Riding a jet ski is a fun activity and it is regarded as an exciting sport even for those who are beginners. One key part that enables a jet ski’s operation is the impeller. Whether you’re an experienced rider or just learning about jet ski mechanics, understanding how the impeller works will assist you in achieving optimal performance, correcting defects, and exploring improvement options. In this comprehensive guide, you’ll learn everything you need to know about how the impeller works, repair methods, and modifications to increase the power and performance of your jet ski.

Basics of Jet Ski Impellers

What is an Impeller?

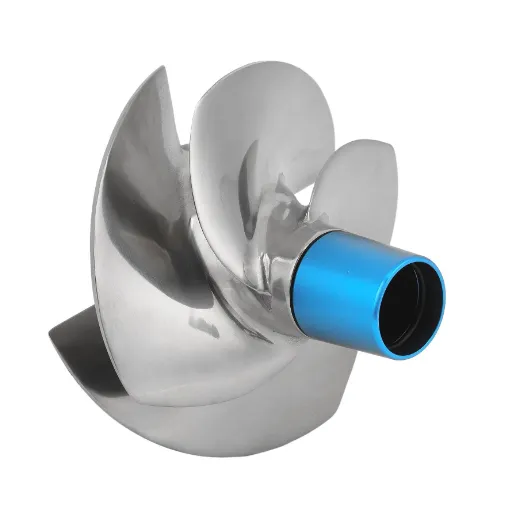

One of the most important parts of a jet ski is the impeller, which acts as its propulsion mechanism. It is essentially a rotor, or a fan, which is used to gather water and expel it with tremendous force to produce thrust. Housed inside the pump of the jet ski, the impeller takes the energy produced by the engine, which in turn accelerates the water inside the system, allowing the vessel to move forward.

The way an impeller works is by generating a strong water stream, or in other words, a jet of water under pressure. As the impeller turns, it draws in water from the underside of the jet ski’s pump through the intake grate and discharges it at high speed through the rear jet-drive nozzle. This process is what powers the motion of the jet ski, making the impeller crucial for both speed and handling.

⚠️ Important: A jet ski will not be able to function at maximum capacity if the impeller is not in good condition. If the blades are nicked or bent, efficiency will decrease and performance will drop. It is therefore necessary to periodically check and service the impeller to guarantee trouble-free operation and best performance from your jet ski.

How Jet Ski Impellers Work

Impellers are an integral part of jet skis. They are responsible for sucking in water via an intake grate located on the bottom part of the hull. The impeller consists of rotating blades that suck up water and then push it under pressure through a small nozzle at the rear end of the jet ski. This creates a powerful jet similar to a fire hose, and this force of water is what propels the jet ski and helps control its direction.

The role of the impeller is critical in any jet ski. The impeller ensures that water is properly directed within the pump dynamics and produces enough power to meet the pilot’s requirements for energy and movement. Impellers are finely tuned to ensure that any change in speed, wind direction, or strength doesn’t negatively affect operation—they can handle slow speeds, high-speed operation, and both calm and heavy seas.

💡 Key Insight

The impeller requires routine maintenance to function properly. Any damage, including dents or debris stuck to the impeller, greatly compromises water flow and therefore the power and performance of the jet ski. Regular inspection and timely repair of any deformities will maintain and prolong the life of your craft.

Importance of Impeller in Propulsion System

The impeller is one of the key elements in any jet ski propulsion mechanism. In its operation, it draws water toward the pump and converts it into a jet flow that provides the thrust to move the vessel forward. A malfunctioning impeller means a jet ski that cannot effectively propel itself or operate, making it an essential component of the system.

Another significant function of the impeller involves maintaining optimal water flow to ensure power can be effectively and consistently produced. The design and upkeep of an impeller should permit smooth water flow within the pump even as both speed and turning of the jet ski are enhanced. This advances the complete performance of the jet ski in motion and in different types of waters, where precision and steering are paramount.

💰 Cost Efficiency: A well-maintained impeller helps reduce fuel consumption. When the impeller isn’t properly maintained or has degraded, the engine works harder and uses more fuel. Regular monitoring and timely repairs can help save on fuel costs while maintaining optimal performance.

Choosing the Right Jet Ski Impeller

Understanding Impeller Pitch

The pitch of a jet ski impeller measures the distance covered within the water surface during one rotation, similar to a screw thread. For example, an impeller with a 13/19 pitch is designed such that at the inner diameter the pitch is lower at 13 degrees while it rises to 19 degrees toward the outer diameter. This design makes optimal acceleration attainable while still providing potential for high speeds, depending on rider preference.

| Pitch Type | Best For | Characteristics |

|---|---|---|

| Low Pitch | Towing, heavy loads, choppy water | Better acceleration, improved pulling power, ideal for rapid take-off situations |

| Mid-Range Pitch | Recreational cruising | Balanced acceleration and speed, versatile for various conditions |

| High Pitch | Top speed, smooth water | Maximum speeds achievable, best for riders focused on velocity |

🔧 Pro Tip: It’s important to note that modifications to your jet ski’s design may require pitch adjustments. Mechanical changes like bigger engines, more efficient exhausts, and intake system adjustments affect impeller performance. Always examine the impeller when performance enhancements are made, and consider consulting manufacturers or skilled professionals to select the right option.

Factors to Consider When Selecting an Impeller

It is very important to select the most suitable impeller for your boat’s performance, operation, and reliability. Here are the key factors to consider:

1. Power and Speed Range

Select an impeller appropriate for your engine’s horsepower and RPM range. Misusing the engine by overworking or underworking it can reduce efficiency in terms of overall performance and fuel consumption. Review your engine specifications to determine the best match.

2. Pitch and Blade Shape

The pitch determines how much water is displaced with every rotation and affects both acceleration and maximum speed. Lower pitch impellers provide better acceleration under heavy loads or in turbulent water, whereas higher pitches are ideal for speed runs. The blade shape also determines water entry efficiency and turning capability.

3. Materials for Better Longevity

Most impellers are constructed using stainless steel, aluminum, or composite materials:

- Stainless Steel: Can withstand wear and corrosive forces, making them ideal for demanding performance conditions and marine situations

- Aluminum: Mid-range durability and cost

- Composite Materials: Lighter and cheaper, suitable for less demanding recreational use

4. Usage Conditions

Consider the settings where your watercraft will be primarily used. Shallow waters with debris may require more durable impellers, while deep, clear waters allow for performance-focused options.

5. Cost and Maintenance Requirements

Beyond the initial investment, analyze the maintenance needs associated with each material. Higher quality materials may require more upfront investment but will decrease repair and replacement costs over time.

Taking these considerations into account and staying updated on the newest trends and innovations in impeller technology can vastly improve your watercraft’s efficiency. It’s also worth using modern computer models and performance measurements supplied by manufacturers when selecting the best impeller for your specific purpose, environmental conditions, and jet ski characteristics.

Repairing Your Jet Ski Impeller

Common Issues with Jet Ski Impellers

The jet ski impeller’s blades are critical for maximum operation. However, several issues may present themselves during use:

🔴 Physical Damage to Blades

Probably the most common issue involves physical damage to the blades. Rocks, weeds, sand, or other solid objects can get inside during pump operation and chip, dent, or bend the blades. Once deformed, blades cannot perform optimally because there is no uninterrupted flow of water. Always check the intake grate area to prevent debris from reaching the impeller.

🔴 Wear and Deterioration

Over time, impellers are subjected to tremendous stress and friction, which leads to surface wear. This not only makes the impeller less efficient in moving water but also contributes to cavitation—the formation of small bubbles near the impeller that causes thrust loss, vibrations, and potential damage to mechanical components. Monitor impeller condition regularly and replace worn parts promptly.

🔴 Improper Installation or Alignment

Even minimal misalignment can result in inappropriate wear and tear, vibration, and damage to the drive shaft and surrounding components. Always ensure the impeller has been installed properly, or seek professional service if you’re uncertain. Regular check-ups are necessary to maintain proper alignment and avoid complications.

Step-by-Step Guide to Impeller Repair

Repairing the pump of any jet ski can be complex and requires careful attention. Follow these steps for the best repair results:

Step 1: Safety First, Always

Disconnect the battery to prevent accidental starting. Ensure the jet ski is on an even surface and wear protective clothing, including gloves and goggles. Assemble required equipment including socket wrench sets, torque wrench, marine grease, and your jet ski’s repair guide.

Step 2: Accessing the Impeller

Remove the rear cover or seat to gain access to the impeller housing. You may need to unscrew bolts or disengage clamps, depending on your jet ski model. Check for any debris or damage around the work area.

Step 3: Disassemble the Pump

Carefully remove the pump assembly, which contains the impeller. This usually involves detaching the entire unit from the jet ski’s backside. Be careful not to disturb seals or gaskets during removal.

Step 4: Remove the Impeller

Use an appropriate removal tool for your specific jet ski model. Connect it to the impeller and turn counter-clockwise. Carefully inspect for wear, pitting, or mechanical damage on the impeller blades. If severely damaged, replacement may be necessary.

Step 5: Housing Assessment and Cleaning

Once the impeller is out, inspect the housing for scratches, cracks, or sediment that might affect performance. Use a soft brush and appropriate marine cleaner to remove all debris.

Step 6: Install the Repaired or New Impeller

Replace the repaired impeller back onto the shaft, securing it in position. Apply marine bearing grease to the threads to protect against future corrosion and ensure smooth operation.

Step 7: Reassemble the Pump and Housing

Carefully reassemble the pump and housing assembly, tightening all bolts to the required torque per manufacturer specifications. Ensure all seals and gaskets are properly positioned to prevent leakage.

Step 8: Test for Functionality

Reconnect the battery and test the jet ski in water. Look for any strange noises, excessive vibration, or power loss. If everything operates smoothly, the repair is complete!

Preventing Damage to Your Jet Ski Impeller

The impeller has a significant effect on your jet ski’s propulsion, and every user should try to prevent damage. Here are essential prevention strategies:

✓ Best Practices for Impeller Protection

- Avoid Debris and Shallow Waters: Rocks, sticks, and other objects can lodge in the propeller, causing jamming or severe wear. Sand may cause gradual wear over time. Always confirm water depth and avoid visible hazards before sailing.

- Conduct Thorough Inspections: Clean the intake grate and impeller areas after each ride to prevent fouling. This helps maintain optimal performance.

- Check the Wear Ring: Frequently inspect the wear ring that interacts with the impeller. A broken or abused wear ring will result in propulsion failure and potential impeller damage. Replacing a worn wear ring can significantly extend impeller life.

- Proper Starting Procedures: Only start your jet ski after ensuring water depth is sufficient to prevent the impeller from impacting the bottom. Never operate aggressively in substandard waters where debris might get sucked in.

- Practice Careful Operation: Aggressive acceleration and sudden maneuvers in debris-filled waters increase damage risk. Careful steering and routine maintenance will help you use the impeller longer with fewer interruptions.

Replacing and Upgrading Your Jet Ski Impeller

Signs It’s Time to Replace Your Impeller

Understanding and recognizing early signs of a failing impeller can prevent extensive damage. Watch for these symptoms:

| Warning Sign | What It Means | Action Required |

|---|---|---|

| Decreased Acceleration/Top Speed | Bent or damaged blades reduce smooth water propulsion | Inspect impeller for damage; consider replacement |

| Excessive Vibration/Shaking | Damaged or out-of-balance impeller; debris in intake | Clean intake and inspect for damage or imbalance |

| Cavitation | Air bubbles near impeller causing thrust loss | Check for wear; address immediately to prevent overheating |

| Poor Throttle Response | Engine revs increase without corresponding speed gain | Inspect impeller and wear ring for damage |

| Prolonged Use Without Replacement | Natural wear from continuous operation | Follow manufacturer’s replacement guidelines |

📋 Manufacturer Guidelines: Most manufacturers provide guidelines on when to inspect and replace the impeller based on operating hours. Consult your owner’s manual for specific recommendations. Even with regular maintenance, impeller performance gradually decreases over time due to continuous contact with water and elements.

How to Upgrade Your Impeller for Better Performance

Upgrading your vessel’s impeller to enhance efficiency is straightforward if you follow the correct procedures:

🔧 Upgrade Process

- Select the Right Replacement: Choose an impeller specific to your jet ski’s make and model. Research aftermarket performance impellers, OEM options, or custom-made impellers to eliminate fitment complications.

- Gather Required Tools: Assemble all necessary equipment including spanners, sockets, and a splined removal device designed for easy extraction without damaging components.

- Remove the Jet Pump Assembly: This typically requires removing several bolts and seals before pulling the pump unit out. Take care not to disturb sealing components.

- Remove the Old Impeller: Use the spline tool to hold the old impeller in place and unscrew it. Clean and examine the housing for any wear, tear, or foreign bodies.

- Install the New Impeller: Screw the new impeller onto the driveshaft, following recommended torque levels precisely.

- Reassemble and Test: Remount the jet pump, ensuring all seals are properly positioned to avoid leakage. Conduct trial runs to identify any excessive vibrations or abnormal noise.

A modified impeller enhances performance and possibly increases fuel economy and control, making the effort worthwhile. Give due regard to manufacturer guidelines and take time to ensure proper installation.

Professional Services for Jet Ski Impeller Replacement

It’s prudent to seek professional services for jet ski impeller replacement, as this guarantees optimal performance. Professional training assists technicians in carrying out installation tasks with specialized instruments and expertise.

✓ Benefits of Professional Installation

- Comprehensive Inspection: Professionals thoroughly inspect connected parts like wear rings and drive shafts to prevent future failures

- Proper Installation: Studies indicate that 20% of DIY improvements waste productivity due to incorrect placement or sealing defects. Professional services bypass this risk by ensuring proper fitment and alignment

- Performance Optimization: Service centers use state-of-the-art equipment to diagnose and select optimal impeller designs based on your riding style, jet ski type, and water conditions

- Warranty Protection: Most professional installations include warranties for their work, minimizing risks to your investment

- Enhanced Efficiency: Proper professional installation improves fuel efficiency and overall performance

Maintaining Your Jet Ski Propulsion System

Regular Maintenance Routines for Jet Ski Impellers

Proper care of your jet ski’s impeller significantly boosts service life and ensures optimal performance. Here’s a comprehensive maintenance routine:

🔍 Regular Inspection Checklist

- Visual Inspection: Examine the impeller body for minor injuries like scratches, rust, or bent fan blades that might cause damage or cavitation

- Debris Removal: Clean accumulated substances such as weeds or shells after each use. A gentle brush or marine-safe cleaner will maintain the finish without causing damage

- Wear Ring Inspection: Check the space between the impeller and wear ring. Incorrect clearance will decrease thrust and cause shaking. Replace the wear ring when necessary

- Freshwater Flushing: Routinely rinse and flush with fresh water, particularly after saltwater operations, to prevent salt corrosion

- Professional Service: Follow manufacturer recommendations for professional inspections based on operating hours. Tasks like balancing or replacement should be handled by trained personnel

These activities boost propulsion system performance and make time spent on water more enjoyable and reliable.

Tips for Enhancing Fuel Efficiency

Making the most of your fuel tank while riding a jet ski is about doing the right thing both on and off the water. Here are proven strategies:

⛽ Fuel Efficiency Strategies

Engine Maintenance

Keep the jet ski engine in optimal working order by following the manufacturer’s maintenance schedule. Clear accessible parts, ensure proper lubrication, and maintain clean filters. A well-maintained engine consumes significantly less fuel.

Hull and Body Inspection

Check for damages and remove any unwanted objects. Reducing deformation leads to smoother gliding and requires less energy to maintain speed.

Operating Techniques

Avoid rapid acceleration and maintain constant speeds without repetitive starting or stopping. Design your route strategically to avoid unnecessary distance and wasted time. Smooth, consistent operation significantly reduces fuel consumption.

Weight Management

A lighter watercraft burns less fuel. Carry only essential gear if fuel efficiency is a priority. Every pound counts when it comes to performance and consumption.

Water Conditions

Calm waters are easier to navigate than rough waters, requiring less power and fuel. Plan your rides during favorable conditions when possible.

💡 Modern Technology: Many current jet skis come with Eco or fuel-reducing modes that optimize engine operation while consuming less fuel. Using these technologies along with recommended fuel grades provides the highest possible efficiency. Through thoughtful behaviors, regular maintenance, and leveraging technology, you can cut down fuel expenses while promoting environmental conservation.

Keeping Your Jet Ski Running at Top Speed

Your jet ski needs consistent attention to maintain peak performance. Follow these essential maintenance practices:

🚀 Peak Performance Maintenance

- Oil Changes: Follow manufacturer recommendations for oil changes to ensure proper engine lubrication and reduce wear. This is foundational to engine longevity

- Spark Plug Inspection: Check and replace spark plugs regularly. Worn spark plugs cause engine performance drops and reduced efficiency

- Air Filter Maintenance: Clean the air filter frequently to prevent dust from blocking the intake system and causing power loss

- Propulsion System Checks: The impeller is critical to propulsion. Check for foreign objects or damage regularly and clear any blockages immediately. Replace worn-out parts promptly

- Fuel Quality: Strictly use high-quality fuel. Low-grade gas negatively affects engine power and speed performance

- Proper Storage: Store your jet ski safely when not in use. Protect it from extreme temperatures and excessive sun exposure, which can cause wear to both bodywork and internal parts

Observing these maintenance activities while staying attentive to your impeller’s condition will allow you to enjoy thrilling rides every time you power up your jet ski.

References

-

Universal Technical Institute (UTI): This article explains in detail how a jet ski generates forward thrust using a corkscrew-style impeller and provides an overview of its propulsion mechanism.

-

MIT DSpace: This academic resource discusses the design and manufacturing of an electric drivetrain for a jet ski, including coupling a motor to the impeller drive shaft.

-

Oregon State Marine Board: This government website offers information on personal watercraft, explaining how the impeller forces water through a nozzle to create propulsion.

- Click here to read more.

Frequently Asked Questions (FAQ)

❓ What is an impeller jet ski and how does it differ from a prop-driven personal watercraft?

An impeller jet ski uses an enclosed impeller inside the pump housing to push water, unlike prop-driven PWCs where propellers are exposed. The enclosed design prevents debris from jamming and provides easier directional control while in motion. This design variation affects water speed, safety, and maintenance requirements.

❓ How does impeller blade geometry affect performance?

Appropriate design of the leading edge and impeller blade shape enhances water penetration and prevents cavitation, resulting in increased acceleration and higher maximum speeds. Replacing a basic impeller with a high-performance or racing type can help improve acceleration and overall water performance.

❓ When should I replace my impeller and what are the warning signs?

Replace your impeller when you notice poor acceleration, excessive vibrations, overheating, or visible chips on the blades. Impellers wear out over time from debris impacts or cavitation. Signs include twisted or broken leading edges and unevenly worn blade surfaces. Installing the correct replacement promptly prevents damage to the pump casing and performance deterioration.

❓ How does the pump housing contribute to system functionality?

The pump housing draws water in and directs it through a central aperture toward the impeller. Performance impellers may require housing modifications or outer edge trimming. High-speed impellers paired with incompatible housing materials can experience heightened wear. Always check compatibility with your jet ski model and intended use.

❓ What factors should I consider when choosing an impeller?

Consider your riding habits (racing, free riding, towing), watercraft power, and operating environment. Pitch determines the balance between speed and acceleration—low pitch offers quick acceleration while high pitch provides maximum speed. Materials include stainless steel and high-performance alloys, though standard stainless steel satisfies most users. Match the impeller to your specific needs and engine specifications.

❓ What preventive maintenance prolongs impeller life?

Regular inspections of impeller blades and housing, debris cleaning, shaft play checks, and seal condition assessments prevent contamination. Always inspect after hitting something, as even small bumps can damage the leading edge and diminish performance. Proper flushing and storage also ensure durability of impeller components.

Conclusion

🌊 Master Your Jet Ski Performance

The impeller is the heart of your jet ski’s propulsion system, and understanding its function, maintenance, and upgrade potential is essential for every rider. Whether you’re troubleshooting performance issues, planning regular maintenance, or considering upgrades for enhanced speed and efficiency, this comprehensive guide provides the knowledge you need.

By following proper maintenance routines, recognizing warning signs early, and making informed decisions about repairs and upgrades, you’ll ensure your jet ski delivers optimal performance for years to come. Remember that regular inspections, careful operation, and timely professional service are your best investments in maintaining a thrilling and reliable riding experience.

⚠️ Safety Reminder: Always prioritize safety when performing maintenance or repairs. When in doubt, consult professional technicians to ensure proper installation and optimal performance.