Over the recent years, this has been a fantastic time of progress, bringing in new and innovative ways of powering and maneuvering vessels. Within these propulsion systems, impellers and propellers are among the most fundamental elements, as they function in similar ways but operate mechanisms of entirely different nature. With modern boating rapidly evolving, these technologies are being developed to meet the demands for efficiency, sustainability, and accuracy, making the differences between impellers and propellers crucial to understand. This article provides detailed information about impellers and propellers, their primary applications, and the innovations expected to be adopted in 2025 in the marine industry, which will impact the watercraft trade. This guide provides in-depth information for marine engineers, boat enthusiasts, or anyone interested in the future of watercraft technology.

Introduction to Impellers and Propellers

Definition and Functions of Impeller

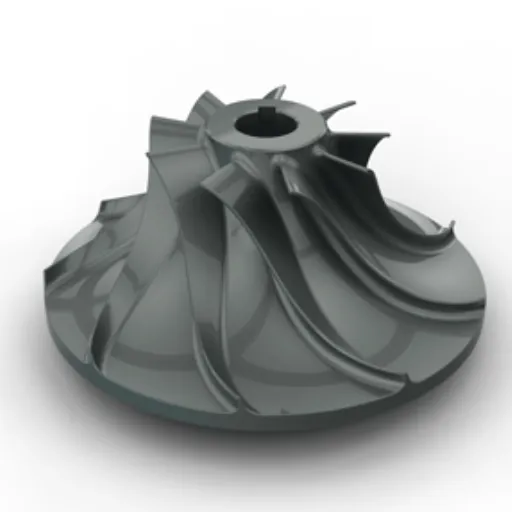

An impeller is a component of pumps or fluid-moving systems that provides energy to the fluid being moved. Drawer impellers typically consist of a rotating disc equipped with curved blades or vanes that direct the fluid away from the center of rotation. The primary function of an impeller is to impart velocity and pressure to the fluid so that it can convert the mechanical energy acquired from a motor or engine into kinetic and potential energy of the liquid.

Impeller Types and Applications

Impellers are extensively used in centrifugal pumps, where they play a crucial role in the circulation of water, desalination, and various fluid-handling operations. According to design and configuration, impellers can be open, semi-open, or closed. Each type features distinct characteristics that affect efficiency and suitability for a given application. For clean fluid pumping, closed impellers are undoubtedly the most efficient option, while for abrasive liquids or those containing solids, open or semi-open impellers are preferred.

Modern developments in impellers focus on the use of materials such as reinforced composites and corrosion-resistant alloys for better durability, especially in marine environments. CFD now enables design engineers to modify impeller geometry to achieve maximum operational efficiency, thereby achieving larger flow volumes, lower power consumption, and more subdued operational characteristics. These developments, therefore, emphasize the importance of impellers in propulsion and fluid control systems, which are critical in almost all industries, including Marine engineering.

Definition and Functioning of Propellers

The name means “propeller”; it is, however, a mechanism that converts rotation into thrust, providing a means of propulsion for a ship or an aircraft. With blades arranged around a central hub, the propeller operates on either aerodynamic or hydrodynamic principles, depending on the medium involved. In essence, the blades are airfoils, shaped to create pressure differentials to thrust while the propeller is turning.

Propeller Performance Parameters

To consider propeller functioning, one must assign fixed values to parameters such as diameter, pitch, number of blades, thrust, efficiency, and noise level, among others. For example, the more blades you put on a propeller, the better the thrust in heavy loading; however, more drag will be created, resulting in reduced efficiency. Advanced propeller design would utilize advanced materials, including lightweight composite materials or alloys that resist corrosion well, to withstand operational stresses under demanding service conditions, such as those in high salinity and high temperatures.

Propeller geometry optimization is an extremely focused subject area in industrial design, guided by thorough computational simulations and operational testing at some point. Especially the blade skewing and custom pitch profiles avoid cavitation, posing the danger of material loss while furthering performance loss. Theoretically, variable-pitch propeller systems adjust the blade angle to meet required operational conditions; therefore, from the operational viewpoint, such a feature is highly desirable. The technologies as mentioned above indeed place the propeller at the forefront of developing the energy-friendly, best-performing propulsion solution.

Overview of Mixing Impeller

Mixing impellers represent a central mechanism in all kinds of mixing and agitation applications in industry settings, ranging from chemical processing, pharmaceutical production, and wastewater treatment. This machine is designed to transfer energy from the motor to the fluid, facilitating proper mixing, dispersion, and homogenization. The impeller design and/or selection are governed by several primary criteria, including fluid viscosity, the impelling or mixing effect, and the geometry of the tank.

Advanced Mixing Technology

Modern impelling technology encompasses various designs, including flat blades, pitched blades, and hydrofoils, each tailored for specific flow types, such as radial, axial, or combined flow. The advent of CFD enables impeller performance and analysis to be subjected to detailed investigations of flow characteristics and energy consumption. On the other hand, modern materials, such as anticorrosive alloys or composites, extend the service life and reduce maintenance requirements in harsh environments. Such facilities, equipped with variable-speed drives and real-time monitoring, enable operators to fine-tune impeller performance, ensuring maximum efficiency and optimal process outcomes.

Key Differences Between Impellers and Propellers

Understanding the Difference Between Impeller and Propeller

Impellers and propellers are the two essential rotating components used in fluid motion systems; they serve distinct purposes and operate on different principles.

| Aspect | Impellers | Propellers |

|---|---|---|

| Operating Environment | Enclosed systems (pumps, turbines) | Open systems (marine, aviation) |

| Primary Function | Generate pressure and flow | Create thrust for propulsion |

| Efficiency Range | Up to 85% (hydraulic) | Up to 90% (thrust) |

| Design Focus | Pressure differential | Thrust generation |

An impeller is essentially designed for an enclosed system, like a pump, turbine, or compressor, where it primarily serves to transmit energy from a motor or engine to the fluid being handled. In essence, it develops pressure to either force the fluid through a piping system or into an enclosed volume. Impellers typically feature curved blades attached to a central hub, designed to handle either liquids or gases under carefully controlled conditions. Theorizing efficiency would be based on flow rate, head pressure, and energy consumed. Modern impellers can theoretically achieve hydraulic efficiencies of more than 85%, depending on their design and application.

While underwater turbines operate in more closed systems, open propellers operate in open systems, such as in marine propulsion or aviation. Their main task is to create thrust by imparting acceleration to the fluid, thus forcing a ship or airplane to move in the same direction as the thrust. The blades of a propeller, being helical and thin, require minimal drag force to act upon them, with thrust, efficiency, and angular velocity serving as their key performance parameters. The modern designs of a propeller, employing highly curved blade shapes and CFD modeling techniques, allowed for approximately a 15% efficiency gain compared to conventional designs.

Key Operational Distinction

The primary point of differentiation lies in the operating environment for each equipment. Impellers operate in confined spaces under pressure, whereas the propeller requires an environment free from the flow of the fluid. This functional divergence has led to a separate set of materials, engineering, and optimization standards considered for each application to achieve maximum efficiency and versatility toward their respective goals.

Comparative Analysis: Impellers vs Propellers

A detailed study of impellers and propellers reveals essential differences in their performance parameters and design structures at work under varying operational conditions. Impellers, as components of pumps, turbines, and compressors, are designed to impart energy to a fluid through rotary motion within a narrowly controlled environment; thus, pressure energy is generated. The pressure energy thereby gained would find use in applications where pressurization and flow regulation are necessary, such as water supply and industrial processes.

The propellers, in effect, primarily convert rotational motion to thrust force in an open medium like air or water. This essential characteristic makes propellers indispensable in aviation and marine propulsion systems. Modern aerodynamic and hydrodynamic research has investigated blade profiles and materials to ensure they are optimally adapted for maximum operating efficiency in varying load conditions. For example, setting the blade pitch angle to an optimum level and using advanced composite materials have demonstrated a considerable reduction in drag and the maximization of thrust-to-power ratios.

Performance Comparison

Performance testing shows that impellers operate at high-efficiency levels when maximum fluid pressure buildup is required, whereas propellers are good at providing constant thrust with minimum energy dissipation. The same distinctions were portrayed by CFD analysis and by experimental validation. High-end impellers in centrifugal pump applications may achieve greater than 70 percent efficiency. In contrast, state-of-the-art propellers achieve a thrust efficiency of nearly 90 percent for certain vessel speeds.

The evolution of these technologies consistently centers on improved energy efficiency, reduced operational wear, and enhanced material properties. With impellers and propellers being manufactured through 3D printing and precise machining, these technologies continue to evolve, allowing them to address specific industrial problems with greater efficiency. However, it is this advancement that also demonstrates that these machines have their own distinctive yet complementary role to play in the mechanical systems of various industries.

Practical Applications and Specific Case Examples

Impellers and propellers are considered vital components in the world of engineering, where their specific functions find fulfillments in varied applications. For instance, in the marine world, propellers form an integral part of the system that propels a ship, ranging from cargo vessels to submarines. Over the years, significant efforts have been made in hydrodynamic modeling to achieve energy conservation and fuel reduction, thereby balancing the aesthetics of sustainability in the engineering industry.

Real-World Case Studies

Marine Applications:

Case studies provide further insight. For instance, consider the retrofitting of impeller-driven pumps in desalination projects, where material enhancements and design changes, driven by environmental factors such as high salinity, have significantly increased operational life.

Aerospace Applications:

On the other hand, aerospace engineering studies demonstrate the use of propeller technology in unmanned aerial vehicles (UAVs) for enhanced efficiency in certain low-speed flight conditions, primarily for surveillance and delivery operations.

Another vital function of impellers is optimizing fluid transport in pump systems. These are primarily used in buildings such as water treatment plants and chemical processing units, where high precision and reliability are essential. CFD tools have been applied to impeller design to improve flow rates and reduce cavitation.

These examples demonstrate that specific innovations in impeller and propeller technologies are well-suited to address the challenges posed by various operational conditions, thereby underscoring the significant relevance of these technologies to contemporary engineering systems.

Types of Impellers and Propellers in Boating

Centrifugal Impellers

Centrifugal impellers are required for applications where a fluid or gas must be moved through a confined space. These impellers impart rotational kinetic energy to the fluid, thereby generating a steady flow at high pressure. Meanwhile, the fluid enters near the rotation axis and is directed outward by centrifugal force through the impeller vanes. Centrifugal impellers are typically made from stainless steel, aluminum, or composite alloys, offering good corrosion resistance and durability under high-stress conditions.

Performance Specifications

For modern centrifugal impellers, performance is the primary target of maximum energy-saving CFD simulations; many losses are associated with pressure ratios. In multi-stage centrifugal impellers, such as those found in pumps and compressors in industries, efficiency is enhanced to achieve a higher discharge pressure level. Ab-initio data have reflected an energy efficiency of 85% in idealistic operations; hence, these impellers are the backbone of the petrochemical, power generation, and water treatment industries. In the meantime, advanced additive manufacturing technologies enable increasingly complex impeller geometries, thereby further enhancing performance and reliability in demanding applications.

Types of Propellers Used in Marine Settings

There are numerous propeller types used in marine propulsion, each designed for specific advantages and adapted to particular operational conditions. The major types are FPP, CPP, ducted propellers, and azimuth thrusters.

Fixed-Pitch Propellers (FPPs)

Fixed-pitch propellers are rigid propellers with blades that cannot be altered in angle during operation. As these propellers are relatively simple, cheap, and strong, they find use in vessels that undergo continuous operations. It is contrary to the CPP system that achieves an excellent efficiency range of 60 to 80% under normal conditions, depending mainly on hull design and engine matching.

Controllable-Pitch Propellers (CPP)

On the contrary, the pitch of an FPP cannot be changed, while, in contrast, CP propellers allow the blade angles to be changed during use to give a controlled thrust, better suited to take care of fuel efficiency under various operating conditions. They are commonly used in complex naval or cruise vessel operations, as they must function dynamically in maritime environments.

Ducted Propellers

Ducted or nozzle propellers are equipped with a cylindrical shroud that encases the blades. This actually increases the thrust generated, especially at lower speeds. The design is typically used in tugboats and other vessels that require strong pulling power. Research has shown that ducted systems can improve thrust by up to 30% over conventional open propellers under certain conditions.

Azimuth Thrusters

Azimuth thrusters rotate the propulsion unit through 360 degrees, providing an unusual degree of maneuverability and operational flexibility. It is these systems that are so sought after in dynamic positioning applications, such as offshore drilling vessels or research vessels. Despite initial high costs, the ability to ensure accurate navigation and moving fuel efficiency justifies their employment in modern fleets.

Choosing the appropriate marine propeller type is a multifaceted decision that considers vessel size, operational environment, speed requirements, and target fuel consumption. Modern propeller designs are the ones pushing for maximum achievement and perfection in the industry, although aided by material science and CFD.

Innovations for Mixing Impellers in Agitated Tanks

Nowadays, efficient and innovative mixing impellers are crucial for enhancing the efficiency and performance of an agitated tank system in various industries, including chemicals, pharmaceuticals, and wastewater treatment. Increased mixing efficiency, power reduction, and scaling up for both laminar and turbulent flows have driven the development of improved impeller designs.

Advanced Impeller Technologies

High-Efficiency Hydrofoil Impellers:

A key technological feature lies in the incorporation of high-efficiency hydrofoil impellers, characterized by blades that are streamlined to minimize drag and maximize fluid flow. Such impellers provide better generation of flow with minimum shear rates and thus are desirable where the material needs to be handled gently (such as in bioprocessing or where a very gentle suspension of fine particulates is required).

Radial Flow Impellers:

Radial flow impellers, meanwhile, discharge fluid primarily in a horizontal direction and, therefore, are often used in cases where either the fastest heat transfer or mixing of gas and liquid processes are needed, e.g., aeration.

Analytics behind data-driven performance analysis, with an emphasis on CFD simulation, places impeller design at the forefront by highlighting critical variables such as flow pattern predictability, power number efficiency, and mixing time. For example, paddle and hybrid impeller comparisons demonstrate improvements in energy efficiency of up to 30% in specific applications, while maintaining consistent mixing results. Such developments enhance process reliability and green operations by reducing energy requirements in the industry.

The future of mixing impeller technologies continues to unfold, with ongoing research into innovative materials and real-time performance adjustability according to process conditions. A better understanding of mixing dynamics yields precise results tailored to specific industrial needs.

Technological Trends by 2025

Significant Advancements in Impeller and Propeller Designs

The sphere of design of impellers and propellers is undergoing tremendous advances, owing to developments in computational modeling, materials technology, and precision manufacturing. Thus, CFD has become duly established and enables engineering simulations to predict and optimize fluid flow patterns, along with pressure distributions around blade surfaces, with an unprecedented degree of accuracy. Designs are modeled to minimize turbulence and maximize energy conversion, thereby resulting in operational cost savings.

Revolutionary Design Innovations

Advanced Materials

Composite materials and high-strength metallic alloys providing light weight with corrosion and wear resistance

3D Printing

Complex geometries previously impossible with traditional manufacturing

Real-Time Monitoring

Integrated systems providing continuous data on vibrations and fluid flow

The material innovations, such as composite materials or high-strength metallic alloys, have further revolutionized these components. Such materials are light and simultaneously resistant to corrosion and wear, making them ideal for harsh installations such as chemical processing plants and marine applications. Additionally, advanced surface treatment and coating methods are applied to combat and curb biofouling and cavitation attacks, thereby extending service life.

3D printing and additive manufacturing methods also transform the production of these components. They permit the generation of complex geometries that were previously impossible with traditional manufacturing, thereby increasing functionality and performance. Real-time monitoring systems integrated into impeller-propeller design systems now continuously transmit data on vibrations, disturbances in fluid flow, and structural integrity to the operator, allowing for proactive maintenance and optimized operating parameters.

Together, such advances make impellers and propellers an enabling technology for energy-efficient and high-performance fluid mechanics in various industries.

Effect of AI on Boating Technology

Boating technology changed overnight with AI systems that allowed for more automation, increased predictive analytics, and seamless integration with sophisticated manual and semi-manual navigation schemes. Currently, AI algorithms are being used to enhance the performance of vessels by optimizing routes, fuel consumption, and engine efficiency. The real-time suggestions come from algorithms that sort through enormous amounts of data combinations from various sensors, GPS systems, and weather forecasts, enabling operations to be realized with safety and efficiency.

AI Applications in Marine Technology

- Environmental Sustainability: The integration of AI improves the reliability and safety of boating operations while promoting sustainability with reduced energy consumption and emissions, thereby supporting global environmental standards.

Predictive maintenance is considered yet another prime application of AI in boating technology. Additionally, autonomous navigation systems developed through machine learning enable vessels to react to changing maritime situations such as currents, wind patterns, and traffic in the vicinity. The integration of AI improves the reliability and safety of boating operations while promoting sustainability with reduced energy consumption and emissions, thereby supporting global environmental standards. With this growing AI role, we have inevitably seen the transformation of current maritime practices.

Data Analysis: Trends in Boating Equipment

The modern boating equipment trends reflect a significant penetration of advanced technologies focused on safety, efficiency, and environmental compatibility. The data reveal an increase in the setup of integrated navigation systems using GPS, radar, and sonar to enhance ecological comprehension. Promotions for electric and hybrid propulsion systems are on the rise due to the need to minimize carbon emissions and stricter environmental laws.

Current Equipment Trends

Navigation Systems

GPS, radar, and sonar integration

Green Propulsion

Electric and hybrid systems

Communication

AIS transponders and satellite connectivity

Safety Devices

Personal locator beacons and MOB alerts

The Marine Communication Systems, AIS Transponders, and Satellite connectivity underneath are increasing implementations in real-time data sharing and coordination between vessels. Wearable safety devices, such as personal locator beacons and man-overboard alert systems, again underscore the focus on crew and passenger safety. Additionally, the market for smart sensors and IoT-enabled devices, which measure vital operational metrics such as fuel consumption, engine performance, and weather conditions, is experiencing rapid growth. The changes underscore how the industry is paralleling broader trends in automation and sustainability.

Conclusion and Future Outlook

Summary of Key Points

From the above discussion, I understand that advanced technologies, such as personal locator beacons (PLBs), man-overboard (MOB) alerting systems, and IoT sensors, are significantly impacting the operational efficiency and safety of the industry. Such measures are yet another manifestation of crew and passenger safety being at the top of the industry’s list of priorities, alongside various indicators for fuel consumption, engine performance, and weather forecasting. In this respect, these intelligent, connected systems improve operational agility while facilitating the deeper integration of automation and digitalization within the industry.

Industry Evolution Drivers

Moreover, I understand that sustainability is a driving force shaping the future of this sector, in conjunction with IoT technology and smart sensors, which enable the efficient use of scarce resources and reduce environmental impact. By capitalizing on these technologies, the industry demonstrates its commitment to eco-friendly operations and adapting to ever-changing regulatory and societal pressures within agro-industries. Primarily from the end of these evolutions emerges a forward-looking operating plane, in which safety, innovation, and environmental stewardship are considered the foundation on which the long-term viability of the industry rests.

Future Trends in Impeller and Propeller Technologies

When it comes to what I see as the future for impeller and propeller technologies, the increasing use of advanced materials and intelligent systems is likely to be the main feature in this projection. One trend I see emerging is the use of composites—a material with a superior strength-to-weight ratio that reduces weight, which is quite appealing from a performance perspective, as it reduces the load that the system has to hold. So, in effect, these materials enhance efficiency while also improving durability and environmental resistance. On the other hand, more advanced manufacturing techniques, such as additive manufacturing or 3D printing, can allow for highly customized and complex geometries that maximize application efficiency and performance.

Future Technology Integration

- 1

Smart Sensor Integration: Embedding sensors directly into impellers and propellers for real-time performance feedback including vibrational patterns, stress loads, and degrees of wear. - 2

AI-Driven Optimization: Machine learning algorithms analyzing data to provide performance improvement suggestions and identify failures before they occur. - 3

Sustainable Design: Electric and hybrid propulsion systems with advanced impeller and propeller designs to reduce emissions and fossil fuel dependence.

I also expect the inclusion of intelligent sensor-based systems to take center stage in the evolution of these technologies. By embedding sensors directly into impellers and propellers, operators obtain real-time feedback on performance, including vibrational patterns, stress loads, and degrees of wear. These data-driven techniques enable predictive maintenance, less downtime, and greater safety. Additionally, AI and ML algorithms may then analyze the data and provide suggestions on how to improve performance or identify failures before they occur.

And because of sustainability issues, the innovation will only increase; electric vehicles themselves and hybrid propulsion systems with state-of-the-art impeller and propeller design stand to reduce emissions and dependence on fossil fuels. This works in tandem with global efforts to reduce the environmental impact of transport and industry. Together, these technicalities indicate a significant transformation in the design, manufacture, and operation of impellers and propellers, maintaining a lead in innovation within their respective domains.

Some concluding thoughts on the impeller vs. propeller

My approach to choosing between an impeller and a propeller involves thoroughly examining the specific operational requirement that an application must meet. An impeller is typically selected for applications where fluid containment, high pressure, and efficient liquid movement are required, such as in centrifugal pumps, turbines, or industrial fluid transport systems. An impeller ensures the flow and pressure in these scenarios. I would opt for a propeller when exacting thrust or movement in either water or air is required, such as in marine vessels, aircraft, and propulsion systems, where speed and dynamic motion take center stage.

Selection Criteria

I would also consider the engineering and operational surroundings of each device. For example, impellers generally perform better in closed systems and less well in testable efficacy, where the energy transferred into the fluid becomes a critical factor. Propellers, meanwhile, perform best in open areas where the streamlined design could potentially maximize the kinetic energy imparted onto the surrounding medium. Maintenance prefers nonof this, energy efficiency, and material durability further guide the higher-level selection process, implement research into a component that meets technical and environmental criteria.

Therefore, in choosing between impellers and propellers, one does not merely step into an overarching decision but instead tries to match the attributes and advantages of each candidate with the demands peculiar to that project. Through a systematic approach to studying the performance parameters, environmental conditions, and expected objectives, I can essentially arrive at the most relevant opinion.

Reference Sources

- Impeller vs Propeller: What’s the Difference? – Easia Home

- Impeller vs. Propeller: What’s the Difference? – GlobalSpec

- Boat Impellers vs. Propellers: Key Differences Explained – Fine Homes and Living

- Impeller vs Propeller: What’s the Real Difference? – CSG Extrusion

- The Difference Between Propellers and Impellers – YouTube

- Find more info now.

Frequently Asked Questions (FAQs)

Is there a difference between an impeller and a propeller?

Through their design and purpose, an impeller and a propeller are mainly distinct. It consists of a rotor moving fluid inside a pump, typically a centrifugal pump, wherein a suction force is created that sucks liquid in and forces it out. A propeller, on the other hand, is a type of fan that generates thrust by pushing fluid backward to propel a vehicle, e.g., a boat or an airplane. Both cause motion; however, in general terms, impellers are used for mixing and fluid transfer, while propellers are used for propulsion in various vehicles.

How do impellers operate in washing machines?

These impellers in washing machines form an integral part of the washing preparatory process. They create an agitating rotational movement in the laundry, which enables water and detergent to enter the fabric correctly. Impellers pull the liquid through the clothes, creating fluid movement that helps to detach dirt and stains. The conventional agitators may be a bit harsh, but these are designed to be much gentler on clothes, making them perfect for delicate fabrics that can withstand a good wash. This type of setting also uses less water for each washing cycle.

Mixing impeller types is what?

Mixing machinery needs a very specific impeller to carry out its operations. Axial flow impellers would move fluids in a direction more parallel to that of the impeller shaft, making them suitable for mixing fluids with low viscosity. Radial flow impellers direct fluids outward from the center, making them effective for high shear mixing or when solids are in suspension. Mixed-flow impellers work as a combination of axial and radial flow impellers, allowing them to be used in a wide range of industrial mixer setups. The impeller design is a parameter that significantly contributes to the mixing efficiency.

What are the differences that impellers and propellers make in fluid movement?

Impellers, acting as fluid movers, are different from propellers with respect to their principles of operation. Typically, an impeller rotates within a casing, with the liquid entering at the center and being pushed outward through a volute ring, thereby inducing an increase in pressure according to Bernoulli’s principle. They are used in systems such as centrifugal pumps, where fluid movement needs to be facilitated efficiently. On the other hand, propellers are described as pushing the fluid away from the blades by converting rotational movement into a linear one. This fundamental difference in function translates into distinct fields of application, with impellers primarily used for fluid transfer and mixing, while propellers are utilized for propulsion.

Could you explain the basic design of an impeller used in centrifugal pumps?

To begin with, the impeller design in a centrifugal pump is crucial for its efficient operation. Generally, an impeller is a type of rotary instrument with blades designed to impart motion to a fluid by centrifugal force. These were created with differing blade shapes and angles that affect the rate of flow and pressure developed by the pump. The proper impeller design enables flow to enter the impeller axially and exit radially, thereby achieving the optimum energy conversion from the motor to the fluid. Furthermore, consideration must be given to materials and design parameters based on the viscosity of the liquid on which the unit operates, ensuring satisfactory performance even under varying conditions.

What is the difference between axial and radial flow turbines?

The axial and radial flow turbines differ primarily in terms of the direction of flow and the nature of their various design peculiarities. Axial flow turbines enable fluid to flow parallel to the axis of rotation from both the inlet and outlet sides, making them suitable for applications that require high flow rates with minimal pressure increments. Conversely, radial flow turbines send the fluid radially outward with respect to the axis, thereby ensuring greater pressure generation but generally lower flow rates. These peculiarities govern their efficiency and applicability; axial flow turbines are typically erected in large-scale power generation, while radial flow turbines are more suited for use under conditions that demand high pressure, such as water supply schemes.