Boating enthusiasts and perhaps even marine engineers constantly seek any evolution that pushes performance to the very extremes. One such new development, poised to dominate the market in 2025, is the four-blade propeller. But how does it really make the boat faster while improving its overall efficiency? This article examines the inner workings and mechanics of four-bladed propellers that are revolutionizing the modern view of boating. From fiery acceleration to nimble handling, we’ll talk about what makes this shipwide the real deal for any speed-minded sailorman. A thorough treatise on the next step in propellers awaits, offering useful insights, whichever side of the helm you stand on: seasoned skipper or technical enthusiast.

Understanding Propeller Types: 3-Blade vs 4-Blade

Fundamental Mechanics of Propeller Function

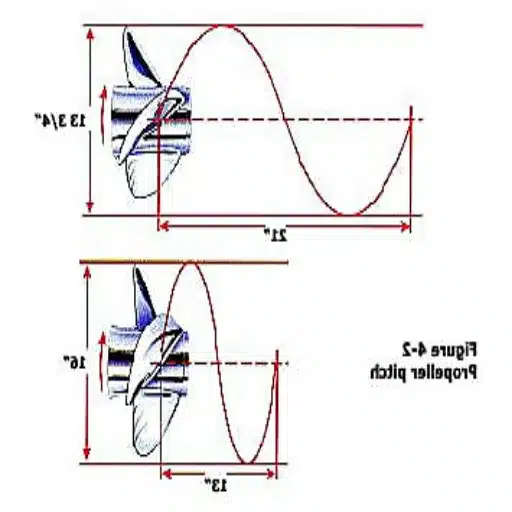

The propeller converts rotational energy from the engine into thrust, driving the boat through the water. The middle part of this process is the surface interaction between the blade and water. Each blade has a pitch, which is the angle at which the blade cuts through water, used to determine the distance a boat moves forward with each rotation. This interaction generates lift much as airplane wings do, but in the medium of water.

Later advancements introduced variable-pitch designs and improved hydrodynamic efficiency. For example, propellers crafted from lightweight yet strong materials, such as stainless steel or aluminum, contribute to improved reliability and faster acceleration. Additionally, propellers with cupped blades—which feature a slight curve on the trailing edge—reduce slippage while enhancing grip on the water, resulting in improved fuel efficiency and speed.

Performance studies of different marine equipment confirm that performance changes considerably with the number of blades. For example, a three-blade propeller has less drag and, hence, more top speed, making it an excellent choice for lighter boats. On the other hand, four-blade propellers offer excellent control and acceleration, particularly when heavily loaded or in rough waters. The latest designs in propeller development incorporate such traits, thereby allowing for optimal sailing conditions approved by everyone.

Comparison of 3-Blade and 4-Blade Propellers

The performance characteristics of propellers with three and four blades, however, largely depend on the usage case and vessel types. A 3-blade propeller is clear in giving higher top speeds. With less surface area in view, resistance through drag is formed less. Hence, it is allowed to move with a faster rate through water. Therefore, 3-blade configurations gain popularity among speedboats and lightweight crafts where speed is the top priority.

Conversely, 4-blade propellers provide better thrust and stability, particularly at low speeds. An added blade yields a greater surface area, allowing for smoother operation, improved grip on water, and reduced vibration. These are essential features for heavy vessels in turbulent waters, providing proper handling and acceleration. Additionally, 4-blade propellers excel in tight turns and offer improved fuel economy under heavy loads, thanks to their enhanced traction.

This modern propeller technology and materials enhancement refine the features of a propeller. For example, CFD testing is performed to study the flow of fluid around the blades, optimizing the curvature and pitch angles of propeller blades to maximize either speed or torque, as desired by manufacturers. Advanced alloys and coatings are now used to maximize corrosion resistance and durability, enabling them to serve their purpose even under adverse marine conditions. The distinction between 3-blade and 4-blade propellers is a fine one, and it’s worth considering in terms of speed, control, and the specific working requirements of the vessel.

⚡ Performance Comparison Summary

| Feature | 3-Blade Propeller | 4-Blade Propeller |

|---|---|---|

| Top Speed | Higher | Moderate |

| Acceleration | Good | Excellent |

| Vibration | Higher | Lower |

| Heavy Load Performance | Limited | Superior |

Advantages of Using a 4-Blade Prop

A 4-blade propeller offers a range of benefits that make it a preferred choice for specific vessel operations. With its large blade areas, it provides more thrust and lift, especially at slow speeds. This makes it ideal for holding effective performance in heavy boats, like pontoons or loaded vessels. Also, 4-blade props offer more stability and a very smooth reaction to steering that reduces vibration and better control, which is required for applications needing tight control maneuvering, such as water sports or fishing trips.

Furthermore, in terms of design the 4-blade propeller reduces cavitation when air pockets disrupt aerodynamic thrust. This ensures extremely steady and reliable performance in challenging situations, from choppy waters to strong currents. Another well-loved feature is its improved fuel efficiency at cruising speeds, resulting in cost savings on long-haul voyages. Hence, all these couplings make 4-blade propellers an ideal option for operators looking to strike a balance between power, control, and ruggedness.

🔥 Key Benefits of 4-Blade Propellers

- Enhanced Thrust: Superior performance at low speeds and heavy loads

- Reduced Vibration: Smoother operation and improved comfort

- Better Control: Improved maneuverability for water sports and tight spaces

- Cavitation Reduction: More reliable performance in challenging conditions

- Fuel Efficiency: Cost savings during extended cruising

The Role of Propeller Efficiency in Speed Enhancement

Speed according to Propeller Design

A vessel is designed to optimize speed and performance through its propeller design. A fully functioning propeller will help generate thrust, limit drag, and direct water flow appropriately. Some of the factors affecting hydrodynamic performance are number of blades, pitch, diameter, and material in use. High-pitch propellers move more water per rotation and are thus suitable for vessels that require higher operational speeds. In contrast, smaller diameter propellers will generate less thrust at low speeds, though they arguably produce somewhat higher speeds in ideal conditions.

Blade shape determines speed completely. For example, the cupped blades are purposely designed to have minor curves on their edges, minimizing water slippage and thereby providing the vessel with steady and precise acceleration. In addition, the use of high-tech materials, such as stainless steel, provides more rigidity to the blade, meaning it does not distort at very high RPM and is therefore more efficient.

Enhanced computational fluid dynamics techniques now allow manufacturers to simulate water flow and turbulence, thereby facilitating innovations in propeller designs tailored to specific vessel types. For example, dual-blade profiles or hybrid propeller designs strike a balance between speed and fuel economy, aspects that are critical to both racing and commercial operators. Utilizing these developments will ensure the vessel maintains an optimal speed when confronted by opposing water conditions.

Factors Influencing Propeller Efficiency

There are several key factors that impact propulsive efficiency, particularly in relation to recent technological advancements. One of the most important factors is the shape of the blade and its pitch, as this directly affects the flow of water over the propeller’s surface. Properly designed blades minimize turbulence and drag, resulting in smoother operation and greater fuel savings.

The other factors relate to the materials used in manufacturing the propeller. Advanced composites and alloys, such as carbon fiber or nickel-aluminum bronze, are highly dense yet resistant to corrosion, thereby increasing their lifespan and efficiency in freshwater or seawater environments.

Depending on environmental conditions, such as water density or salinity, efficiency varies. For example, a propeller designed to operate in dense, cold water may yield poor results in a warmer, less dense setting, thereby necessitating regional adjustments to design and performance tuning.

Finally, the use of proper maintenance and good surface finish can help decrease energy loss. Even relatively minor damage or biofouling can disrupt smooth hydrodynamic flow, causing ships to travel more slowly through the water and consume more fuel. Proper cleaning, polishing, and inspection keep the propeller efficient and prolong its lifespan, thereby ensuring a high level of performance in diverse operational conditions.

Examples of Speed Improvement in the Real World

Ship propulsion has gained fame in speed improvement: the truly advanced propeller designs have considerably decreased fuel consumption and increased travel times. In the case of cargo ships, another example is that energy-saving devices, such as high-performance ducted propellers, have resulted in propulsion efficiency improvements of up to 10%.

Also believe it or not, teams in competitive sailing have merged the very latest propeller technology with computer-modeled flow analysis. Some of America’s Cup teams applied their hydrofoiling technologies, combined with purportedly optimized propeller designs, to generate never-before-seen speeds while maintaining control even as sea conditions changed around them.

Another case in point exists within the field of aviation. Contemporary jet engine turbines resemble propellers in that they incorporate aerodynamic refinements to decrease drag and increase thrust force. Such developments, therefore, promote faster travel times, as well as improved fuel efficiency, in line with global efforts to reduce carbon emissions.

That is how innovations in propeller efficiency, which directly affect speed enhancement, span across many fields and are a testament to wider engineering developments that contribute to the success of operations.

Innovations in 4-Blade Propeller Technology for 2025

Emerging Materials and Designs

Refining 4-bladed propeller technology in 2025 has led to the development of revolutionary materials and designs that significantly enhance performance and environmental quality. A key development is in the engineering realm of composite materials, such as carbon fiber-reinforced polymers. Compared with aluminum or steel, these materials are extraordinarily light, and in thus doing, they help to keep low the total weight of the propeller while providing a high degree of strength and durability. Consequently, the lighter weight reduces energy consumption in various vehicles, from marine vessels to aircraft, thereby improving efficiency and lowering operational costs.

Previously, improved blade geometries optimized fluid flow. Computational simulation has made it possible for engineers to develop sophisticated blade profiles that generate maximum thrust while minimizing noise and vibration. With swept tips and edges designed to reduce vortices, these designs are intended to maximize performance while also adhering to stricter noise regulation standards, particularly in aircraft and marine environments. Such innovations demonstrate how materials science, combined with engineering precision, is finally coming together to raise standards in propeller technology, with performance, cost, and environmental benefits aligning seamlessly.

Technological Impact on the Propeller’s Performance

Continuous improvements in materials science have significantly altered the propeller’s design, enabling enhancements in performance, longevity, and sustainability. For example, composite materials, including carbon fiber-reinforced polymers, are increasingly being used for their excellent strength-to-weight ratio. With weight reduction while maintaining structural integrity, propellers consume less fuel in both aviation and marine applications. These propellers can also be treated with advanced coatings, such as hydrophobic or anti-corrosion coatings, to increase their life by reducing wear and resistance during operation.

Using cutting-edge technology enables the creation of more amazing geometrical designs, with complex shapes and extreme precision. This way, engineers can refine the structures to achieve optimal air flow and good hydrodynamic features. This essentially explains why data-driven simulation tools serve as the best complement to these advances, as they simulate flow dynamics and performance metrics during the design stages. The ability to model such parameters thus results in the manufacture of propellers that have improved efficiency, reduced pollution, and higher environmental standards, emphasizing how technology-driven innovations are transforming this segment.

Boating Industry Case Studies

💡 Fuel Efficiency Innovation

European Yacht Constructor: A yacht constructor from Europe led the market when its set of vessels had been outfitted with new-generation propellers to maximize fuel efficiency. They utilized modern computational fluid dynamics (CFD) methods, with more than 200 design alternatives simulated to evaluate their hydrodynamic performance. Testing in comparison with traditional design models showed a 15% reduction in fuel consumption with their new design; additionally, noise and vibration levels were also reduced. This led to the apparent benefits of lowering operational costs, which formed the basis for supporting environmental initiatives by reducing CO2 emissions.

⚡ Electric Propulsion Systems

Electric Boat Company: The emerging electric boat company innovated with a fully electric propulsion system integrated with lightweight, highly efficient propellers. The system monitors performance in real-time to vary thrust and deliver best performance under different load conditions. Field tests conducted during the 6-month pilot program demonstrated a 20% increase in total energy efficiency and the complete absence of exhaust emissions. This approach has made the company a pioneer in sustainable marine technology, gaining the attention of eco-friendly consumers.

🚢 Commercial Fleet Retrofit

Global Shipping Company: A global shipping company successfully retrofitted an aging fleet of commercial vessels with state-of-the-art propeller systems designed to meet stringent environmental regulations. Among other things, retrofitting involved bespoke adaptive pitch propellers whose angle changes in response to speed and load requirements. Data collected after implementation showed a 10% improvement in fuel economy and a reduction in NOx emissions of more than 25%, thereby enabling the vessels to meet the IMO Tier III Standards fully.

Thus, these cases draw attention to the importance that advanced design technologies and sustainable approaches can make in solving environmental and operational problems in the boating industry.

Choosing the Right Prop for Your Boat: 3-Blade vs 4-Blade

Understanding Your Boat’s Needs

Choosing between a 3- and 4-blade prop depends on intent and how it matches an engine to boating conditions. The 3-blade propeller is often sought after for its higher top-end speed, making it popular among boats that prioritize speed and agility. The lower drag on it and its lighter weight give the boat slight acceleration, particularly in calm waters.

Whereas four blades result in better handling and fuel economy, especially in rough water or with heavy loads, they provide truer thrust and more grip, which is beneficial for water skiing, for example. Your propeller with the extra blade will also be less prone to vibrate, providing a smoother and quieter ride.

Consider details such as boat size, how much weight it is common for it to carry, and mainly, whether it is for working or pleasure use before making an informed decision. Having the wrong prop will probably not fit or work well. Based on an in-depth examination of the factors mentioned above, your boat’s real efficiency can be precisely achieved, and your water outings rewarding.

Performance Indicators to Look at

When evaluating performance indicators for a boat, it is essential to focus on key factors such as efficiency, speed, handling, and other relevant aspects. The pitch selection of a propeller is crucial in determining the engine revolutions per minute (RPM). A higher pitch might give higher speed at the cost of acceleration while a lower pitch would give better thrust but less top speed. The diameter of the propeller is also one of the parameters taken into consideration, as it indicates how well a propeller will push the water; the bigger the diameter, the better it is for heavy boats.

This is just another important metric. Slip percentage is a measure of the difference between how far theoretically the propeller should travel through the water in one rotation and the actual distance covered. Thus, lower slip percentages imply better performances and greater efficiencies. Last but not least, consider the fuel efficiency: An efficient propeller will certainly enhance your speed while also reducing fuel consumption, which guarantees cost savings over long hours of driving. This kind of analysis of all key performance metrics will put an end to further trial and error in attempting to fine-tune your boat.

🎯 Key Performance Metrics to Monitor

- Propeller Pitch: Determines RPM and speed vs. acceleration balance

- Propeller Diameter: Affects water displacement and thrust generation

- Slip Percentage: Measures efficiency – lower is better

- Fuel Efficiency: Overall cost-effectiveness during operation

Expert Recommendations for 2025

In 2025, an integrated approach to maximizing performance and exploiting the latest technologies would sales better. In the opinion of the experts, sustainable innovations should form the focus while encouraging materials and designs that less damage the environment while maintaining efficacy. For example, lightweight composite propellers that reduce drag while maintaining durability have attracted attention in both the recreational and commercial boating industries.

In addition, precision optimization technologies will transform performance assessment and adjustment. Such cutting-edge, AI-based tools can now accurately predict speed, slip ratios, and fuel consumption through dynamic simulations, allowing for finer adjustments to suit the specific requirements of a given situation. By applying such technologies, decision-making can be made in real-time while ensuring the boat’s peak efficiency.

Safety again is highly emphasized, with investments being advised in smart diagnostic systems for recognizing anomalies in engine performance, temperature anomalies, or issues involving critical mechanical parts to prevent them from failing during a voyage. Hybrid propulsion systems have been gaining momentum because they offer the flexibility that lies between traditional and fully electric engines, including reduced emissions during operation.

Last but not the least, experts advise that data convergence be a priority in maritime navigation. Thus, centralized digital dashboards that integrate GPS technology into a single interface, comprising weather forecasts and condition monitoring, are becoming indispensable in modern boating situations, helping to increase the accuracy of navigation and enhance the user experience. By adopting and aligning with advanced solutions and marine trends, the boat owners and operators might ensure that they stay competitive and efficient throughout the year.

Future Trends in Propeller Design and Boating Efficiency

Predicted Advances in Propeller Technology

The future of propeller technology shall be defined by innovations that will focus on efficiency, sustainability, and adaptability. One of the significant changes is the innovative application of composite materials, including carbon fiber-reinforced plastics, which provide lightweight yet highly durable alternatives to traditional metal alloys. On the one hand, such materials help reduce the overall weight of the vessel; on the other hand, they aid in improving fuel economy due to reduced drag.

Another trend concerns the development of biomimetic propeller designs. These designs, inspired by marine life forms such as dolphin or whale fins, aim to improve hydrodynamic performance, reduce noise levels, and also vibration. Studies now show that they are very much capable of providing a smoother operation and substantial energy savings.

In the digital age, propellers are evolving toward the development of “smart” propelling systems. These incorporate sensors and IoT technology for the real-time monitoring of parameters, such as performance. They apply optimal changes according to changing water conditions or load demands. Together with AI-powered control systems, innovative propeller systems can significantly enhance efficiencies while reducing wear and maintenance costs.

In the last term, the greening aspects come into play in the application of electrically powered and hybrid propulsion. Along with improving the designs of electric motors integrated with propellers, quieter and emission-free operations are becoming possible, which favors operating these vessels in ecologically sensitive waters. Now, enhanced battery technology does its part in further supporting long ranges and greater reliability.

🚀 Emerging Propeller Technologies

Composite Materials

Carbon fiber reinforced plastics

Biomimetic Design

Marine life-inspired geometry

Smart Systems

IoT and AI integration

Electric Propulsion

Zero-emission operation

These emerging technological advances signal a paradigm change in propeller design, where efficiency, adaptability, and eco-conscious engineering are the new criteria for the boating industry.

Environmental Considerations in Propeller Design

When environmental factors are considered in the design of propellers, I seek solutions that prioritize sustainability without compromising other aspects of performance. And one such aspect has a significant impact on underwater noise pollution. Noise generated by traditional propellers can disrupt marine life, particularly species that rely on echolocation or sensitive soundscapes. By adopting advanced materials and innovative blade shapes, it is possible to create propellers that significantly minimize noise emissions, promoting a healthier aquatic environment.

The other vital element to consider is how to improve fuel efficiency in the interest of reducing carbon emissions. Highly efficient propeller designs achieve this by having blade angles optimized and smooth, as well as aerodynamic contours. They require less energy to operate, so they consume less fuel. This reduction in fuel consumption translates to lower operating expenses—a development with significant environmental benefits when considered in the context of reducing emissions.

Materials, too, are paramount in contemporary propeller designs. By choosing materials that are both eco-friendly (recyclable or biodegradable) and of high quality, we mitigate the long-term environmental impact of our boat equipment. Altogether, navigations in this manner are shaping the industry in the direction of protecting marine ecosystems while keeping pace with the demands of modern propulsion technology.

Next Generation of Boating Innovations

When I think about the next generation of boating innovations, I envision an industry where sustainability blends indisputably with state-of-the-art technology. Propulsion systems are evolving, with electric and hybrid engines gaining more acceptance for their ability to minimize emissions without compromise on performance. This avenue is set against the backdrop of global environmental objectives, keeping in mind patrons who are environmentally conscious, including myself, an environmental advocate for the restoration of the marine environment.

Another exciting development is the use of innovative technologies on a vessel that prospers with connectivity and control. The new navigation system features real-time performance monitoring from operators and automated docking solutions, providing an entirely new perspective on the relationship between humans and vessels. These innovations give me peace of mind and an enhanced user experience, making it all safer and more efficient.

That indeed presents an intriguing prospect if renewable energy sources, such as solar panels, were ever to find their way into boat designs. I believe this would help make the boating industry more self-sustaining, thereby reducing its dependence on traditional fuels. Paired with eco-friendly materials and designs aimed at reducing water pollution, the future of boating looks relatively brighter and responsible.

📚 Reference Sources

-

3 vs 4 Blade Propeller Guide for Maximum Efficiency – Discusses the benefits of 4-blade propellers, including maneuverability and thrust.

-

Exploring the Pros and Cons of 4 Blade Prop vs 3 Blade Prop – Highlights the efficiency and fuel-saving advantages of 4-blade propellers.

-

Boat Propeller Information You Need to Know – Explains how additional blades improve acceleration and grip on water.

-

3 or 4 Blade Prop: Which is Better for Planing Faster? – A discussion on the traction and speed benefits of 4-blade props.

-

Which is Better: 4 Blades or 3 Blades? – Examines the trade-offs between 3-blade and 4-blade propellers, including drag and horsepower requirements.

Frequently Asked Questions (FAQs)

Which provides a 4-blade prop with increased speed?

Yes, a 4-blade propeller can increase speed under favorable conditions, such as those dictated by boat hull design and engine power. Typically, a 4-blade prop offers better acceleration at slower speeds, which in the overall picture accounts for more speed being attained. It can increase thrust in the water while reducing drag, in some cases; however, at other times, there may be a trade-off, such as increased vibration or a slight loss in top speed. You must factor pitch and diameter, along with the extra blade. Again, it depends on the vessel, so testing for different props will be the best way to decide.

How would a 3-blade prop compare to a 4-blade prop?

A 3-blade prop generally provides higher top speeds due to its lower drag compared to a 4-blade prop, offering an advantage in racing or high-speed applications. However, 4-blade props tend to offer better acceleration and handling, especially in rough waters or when heavily loaded. More blades provide more thrust and, in consequence, may be more efficient than with fewer blades at lower RPMs. A 4-blade prop is suitable if you plan to cruise or carry heavy weights with your vessel. On the other hand, if speed is the only concern and you can compensate for the lower acceleration, then the 3-blade prop would better fit your needs.

What are the factors that affect 4-blade prop performance?

Several factors influence the performance of a 4-blade prop, including its pitch, diameter, and blade design. The pitch affects how far the prop theoretically moves through the water in each rotation, while the diameter affects thrust and grip. Nevertheless, the horsepower and torque of the engine are also paramount in determining the performance of any 4-blade propeller. Lastly, the hull design of the vessel will also affect the rate at which a propeller may translate power into speed. For optimal performance, both propulsion-related factors must be tuned appropriately in conjunction with the vessel’s characteristics.

Can a four-blade propeller decrease vibrations?

Vibration reduction with 4-blade propellers is typical, as the working principle involves thrust being applied through different blades arranged in a specific manner. With more blades in the water, the load is distributed, allowing the boat to have a comparatively smooth riding experience with reduced vibrations transmitted to the hull. Large vessels or those with large engines would greatly enjoy such vibration management. However, vibrational interference could come from many other sources, and a propeller balanced for working against a hull suffices. Also, proper maintenance of the equipment and ensuring a propeller in good condition would reduce vibrations as well.

What does pitch do to the speed of the 4-blade prop?

The pitch used for a 4-blade is a tremendous influence on its speed and efficiency. The high-pitch propellers made a boat go faster, yet it may require maximum power from the engine, thereby lessening acceleration. The lower setting may be better for improved acceleration and performance at speed. It is necessary while towing a boat, especially in choppy waters. The right pitch thus becomes crucial, as it balances speed and fuel economy, because the pitch governs engine performance at various RPMs. The best pitch on your 4-blade will ultimately depend on your boating needs and conditions.

How many blades should I go for in my boat’s propeller?

Thanks to your intention and how you want your boat to be utilized, the number of blades supplied in your prop should be determined. A 4-blade prop provides faster acceleration as well as better handling, particularly at low speeds; therefore, it is usually opted for by recreational boaters and those who are towing a load. On the other hand, 3-blade types are typically preferred for achieving top speed and efficiency, especially in racing situations. So, if smoothness in the ride is more important to you than vibrational effect from the prop, silky-ride 4-blades will be perfect for you. That being said, striking a balance between the contradictory needs of speed, acceleration, and performance should help you make the best choice for your prop.