Understanding the working principle behind a 2-cycle engine is essential for all those working on everything from lawnmowers to outboard motors. However, what sets these motors apart is their operating procedure, specifically the stroke cycle. In this article, we will clarify the meaning of the term “2-cycle” by explaining the number of strokes involved, what all of those strokes do, and the distinctions between this and other engine types. For all DIY enthusiasts, small engine mechanics, or anyone who wonders how these machines power tools, this comprehensive 2025 guide is what they’ve been needing all along. Within, we’ll delve into how this fast and light engine design has given shape to the tools we rely on daily.

Understanding Engine Strokes

What is a Stroke in an Engine?

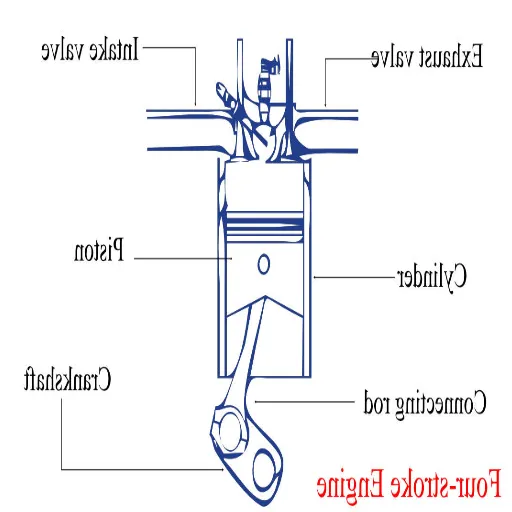

A stroke in an engine is that peculiar movement of the piston inside a cylinder, either upward or downward, that corresponds to a part of the working cycle. Typically, the entire working cycle of an internal combustion engine comprises several strokes, each characterized by the performance of a specific function, such as intake, compression, combustion, and exhaust. The movements of the piston are timed in perfect harmony with the crankshaft to maximize the conversion of fuel into useful mechanical power. Owing to these, the very design and number of strokes determine an engine’s efficiency, power output, and fuel consumption-a concept any person ought to grasp in the world of engines.

An engine comes with categorized functions depending upon the number of strokes in the operational cycle, with two-stroke and four-stroke kinds of engines. In a two-stroke engine, a power stroke is completed within two strokes of the piston, with one upward stroke for every rotation of the crankshaft. Intake and compression occur in one stroke, while combustion and exhaust take place in the other. Two-stroke engines are, thus, the lighter ones. The more straightforward and smaller the design, the higher the power it can generate in less time, and they are mostly used in smaller machines, such as chainsaws and motorcycles.

Turned the other way, it takes four piston strokes (two revolutions of the crankshaft) to complete a cycle in a four-stroke engine. This design treats each function as a separate stroke: intake, compression, combustion, and exhaust, allowing for improved fuel consumption, reduced pollution, and enhanced engine longevity. Four-stroke engines are used in large-scale applications, such as automobiles, industrial plants, and similar settings. Once you understand the differences, it becomes easier to determine the proper type of engine for optimal efficiency, power, and usage.

Overview for Two-Stroke and Four-Stroke Engines

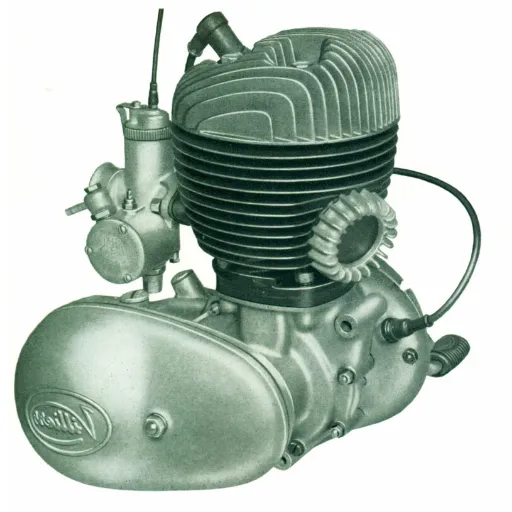

With their unique features, two- and four-stroke engines are suited to specific applications. Two-stroke engines are simple and lightweight; hence, they are highly preferred in smaller machinery, such as motorcycles, chainsaws, and outboard motors. By completing a power cycle within two strokes, these engines are more capable of giving out power about their small size. However, this efficiency comes at a price: high fuel consumption and the emission of pollutants due to incomplete combustion.

On the other hand, four-stroke engines surpass other engine designs in terms of fuel economy and environmental aspects. The reason is that they allow each phase of the combustion cycle to take place in separate strokes, thereby ensuring the highest possible fuel combustion, cleaner exhaust emissions, and improved mileage. It is thus the choice for larger vehicles, such as cars, and machines demanding durability and consistent performance. While these engines are heavier and more complex to build, their longer life span frequently makes up for these disadvantages.

This has paved the way for people to think of these two-engine types as the same kind; hence, the existence of very thin demarcations between them. Two-stroke engines have incorporated newer technologies, such as direct fuel injection and new-generation lubricants, which improve emissions levels and fuel efficiency. Conversely, modern four-stroke engines enhance both power and efficiency by incorporating turbochargers and hybrid systems. Hence, when selecting an engine, it is essential to consider the specific use case and environmental factors, as well as the required power, all of which contribute to making the correct choice for the engine.

Importance of Stroke concerning Engine Performance

The number of strokes that a gas engine can accommodate plays a significant role in determining the engine’s ability to exhibit a specific set of performance characteristics. Two-stroke engines, due to their simplicity and compactness, are generally accepted as having a higher power-to-weight ratio and are therefore applied in motorcycles, chainsaws, and small marine engines. Less weight means fewer moving parts, which implies less maintenance and quicker operation. Developments in direct injection systems and synthetic lubricants have significantly reduced the stigma associated with higher emissions and fuel consumption, thereby maintaining their prominence.

Conversely, four-stroke engines are, thus, more efficient, longer-lasting, and cleaner in terms of emissions. Although often less powerful in iteration, fuel combustion in four-stroke engines is more efficient, resulting in increased torque and lower pollutant emissions compared to two-stroke engines. The fuel efficiency and adaptability of four-stroke systems have been significantly enhanced by turbocharging, variable valve timing, and hybrid electric integration, particularly in the automotive, aviation, and power generation industries. Hybrid automotive engines can feature up to a 30% increase in fuel efficiency by applying these modern technologies.

An essential component of engine design is matching the stroke cycle to the intended application. Power delivery, environmental, and lifecycle cost analyses maintain the engineering freedom to choose the most appropriate engines. Some industries require machines that are lightweight and possess high output; thus, these industries prefer two-stroke engines that are optimized. The other is the industry’s preference for machines that last long and have minimal emissions, where such areas are predominantly found, and some kind of ‘modern’ four-stroke power sources are considered. This tuning capacity, facilitated through an innovative channel, has likely kept both engine types relevant in terms of performance and sustainability today.

How 2-Stroke Engines Work

The Combustion Process in a 2-Stroke Engine

Key Process Overview

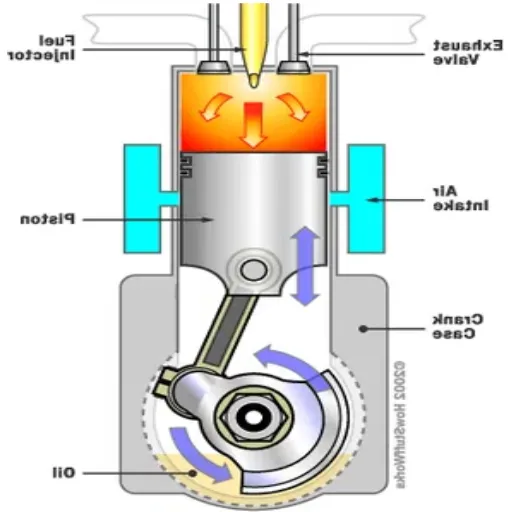

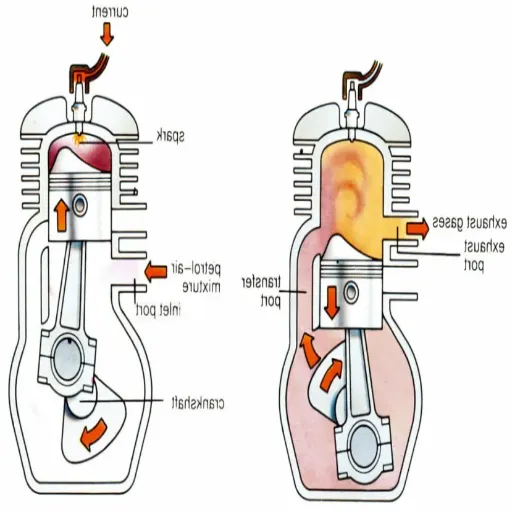

With a very compact design, the 2-stroke engine operates in a much simpler manner. The design permits the two-stroke engine to generate full power during those two strokes. The process begins with the intake and compression strokes, during which the air-fuel mixture is drawn into the cylinder through specially designed ports. As the piston moves upward, it compresses the mixture, triggering a more explosive ignition. Immediately after the compression stroke, the power and exhaust stroke begins as the spark plug initiates ignition of the blast with a rapid expansion of gases that drive the piston downwards to produce power. At the same time, the burnt gases are pushed out of the exhaust port, thereby minimizing the release of exhaust gases along with the incoming fresh charge.

With remarkable power-to-weight ratios, these engines are a perfect fit for applications that demand power in compact packages, such as motorcycles, chainsaws, marine outboard motors, and the like. While 2-stroke engines are recognized for their simplicity and efficiency, recent developments in port design and combustion optimization aim to reduce their historically higher emissions and meet modern environmental standards without compromising their hallmark advantages.

Advantages of 2-Stroke Engines

🏗️ Lightweight Construction

Highly valued and generally chosen for situations where space and weight are at a premium

⚡ Excellent Power Output

Provide excellent power output for their capacity, serving best in applications such as motorbikes, snowmobiles, and handheld power tools

🔧 Simple Design

Fewer moving parts than a 4-stroke engine, making them easier to maintain and manufacture at lower costs

🔄 Quick Repairs

Allow for quicker repairs, reducing downtime and increasing use in recreational or professional realms

📈 Enhanced Efficiency

Recent improvements include direct fuel injection (DFI) and electronic control systems for accurate fuel metering

Recent improvements in 2-stroke engine workmanship have significantly enhanced fuel efficiency and reduced emissions profiles. Direct fuel injection (DFI) and electronic control systems, for instance, enable accurate fuel metering with the goal of minimizing waste and promoting clean combustion. These developments contribute to making the two-stroke engine greener while also ensuring that reduced fuel consumption translates into cost savings over time. With this combination of efficiency, performance, and versatility, it is no wonder 2-stroke engines remain a viable option in various industries.

Typical Applications of 2-Stroke Engines

🚢 Marine Industry

Predominantly used in outboard motors for both recreational and commercial boats. These engines are particularly suitable for smaller crafts due to their lightness and steadiness in power generation, enabling both maneuvering and speed.

🛠️ Power Tools & Landscaping

Common in light-duty power tools such as chainsaws, leaf blowers, and string trimmers. These tools are highly dependent upon the portability and dependability of 2-stroke engines, allowing operators to work in outlying places without lugging bulky power sources.

🏍️ Motorcycles & Racing

Mountain bikes and racing motorcycles are highly dependent on 2-stroke engines for rapid acceleration and ability to navigate rough terrain. Racing has featured two-stroke engines for their preference for torque and weight in smaller motorcycle categories.

🌾 Agricultural Equipment

Used in irrigation pumps, sprayers, and motorized cultivators. Their simplicity makes them easy to maintain and operate, which is why they have applications in field work.

🔌 Portable Generators

Two-stroke technology is the heartbeat of portable generators, providing power where access has been denied. Their adaptability enables them to meet changing demands of various industries.

The adaptability of 2-stroke engines has enabled them to meet the changing demands of various industries, from recreational vehicles and outdoor tools to commercial marine engines. Thanks to advancements in efficiency and reduction of emissions, it remains a major force in modern mechanical usage.

Comparing 2-Stroke and 4-Stroke Engines

Key Differences Between a 2-Stroke and a 4-Stroke Engine

When comparing 2- and 4-stroke engines, the significant differences lie in their working, efficiency, and uses. A 2-stroke engine finishes a power cycle (intake, compression, combustion, and exhaust) in just two strokes of the piston, while a 4-stroke engine requires four strokes of the piston to complete the power cycle. That fundamental difference introduces huge differences in performance and application.

🔋 Power Output and Efficiency

A 2-stroke engine produces power on every revolution of the piston, allowing it to generate more power for its size. However, it tends to burn fuel faster, making it less efficient compared to its counterpart, due to incomplete combustion and the potential mixing of fuel with lubricating oil. The 4-stroke varieties, by contrast, generate power on every two revolutions and stand out as more fuel-efficient and environmentally friendly, as their fuel consumption and emission levels are well controlled.

🔧 Durability and Maintenance

They require less frequent maintenance due to their simpler design and fewer moving parts. The 2-stroke engines are lightweight and cost-efficient. However, a shorter life span arises from the higher wear and tear on the components inside them. Compared to 4-stroke engines, 2-stroke engines are more durable and built for longevity. However, their operating weight and maintenance procedures present challenges to particular applications in the realm of portable functions.

🎯 Applications and Suitability

Because they are light and have a high power-to-weight ratio, 2-stroke engines are generally used in chainsaws, dirt bikes, and, of course, outboard motors. Whereas 4-stroke engines focus on steady, fuel-efficient performance and excel in applications such as cars, large motorcycles, and stationary equipment, where durability and emission standards are particularly important.

🔊 Noise and Vibration Levels

2-stroke engines and 4-stroke engines exhibit distinct operational characteristics, resulting in varying sound and vibration levels during their operation. These vibrations are produced by rapid power cycles on 2-stroke engines; however, 4-stroke engines provide smoother running with lower noise levels, which is very important in residential and urban settings.

These disparities between them make them excellent in other working conditions. Two-stroke engines excel in both light and high-power applications, whereas four-stroke engines gain popularity in places where efficiency, durability, and environmental considerations are paramount. An understanding of this difference should ensure the selection of the right engine for optimal performance, tailored to specific performance requirements.

Performance Parameters: 2-Stroke vs 4-Stroke

When evaluating performance metrics, it is essential to understand how they distinguish between 2-stroke and 4-stroke engines to select the appropriate type. Some of the key metrics include power output, fuel efficiency, maintenance requirements, emissions, and lifespan. The following comparative table describes these differences in detail:

| Metric | 2-Stroke Engine | 4-Stroke Engine |

|---|---|---|

| Power Output | Higher power-to-weight ratio, ideal for small machines | Lower power-to-weight ratio but steady and reliable |

| Fuel Efficiency | Less fuel-efficient due to incomplete combustion | More fuel-efficient with complete combustion |

| Maintenance | Requires frequent maintenance (e.g. refueling, repairs) | Longer intervals between maintenance |

| Durability | Shorter lifespan due to faster wear and tear | Longer lifespan with proper care |

| Emissions | Produces higher emissions | Produces cleaner emissions |

| Weight | Lightweight and portable | Heavier, less portable |

| Applications | Best for tools like chainsaws and motorcycles | Common in cars, lawnmowers, and generators |

Such information serves well in meeting specific performance and environmental requirements, thus optimizing the usage from either an individual or industrial perspective.

Environmental Impact of 2-Stroke and 4-Stroke Engines

The environmental impacts of two-stroke and four-stroke engines are emissions, fuel requirements, and maintenance. These engines are lightweight and can deliver greater power; however, two-stroke engines are less fuel-efficient and tend to produce more emissions due to the incomplete combustion of fuel and the mixing of oil with gasoline. Hence, more hydrocarbons and particulate matter are released into the atmosphere, and their accumulation leads to environmental destruction.

Two-stroke engines are relatively dirty during fuel combustion and therefore produce more carbon monoxide and hydrocarbon emissions than four-stroke types. With higher fuel efficiency comes lower fuel consumption, which, over time, reduces the environmental footprint. Concentration of efforts on emission control technologies, with the introduction of the catalytic converter having the most significant impact, further reduces the ecological impact.

According to studies, shifting toward greener options, such as 4-stroke alternatives or blending biofuel, can result in a significant reduction in the carbon intensity of transport and industrial applications. Thus, since regulators across the globe are increasingly leaning toward lower-emission engines, the chances of innovations with a sustainable goal are practically high. Therefore, an engine type should be considered in light of not just immediate performance parameters, but also environmental consequences that lean toward cleaner ecosystems and better health.

Future Trends in Engine Technology for 2025

Innovations for Two-Stroke Engine Design

The advances in 2-stroke engine technology implemented allow the classic design to perform better and be more environmentally compatible. Examining modern designs, we observe that they aim to address the traditional drawbacks of 2-stroke engines, namely emissions and fuel consumption, while retaining the advantages of simple construction, high power density, and lightness.

🔧 Direct Fuel Injection

In these systems, the fuel is directly injected into the combustion chamber, eliminating virtually all unburned hydrocarbons and resulting in increased fuel efficiency and reduced emissions.

🛢️ Enhanced Lubrication

Enhanced lubrication techniques, such as semi-dry sump, are being used, which limit oil consumption and reduce oil spillage into the environment compared to older 2-stroke configurations.

💻 Electronic Control Systems

Electronically controlled systems for engine performance optimization that adapt in real-time, delivering maximum power under varying loads and attaining better efficiency.

🌱 Alternative Fuels

Manufacturers are exploring the possibilities of alternative fuels, including bio- and synthetic e-fuels, designed to run in 2-stroke engines to reduce carbon footprints.

🏗️ Advanced Materials

Materials used for engine construction are being increasingly proportioned with composite materials, which are lighter while retaining their load-bearing qualities.

Another groundbreaking integration brought about is the development of electronically controlled systems for engine performance optimization. Depending on operating conditions, the system adapts in real-time, delivering maximum power under varying loads and attaining better efficiency by incorporating technologies such as variable valve timing (VVT) and advanced electronic control units (ECUs).

On the other hand, manufacturers are exploring the possibilities of alternative fuels, including bio- and synthetic e-fuels, designed to run in 2-stroke engines to reduce carbon footprints. Aligned with global emissions regulations and sustainability goals, these fuels are a possible avenue for the test of time.

In addition, the materials used for engine construction are being increasingly proportioned with composite materials, which are lighter while retaining their load-bearing qualities. Enabling better performance and thus improved fuel economy, this is equally important in marine and light industry applications, where 2-stroke engines are more prevalent.

🔮 Future Outlook

Overall, it is evident that the current trend of combining innovations in fuels, electronic controls, and environmentally friendly materials is ushering in a new era for these two-stroke types of engines. In conceptualization, modern design alterations make two-stroke engines equally viable in sectors seeking suitable, cost-effective, and environmentally friendly solutions.

Predicted Market Trends for Two-Stroke Engines

The two-stroke segment was expected to exhibit steady growth during the forecast period, driven by technological advancements and increasing demand for compact, high-performance engines. The marine industry, recreational vehicle manufacturing, and small machinery are increasingly accepting small-sized engines that provide power and fuel efficiency. According to recent reports, the global market for two-stroke engines is expected to grow at a CAGR of 5-7% over the next five years, driven primarily by the significant influence of the Asia-Pacific and North American regions.

📈 Market Growth Drivers

- Recreational Power Sports: Including dirt bikes, snowmobiles, and personal watercraft, which demand lightweight yet durable engines capable of producing high torque

- Emerging Markets: Particularly in Southeast Asia, where motorcycles and small marine vessels are still typical applications of two-stroke engines

- Government Investment: More funds into cleaner engine technologies, possibly opening new opportunities for manufacturers

- Innovation Focus: Digital controls, predictive maintenance, and environmentally friendly materials driving demand

This upward trajectory is also supported by the recreational power sports segment, which includes dirt bikes, snowmobiles, and personal watercraft, which demand lightweight yet durable engines capable of producing high torque.

The role of emerging markets, particularly in Southeast Asia, where motorcycles and small marine vessels are still typical applications of two-stroke engines, is expected to provide the industry with the impending thrust. Governments in these regions are now investing more funds into cleaner engine technologies, possibly opening a new window of opportunity for manufacturers. Industry experts forecast that the ever-evolving emission regulations and fuel standards will spur innovation, enabling two-stroke engines to become competitive enough to address a wider variety of application requirements.

They are likely to witness an ever-increasing demand for two-stroke engine products if manufacturers can create products that integrate digital controls, predictive maintenance, and environmentally friendly materials.

Impact of Regulations on Engine Types

Regulations regarding emissions and efficiency standards shape the landscape of engine development and adoption across industries. For example, strict emissions regulations have stimulated the development of higher-grade technologies, including enhanced two-stroke and four-stroke engines. These regulations call for the reduction of CO2, NOx, and particulate matter emissions, pressing manufacturers to develop gigs and meet the criteria.

Due to its greater emissions, the two-stroke engine received unfavorable attention despite being small and powerful. In marine, industrial, and small vehicle applications, direct fuel injection and the efficient combustion process have been key factors in saving fuel. Four-stroke engines remain competitive in the fuel-efficient and durable sectors, keeping pace with application-oriented upgrades such as variable valve timing and hybridization that receive regulatory approvals.

Opposing data highlight the significant impact of these regulations on market trends. The two-stroke engine market globally grows steadily with innovations toward compliance, whereas the four-stroke segment occupies a significant space in the automotive and power generation industries. Such a regulatory drive does more than hold up and create impetus for research and collaboration, envisioning a cleaner, greener array of engine technologies for varied applications.

Case Studies and Data Analysis

Real-World 2-Stroke Engine Applications

🏍️ Motorcycle Industry Case Study

From my experience, 2-stroke engines present an extremely versatile array to industries and applications where compactness, simplicity, and power-to-weight ratio come into play. One exemplary instance is the motorcycle/scooter industry: Their relatively light design and top post-Hills performance make them a great selection for urban transport. The riders often cherish the fast acceleration and low maintenance, which are important qualities when traversing bustling city streets.

🛠️ Outdoor Power Equipment

Elbowing its way in, the 2-stroke engine also finds quite a good home in outdoor power equipment such as chainsaws, leaf blowers, and brush cutters. These tools demand high power output and the ability to operate under demanding conditions from an engine. Landscapers and forestry workers favor 2-stroke engines for their ruggedness and portability, which are often used in harsh conditions.

⛵ Marine Applications

Another example worthy of attention is in marine outboard motors. Most small fishing boats and recreational watercraft use 2-stroke engines because they are simple and very reliable when operating in open water. These engines can release consistent power from a compact framework, making them indispensable in these conditions. These examples justify the continued relevance of 2-stroke engines, despite modern low-emission technologies, recognizing their application and importance in certain fields.

Data on Efficiency and Performance of 2-Stroke Engines

📊 Performance Analysis

In assessing the efficiency and performance of 2-stroke engines, I notice certain distinctive advantages offered by their design, particularly when the power-to-weight ratio is of paramount concern. Since these engines have fewer moving parts compared to 4-stroke engines, they are lighter and can be serviced more quickly and with greater ease. The simplicity of the setup can make these machines reliable, particularly under demanding situations such as in marine usage or with small machinery. Another aspect of this design is that it allows for a significantly higher power output for its size, which makes 2-stroke engines a preferred choice in certain industries, despite advances in other technologies.

From my perspective, a crucial aspect regarding the efficiency of 2-stroke engines is this trade-off. They are very powerful for their size and weight, but tend to consume more fuel and emit more pollutants than modern 4-stroke ones. However, recent developments, aided by direct fuel injection and an upgraded lubrication system, have done much to correct the shortcomings. These technologies lead to improved fuel economy and reduced environmental impact. Thus, 2-stroke engines can still hold their ground on the niche scale.

In my opinion, one of the most special traits is the adaptability, which is why two-stroke engines have such eternal appeal. By their nature, wherever the concern of application for green alternatives is utmost, practical performance in niche applications with compactness, simplicity, and power has never matched that offered by 2-stroke engines. Small recreational vehicles and marine services, where small size and rugged performance remain necessary, tend to represent an ideal environment in which the 2-stroke continues to offer excellent mileage.

Consumer Preferences-2-stroke vs 4-stroke Engines

⚡ 2-Stroke Preferences

My choice between a 2-stroke and a 4-stroke engine is dependent on the application and what I value as a user. If I want more power, a simple engine, and lighter weight, then conversely, I select a 2-stroke. Due to its high power-to-weight ratio and simplicity of mechanics, it is best suited for applications such as motocross bikes, chainsaws, or other equipment where sheer speed is required. I appreciate that the 2-stroke engine has somewhat simplified maintenance, even if it is more fuel-hungry and potentially more polluting.

🔋 4-Stroke Preferences

On the other hand, set number 5, which prioritizes fuel efficiency, durability, and eco-friendliness, would prefer the 4-stroke motor. More suitable for long-term investment are quiet engines, generally speaking, and they are more fuel-efficient for these applications. These engines are excellent in any condition, as they are smooth and emit fewer pollutants, while weighing heavily on the decision criteria due to environmental and operational cost factors.

While 2-stroke engines can deliver a great performance and ease of use, 4-stroke engines focus on sustainability and efficiency. Therefore, the packaged engine will always depend on the actual requirements that need to be realized through the engine.

📚 Reference Sources

-

Two-stroke engine – Wikipedia

Explains the mechanics of a two-stroke engine, detailing how it completes a power cycle in two strokes. -

Difference Between 2 Stroke & 4 Stroke Engines – Castrol USA

Highlights the differences between 2-cycle and 4-cycle engines, focusing on the two-stroke process. -

What’s The Difference Between A 2 Stroke And A 4 Stroke Engine? – Valvoline

Provides a clear explanation of how a 2-stroke engine operates, including its compression, ignition, and exhaust processes. - Click here to read more.

Frequently Asked Questions (FAQs)

❓ How Many Strokes Are There in a 2-Stroke Engine?

In a 2-stroke engine, just two strokes of the piston complete the power cycle, and therefore just one crankshaft revolution is sufficient to produce power. Hence, it allows for a smaller-sized engine than one with a 4-stroke, which requires four strokes to complete a cycle. The intake and exhaust of a 2-stroke engine are concurrent processes, allowing for more straightforward operation and fewer moving parts. You may find the application of this design in anything from motorcycles to outboard engines. Generally, 2-stroke engines have higher power-to-weight ratios and are therefore more popular in outdoor applications.

⚖️ What Is the Difference Between a 2-Stroke and 4-Stroke Engine?

The main difference between a 2-stroke and a 4-stroke engine lies in the number of strokes needed to complete the combustion cycle. A 4-stroke engine completes its combustion cycle in four strokes, distinguishing intake, compression, power, and exhaust strokes. On the other hand, in 2-stroke engines, some of these processes are combined so that they get accomplished in two strokes. The design is thus simpler, although 2-stroke engines tend to emit more pollution due to burning oil mixed with fuel. Additionally, 4-stroke engines are generally more fuel-efficient and require less frequent servicing, as they tend to be more complex in design.

🔧 How Does a 2-Stroke Engine Work?

A two-stroke engine accomplishes a complete combustion action under just two strokes of the piston. During the first stroke, as the piston strokes downward into the cylinder, suction is created to draw in the air-fuel mixture through the inlet port, and at the same time, burned gas is released through the exhaust port. Once the mixing of gases has ceased as the piston passes upward, it compresses the mixture in the combustion chamber. Then, after ignition by the spark plug, it simultaneously imparts a power stroke, allowing the piston to move downward again. Hence, this design enables an engine that punches well above its weight in power output and is, therefore, widely used in motorcycles and outdoor power equipment.

🔩 Main Engine Parts of a 2-Stroke Engine: What Are They?

The chief components of any 2-stroke engine are, among others, the piston, the cylinder, the crankshaft, and ports (intake and exhaust). The piston is essential as it moves up and down inside the cylinder, compressing the fuel-air mixture and generating power from the combustion process. The crankshaft converts the linear motion of the piston into rotational motion, enabling the engine to operate. The intake and exhaust ports enable efficient penetration of the air-fuel mixture into the combustion chamber and the exit of exhaust gases, respectively. Fewer moving parts in a 2-stroke engine imply it’s simpler and lighter.

🛢️ Why Do These 2-Stroke Engines Require Oil in the Fuel?

Two-stroke engines require oil in the fuel to lubricate their internal working parts; this type of lubrication system is absent in four-stroke engines. Being shed into the intake and exhaust stroke at the same time, the engine oil gets burned along with the fuel, which increases emissions. The oil helps reduce friction between moving parts, such as the piston and cylinder wall, so that the engine can operate smoothly over the long run. However, this type of design tends to consume more oil and fuel, which is why it’s essential for outdoor power equipment and motorcycle owners to be aware of this.

⚡ What Does the Spark Plug Do in a 2-Stroke Engine?

Spark plugs play a crucial role in igniting the compressed fuel and air mixture within the combustion chamber of a two-stroke engine. When the piston moves up and compresses the mixture, the spark plug generates a spark when sufficient pressure exists to ignite the mixture. The rapid expansion of gases resulting from the ignition pushes the piston downward for the power stroke. Performance-wise, the timing of the spark needs to be ideally in sync to ignite the mixture best. The spark plugs do a fine job of running the engine and achieving efficient performance under various working conditions.