When we consider the various processes involved in small engines, few things are as basic or as often misunderstood as the stroke. It is suitable for any seasoned mechanic, avid DIY enthusiast, or the average person curious about powering tools or motorcycles with a two-cycle engine. Essentially, this comprehensive guide aims to illuminate the operation of two-stroke engines in 2025, explaining their unique design and operation, as well as the reasons why this engine has become commonplace in a wide range of applications, from chainsaws to dirt bikes. Expect to be informed about the number of strokes and the reasons for choosing this fantastic and versatile type of engine, scientifically. By then, you would just have learned the theory and practical insights needed to use this in real-life applications.

Understanding Engine Strokes

What is a Stroke Engine?

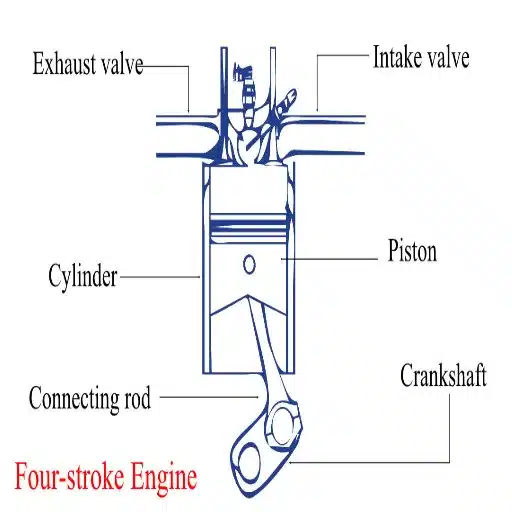

The stroke engine is simply an internal combustion engine whose piston’s motion completes all processes required for power generation by an engine. A stroke is simply a movement of the piston in the cylinder in either upward or downward direction; hence, it forms any phase of the engine- intake, compression, combustion (power), or exhaust. The terms “two-stroke” or “four-stroke” refer to the number of piston strokes required to complete one full cycle of engine operation.

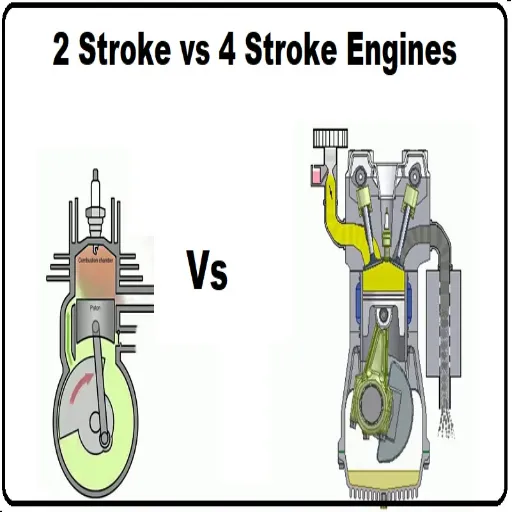

Key Insight: Here, two-stroke engines complete a power cycle with two strokes of the piston (one revolution of the crankshaft); hence, they are simpler to build, lighter in weight, and quicker in generating power than four-stroke engines. Conversely, the full cycle takes four strokes (two revolutions of the crankshaft) in the four-stroke engine, making it more fuel-efficient, less polluting, and better suited for long-lasting engine life. Modern advancements continue to gradually enhance both systems for improved performance, reduced emissions, and enhanced efficiency across various industries.

The Basics of Two-Stroke and Four-Stroke Engines

Recent technological developments have brought improvements to both two-stroke and four-stroke engines, enabling them to meet today’s demands for performance and environmental sustainability. Being the simplest and boasting the best power-to-weight ratio, two-stroke engines are being considered for new technologies, including fuel injection and innovative lubrication methods. These improvements have resulted in a reduction of emissions and an increase in fuel efficiency, making them suitable for marine transportation, air tools, or motorcycles.

Four-stroke engines are still being used in automotive and industrial applications due to their better longevity and efficiency. Recent enhancements in the design involved turbocharging and hybridization, where an ECU controls them more precisely than ever. For example, variable valve timing technologies enhance power output and fuel economy simultaneously.

Modern Update: Modern two-stroke engines and their pollution potential are becoming increasingly similar, while four-stroke engines remain the preferred choice for applications that demand reliability and low operational costs in the long run. Currently, with research and development ongoing, engines are being developed, making them both versatile and efficient in serving various industrial purposes.

How Many Strokes Are There in a Two-Stroke Engine?

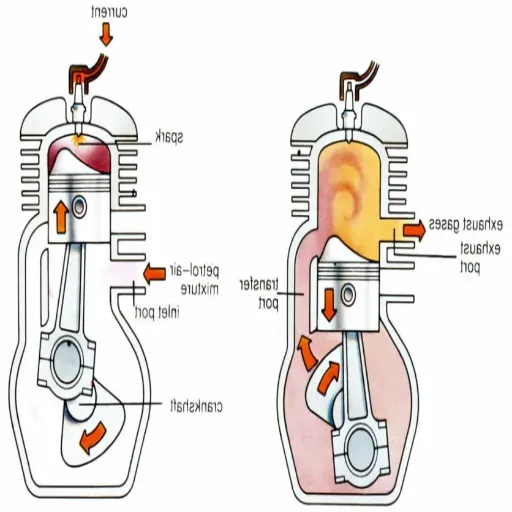

A two-stroke engine has a power cycle consisting of only two strokes of the piston. These consist of compression and power/exhaust strokes, with both intake and exhaust being simultaneous. Thus, more power is produced on every crankshaft revolution, compared to four-stroke engines, with a higher power-to-weight ratio and size.

In modern times, two-stroke engine technology has evolved to incorporate direct fuel injection and advanced oil management systems, resulting in improved performance and significantly reduced emission levels. Industry data suggest that these engines are used in applications that require high power-to-weight ratios, such as motorcycles, chainsaws, and marine outboard motors. These engines meet the need for a sudden burst of energy, while continually improving the environment and efficiency of operation.

Comparative Analysis of 2-Stroke and 4-Stroke Engines

Differences Between 2-Stroke and 4-Stroke Engines

| Aspect | 2-Stroke Engine | 4-Stroke Engine |

|---|---|---|

| Power Strokes | Two strokes (one crankshaft revolution) | Four strokes (two crankshaft revolutions) |

| Efficiency | Lower fuel efficiency, higher emissions | More fuel-efficient, cleaner-burning |

| Complexity | Simpler design, fewer moving parts | More complex with valve mechanisms |

| Maintenance | Easier maintenance, lighter weight | Higher maintenance but more durable |

| Applications | Chainsaws, dirt bikes, marine motors | Automobiles, generators, large machines |

🔧 Power Strokes

The primary difference between a 2-stroke and a 4-stroke engine lies in the number of strokes required to complete one power cycle. In a 2-stroke engine, two strokes of the piston (one revolution of the crankshaft) accomplish this, thus enabling a wider power output relative to its size. In contrast, a 4-stroke engine requires four strokes (two revolutions of the crankshaft) to complete the same task.

⚡ Efficiency

Generally speaking, 4-stroke engines are more fuel-efficient and cleaner-burning than 2-stroke engines, mainly because these engines have separate strokes for intake, compression, combustion, and exhaust, all acting in distinct phases. Two-stroke engines offer more power in less weight and size, but they generally burn oil mixed with fuel, resulting in higher emissions and poorer efficiency.

🔩 Complexity and Maintenance

2-stroke engines are relatively simple, as they lack many moving parts and operate without valves, instead relying on ports. This accounts for their lighter weight and ease of maintenance. Therefore, the added complexity that 4-stroke engines carry, i.e., their valve mechanism, necessitates higher maintenance but also offers higher durability and reliability.

🏭 Application Suitability

Due to their lightweight design and ability to produce power quickly, 2-stroke engines are commonly used in smaller, portable tools and vehicles, including chainsaws, dirt bikes, and marine outboard motors. Where durability, efficiency, and long-term performance are paramount, 4-stroke engines reign supreme in the domains of automobiles, generators, and large machines.

Environmental Impact: In continuation, innovations in engine designs shall always address ecological concerns. Notably, 4-stroke engines emit less pollution compared to 2-stroke engines. On the contrary, the burning of an oil-fuel mixture by the latter could increase particulate emissions; however, direct fuel injection in current technologies tends to mitigate these drawbacks in modern 2-stroke engines.

These key differences must be understood when choosing between engine types, considering a blend of performance, application, and environmental impact.

Performance Parameters of Two-Stroke Engines

The two-stroke engine has been regarded particularly because it can pack maximum power in a tiny dimension and weight. Two-stroke engines meet the engine’s performance expectations in terms of maximum power-to-weight ratio; hence, such engines are best suited for applications such as motorcycles, chainsaws, and marine outboard motors. Simplicity in design means fewer moving parts to break down, thereby minimizing the time and cost of maintenance —a notable advantage for the two-stroke engine.

Performance Trade-off: Being fast and powerful, these were soon acknowledged to be fuel-hungry and short-lived. Generally speaking, two-stroke engines consume more fuel due to incomplete combustion cycles, which affects their overall efficiency. Recent engine technologies including direct fuel injection (DFI) are eliminating inefficiencies, thus raising fuel economy by about 50% and lowering emissions.

Torque and acceleration delivery are fantastic features of the two-stroke engines. They provide maximum torque over a broader range of RPMs, resulting in quicker acceleration and improved responsiveness, especially for high-demand applications. However, these advantages present a challenge in terms of durability due to increased wear from higher engine cycles.

Horsepower, torque curve, specific fuel consumption, and operational life are some of the key metrics observed to study these engines across their industries. Insights from modern engineering show that education aided by technology is making newer developments possible, thus allowing two-stroke engines to compete in performance-based markets while complying with today’s stricter environmental regulations.

Environmental Impact of 2-Stroke and 4-Stroke Engines

As a measure of their environmental impact, one has to consider their emissions, efficiency, and fuel consumption. Two-stroke engines tend to be less fuel-efficient, consume more oil, and emit higher quantities of unburned hydrocarbons and particulate matter into the air. This contributes to increased air pollution levels, which are aggravated by the applications in which these engines are typically used, such as small vehicles, motorcycles, and marine equipment. The design itself offers a simpler and lighter construction; however, this compromises the precision of fuel combustion, raising an even greater environmental footprint.

🌱 Four-Stroke Environmental Advantages

On the other hand, as a consequence of their arduous architecture, which supports controlled intake, compression, combustion, and exhaust strokes, four-stroke engines are found to have better fuel efficiency and lower emissions. These engines produce lower amounts of harmful gases to the environment, such as carbon monoxide and nitrogen oxides, which fairly closely align with the most stringent modern emission standards, including Euro 6 and EPA Tier 4. Thus, technological advances in catalytic converters and direct injection techniques have further reduced the environmental impact while ensuring a higher power output.

Recent advances in different engine types generally aim to minimize environmental drawbacks. Thus, in recent years, fewer two-stroke designs with improved emission control and better lubrication systems have started to fill the performance gap with four-stroke engines. On the other hand, employing electric or other hybrid technologies in conjunction with biofuel alternatives for four-stroke engines helps further reduce greenhouse gas emissions and fossil fuel dependency. These improvements indicate a progressive direction to greener and sustainable applications for internal combustion engines across all industries.

Applications of Two-Stroke Engines

Where Two-Stroke Engines Are Commonly Used

Two-stroke engines are widely applied when simplicity, lightweight structure, and a good power-to-weight ratio are essential. In some small equipment, such as chainsaws and leaf blowers, where smallness and portability are assets, it’s quite common to find two-stroke engines. These engines are also mounted on motorcycles, snowmobiles, and outboard motors for boats, ensuring adequate power while keeping the equipment lightweight.

Such engines find use in industries and agriculture, balancing miniaturization with a reasonable level of performance suitable for small generating sets, water pumps, and dirt tillers, among other applications, especially in remote or rural areas where ease of repair and maintenance is a priority. Two-stroke engines, thanks to advancements in modern inventions such as direct fuel injection and improved lubrication systems, are experiencing a revival and continue to hold an important place in various industrial settings.

Case Studies: Two-Stroke Engines in Modern Technology

🚢 Revolution in the Marine Industry

Two-stroke engines have been a significant source of power in the marine industry, primarily through lightweight outboard motors for small boats and personal watercraft. Recreational purposes and small-time fishing require a simple design that is compact and has a high power-to-weight ratio. To illustrate, the Evinrude E-TEC engine series has significantly improved efficiency standards by incorporating direct fuel injection technology, resulting in a 20-percent reduction in fuel consumption compared to older two-stroke models, while also reducing hydrocarbon emissions. Furthermore, improvements in noise reduction have made them more acceptable in environmentally sensitive aquatic areas, thereby providing a better user experience and promoting sustainability.

🚁 Role in Drones and UAVs

The growth of unmanned aerial systems (UAS), such as drones, has paved the way for another avenue of utilizing two-stroke engines. Newer two-strokes are often used in larger drone types because they provide consistent and reliable power for an extended period. For instance, hybrid systems, which combine electric motors with two-stroke engines, are being experimented with by manufacturers as a way to optimize operation and efficiency. This hybridization enables heavier payloads or longer operations from drones, particularly in applications such as precision agriculture or search and rescue. Recent research suggests that hybrid UAV systems can reduce operational costs by nearly 30% and maintain the fuel efficiency of such systems, coexisting in harmony with traditional and current engine technologies.

Together, these case studies shed light on how two-stroke engines, integrated with newer technologies and designs, continue to evolve to suit equipment that requires lightweight design, high efficiency, and adaptability. Their metamorphosis symbolizes a capacity to cater to industrial demands while not being at odds with modern aspirations in environmental and economic aspects.

Advantages of Using a Two-Stroke Engine in Small Engines

The two-stroke engines offer several distinct advantages when used in small engine applications, thus becoming a spirit of various industries. First and foremost, the two-stroke engine design is compact and lightweight, which makes it easier to port and use. This is an attractive feature when applied to instruments and vehicles, such as chainsaws, scooters, and outboard motors, where agility and maneuverability are paramount.

- ⚡ Superior Power-to-Weight Ratio: Another trait of two-stroke engines is their efficiency. Compared to four-stroke engines, two-stroke engines have two strokes to complete a power cycle and hence generate greater horsepower from a smaller volume. This results in a better power-to-weight ratio, which is crucial for compact machinery that performs heavy-duty tasks.

- 🔧 Mechanical Simplicity: Again, two-stroke engines are mechanically simple designs with fewer moving parts. This means lower chances of mechanical failure, less maintenance, and hence, lower overall running cost. Another aspect of the design is that it is capable of operating in different orientations, providing more versatility to devices that require use at odd angles.

- 🌿 Modern Environmental Improvements: With the evolution of fuel injection and combustion technologies, modern two-stroke engines have effectively addressed the traditional problems of emissions and fuel inefficiency. Modern two-stroke engines, which run with direct fuel injection, produce significantly fewer exhaust emissions than their predecessors, thereby further optimizing fuel consumption. This makes the contemporary two-stroke engine both environmentally and economically capable.

The abovementioned advantages make the two-stroke engine practical and highly adaptable, especially in small-sized applications where power, efficiency, and reliability are of primary concern. The longevity of the two-stroke engine across various industries is evidence that it continues to meet evolving customer and environmental demands.

Future Trends in Engine Technology for 2025

Innovations in Two-Stroke Engine Design

The future of two-stroke engine designs is projected to be driven by the most recent developments in materials, combustion technologies, and precision engineering. Prominent among the numerous changes is the integration of direct fuel injection systems, which allow for high fuel efficiency by dispensing fuel only when needed, thereby reducing emissions. The other side is the use of high-strength and lightweight alloys for engine components, thereby sensitively reducing weight while improving the durability of these engines for newer applications.

🔋 Electrification Integration

Electrification also drives design trends, which hybrid two-stroke engines are at the crossroads of, harnessing their own power-to-weight advantage with the efficiency and environmental friendliness of the electric motor. Yet, developments in lubrication systems are also viewed with great optimism, as they aim to reduce oil consumption and extend engine life, which should be the very solutions to the long-standing issues of maintenance and environmental safety.

Cast into the future: Sophisticated computer modeling and AI have made it possible to ensure the utmost calibration of engine performance. Designers utilize these tools to optimize combustion dynamics, thermal efficiency, and part durability with greater control than ever before on engines that are purported to be cleaner, more powerful, and highly efficient. Such developments demonstrate that two-stroke engines remain highly relevant and are instrumental in the development of sustainable technologies for the future.

In Prospect: the Evolution of Engine Strokes

The evolution of engine strokes is geared toward meeting rising demands for sustainability, efficiency, and industrial adaptability. A major trend will witness the hybridization of these systems, uniting internal combustion capabilities with higher electric propulsion systems, greatly curtailing the pipeline of greenhouse gas emissions while retaining power, workability, and versatility.

⛽ Alternative Fuels

Application of alternative fuels, such as hydrogen, biofuels, and synthetic e-fuels offering considerable reductions in carbon footprints.

🧪 Advanced Materials

Lighter alloys and top-grade composites enhancing durability while reducing total weight and energy consumption.

🤖 AI Integration

AI and machine learning supporting dynamic stroke performance optimization for maximum efficiency.

The new generation will develop electronic combustion systems that dynamically adjust to efficiency specifications. The use of AI and machine learning will support engines in maintaining ever-changing stroke performance based on control methods for injection, timing, and pressure, thereby maximizing energy outputs and minimizing emissions. Additionally, modular engine architectures will become increasingly common as manufacturers and end-users seek to design an engine specifically for their purposes, without compromising that exercise for efficiency or scalability.

These technologies exemplify the attitude of equalizing progress and environmental responsibility, moving toward engines that score higher in performance while advancing the world’s sustainability goals.

Engine Development: Electric Alternative

⚡ The Electric Revolution

Electric alternatives have really changed the very landscape of engine development. These days, electric motors can be used in transportation, industrial machinery, and even aerospace, as opposed to combustion engines, which are perhaps more polluting but less efficient. This advancement is being fast-tracked in due course to minimize greenhouse gas emissions and maximize reliance upon renewable energy sources. Equipped with such high energy efficiency, electric motors and solar converters can convert more than 85 percent of the available electricity into mechanical energy, which is significantly higher compared to the internal combustion engine, which converts just 30 percent.

In addition, the provision is applicable across numerous industries since electric alternatives can be scaled from tiny motors in consumer electronics to relatively large and powerful systems moving EVs or cargo vessels. Battery technology is continually improving, with factors such as energy capacity, durability, and fast charging rates advancing, making the electric solution increasingly competitive. Another cycle of innovation is accelerating acceptance in the electric domain, driven by advancements in solid-state batteries and ultra-fast charging stations. These changes reduce environmental impact while also yielding promised quiet, more reliable, and low-maintenance engines, thereby shifting the direction for the way forward in industrial and transportation solutions.

Conclusion and Key Takeaways

Summarizing the Differences Between 2-Stroke and 4-Stroke Engines

Deciphering the differences between the 2-stroke and 4-stroke engines is paramount to determine which optimally meets a given use. Essentially, a 2-stroke engine undergoes a power cycle in just two strokes of the piston, resulting in simpler mechanical assembly and a higher power-to-weight ratio. This is suitable for applications that require a lightweight or compact design, such as chainsaws or motorcycles. Unfortunately, they also require more fuel and pollute more due to incomplete combustion.

The 4-stroke engine, however, operates the power cycle in four piston strokes, resulting in better fuel economy and lower emissions. They are sturdy and thus offer smooth functioning, often becoming a reliable companion for vehicles, lawnmowers, and heavy-duty machinery. However, it is clogged with a complicated design and requires more frequent maintenance than two-stroke engines.

Decision Factor: Operational demands, environmental regulatory impingements, and longer-term cost considerations govern the choice between the two; both types of engines have roles to play in given sectors.

More on Engine Strokes and Beyond

Thinking about engine strokes, I think that both 2-stroke and 4-stroke engines are of equal importance depending on their intended use. 2-stroke engines are simple, portable, and have a high power-to-weight ratio, which places them at the forefront for small tools such as chainsaws and smaller vehicles. Whereas, 4-stroke engines are more efficient, emit much lesser pollution, and are more durable—which is why they are applied mainly in scenarios demanding long-duration operations with constant performance, like cars and heavy machines. Each engine has its shine in a particular industry, and thus, the situation will dictate what is more workable—low maintenance, cost, or environment.

🔮 Future Outlook

In my view, looking toward the future of engine technology, the shift is toward more environmentally and sustainably oriented solutions. Developments in hybrid engines, battery-powered schemes, and alternative fuels are transforming the industry landscape, particularly in relation to environmental issues on a global scale. The traditional 2-stroke and 4-stroke designs would likely evolve, although they will almost certainly remain in some form in rare applications, leveraging their unique advantages that cannot be replicated. I believe that this combination of traditional and new elements will characterize the engine industry going forward: essentially, efficiency on one side and environmental considerations on the other.

Further Reading on Engine Technologies

Certainly, I’ll give a brief first-person response about resources for further reading on engine technologies. In my opinion, Engine Technology International or Automotive Engineering Magazine would be the best places to start. These publications feature research on the latest developments, including updates on hybrid and electric powertrains, as well as alternative fuel systems, and delve deeply into the area of combustion-engine development. Thus, these magazines are best for both experts and hobbyists alike.

Another article of knowledge comprises the academic literature and technical papers, particularly those issued by organizations such as the Society of Automotive Engineers (SAE). SAE publishes research-driven, deeply focused technical papers on the latest advancements in engine technologies, including fuel efficiency innovations, emission controls, and lightweight materials. Their technical standards and reports are very useful for developing a profound understanding of the industry’s direction.

Finally, whatever packets of time exist may be filled with application-oriented pointers from the stories and blogs of automotive and engineering firms. The websites of Bosch or Cummins frequently include special areas dedicated to their latest investigations into engine technology. Together, these resources provide a great backdrop for investigating a dynamic and rapidly progressing field like engine development.

Reference Sources

- Wikipedia: Two-stroke engine – A detailed overview of two-stroke engines, including their mechanics and applications.

- Castrol® USA: Difference Between 2 Stroke & 4 Stroke Engines – Explains the differences between two-cycle and four-cycle engines, focusing on their operation.

- Prime Source Co: The Difference Between a 2-Stroke and 4-Stroke Engine – Discusses the combustion cycle and how two-stroke engines complete it in two piston strokes.

- Quora: What’s the difference between a two-cycle and a 2-stroke engine – A community discussion on the mechanics and terminology of two-stroke engines.

- Edgar School District: Two-Cycle and Four-Cycle Engines (PDF) – A technical document explaining the differences between two-cycle and four-cycle engines, including stroke mechanics.

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What are the advantages of a two-stroke engine?

The primary advantage of a two-stroke engine is its better power-to-weight ratio. Since it completes the power cycle in two strokes, it can deliver power at a faster rate and thus finds many typical applications in various lightweight devices, such as motorcycles and chainsaws. Another advantage of this is the omission of the valve in the engine; therefore, this engine has a simpler design that is easier to manufacture and maintain. Users must, however, be aware that the two-stroke engine generally consumes more fuel and emits more pollutants into the atmosphere compared to conventional four-stroke engines. This could result in a significant trade-off, depending on the application and emission regulations.

🛢️ How does the lubrication of a two-stroke engine take place?

Lubrication in a two-stroke engine is achieved by mixing oil with fuel, in contrast to a four-stroke engine, which has its own dedicated oil system. This mixture is essential, as it lubricates the engine components in the fuel phase as it enters the combustion chamber. The engine oil, therefore, keeps moving parts, such as the piston and crankshaft, from wearing down quickly. Higher emissions may occur, however, in this method because some of the unburned oil is released with the exhaust gases. On the other hand, the easy method of lubrication goes a long way in keeping the two-stroke engine light and compact.

🔄 How many strokes does a 2-stroke engine have in a power cycle?

Basically, a two-stroke engine produces power with two strokes of the piston during one power cycle. Hence, for every one crankshaft turn, the engine essentially has one power stroke. Building this way makes a smaller engine, great for motorcycles and chainsaws. Whereas a four-stroke engine considers a power cycle to be the completion of four strokes, a two-stroke engine streamlines this process into two, thus increasing the power-to-weight ratio. This very efficiency makes the two-stroke engine so popular among small engine applications.

⚖️ What is the difference between a two-stroke engine and a four-stroke engine?

The fundamental distinction between two-stroke and four-stroke engines lies in the different orders of operation. The two-stroke engine completes the power cycle with two strokes of the piston; the four-stroke engine requires four different strokes: intake, compression, power, and exhaust. These fundamental differences result in variations in engine design, efficiency, and maintenance. For example, two-stroke engines tend to be lightweight and simple in design, making them operationally more straightforward; however, they consume more fuel and produce more emissions. On the other hand, four-stroke engines are more fuel-efficient and less polluting due to their complex valve and exhaust systems.

🔧 What parts of a two-stroke engine are essential?

The principal engine parts in a two-stroke engine include the piston, cylinder, crankcase, and exhaust port. During the power stroke, the piston moves down through the cylinder, compressing the fuel mixture for ignition. In the exhaust stroke, it moves up and pushes the exhaust gases into the exhaust port. However, a two-stroke engine lacks valves, unlike a four-stroke engine, which relies on ports for the intake and exhaust processes. This design results in a simpler engine with reduced weight and complexity, but presents its own set of lubrication and emission challenges.

🔄 How is the movement of the piston different in a two-stroke engine?

The movement of the piston in a two-stroke engine is highly functional in relation to the power cycle of the engine. When the piston moves down the cylinder, it initiates a power stroke; while as it moves upwards, the exhaust stroke takes place. This occurs in two strokes; thereafter, there is one power stroke for every revolution of the crankshaft. It thus becomes a more efficient engine in terms of size and weight; hence, it holds applications such as outboard engines and lawn mowers. However, because of this swift movement, issues of lubrication must be carefully considered, as the fuel and oil are closely intertwined.