techniques

⚖️DIY vs. Professional Propeller Repair

More crucial to consider when choosing between DIY and professional propeller repair is the complexity of the damage, the resources required, and the potential outcome involved.

🔧 DIY Repair

✅ Suitable For:

- Small dents or scratches

- Minor surface imperfections

- Basic maintenance tasks

- Aluminum propeller minor repairs

🛠️ Tools Needed:

- Files and sandpaper

- Specialized hammers

- Basic measuring tools

⚠️ Caution:

Great care is necessary to ensure that the propeller is perfectly balanced afterward, considering improper balancing will lead to problems such as vibration or poor efficiency.

👨🔧 Professional Repair

✅ Required For:

- Bent blades

- Cracks and structural damage

- Loss of material

- Stainless steel repairs

🏭 Professional Tools:

- Measuring devices for blade pitch

- Advanced welding procedures

- Precision balancing equipment

📊 Efficiency:

Statistics from marine maintenance reveal that propellers repaired by professionals often retain 95% of their original efficiency.

DIY repair can be done for minor issues, such as small dents or scratches. Generally, minor repairs use tools such as files, hammers, or sandpaper, and the process is carefully navigated to avoid hitting or damaging the propeller further. For instance, minor dents on aluminum propellers can be repaired by knowledgeable boat owners, especially those with prior experience in the procedure. However, great care is necessary to ensure that the propeller is perfectly balanced afterward, considering improper balancing will lead to problems such as vibration or poor efficiency.

Bent blades, cracks, loss of material-these are some of the severe damages that require professional attention. Professional workshops utilize specialized tools, including measuring devices for blade pitch and advanced welding procedures, to restore the propeller to its original design specifications. Balancing and testing are also carried out by professionals who prescribe maximum performance to prevent inefficiency or stress from occurring in an engine due to an imbalanced propeller.

Bottom Line: While DIY repairs are cheaper and more convenient for minor adjustments, severe damage requires entrusting professionals to ensure calibration is done correctly, thereby extending the propeller’s life. In fact, regular inspections, along with the right repair option, are key ingredients in maintaining the overall performance of the vessel.

📋Step-by-Step Repairing of Outboard Propeller

Complete Propeller Repair Process

Follow these steps for professional-quality repairs

Assessment and Identification of Damage

A careful examination of the propeller will reveal visible damage, such as bends, cracks, or chips, in the blades. Use a straight edge to check the blade surface for any distortions, confirming proper alignment. Minor chips and dings can be repaired, while more serious structural damage may require replacement. Do not allow small deformations to sit idly by; small deformations can cause vibrations or loss of efficiency.

Propeller Removal

Remove the propeller from the shaft after loosening and removing the nut from the propeller using the appropriate socket or wrench. Remove the cotter pin if present. Mark the propeller position if exact alignment will be critical upon reassembly. Use gloves to avoid contact with the sharp edges of the blades or with any deposits along the shaft that may irritate the skin.

Cleaning and Maintenance

Before installing the propeller on the shaft, it must be cleaned of debris, marine growth, or signs of corrosion. A non-abrasive cleaner, generally combined with a wire brush or cloth, should work fine. The hub and shaft must be clean and free from obstructions to ensure their smooth reinstallation. Along with cleaning, it is also good to regularly inspect for hidden cracks or areas of wear and tear.

Blade Repair and Balancing

For minor damage to the blade, use an appropriate resin or filler compound designed for marine use to fill chips or dents. Following the setting of the material, it is sanded until it conforms precisely to the original shape of the blade. Balancing of the propeller is then undertaken using a balancing machine to maintain optimum performance and minimize vibration during operation.

Hub Inspection and Replacement

Examine the propeller hub for signs of wear and fatigue. A damaged hub usually compromises propulsion efficiency or causes excessive vibrations. Replace the rubber hub insert if you feel competent; otherwise, seek professional assistance to have it pressed in using correctly calibrated equipment.

Reassembly and Reinstallation

Apply a thin layer of waterproof marine grease to the shaft before installing the propeller for corrosion prevention and ease of removal during future repairs. Slide the propeller onto the shaft, ensuring it fits snugly with the splines. Attach the nut and cotter pin (if applicable) and tighten the nut to the torque specifications recommended by the manufacturer.

Testing and Final Adjustments

Once reinstalled, test the propeller by operating it at low speed in shallow water or at a testing facility. Be aware of vibrations, unusual noises, or power loss. If adjustments are needed, either repeat the repair steps or seek more advice from a professional technician.

✅ Final Note

Following this guide, all outboard propeller repairs are performed in a methodical and precise fashion so that they remain functional for a longer time than they would otherwise. Considering the best results, always consult your engine manufacturer’s specifications and recommended procedures.

🎯Marine Propellers: Precision Repair Techniques

Depending on the application and operating conditions, marine propellers are typically made from aluminum, stainless steel, or bronze, each with its own advantages.

🔶 Aluminum Propellers

Characteristics: Fast to manufacture and cheap, mainly found on small recreational boats.

Repair Method: Surface dents and nicks can generally be repaired by reshaping with special hammers, polishing, and restoration of aerodynamics and balance.

⚡ Stainless Steel Propellers

Characteristics: Greater strength than aluminum and well-suited for high-performance applications due to exceptional corrosion resistance.

Repair Method: Scratches and significant deformations are repaired through welding or high-precision machining, ensuring subsequent grinding in accordance with specifications.

🟤 Bronze Propellers

Characteristics: Selected for harsh saltwater environments due to excellent durability; often utilized by commercial and industrial vessels.

Repair Method: Repaired through brazing or soldering, considering the damage to preserve the propeller’s integrity.

⚠️ Critical Warning

Upon improper repairs or negligence in addressing propeller imbalances, operational efficiency may be lost to the tune of at least 20%, while also accumulating stress on the engine and gearbox.

🔬 Quality Assurance

Such risks can be minimized by precisely calibrating pitch gauges and digital balancing devices, ensuring a guarantee of performance after repair. Repair methods should adhere to industry standards, and all refurbished propellers must meet specific criteria in static/dynamic testing to verify their structural integrity and performance under prescribed loads.

Trends in Boat Propeller Technology for 2025

🚀Materials and Design Innovations for Propellers

Recent developments in boat propellers have had a significant impact on materials and their aerodynamic designs, focusing on efficiency.

🌟 Revolutionary Material Advances

Carbon Fiber Composites

High-strength, lightweight carbon fiber-reinforced polymer materials offering superior durability, corrosion resistance, and strength.

Weight Reduction

Significantly reduces total propeller weight, increasing fuel efficiency and vessel handling capabilities.

🖥️ Advanced Hydrodynamic Analysis

The other area of focus for innovation is advanced hydrodynamic analysis, along with the application of CFD software for propeller design. Armed with these tools, an engineer can fabricate blade geometries that minimize the creation of cavities while maximizing thrust and energy transfer.

Biomimetic Innovation: Biomimetic designs inspired by marine life, such as humpback whales, have led to the development of serrated-edge propeller blades that reduce drag and enhance laminar flow characteristics.

📊 Performance Data

Efficiency enhancement from hybrid-material propellers vs. conventional types

Systems enabling blade replacement and custom configurations

According to recent data from marine performance tests, hybrid-material propellers, which feature metal cores with composite exteriors, provide a 15-20% efficiency enhancement compared to conventional types. Modular propeller systems have also gained momentum, enabling blade replacement and custom configurations to meet varying degrees of performance requirements, thereby endowing operators with both versatility and long-term savings.

The entire set of developments aims to strike a balance among the growing need for sustainability in marine engineering, stricter environmental regulations, high-performance demands, and reliability in various operating conditions.

🌱Emergence of Propellers of Eco Design

🌍 Sustainable Marine Engineering

Reducing environmental impact while safeguarding operational efficiency

Eco-designs brighter propellers, thus playing a paramount role in the realm of contemporary marine engineering, aimed at the immediate reduction of environmental impact while safeguarding operational efficiency.

🔬 Advanced Materials

- Lightweight composites

- Corrosion-resistant alloys

- Longer-lasting behavior

- Reduced environmental impact

🖨️ Manufacturing Innovation

- 3D printing technology

- Highly efficient geometries

- Optimized water resistance

- Reduced fuel consumption

🌊 Hydrodynamic Improvements

- Special blade curvature

- Tip modifications

- Reduced cavitation

- Minimized noise pollution

📈 Performance Benefits

Fuel economy improvement from enhanced design

Greenhouse gas emissions reduction

Such propellers have been conceived from more modern materials, for example, lightweight composites and corrosion-resistant alloys, thereby conferring attributes such as longer-lasting behavior and reduced environmental impact. Additionally, cutting-edge production technologies, such as 3D printing, enable the manufacture of highly efficient propeller geometries. This optimizes less water resistance and fuel consumption.

A hydrodynamic improvement can diminish propeller performance, as special blade curvature and tip modifications significantly reduce cavitation and noise pollution. Industry studies indicate that improved design can achieve a fuel economy of nearly 15%, thereby reducing the amount of greenhouse gases released into the atmosphere. This may be taken even further, with energy-saving devices, such as pre-swirl stators or contra-rotating propellers, which reportedly achieve higher efficiency in vessel propulsion systems.

Economic Impact: Eco-friendly propeller design is not only better for environmental compliance, but it also remains an economically attractive option. These innovations provide increased long-term value for ship owners and operators by reducing operating costs through enhanced energy efficiency. This combination of environment and performance illustrates the growth toward greener and more powerful propulsion system solutions in the global shipping industry, particularly within the maritime sector.

⚡Technology Impact on Propeller Performance

Modern propeller systems have undergone technological updates to enhance their performance in areas such as fuel efficiency, noise reduction, and hydrodynamic optimization.

💻 CFD Simulations

Capabilities: Analysis of fluid flow around propellers and prediction of cavitation patterns on blades

Benefits: Modification of blade geometry to produce optimum thrust with minimal drag

🔬 Advanced Materials

Types: Advanced composites and superalloys revolutionizing manufacturing

Properties: Robust, corrosion-resistant, capable of withstanding rigorous marine conditions

⚙️ CRP Technology

Innovation: Counter-rotating propellers and tip vortex-free technology

Result: Eliminates energy losses and increases thrust efficiency

📡 Real-Time Monitoring Systems

Another key factor leading to improved efficiency of propellers is the application of data gathered from real-time monitoring systems. Using smart sensors integrated with IoT, operators monitor vibration, pressure, blade stress, and operating parameters during real-world usage.

Monitored Parameters:

- Vibration patterns

- Pressure variations

- Blade stress levels

- Operating parameters

Benefits:

- Predictive maintenance

- Longer life expectancy

- Consistent performance

- Profit realization

CFD simulations have long been considered essential in propeller design exercises, as they enable the analysis of fluid flow around the propeller, prediction of cavitation patterns on the blade, and modification of the blade geometry to produce optimum thrust with minimal drag. These modeling techniques are used to design higher-performance propellers that can minimize fuel costs and operational expenses.

Novel materials, such as advanced composites and superalloys, have entered the scene, revolutionizing the propeller manufacturing industry. These materials are therefore robust, corrosion-resistant, and capable of withstanding the most rigorous marine conditions. Further thrust improvements have been observed with the advent of CRP and tip vortex-free technology, which eliminates energy losses and thereby increases thrust efficiency.

Industry Direction: Such technological developments not only ride the wave of the global shipping industry’s push for decarbonization but also draw a clear line toward a faster timeframe for implementing sustainability standards. On the other hand, they tend not to, at least presently, compromise the performance of the vessel.

Case Studies and Data on Propeller Performance

📋Real-Life Examples of Boat Propeller Repairs That Work

Modern techniques and case studies of repair methods emphasize the importance of precision in restoring a propeller to a state of perfection, resulting in measurable increases in performance and energy efficiency.

🚢 Commercial Cargo Ship Case

Problem:

Cavitation damage to propeller affecting fuel efficiency

Solution:

Laser welding methods to restore original shape and balance

Fuel consumption reduction achieved

⛵ Recreational Yacht Case

Problem:

Minor cracks on blades detected during routine maintenance

Solution:

High-precision 3D scanning and computational modeling for repair

Propulsion efficiency increase

For example, a commercial cargo ship undergoing repair for cavitation damage to its propeller achieved a fuel consumption reduction of up to 10% as a result of restoring the original shape and balance of the propeller using laser welding methods, thereby addressing the hydrodynamic inefficiencies.

This was another attractive situation where minor cracks on the blades were detected during routine maintenance of a recreational yacht. Experienced experts conducted high-precision 3D scanning and computational modeling to analyze the damage and then repair the fracture without compromising the propeller’s structural integrity. The post-repair testing revealed that thrust performance had actually improved, resulting in enhanced maneuverability and a 7% increase in propulsion efficiency.

🔬 Advanced Diagnostics Integration

Such instances, therefore, caught with an example serving to support the argument in favor of introducing diagnostic technologies, such as ultrasound testing and non-destructive evaluation (NDE), into the propeller repair process. When coupled with precision engineering, these methodologies not only restore functionality but also optimize vessel operation, reducing maintenance costs and facilitating long-term sustainability initiatives in the maritime domain.

📊Statistical Analysis of Propeller Efficiency

I approach propeller efficiency from a statistical analysis viewpoint, emphasizing parameters that can be measured, such as thrust, torque, and overall propulsive performance under specific conditions.

📈 Measurement Parameters

Forward propulsion force

Rotational force

Consumption measurement

Vessel speed analysis

Before and after repair, fuel consumption rates and vessel velocity are studied to see how changes or improvements effected during repair affected these key parameters. With the help of statistical tools such as regression analysis and control charts, I identify trends and anomalies in propeller performance, which enables an evidence-based evaluation of efficiency gains.

🔬 Data Acquisition Process

This and that are undertaken with the data acquisition process to ensure accuracy. The technique utilizes advanced instrumentation and diagnostic systems to accurately capture water flow dynamics, cavitation effects, and operational loads during testing. From the comparison of the performance data with baseline data, it is thereby computed how the propulsion efficiency improves in percentage and how much the operational energy consumption is reduced.

🎯 Analysis Benefits

This, in detail, provides proof of the opportunity for repair techniques and guides future repair optimization toward cost-effectiveness and environmental sustainability in maritime operations.

💡Lessons Learned from Common Propeller Issues

Through my studies of common problems with propellers, it appears that if recognized early and constantly observed, performance deterioration can be mitigated accordingly.

🔍 Early Detection

Cavitation, blade erosion, and alignment problems often arise due to operating stresses and improper maintenance practices.

Detection Methods:

- Vibration analysis

- Underwater inspection

- Advanced diagnostic tools

🛡️ Material Enhancement

Material selection and surface treatment emphasis increases the durability of the propeller.

Improvements:

- High-performance alloys

- Surface coatings

- Corrosion resistance

- Fouling protection

⚙️ Precision Engineering

Repair methods employing precise engineering techniques help restore performance almost to original level.

Techniques:

- Dynamic balancing

- Hydrodynamic profiling

- Energy loss reduction

With the use of advanced diagnostic tools, I can already notice abnormal performance well before it matures into significant, more expensive problems. For instance, vibration analysis and underwater inspection are effective methods for detecting misalignment or structural defects in propellers.

Another key lesson is the emphasis on material selection and surface treatment to increase the durability of the propeller. High-performance alloys and surface coatings offer improved resistance to corrosion and fouling, thereby extending the operational life of the bath propeller. Thus, it is assumed and believed that this would result in lower repair costs and more efficient propulsion over time. Additionally, I observed that repair methods employing precise engineering techniques, such as dynamic balancing and hydrodynamic profiling, helped restore performance almost to its original level, thereby reducing energy losses.

🤝 Collaborative Solutions

Ultimately, the operational team and maintenance personnel must collaborate to develop proactive solutions for recurring issues. Setting up a clear communication channel or rewarding the sharing of lessons learned from failures ensures that practical plans are successfully built upon past maintenance experiences. This, through repair protocols, contributes to making propulsion systems more robust and reliable, ultimately enhancing vessel performance while reducing environmental impact.

Reference Sources

- 2025 Guide to Repairing a Spun Prop or Lower Unit – A step-by-step guide to addressing common propeller issues.

- The Ultimate 2025 Checklist on How to Reduce Boat Propeller Noise – Focuses on identifying and solving propeller noise problems.

- The Essentials of Boat Propeller Repair – Covers cleaning, inspecting, and repairing propellers effectively.

- How to Master the Art of Boat Propeller Repair – Offers tips on seasonal inspections and maintenance.

- The Hidden Signs Your Boat Propeller Needs Repairs – Highlights critical signs of damage and how to address them.

Frequently Asked Questions (FAQs)

What are the signs one can expect from a damaged boat propeller?

Vibrations felt upon operation, reduced boat performance, and visibly damaged prop blades, such as nicks and bends, constitute common signs of a damaged boat propeller. If a different or unusual noise is heard, or if the vessel is frequently being towed back to shore, that could be yet another signal of prop damage. Most importantly, frequent checks for any signs of wear are necessary, especially when stainless steel propellers are used, as they can sustain severe damage if they strike anything underwater. Addressing these damages at an early stage will surely spare you from massive expenditures later.

How does the restoration process on the boat propeller proceed?

The boat propeller repair process usually begins with a thorough inspection of the prop for any bent, cracked, or nicked blades. After assessing the condition of the propellers, repair specialists will weld the damaged area or replace the blade, depending on necessity. Precision must be meticulously maintained when dealing with stainless steel props to ensure they remain balanced and function properly. After repairs, the prop will likely get re-tuned to restore peak efficiency in its operation. Turnaround times depend on the severity of the damage and the shop’s busy schedule.

What are the merits of stainless steel boat propellers?

With durability and resistance to corrosion being primary advantages of stainless steel over aluminum, the stainless steel variety offers better performance, especially in terms of speed and fuel efficiency. It can withstand more abuse and last longer, making it a worthwhile choice for boaters. Additionally, the blades typically feature a better design, which enhances handling and reduces vibration. This new undertaking is an excellent time to consider going stainless.

What would typically be the repair cost of a boat propeller?

Depending on the type of repair and propeller material, the prices for various boat propeller service repairs can vary widely. Minor welding or blade straightening, for example, would usually be more affordable than repairs involving replacement parts. On an average day, you might pay anywhere between $100 and $500, depending on the severity of the damage and the prop shop’s pricing structure. A fresh prop, such as an Acme or Michigan Wheel, would, of course, put you out more money. Still, it could improve performance and hold up better.

When should I consider changing a damaged prop?

The price of a new propeller can range into the hundreds of dollars or more. It should be replaced when a repair would cost 50% or more of the price of a new one, or if its damage truly hinders its performance. If the prop has been bent and repaired multiple times previously, it is likely to retain its original efficiency only after a complete overhaul. Another thing to consider is when you experience continuous vibrations and low fuel mileage; these are both signs that it’s time to replace it. Finding the correct size and type of propellers and driving your boat with either stainless steel or aluminum will significantly enhance its performance.

What types of boat propellers are available for outboard and sterndrive engines?

The principal types of props for outboard and sterndrive engines include aluminum and stainless steel. Aluminum props are typically more affordable and suitable for the casual boating trend, whereas stainless steel props offer greater durability and improved performance. You will also find a few special designs, such as four-blade props, which give better thrust and handling. Consider the diameter and pitch of the propeller, among other factors, to ensure your engine performs well. Asking a propeller shop or repair specialist might help you make the right choice.