The rotation direction of a propeller, whether left-hand or right-hand, is a significant determinant of engine performance, efficiency, and other operational dynamics. It is this very difference between the two rotations that often affects performance for boaters, aircraft enthusiasts, and engineers. This blog looks at technical basics and practical application factors of left-hand versus right-hand propellers, discussing the complete equation of how rotation affects thrust, stability, and wear. At the conclusion of this article, you will have a clear understanding of both types of rotation, and you should be able to apply this knowledge to make an informed decision about your engine’s performance and longevity.

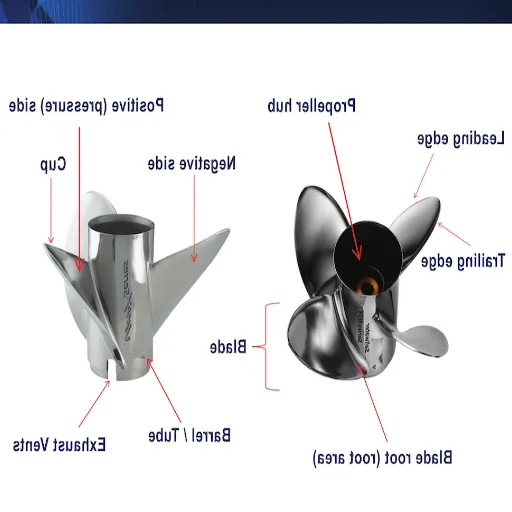

Introduction to Propeller Types

What Is a Right-Hand Propeller?

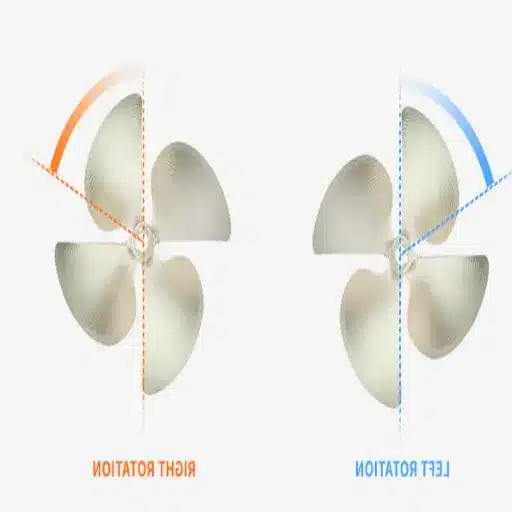

When viewed from behind the vessel, the right-hand propeller is seen to rotate clockwise. This propeller generates thrust by forcing the water backward as the engine turns its blades. Since their rotation is standard in many engines, right-hand propellers are used in virtually all marine applications. They find themselves in single-engine configurations, wherein they offer the simplest solutions on the market, corresponding to conventional systems.

Right-Hand Propeller Characteristics

- Rotation: Clockwise when viewed from behind

- Applications: Standard in most marine engines

- Configuration: Ideal for single-engine setups

- Thrust Generation: Forces water backward for forward motion

The right-hand propeller’s characteristic rotation affects several performance parameters, such as torque and steering. For forward thrusts, the clockwise rotational torque effect may cause the vessel to veer slightly to one side, depending on specific hull design characteristics and other contingent factors. An effect worth considering when designing or making use of a particular boat because it assists in the stability and handling of the craft at large. Considering these factors helps the vessel perform better and also reduces wear and tear on the machinery over time.

What Is Left Hand Propeller?

As the name suggests, a counterclockwise propeller has its rotation in a counterclockwise direction when sighted from the stern of the boat. In contrast, the right-handed one, being more common, rotates clockwise. Such left-handed propellers are often used in twin-engine setups to counteract the torque effects produced by the propellers rotating in opposite directions. When combined with a right-hand propeller, the two opposing forces cancel each other out, thereby enhancing the directional stability of the craft and lessening the unwanted yaw.

Left-Hand Propeller Characteristics

- Rotation: Counterclockwise when viewed from behind

- Applications: Specialized twin-engine configurations

- Purpose: Counteracts torque effects

- Benefits: Enhanced directional stability and reduced yaw

The performance of a left-hand propeller is dependent on numerous factors, including pitch, diameter, and blade design. These parameters decide the efficiency of converting engine power into thrust while minimizing drag. Typically, left-hand propellers are used in situations that require precise handling and better control, such as offshore fishing boats, recreational crafts, or specialized commercial vessels.

Understanding Propeller Rotation Effects

The ultimate effect of propeller rotation on vessel performance and handling is of utmost importance. A left-hand propeller turns counterclockwise as viewed from aft, which has a direct influence on water flow and thrust direction. This rotation reduces torque effects and improves balance, thereby facilitating smoother operation. A reduction in torque effects is particularly beneficial in a twin-engine combination, where two propellers counter-rotate to enhance boat stability and steering accuracy.

Research Findings

According to research, cavitation—a disruptive flow of vaporizing bubbles—is to be reduced with proper indication of propeller rotation, thus securing uniform thrust and improved fuel economy. By concentrating on this fact, boat owners can gain performance advantages through decreased wear on engine components and improved maneuverability in tight or adverse conditions.

Mechanics of Propeller Rotation

Effects on Performance of Left- and Right-Handed Propellers

The thrust distribution, stability, and handling are highly dependent on the propeller’s orientation, specifically whether it rotates left- or right-handed. A right-hand propeller rotates clockwise while seen from the rear end of the aircraft, whereas the left-hand propeller turns in an anticlockwise direction. Consequently, it imparts specific characteristics to the plane with respect to torque effect, aerodynamic efficiency, and yaw tendencies.

| Propeller Type | Rotation Direction | Torque Effect | Application |

|---|---|---|---|

| Right-Hand | Clockwise | Left roll tendency | Single-engine aircraft |

| Left-Hand | Counterclockwise | Right roll tendency | Twin-engine configurations |

| Counter-rotating | Both directions | Neutralized effects | High-performance aircraft |

For example, in single-engine aircraft with right-hand propellers, the torque effect causes the aircraft to roll to the left due to Newton’s Third Law of Motion, and pilots counteract this by applying right rudder. With twin-engine aircraft and contrarotating propellers, one is left-hand and the other is right-hand- this effect cancels out, allowing for better balance against asymmetrical thrust. It improves control during engine-out scenarios since symmetrical thrust reduces yaw forces and eases handling.

Performance Data

Sharing current data from aerodynamic tests, we find that contrarotating propellers have greater efficiency, as they generate thrust and lose very little energy through the rotational airflow. Additionally, they create less drag during the cruise and climb phases, thereby allowing for greater fuel efficiency and range. Nowadays, aircraft manufacturers use advanced CFD methods for propeller design and optimization to obtain certain energy transfer results and to alleviate torque-induced effects, thereby leading to smooth operations, better safety, and overall better performance in all kinds of aviation-related applications.

Key Differences Between Left-Hand and Right-Hand Props

One method of classifying propellers is based on the direction of rotation of the blades, a distinction that sets parameters for their function and use. The left-hand propeller turns counterclockwise when observed from behind. The propeller that is considered the right-hand, however, turns clockwise. This difference in the direction of rotation can prove very useful in counteracting unintended torque effects.

Design Differences

- Blade configuration variations

- Attack angle modifications

- Efficiency optimization

- Drag minimization features

Operational Benefits

- Reduced asymmetrical thrust

- Improved ground handling

- Enhanced landing performance

- Better in-flight maneuverability

Typically, in twin-engine aircraft, one engine is fitted with a left-hand propeller and the other with a right-hand propeller, which complements each other in opposing yaw and increasing stability. Design-wise, the blade configuration and attack angle vary from one type to another. These differences are designed to ensure maximum efficiency in converting the power delivered by the engine into thrust, while minimizing drag to the lowest possible value.

Furthermore, the pilot or engineer may wish to consider the specific needs of an aircraft, depending on its intended purpose, load balancing, or aerodynamic efficiency, before deciding on the type of propeller that is best suited. From an operational perspective, on most twin-engine planes, the thrust acts asymmetrically. However, the relative propeller setting of one engine against the other does significantly reduce it. As a result, the airplane handles much better on the ground, during landings, and during minor in-flight maneuvers. Further development in materials science and computational analysis has improved the operation of both types, enhancing their performance, durability, smoothness of rotation, and low maintenance requirements, thereby improving performance across all aviation platforms.

Choosing the Right Propeller for Your Needs

Factors Affecting Prop Selection

Several significant factors influence performance, efficiency, and aptitude for a particular situation when choosing a specific propeller. These factors will assure the safest and most functional operation in severe conditions. Here are the essential considerations:

Essential Selection Considerations

Material Composition

When choosing between aluminum and composite propellers, the decision depends on the desired balance of durability, weight, and cost. Aluminum propellers offer durability and affordability, but are heavier. In contrast, composite options are lighter and thus more resistant to corrosion, making them suitable for marine or specific aviation applications.

Blade Count and Pitch

The blade count determines the thrust and drag. As a general rule, fewer blades maximize speed and efficiency. On the contrary, increased blade counts generate thrust and reduce vibration. At the same time, pitch —the distance a propeller moves forward in one revolution in an idealized shaft of liquid —should be in sync with the power curve of the engine, to maximize acceleration and fuel economy.

Diameter and RPM Match

Proper matching of a propeller diameter to engine RPM ensures balanced power output and prevents excessive engine load. A big diameter can provide thrust at low speed for towing or heavy loads, while a diameter with high RPM can be used for applications requiring speed.

Working Conditions

Consider environmental factors, including altitude, water salinity, and temperature. For instance, high-altitude use requires a special propeller optimized for the thin air, whereas marine-type propellers resist corrosion by salt water and perform well under varying water conditions.

Load and Performance Demands

Assess the workload the prop must be subjected to. Lugging a heavy load through the air or towing anything in the water calls for a sturdy, high-torque setup. Alternatively, for disturbing high outputs, a thin, high-performance design is chosen.

Each of these considerations proves to be a considerable factor in matching your propeller to its intended assignment to work reliably under the most critical circumstances. By spending time selecting the right propeller to use, you not only increase efficiency but also increase the longevity of your machinery.

Single Engine vs Multi-Engine Considerations

Depending on the choices in propellers, one gradually becomes aware of the unique requirements of one- and two-engine propelling systems. Single-engine systems are characterized by their simplicity, fuel economy, and reliability, which make them ideal for smaller craft or limited space applications. Single-engine propellers are designed for optimal thrust and performance to compensate for the absence of a secondary power source.

| Configuration | Characteristics | Best Applications | Key Benefits |

|---|---|---|---|

| Single Engine |

|

|

|

| Multi-Engine |

|

|

|

On the other hand, with a multi-engine setup, a division of complexity involving precise synchronization between engines is imposed. Quite simply, it is a configuration used for larger vessels that require more power, redundancy, and thrust distribution for the sake of performance and safety. Multi-engine setups employ special propellers designed to alleviate cavitation and increase efficiency in their coordinated operation.

Studies suggest that multi-engine arrangements, if subjected to proper propeller selection and maintenance, can be beneficial for fuel economy and improvements in reliability under harsh conditions. Depending on the needs of operators, a propeller is selected that best suits those needs, and as a consequence, benefits the overall performance and lifespan of single- or multi-engine systems.

Successful Applications of Each Propeller Type

Fixed-Pitch Propellers

Wherever simplicity, durability, and cost-effectiveness are essential, these propellers excel. They are commonly found in smaller craft and leisure boats whose operational predictability is paramount. Fixed-pitch propellers ensure constant performance and low maintenance requirements, as they do not have any moving parts. For instance, small fishing boats work best with them in a variety of conditions, allowing smooth running for long hours, and so does the recreational sailboat. The studies go on to emphasize their efficiency in constant speed scenarios, especially in calm waters.

Variable-Pitch Propellers

These are widely utilized wherever adaptability to varying loads and speed requirements is necessary, with ferries and offshore supply vessels being prime examples. Operators can adjust the blade angles on the fly to suit varying conditions, which increases fuel economy and thrust. Commercial shipping operations find lower energy consumption especially useful when numerous speed changes or operational adjustments occur. It is said that when implemented correctly, variable-pitch systems that enhance route efficiency could reduce fuel consumption by up to 15% on multipurpose routes.

Controllable-Pitch Propellers (CPP)

These propellers find excellent operation in vessels wherein high maneuverability is demanded, such as tugboats, military ships, and cruising liners. CPP systems enable real-time adjustments of blade angles to achieve maximum power output with minimal cavitation during abrupt direction changes, thereby maintaining vessel stability. In the real world, these systems have proven effective in reducing response times and improving fuel economy in operations that involve frequent stops or docking maneuvers.

Ducted Propellers

These absolutely highly efficient propellers are generally used in the marine transport of heavy cargoes, namely barges and tankers, wherein steady thrust must be maintained. Enclosed in either a nozzle or duct, such propellers enhance performance by directing the flow of water, thereby increasing thrust at lower speed ranges. Research reveals that ducted propellers can enhance thrust by up to 20% at slow speeds, making the use of these devices almost a necessity for towing and other high-drag operations.

Surface-Piercing Propellers

Primarily used for extremely high-speed applications, such as fast patrol boats and racing boats, these propellers effectively complete their job by being partly submerged, thereby maximizing their efficiency. This keeps the drag low, and the amplified thrust allows vessels to appreciate considerable increments in speed. Studies in marine facilities have demonstrated that surface-piercing propellers can increase top speed by 25-30% under optimal conditions, affirming their suitability for performance-oriented applications.

Application Summary

These examples illustrate how propeller type can be selected on a case-by-case basis to meet specific demands in different marine environments, thereby enhancing working performance, reliability, and efficiency.

2025 Trends in Propeller Technology

Innovations in Propeller Design and Materials

An evolutionary shift has occurred in the maritime sector, with advancements in propeller technology aimed at improving performance and sustainability. The incorporation of composite materials ranks among these innovations. Being lightweight and very durable, carbon fiber and advanced polymers now rival traditional metals, such as bronze or aluminum, in every respect. These composites help reduce the overall weight of vessels, thereby offering fuel savings by minimizing drag. In return, operational costs and carbon emissions diminish.

Composite Materials

- Carbon fiber integration

- Advanced polymer construction

- Weight reduction benefits

- Enhanced durability

- Reduced operational costs

Biomimicry Systems

- Marine life-inspired designs

- Whale and dolphin propulsion analysis

- Improved flow dynamics

- Cavitation minimization

- Enhanced performance

Variable Pitch Systems

- Real-time angle adjustments

- Load optimization

- Speed adaptation

- Enhanced vessel efficiency

- Varying navigation patterns

3D Printing Technology

- Complex geometry production

- Rapid prototyping capabilities

- Customized designs

- Material waste reduction

- Faster implementation

Yet another advance is computer biomimicry systems. Engineers are analyzing marine hydrodynamics, such as the propulsion of whales and dolphins, to find ways of improving propeller characteristics. These bio-inspired solutions prioritize flow dynamics and minimize cavitation, thereby enhancing life and performance under various operational conditions.

An alternative pitch propeller system has also garnered its share of attention as a significant new technical development. This mechanism enables load angle adjustments to optimize thrust at varying speeds and loads, thereby improving the overall efficiency of the vessel. This benefits vessels with varying navigation patterns, such as cargo ships with differing loads, greatly.

Manufacturing has seen significant innovation, with 3D printing at the forefront. Advanced additive manufacturing techniques enable the production of highly tailored and complex propeller geometries that were once beyond reach. This freedom of design enables rapid prototyping, allowing for the faster execution of cutting-edge designs while minimizing material waste concurrently.

Coating Technologies

Furthermore, coating technologies are among the most recent advancements that improve the performance of propellers. Nanotechnology-based anti-fouling and low-friction coatings combat marine growth and surface resistance, thereby significantly extending maintenance periods and ensuring long-term performance.

Collectively, these innovations serve as markers of the significant thrust in the maritime sector for efficient, green, and high-performance propulsion systems, thereby defining the future of marine transport and operations in unprecedented ways.

The Rise of Smart Propellers and Automation

The smart propellers represent a maritime technological breakthrough that combines advanced engineering with digital automation, giving a new lease of life to ship propulsion. These innovative systems utilize embedded sensors, data analytics, and real-time monitoring to optimize performance. Having estimated parameters such as water current, vessel weight, and propulsion efficiency, the smart propellers dynamically adjust their blade angles and rotational speed to provide maximum thrust while minimizing fuel consumption.

Smart Propeller Features

Real-time parameter monitoring

Performance optimization algorithms

Blade angle and speed optimization

Wear pattern analysis

Automation integration enhances their capability by allowing predictive maintenance. By analyzing wear patterns and operational data, potential problems are detected before they can cause downtime or necessitate expensive repairs. Additionally, real-time communication with the onboard management system or the shoreside control center provides higher precision in navigation, resulting in increased safety and operational reliability.

Newer technologies of smart propellers often lead to greater environmental impacts, which industry stakeholders may not have considered. Such systems also reduce energy consumption and increase fuel efficiency, thereby contributing to the reduction of greenhouse gases, which aligns with global sustainability goals and regulations. Since vessel performance improvement and profit-saving opportunities already exist, this combination of smart propellers and automation appears to foreshadow a green and efficient future for maritime operations.

Environmental Impact and Energy Efficiency

Such advances in smart propellers and automation have significantly reduced the environmental footprint of the maritime industry. Smart propellers, enabled by the latest technologies, have been shown to provide up to a 20% reduction in fuel usage, which in turn translates to significant drops in carbon dioxide and sulfur oxide emissions. These innovations align with the conditional target set by the International Maritime Organization to reduce greenhouse-gas emissions by at least 50% by 2050 compared to 2008.

Environmental Benefits

- 20% reduction in fuel usage through smart propeller technology

- Significant CO2 emission reduction contributing to climate goals

- Lower sulfur oxide emissions improving air quality

- IMO compliance with 50% emission reduction targets by 2050

Also, energy optimization is further enhanced by real-time monitoring and adaptive technology within the systems operating under variable ocean conditions. Dynamic pitch adjustments, based on load and propulsion requirements, enable ships to operate with maximum efficiency and minimal energy loss. These achievements will enable the maritime industry to meet sustainability criteria, provide ship operators with long-term cost savings, and give them a competitive edge in an increasingly environmentally conscious market. High-efficiency systems will, therefore, have a wider application, helping to cement a more sustainable future in the shipping sector worldwide.

Conclusion: Making the Right Choice

Summary of Key Takeaways

From a sustainable perspective and considering cost efficiency in the maritime industry, the choice of highly efficient propulsion systems stands out as the most prominent decision. With these systems, it is evident that fuel consumption can be substantially reduced; therefore, the emission of greenhouse gases also decreases, making it a necessity for any modern ship operator. From an environmental perspective, such technology helps combat climate change globally and meets the ever-growing demand for green shipping.

Key Benefits Summary

- Environmental Impact: Substantial reduction in fuel consumption and emissions

- Cost Efficiency: Significant operational cost savings throughout vessel lifecycle

- Performance: Optimal performance with reduced energy wastage

- Competitiveness: Enhanced market position in environmentally conscious industry

On the operational front, the use of high-efficiency propulsion systems results in significant cost savings throughout the vessel’s life. Reduced energy wastage and optimal performance aid in lowering operational costs, thereby providing operators with a more attractive return on investment and greater competitiveness in an ever-changing marketplace. On both counts, integrating these machines will help ship operators achieve sustainability benchmarks while advancing their market position in the increasingly environmentally conscious world. That is why the industry must remain proactive about sustainability, yet profitability and efficiency should not suffer.

Future Outlook for Propeller Technology

Propeller technology is expected to evolve to meet the increasing demands of sustainability, efficiency, and innovation. In other words, advancements will focus mainly on integrating novel materials and designs to improve performance, with a greater emphasis on reducing fuel consumption and lowering emission levels. In this sense, for example, lightweight composite materials and biomimetic design concepts inspired by nature are already gradually gaining traction in the industry. Such inventions provide better thrust efficiency, while also adhering to environmental laws that have become increasingly stringent, ensuring that shipping operators can comply without compromising their operations.

Material Innovation

- Lightweight composite materials

- Biomimetic design concepts

- Nature-inspired solutions

- Enhanced thrust efficiency

Digital Integration

- AI and data analytics

- Real-time monitoring

- Predictive maintenance

- Autonomous response systems

Collaborative Development

- Technology supplier partnerships

- Shipbuilder collaboration

- Regulatory body cooperation

- Innovation acceleration

Digital integration will be a systemic force in evolving the next generation of propeller technology. AI and data analytics can be leveraged for real-time performance monitoring and predictive maintenance, thereby reducing downtime and operating costs. Moreover, by empowering ships with autonomy that allows them to respond dynamically to changing conditions, such as speed, sea current, and load, the systems can considerably conserve efficiency and minimize general wear and tear.

Lastly, the most significant investments will be made in research and efforts to encourage collaboration between technology suppliers, shipbuilders, and regulatory bodies, thereby fostering the full capacity of these technologies. Such a collaborative spirit will further promote innovation and help realize the maritime industry’s short-term objectives of achieving a green footprint and securing profits in a competitively challenging global environment.

Left-Hand vs Right-Hand Propellers: Final Considerations

Propellers left-handed or right-handed are for different purposes in the maritime industry, and an understanding of the differences is therefore instrumental to the correct performance of a vessel. “Which is better?” is primarily conditional upon the varying requirements. In single-screw ships, the left-hand or right-hand propeller is chosen according to the engine’s direction of rotation, but, in the case of twin-screws, one of each–counter-rotating, that is–is far better as it cancels torque, hence improving both the maneuverability and the fuel economy.

Selection Criteria

- Engine Configuration: Single vs. twin-engine requirements

- Vessel Application: Commercial, recreational, or specialized use

- Environmental Conditions: Operating environment considerations

- Performance Objectives: Speed, efficiency, or maneuverability priorities

- Crew Expertise: Operational knowledge and experience

From this perspective, the decision extends beyond technical specifications; it revolves around the operational objectives of the vessel and the expertise of the crew. Right-hand propellers have traditionally been chosen because they are compatible with most engines and gear systems; left-hand propellers, however, may be beneficial in some cases. They may be designed to reverse the rotational effect for specific designs, or they may be in opposition to counter-torque needs. Being optimally efficient will increase tracking performance and decrease maintenance problems over time, as a well-chosen propeller will put less wear on other components.

Ultimately, one must consider all relevant factors, including engine configuration, vessel application, and environmental conditions, during the selection process. An effective collaborative partnership between marine engineers and operators, utilizing the latest design tools, can enable operators to make informed decisions that satisfy both performance objectives and sustainability standards. With advanced planning, propeller selection can bring tremendous benefits to marine operations while serving the larger purpose of modernization and efficiency.

Reference Sources

-

3 Methods to Determine a Left-Hand vs. Right-Hand Propeller – INDCO: Explains the flow direction and rotation differences between left-hand and right-hand propellers.

-

Propeller Rotation Explained: How to Choose Between Left and Right – BoatTest: Discusses how to identify and choose the correct propeller rotation for your needs.

-

Left Hand vs Right Hand Propeller: Understanding Propeller Rotation – Captain Propeller: Provides insights into the importance of rotation direction in multi-propeller setups.

-

Trying to Figure Out if It’s a Left-Hand or Right-Hand Prop? – Reddit: Offers a practical method to identify propeller type using hand positioning.

-

Propeller Right or Left Hand – Marine Engine Forum: Discusses the applications of left-hand and right-hand propellers in dual motor setups.

- Find more info now.

Frequently Asked Questions (FAQs)

What is the difference between a left-hand propeller and a right-hand propeller?

The main difference between a left-hand and a right-hand propeller lies in the direction of rotation. The left-hand propeller screws counterclockwise when viewed from the stern, whereas the right-hand propeller screws clockwise. In simple terms, these differences have some bearing on how the boat is steered and handled on the water; a left-hand prop, for instance, may steer better for somewhat different boat designs. A choice of either left-hand or right-hand can also affect torque and stability whilst steering.

How does one determine which way the propeller shaft rotates?

Without a doubt, the direction of rotation of the propeller shaft is made known by the propeller itself being engaged in the engine. If the propeller turns clockwise, it is called a right-hand propeller, and if it rotates counterclockwise, it is a left-hand propeller. Knowing the rotation of the shaft is crucial for achieving optimal performance from the propeller and ensuring it is properly married to the boat’s transmission system. In some cases, handling and maneuverability depend almost entirely upon whether the propeller is right-handed or left-handed.

Is it possible to change the rotation of the propeller of a boat?

Yes, you can alter the direction in which a boat’s propeller spins, but the change customarily happens when you change the type of propeller you use. Hence, if you have a left-hand prop and you now use a right-hand prop, you have directly altered the rotation to be otherwise. This alteration could alter the handling characteristics of the vessel, particularly in terms of steering feel and the torque applied. Any change in prop ultimately should be considered in terms of the overall performance of the boat, interaction with the rudder, and other affected parts.

How does prop torque influence boat handling?

The propeller’s torque harnesses the power of the wind on a boat, especially when considering the debate between left-hand and right-hand props. A right-hand propeller will rotate clockwise and exert torque that pushes the ship to lean to its left, while just the opposite is exerted by a left-hand propeller. The steerability and smooth navigation of the ship, therefore, are influenced by this torque. Having an understanding of how the propeller imparts torque on your particular type of vessel will enable you to make informed decisions regarding propeller selection and handling improvements.

Is the matter of counter-rotation somewhat beneficial?

Generally, a counter-rotating propeller configuration for large vessels or craft that require extra handling capability offers several advantages. One of the propellers in the counter-rotating system will rotate clockwise, while the other will rotate counterclockwise; thus, the counteracting torque forces cancel each other out. To put it simply, the boat will not lean to one side or the other, thereby stabilizing it during operation due to this configuration. Such a setup will also increase thrust and improve efficiency, thereby making it a prime choice for all boaters seeking optimal performance.

How does one choose between a left-hand and a right-hand prop for his engine?

Choosing between a left-hand and a right-hand propeller for your motor is predicated upon several factors in a given situation-boat design, intended use, or sometimes, a matter of pure preference. If the boat is designed for a specific type of rotation, the propeller should be matched accordingly for optimal results. Consider steering, torque, and handling from both options. Consulting a forum or a marine specialist will provide you with concrete references tailored to your motor and boat type, enabling you to make an informed decision that meets your specific needs.