Internal combustion engines, two-stroke and four-stroke engines continue to be a hot topic among engineers, enthusiasts, and trade personnel. These two engine types serve as the basic engines that power innumerable machines, from motorcycles to generators, with each having certain advantages and disadvantages. The fundamental differences between two-stroke and four-stroke engines must come to the fore for both those in the automotive and industrial sectors and also for consumers who want to make sound decisions concerning performance, efficiency, and maintenance. This article shall walk you through the varied mechanism, uses, and benefits of these engines to equip you with a sound understanding with which you can navigate this important subject in 2025 and beyond.

Fundamental Differences in Engine Design

Overview of Two-Stroke Engine Design

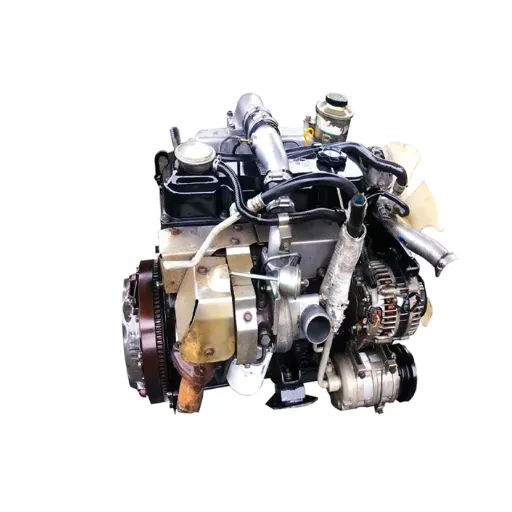

A two-stroke engine is one whose combustion cycle is much simplified and completed within two piston strokes—one stroke for compression and another for exhaust. In comparison to the four-stroke engine, which processes intake, compression, power, and exhaust in four separate strokes, a two-stroke engine combines these steps and is, therefore, extraordinarily powerful in relation to its size and weight.

The essential components of a two-stroke engine are basically its cylinder with a piston and crankshaft, intake, and exhaust ports. In contrast to four-stroke engines equipped with up-and-down valves, a two-stroke engine is port-controlled by openings on the walls of the cylinder where the air-fuel mixture and exhaust gases enter and exit, respectively. When the piston is on the upward stroke, it compresses the air-fuel mixture while drawing a fresh charge of mixture into the crankcase. Then, during the downward stroke, the spark ignites the mixture, which then undergoes the power stroke and forces out the exhaust gases as the piston exposes the exhaust port.

Compactness, simplicity, and a high power-to-weight ratio are attributes of this engine. These features have made it popular for building motorcycles, outboard motors, chainsaws, and light utility equipment. But with no dedicated inlet and exhaust strokes, pressure waves inside a two-stroke engine can cause incomplete combustion and higher pollutant emissions, hence being less friendly to the environment. Also, two-stroke engines tend to have poorer fuel efficiency when compared to four-stroke ones.

Overview of Four-Stroke Engine Design

There are four basic strokes in the combustion process of a four-stroke engine: intake, compression, power, and exhaust strokes. This design is more efficient than a two-stroke design because it allows for complete combustion and better fuel economy. Two full crankshaft revolutions are taken for the engine to give a power stroke, as a result of which power is delivered to the system very smoothly and evenly.

The power stroke occurs as the piston moves downward, drawing air and fuel mixed in precise proportions into the combustion chamber through the intake valve. Next follows the compression stroke, with the piston moving upward and compressing the air-fuel mixture into high pressure, increasing its potential energy in the process. Toward the end of the compression stroke, a spark from the spark plug ignites the mixture and thus begins the power stroke-the only stroke in the cycle that produces usable work. The piston moves downward under the pressure of rapidly expanding gases and transmits force to the crankshaft.

The final stroke is known as the “exhaust,” whereby the piston begins moving upwards and expels the burnt gas through the exhaust valve, leaving the cylinder free to begin the next cycle. The orderly and systematic series of events decreases unburned fuel emission more than that of the two-stroke, while increasing fuel efficiency. Separate valves for intake and exhaust also contribute to a cleaner and more precise working process that increases the reliability of four-stroke engines and makes them friendly to the environment.

Comparison of Engine Components

Here is an abridged list of engine components: engine block, cylinder, piston, oil filter, air filter, starter motor, crankshaft, camshaft, crankcase, connecting rod, engine valves, timing belt, ignition system, and spark plugs.

| Component | Key Function | Material | Maintenance | Common Issues |

|---|---|---|---|---|

| Engine Block | Core structure | Aluminum/Iron | Low | Cracks |

| Cylinder | Houses pistons | Aluminum | Medium | Wear |

| Piston | Converts energy | Aluminum | Medium | Ring damage |

| Oil Filter | Filters oil | Metal/Paper | High | Clogging |

| Air Filter | Filters air | Synthetic | High | Blockage |

| Starter Motor | Starts engine | Metal | Medium | Failure |

| Crankshaft | Converts motion | Steel | Low | Bending |

| Camshaft | Controls valves | Cast Iron | Low | Wear |

| Crankcase | Houses crankshaft | Aluminum | Low | Leakage |

| Connecting Rod | Links piston | Steel | Medium | Fracture |

| Engine Valves | Regulates flow | Steel | Medium | Burnt valves |

| Timing Belt | Synchronizes parts | Rubber | High | Breakage |

| Ignition System | Sparks ignition | Mixed | Medium | Misfire |

| Spark Plugs | Ignites fuel | Ceramic/Metal | High | Fouling |

Performance Characteristics

Power Output of Two-Stroke vs. Four-Stroke

Two-stroke engines put out power on every single revolution, offering a higher power-to-weight ratio. Four-stroke engines, on the other hand, provide power every two revolutions, offering higher efficiencies and more durability.

| Aspect | Two-Stroke | Four-Stroke |

|---|---|---|

| Cycle Type | 1 revolution | 2 revolutions |

| Output Power | Higher | Moderate |

| Fuel Economy | Lower | Higher |

| Lifespan | Shorter | Longer |

| Mass | Lighter | Heavier |

| Design | Simpler | Complex |

| Pollution | Higher | Lower |

| Sound Level | Louder | Quieter |

Torque and Speed Variations

Torque and speed characteristics differ much between the two types of engines and advantage is given for applications accordingly. A two-stroke engine typically produces a higher torque at lower RPM since it has its power stroke for every revolution. This makes it a very good choice for equipment requiring a quick build-up in power while being compact and lightweight, such as motorcycles or chainsaws. However, they tend to be less efficient and cannot control well at other speeds, unlike four-stroke ones.

In contrast, a four-stroke engine will maintain very steady torque over a wider RPM range. At higher speeds, this results in smooth, consistent performance suitable for the likes of cars, trucks, and generators. Since fuel combustion is more controlled, four-stroke engines enjoy better fuel efficiency and durability than the two-stroke types, further advocating their suitability for long-term operations.

These variations illustrate the importance of choosing a design suitable for the particular need of torque and speed of a mechanical system.

Innovations in Engine Performance (2025)

For the year 2025, a landmark leap in engine technology was motivated by materials science, artificial intelligence, and energy efficiency protocols issues. A chief focus of research involves the design of AI-powered systems to optimize engine performance in real-time. These systems can use predictive analytics to monitor wear on the engine, adjust fuel-to-air ratios, and change and fine-tune engine operations for maximum fuel efficiency with minimum level of emissions.

Other major engineering innovations include the replacement of heavy metal components with lightweight-high-strength composites. These materials contribute to weight reduction in the engine, better thermal conductivity, and provision for operational speeds higher than the usual bearing on durability. The evolution of hybrid and electric engines is dependent on the breakthroughs in battery technology extending the range and reducing the charging time, hence fast-tracking sustainable transportation.

The advancements together altogether bring an edge in the realization of more clean, efficient, and resilient engine solutions, modern-day-working.

Fuel Efficiency and Emissions

Fuel Consumption Comparison

While evaluating fuel consumption, modern engines show a remarkable improvement in the efficiency of older generations. The advanced combustion technologies, reduced weight of vehicle materials, and aerodynamicness all help in fuel reduction for engines of all types. For example, gasoline engines with direct injection systems show fuel efficiencies gaining on the order of 15 to 20% when compared to the conventional ones with port fuel injection. Meanwhile, diesel engines, always considered very efficient, still compete quite well by giving better miles and lower CO2 emissions as against gasoline engine per mile.

The last stretch in fuel saving by hybrid-electric vehicles sees a combination of conventional internal combustion engines with electric motors. They allow 30-50% fuel reduction under urban conditions where braking energy recuperation and pure electric operation are important. Moreover, PHEVs can run all electric for a few miles, thereby killing fuel use and emissions for those periods.

In conjunction, innovations such as cylinder deactivation, turbocharging, and start-stop technology give a boost to fuel economy these days. They do also make vehicles cheaper and hence a feasible alternative to consider in industrial and other commercial operations for reducing the environmental footprint.

Emissions Standards and Innovations

Global emission norms are critical to the development of cleaner and more fuel-efficient vehicles. These regulations place limits on the amount of greenhouse gases and pollutants that vehicles may emit to induce manufacturers to invent new technologies for compliance. By way of pushing these regulations, the governments want to minimize the harmful effects of transportation on air quality and human health.

To address the demands, automobile makers have begun to experiment with advanced applications. One basic innovation is the application of selective catalytic reduction systems in diesel engines, where these systems break down harmful NOx emissions into harmless nitrogen and water vapor. A further promising development lies in deploying particulate filters for both gasoline and diesel engines in the trapping of fine particles before releasing exhaust gases into the atmosphere. Apart from engine improvements, lightweight design materials and enhanced aerodynamics are important factors in reducing CO2 emissions through better fuel economy.

The rapid proliferation of electric and hybrid vehicle technology shows the very nature of a shift in manufacturing towards any type of sustainable cast. Technology for batteries also see improvements, for example through the solid-state battery which has great potential because it can offer higher energy density, faster charging time, and better longevity. Advanced regenerative braking systems combined with energy management software stand as technologies vital for optimization of electric and hybrid powertrains to reduce emissions and energy consumption. The juxtaposition of such brilliant innovations not only displays the evolution of the automotive industry into an international-win-case against climate change but also caters to the current mobility-compliant world.

Environmental Impact of Each Engine Type

- Internal Combustion Engines: Internal combustion engines, which mostly use gasoline and diesel, are among the most important causes of GHG emissions. They emit huge quantities of Carbon Dioxide (CO2), Nitrogen Oxides (NOx), and particulate matter, causing air pollution and global warming. Researchers have estimated that a typical gasoline-powered car emits around 4.6 metric tons of CO2 entering the atmosphere each year.

- Hybrid Engines: Hybrid engines, still featuring internal combustion engines and electric motors, give rise to lower emissions compared to the typical ICEs. By recovering energy through regenerative braking and other means, hybrids have the ability to max their fuel consumption efficiency and allow reduced fuel consumption and tailpipe emissions. Yet, their situation is dependent on fossil fuel usage to a lesser extent, given being heavily conditional on driving modes and usage patterns.

- Electric Engines: Electric vehicles, running on batteries, generate no tailpipe emissions, which make for an environmentally preferable option. The environment has a lot to say about the magnets and power source used for electricity generation. For example, EVs running on renewables would have minimal greenhouse gas emissions. However, the manufacture and recycling of lithium-ion batteries bring in some environmental issues, such as the consequences of resource extraction and inefficient recycling.

- Hydrogen Fuel Cell Engines: The hydrogen-fueled engine, when operating, produces only water vapor, making it another zero-emission engine with promising potential. Yet the production of hydrogen itself can give rise to CO2 emissions, especially when the conventional method of steam methane reforming is employed and the electrolysis is not powered by renewable energy. Advances in the production of green hydrogen remain vital for the technology to achieve its full environmental benefits.

Understanding environmental consequences of each type of engine helps industries and policymakers make informed decisions when steering technological innovation and energy strategies toward sustainable avenues.

Diverse Applications of Each Engine Type

Common Uses for Two-Stroke Engines

The two-stroke engine finds widespread application across different industries and uses mainly because of its design simplicity, less weight, and higher power-to-weight ratio. Following are five common uses of two-stroke engines:

- 1

Motorcycles and Scooters: Two-stroke engines are predominantly preferred by the industry for smaller motorcycles and scooters, more so in regions where affordability and ease of maintenance are major considerations. Their quick acceleration and small size also imply they suit urban transport. - 2

Lawn Equipment: Equipment such as lawn mowers, strimmers, and leaf blowers will tend to be powered by two-stroke engines. Such engines are powerful enough to carry out ordinary and commercial landscaping but remain light and easy to use. - 3

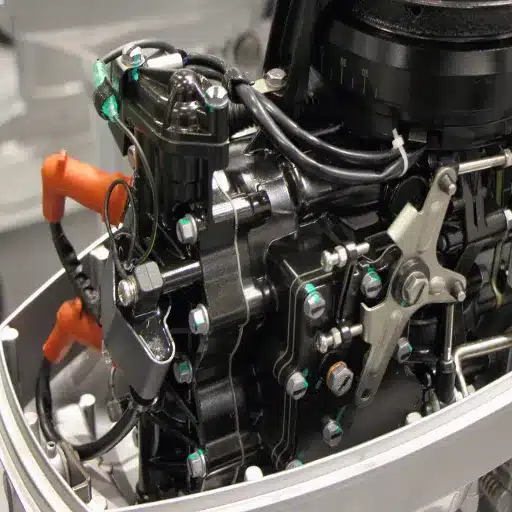

Marine Outboard Motors: Because these boats and small fishing boats can withstand all but the most adverse conditions, the two-stroke engine is favored. The minimum weight is also helpful in reaching higher speeds. - 4

Chainsaws: A majority of chainsaws use two-stroke engines. These engines allow the chainsaws to cut through difficult materials with efficiency. The lightweight nature and power output-fed ergonomics are best suited for forestry and landscaping. - 5

Snowmobiles: Generally used in cold regions, these conveyances are usually powered by two-stroke engines. The engines are renowned for being lightweight and high performing, thus enabling smooth rides over snow-covered terrains.

These applications demonstrate the versatility and utility that define two-stroke applications in both recreational and professional worlds.

Common Uses for Four-Stroke Engines

Four-stroke engines find widespread application within a myriad of fields, exhibiting greater efficiency, longevity, and lesser emission levels than two-stroke engines. The following are five common four-stroke engine applications:

- 1

Automobiles: Four-stroke engines are good for cars and trucks, owing to their lower fuel consumption and emission levels. A four-stroke engine produces decent power and reliability, which helps to commute in the city or for long distances. Thus, modern passenger vehicles support four-stroke engines and, furthermore, hybrid technology to reduce the environmental impact. - 2

Motorcycles: Compared to two-stroke types, the four-stroke motorcycle engine is smoother and quieter in its operation. They also produce fewer emissions and use less fuel, making them perfect for transport both in town and in the countryside. - 3

Lawn and Garden Equipment: Having been fit with four-stroke engines, lawnmowers, cultivators, and garden tractors impart steady, efficient working power for precision and reliability, while at the same time being quite low on noise pollution, offering a pleasant atmosphere in which to work. - 4

Marine Uses: Four-stroke marine engines are usually installed in boat outboard motors. Made for durability and fuel efficiency, they are best suited for recreational and small-scale commercial fishing. They have been made to sustain long hours of operation without causing much harm to the environment through pollutant discharge into the water. - 5

Power Generators: Four-stroke engines have been widely used in portable and stationary power generators. They are able to provide steady and reliable power that is needed for construction sites, emergency backup systems, and outside events. These engines are preferred because of their durability and minimum maintenance requirements.

These applications speak to the adaptability, efficiency, and ecological improvements four-stroke engines carry into each industry in which they operate.

Emerging Applications in 2025

The technology around the four-stroke engine continues to be developed; hence the application profile is growing exponentially. Listed below are five emerging applications into which the four-stroke engine may go in 2025, thus indicating their flexibility and their capabilities of shaping the future:

- 1

Sustainable Agriculture Equipment: Because of their fuel efficiency and low emission, the latest agricultural machinery increasingly deploys four-stroke engines. These engines drive autonomous tractors and harvesters, carry out precision farming, and thus increase crop output enormously and hence lessen environmental impacts. - 2

Hybrid Marine Vessels: Hybrid-powered marine vessels integrate four-stroke engines with electric propulsion systems. These engines provide maximum power for long-distance travels while keeping fuel consumption and greenhouse gas emissions low. This technology is ever so slowly revving up in shipping, to serve the cause of ever-tighter environmental regulations. - 3

Portable Energy Solutions: With the increase in demand for portable, eco-friendly power, modern portable generators using four-stroke power plants have evolved. These generators are most appropriate where disaster relief installations are set, in off-grid renewable energy installations, and remote medical facilities. - 4

Long-Range Aviation Drones: The four-stroke engine is incorporated for heavy-duty commercial and industrial drones. They offer longer flight ranges and higher payload capacities, making them practically suitable for surveying, logistics, and environmental monitoring. - 5

Urban Surety and Micro-Mobility Innovation: Small displacement four-stroke engines are active in urban micro-mobility applications for the fast electrification of scooters and ride-sharing vehicles. During the performance enhancement, these engines work toward the reduction of noise and pollutant emission while giving it a green credit in densely populated urban areas.

Each of these applications innovates for the environment in consideration of the evolution of four-stroke engine technology, thus maintaining its relevance in a sustainable environment.

Future Innovations and Trends

Sharrow Technology and Its Impact

Sharrow Technology is the cutting-edge development concerning propeller, blades, and their design, determined by its peculiar looped-blade geometry. Unlike traditional propeller designs, Sharrow props have an abnormal closed structure that will enhance their efficiency and avoid drag. This technology, therefore, becomes the best for converting wasted energy into smooth operation with greater thrust. Sharrow Technology delivers better anticavitation and drag-lowering performance, thereby enhancing many applications ranging from marine propulsion to aeronautics.

Among the major gains of Sharrow Technology is its fuel efficiency, which is highly improved. Sharrow propellers are capable of granting great energy savings in marine engines by requiring less power to sustain set speeds. Thus, industries for whom sustainability and low emissions constitute concerns stand to benefit much from the new technology. Furthermore, it is observed that engines with Sharrow designs have a longer life because less strain is applied during operation. Hence, going down the route of Sharrow Technology seems a more economic decision for long-term application. Those improvements have put Sharrow Technology on the map as an engineering solution that could meet the surge of interest flowing towards developments that are environmentally conscious.

Sharrow Technology has other fields of application aside from marine- and aeronautical systems. It can be useful in urban mobility solutions, such as in high-efficiency fans and turbines for the purposes of cooling or energy generation. Noise reduction and increased operational precision are the key factors in which these industries benefit from the technology. With further R&D, the Sharrow Technology will assure a promising future for propulsion systems in favor of another energy-efficient solution and environmental solution, whereby willing to fulfill any demands of several industries worldwide.

Electric Propulsion Compatibility

Sharrow Technology has shown immense compatibility with electric propulsion systems. Our propeller designs, unique worldwide, work with the electric motors to make certain that drag and other inefficiencies are reduced and the motors can operate at their highest level. Hence, while this technology promotes environmental sustainability in general, reduced energy consumption means lower emissions, or, in other terms, even in pure electric systems.

Our original shape allows for smoother operation with lesser vibration, which in turn is important for the longevity and reliability of electric propulsion systems. Reduced wear and tear of electric-motor components would mean less maintenance and greater durability, especially in tougher applications like marine vessels and drones. This symbiosis of Sharrow propellers with electric propulsion forms a perfect scenario for those customers who want to shift towards greener alternatives without losing out on performance.

The idea is that the convergence of the company’s technology with electric systems may be a lifeline in another modern-day transportation and energy issue. We intend to support industries through transitions to electric propulsion, offering them solutions that stand on one side of the cutting edge in terms of efficiency, sustainability, and adaptability. We look forward to contributing through continuous development and refinement to the key enabling partners involved in a cleaner and energy-conscious future.

Anti-Fouling Coatings and Foldable Designs

With anti-fouling coatings and foldable designs serving as some of the prominent advancements in material science and engineering technologies, their applicability is evident in key areas of marine and transportation industries. Anti-fouling coatings prevent the growth of unwanted organisms such as algae, barnacles, and bacteria on underwater surfaces. With reduced drag from fouating organisms on vessels, less fuel consumption occurs, and operational costs go down. Moreover, these coatings are environmental friendly because they lessen devoid for abrasive cleaning, which mostly involves toxic chemicals. Some of the new updates in this arena include nanotechnology and self-healing coatings that promise to stay benign for longer against contamination.

In contrast, foldable designs are becoming increasingly important in an ever-compacting world that demands more compact and versatile products. These novel designs have been able to benefit a variety of industries, including electronics and transportation. For instance, foldable bikes and electric scooters are providing urban commuters with space-friendly and practical transportation alternatives, while foldable solar panels allow the portable and efficient capture of renewable energy. Engineers are increasingly relying on materials such as flexible polymers and lightweight alloys to produce designs that are sturdy and easily collapsible at the same time. Such developments not only express the drive toward ease of use but are also reflective of the philosophy of sustainable development and efficient utilization of resources.

By combining anti-fouling coatings with foldable designs and their applications in marine equipment or portable renewable energy systems, manufacturers meet the concept of multitasking products in today’s market. As an example, we could imagine foldable structures coated with anti-fouling substances performing many duties in harsh environments where moisture and organisms might pose a problem. Such designs give rise to advancements in shipping, renewable energy, and portable infrastructure solutions, with minimal environmental impact while making a real difference in practical cases. These developments illustrate how technology and sustainability come together to create a future defined by innovation and efficiency.

References

-

Four-stroke and two-stroke marine engines comparison and application

This document provides a detailed comparison of two-stroke and four-stroke engines, focusing on installation and maintenance costs. -

Comparative analysis of four-stroke and six-stroke internal combustion engines

Although it includes six-stroke engines, this paper also discusses the efficiency and differences between two-stroke and four-stroke engines. -

A Study of Six-Stroke Engine

This study contrasts six-stroke engines with two-stroke and four-stroke engines, offering insights into their thermodynamic differences. - Click here to read more.

Frequently Asked Questions (FAQ)

Q: What is the main difference between the two-stroke and four-stroke engine?

A: The chief distinction between the two-stroke and four-stroke is that the former completes a power cycle in two strokes, while the latter requires four, including the strokes of intake, compression, power, and exhaust.

Q: How does a 2-stroke engine work in opposition to 4-stroke?

A: The two-stroke engine completes 2 stages to complete a power cycle: one power stroke for every revolution of the crankshaft. Conversely, a four-stroke engine generates power every two revolutions and makes four separate stages for the cycle.

Q: What fuel requirements does a two stroke engine have with respect to a four-stroke engine?

A: Essentially, a 2-stroke engine burns a mixture of fuel and oil, allowing its simple construction to efficiently do its job. In contrast, a 4-stroke engine burns fuel only once every four strokes and depends on separate lubricants, whose mechanisms make it efficient for sustained working.

Q: What are the advantages of the two-stroke and four-stroke engines?

A: They are easier to carry because they can be installed more simply, and two-stroke engines provide more power relative to their weight than any other engine type-very popular in applications such as dirt bikes. Four-stroke engines, on the other hand, are generally more fuel-efficient, control emissions better, and are quieter-all qualities desired in a vehicle meant to last long.

Q: Which engine type is more common in dirt bikes?

A: 2-stroke and 4-stroke engines all find application with dirt bikes; it comes down to the kind of performance being sought with the machine. 2-stroke engines are lighter and roar with power, while 4-strokes whisper with torque and smoothness.

Q: How do engine parts differ between two-stroke and four-stroke engines?

A: Two-stroke engines are more straightforward, not carrying complicated elements such as valves-but relying on ports for intake and exhaust. Conversely, and parts of a more complex nature constitute a four-stroke engine: valves, camshafts, timing mechanisms-that complement the four stages of engine operation.

Q: What environmental influence do two-stroke and four-stroke engines have?

A: Two-stroke engines are generally high emitters-they burn oil together with fuel, hence unburned hydrocarbons are released. Four-stroke engines are environmentally suitable as they are fuel-efficient and emit less pollution because they burn their fuel properly.

Q: What is the efficiency of a two-stroke engine compared with one of the four-stroke variety?

A: Though able to generate more power as grossly smaller, two-stroke engines are less fuel-efficient because of incomplete combustion and higher emissions. Four-stroke engines, on the other hand, are heavier and far more complicated from a structural standpoint but are more efficient when running for a longer time; that is why it is preferred in numerous car applications.

Q: Can you define the four stages of a four-stroke engine?

A: The four-stroke engine has four stages: in the intake stroke, the engine takes in an air-fuel mixture; in the compression stroke, the air-fuel mixture is compressed; in the combustion or power stroke, the air-fuel mixture ignited by the spark plug burns, and the energy it releases forces the piston down; and in the exhaust stroke, the combustion gases are expelled from the cylinder. Compared to a two-stroke engine, this cycle helps the engine run more smoothly with more fuel efficiency.

Summary

Understanding the fundamental differences between two-stroke and four-stroke engines is crucial for making informed decisions in 2025 and beyond. While two-stroke engines excel in power-to-weight ratio and simplicity, four-stroke engines dominate in fuel efficiency, environmental friendliness, and longevity. As technology continues to evolve with innovations like AI-powered optimization, advanced materials, and hybrid systems, both engine types are finding new applications while adapting to increasingly stringent environmental standards. The choice between these technologies ultimately depends on specific application requirements, environmental considerations, and long-term operational goals.