An outboard propeller is one of the most overlooked components in the entire boating industry, directly affecting the speed, fuel consumption, and overall handling characteristics of a boat. Whether you are an expert or just stepping onto the boating waters, learning how to install and maintain an outboard propeller will increase performance and guarantee a safe and smooth open-water ride. The guide covers the latest best practices for 2025, giving you insightful knowledge to make every shot count with the boat’s propeller. From installation methods to enhance efficiency and maintenance programs to increase lifespan, this article will become your Go-to Resource when it comes to improving boat performance and handling. Interested in how these tips can boost your boat handling? Keep reading for the expert advice every boater should know in this day and age.

Understanding Outboard Propellers

What is an Outboard Propeller?

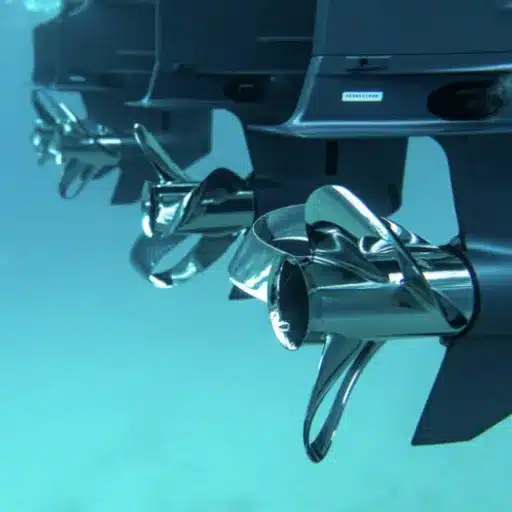

An outboard propeller acts as a vital component of the boat’s propulsion system, converting engine power into thrust that forces the boat through the water. It is typically constructed from aluminum or stainless steel, featuring a central hub with several blades attached. These blades are angled and pitched in a manner that provides the best compromise in performance among speed, acceleration, and fuel economy.

When purchasing an outboard propeller, the weight of the boat, the engine’s horsepower, and the intended use of the ship —whether for cruising, fishing, or water sports —determine the decision. Present-day propellers are machined to perfection to minimize drag and maximize water flow. Pitch, for example, will determine how far forward the boat goes during one rotation of the propeller; lower pitches will give quicker acceleration, while higher pitches will give better top speed.

Knowing these traits of an outboard propeller allows boaters to make an informed choice, improving the boat’s handling, reducing wear on the engine, and enhancing overall performance. The propeller significantly affects speed and power, and when incorrectly chosen, it leads to increased fuel consumption and deterioration.

Types of Boat Propellers: Stainless Steel Versus Aluminum

Choosing between a stainless steel and aluminum propeller is a crucial decision that can significantly impact the maximum efficiency and performance of your boat. These two materials differ vastly in their measures of durability, cost, and use, hence rendering each suitable for some type of boating.

Aluminum Propellers

Aluminum propellers are less expensive, lighter, and the mainstay for use among recreational boaters. They offer performance well-suited for low-horsepower engines, ideal for occasional use. Aluminum propellers can be dented, bent, or otherwise impacted, but the replacement costs are generally lower, thus making them more preferable to those in the economic segment. They are also easier to repair than stainless steel.

Stainless Steel Propellers

By contrast, stainless steel propellers are famed for their resilience and supreme strength. They are much more complex than the aluminum ones, thus withstanding impacts and remaining undeformed when subjected to higher stress. Due to their hardness, stainless steel propellers prevent flexing during rotation, resulting in consistent energy transfer and improved acceleration. In the first initial pay, stainless steel propellers would surely be considered more expensive. Still, their endurance and applicability would return the investment well, especially on high-performance or heavy-duty applications.

Key Considerations:

The trade-off affects users with varying patterns, engine designs, and operating parameters. Aluminum, with its lower price, may be the propeller of choice for casual boaters who operate in shallower waters or waters with debris. However, stainless steel is the answer for those using their boats for water skiing, offshore fishing, and any other high-speed activity, because no other material can match it in strength and performance under pressure.

The trade-off between aluminum and stainless steel allows them to select the material that best suits their use. Maximizing their efficiency on the water and staying inside their budget requires a balancing act of price, frequency of use, and performance.

Key Components of an Outboard Propeller

An outboard propeller is a handy tool for decreasing friction and enabling smooth movement of a boat through the water, which is necessary for correct boat maneuvering. A good knowledge of these elements will help the nautical engineer with propulsion, fuel efficiency, and speed.

Blades

These are the most conspicuous part of a propeller and are responsible for pushing the water. Propellers usually have three to five blades, with fewer blades favoring higher speeds, while more blades give smoother operation and better handling. In essence, the blade design, including the shape, pitch, or rake of the blades, has a profound effect on performance.

Hub

The hub is the middle section of the propeller, through which it affixes to the outboard shaft. It speeds the motion of the blades by transferring all of the power of the engine. Many modern propellers have shock absorbers adapted to the hub, designed to minimize engine synchronizer damage in the event of impact and reduce vibration.

Pitch

Pitch describes how far a propeller would theoretically move in one rotation in the absence of any slippage. A higher pitch means greater speeds, but requires more power; a lower pitch means better acceleration and towing, or handling heavy loads.

Diameter

The diameter is the total width of the circle made by the propeller as it rotates. Bigger diameters are meant for increased thrust under heavier conditions, whereas smaller diameters are for lighter boats and faster speeds.

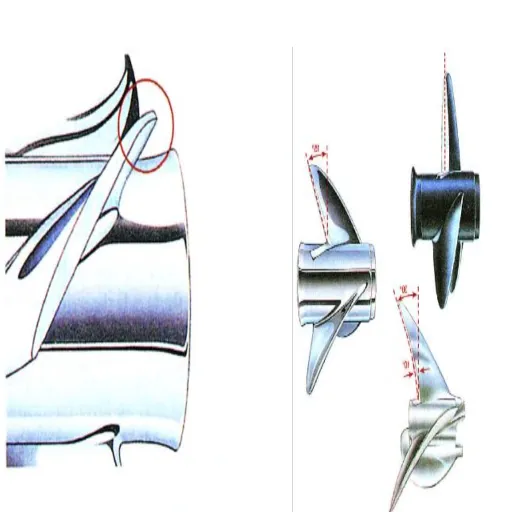

Rake

The angle at which the blades tilt from the central hub, or rake, determines the bow lift. The greater the rake, the less drag is created, which assists in speed and efficient water flow. Conversely, a lesser rake creates more stability and control during rough water.

Cup

Curving the trailing edge of the blade may be advantageous for providing grip in the water. Cupped blades reduce slippage and attain slight gains in the maximum speed of the boat, thereby improving the overall fuel economy.

Materials

A propeller is generally made of either aluminum or stainless steel. Aluminum propellers are less expensive and relatively lightweight, and are therefore suitable for most recreational use. Stainless steel propellers promise ultimate strength and performance, offering a significantly higher degree of resistance to deformation, especially when subjected to heavy loads or high speeds.

Such understanding can help the boater choose a propeller that suits their performance goals, legal requirements, environmental conditions, and other relevant factors. Mismatched propellers may affect top speed and handling directly, along with bringing about excessive wear on the engine and, ultimately, less fun on the water.

Choosing the Right Outboard Propeller

Factors for Optimal Performance

Of all the factors, these are generally considered critical when determining the right outboard propellers for the best performance and a pleasant boating experience:

- Pitch and Diameter: The pitch is the distance the propeller travels through the water during one complete rotation, while the diameter refers to the width of the circle the propeller makes. The pitch and diameter must be considered in pro-con terms: the higher the pitch, the higher the speed; however, the higher the pitch, the greater the strain on the engine. The lower the pitch, the more torque is provided, which allows for more effortless acceleration. Always ensure that the specifications match your boat’s engine capacity and purpose.

- Material: Typically, purchasing propellers involves choosing between aluminum and stainless steel. Aluminum is generally cheaper and lighter in weight. That option would be suitable for entry-level boats or recreational ones. On the other hand, stainless steel provides better stability and performance, so that it may even withstand damage in harsher environments and heavier loads. It goes without saying that it is constantly utilized for high-performance and offshore applications.

- Number of Blades: Propellers come in various configurations, with three, four, or even five blades, which determine their speed, handling, and fuel consumption. Three-blade propellers undergo slight trimming at top speed and are thus valuable for all general applications. Meanwhile, four- and five-blade varieties offer better stability, produce less vibration, and perform better under heavy loads or in choppy waters —a combination preferred for water sports and offshore boats.

- Rotation Direction: Propellers located on the outside of the hull can turn either right-hand, i.e., clockwise, or left-hand, i.e., counterclockwise. In any case, the propeller’s rotation should work in concert with the engine setup and the boating setup so that, especially in multiple-engine systems, it achieves balance and eliminates propeller walk.

- Ventilation and Cavitation: Ventilation occurs when air bubbles disrupt the water flow around the propeller, thereby affecting its performance. When pressure around the blades drops, tiny bubbles of vapor are created, which, over time, cause severe propeller erosion, a phenomenon known as cavitation. Selecting the right pitch, blade design, and the correct number of ventilation holes helps prevent these problems, which otherwise limit the service life of the propeller and affect its performance.

- Boat Usage and Load: The intended usage of the boat is also a significant factor in determining the most suitable type of propeller. High-speed cruising, towing water sports, fishing, or carrying heavy loads are all very different performance demands. For instance, when towing heavier loads, a propeller of lower pitch and more blades is more suitable.

- Propeller Balancing and Maintenance: Maintaining balanced propellers is necessary to ensure smooth operation and prevent excessive wear on the engine casing and other components. Regular inspections should be conducted for dings, bends, or wear, and repairs or replacements should be performed as needed to maintain optimal performance.

Once all these factors have been weighed against their own boat requirements, methods can be considered to improve efficiency and speed, thus contributing to the overall pleasure of boating.

Understanding Pitch and How it Affects Handling

Pitch is defined as the theoretical forward distance that a propeller would move in one complete revolution, assuming there is no slippage. A propeller with a lower pitch allows for quicker acceleration but slower top-end speed, making it suitable for activities requiring quick torque, such as towing wakeboarders and skiers. On the other hand, a propeller with a higher pitch aims for higher speed but needs more power to accelerate, and is therefore applied for cruising or racing.

A very critical concept is the relationship between pitch and RPM of the engine; for every inch of pitch change, engine RPM may change within a band of 150-200 RPM. Having the pitch right allows the engine to operate within the RPM range for which it was designed to achieve optimal performance and fuel economy. Additionally, a proper pitch reduces stress on the engine, thereby prolonging its life, and also enhances the handling and maneuverability of the vessel.

Optimizing performance with modern tools and techniques involves checking engine load and RPM at a given pitch using digital diagnostic systems. When these parameters are optimized in a concerted manner, boat operators have a smooth, balanced combination of acceleration, efficiency, and maneuverability tailored to their specific boating needs.

Popular Brands: Mercury, Yamaha, and Michigan Wheel

Mercury

Most noted for being the innovator of outboard motors, standing for power, reliability, and fuel economy—a marvel born of over 100 years of engineering excellence.

Yamaha

Stands for durability and performance, offering a range of products from recreational to commercial marine goods, with user-friendly designs and impeccable customer service.

Michigan Wheel

Specializes in manufacturing high-performance propellers, with an emphasis on propulsion efficiency and durability, including customized options to meet unusual requirements.

These three brands constitute the marine propulsion systems of today to maintain standards in performance, longevity, and customer satisfaction.

Installation Best Practices

Installation Procedure on a Step-by-Step Basis

1Preparing the Environmental Setup

First and foremost, gather all necessary tools for the installation of this particular unit, such as wrenches and screwdrivers, along with their respective torque specifications provided by the manufacturer. Keep your workspace clean; good illumination would be appreciated, and it should be free of hazards. A flat and stable working surface with good ventilation will be beneficial from both a safety and efficiency perspective.

2Inspection of Propulsion System Components

Before installation, inspect all the components: the propeller, shaft, and sealing mechanisms. Look for any damage or wear. These defects or irregularities must be addressed before installation to prevent potential performance problems in the future.

3Aligning the Propeller Shaft

Ensure the propeller shaft is properly aligned with the engine coupling. Any misalignment creates excessive vibration, thereby reducing the efficiency of propulsion, which can lead to severe long-term damage to the system. For precise results, use dial indicators or alignment tools.

4Installing the Propeller

Slide the propeller onto the shaft, aligning the keyway to seat the key properly. It should fit nicely and not require excessive force. Lubricate the shaft with marine-grade grease to facilitate installation and prevent corrosion.

5Tightening of the Propeller Nut

Use a torque wrench to tighten the propeller nut to the torque recommended by the manufacturer. Excessive torque can damage the threads; insufficient torque can cause the propeller to become loose during operation.

6Install Cotter Pin or Locking Mechanism

Place a cotter pin or locking mechanism to lock the propeller nut in place. Safety-wise, this is critical, as the locking mechanism prevents the nut from loosening while the propeller is in operation. Ensure the pin is bent back correctly and secured according to the design specifications.

7Test for Free Rotation

Manually rotate the propeller to check for smooth and obstruction-free movement. Any resistance or irregularity may indicate misalignment or interference that should be addressed before proceeding.

8Carry Out A Water Test

Once the installation is complete, test the propeller in water to determine its effectiveness and ensure it does not vibrate or exhibit irregularities. Slowly increase the engine speed so it can operate smoothly over a range of RPMs.

9Maintain It Well

After installation, regular maintenance should be scheduled to inspect the propulsion system for buildup, wear, and misalignment. Cleaning and servicing of the system’s components should be performed periodically to extend their lifespan and maintain efficiency.

Additionally, always refer to the manufacturer’s specific instructions and recommendations for proper and safe installation. Focusing on fine details at every step can lead to improved performance, reduced maintenance, and increased operator satisfaction.

Common Mistakes That Should Be Avoided During Installation

⚠️ Critical Installation Mistakes to Avoid

- Neglecting Layout Planning for Installation: One common mistake is that an installation layout is either not planned or not thoroughly planned. For lack of a clear plan or knowledge of spatial requirements, the components may end up slightly off, causing inefficiencies and nearly on performance issues. Be sure to measure correctly and confirm that all equipment placement conforms to the manufacturer’s dimensions.

- Not Considered for Compatibility Checks: The installation of components that may not be compatible with the system can lead to malfunctions and/or long-term damage. One needs to verify that all parts are suitable for the specific propulsion system model in question and conform to the standards outlined in the manuals. Double-check the compatibility of hardware, software, and electrical systems to avoid costly mistakes.

- Improper Fastener Tightening: It appears that safety hazards or premature wear can be introduced when fasteners are not properly tightened during installation. Fasteners that are under-tightened might allow loose components to move around, while fasteners that are over-tightened might just crack the mounts or threads. Perform proper torque settings for fasteners and connectors using a calibrated torque wrench.

- Skipping Preliminary Inspection: Another standard error is neglecting a thorough inspection of parts and surfaces before assembly. Dirt, debris, or unseen wear can compromise system integrity and reliability. Ensure all parts are clean and undamaged before commencing installation.

- Disregarding Electrical Safety Protocols: Mishandling electrical components or failing to establish grounding systems presents a significant safety concern. Insecure installation of wiring or procedures in violation of electrical guidelines could lead to short circuits or equipment failure. The safety protocols outlined in the installation manual should be strictly adhered to to ensure secure and fail-safe electrical connections.

- Rushing Through Calibration: Skipping or rushing through calibration will limit its ability to optimize performance. Correct calibration of the propulsion system will make it more efficient and functional. Therefore, take time to adjust system settings, check the operational parameters, and perform test runs after installation.

By addressing these common errors and adhering to best practices widely used throughout the industry, you will enjoy a smoother installation experience, reduced troubleshooting, and improved performance from your system.

Tools and Materials Needed for Installation

Essential Tools

The smooth installation depends on proper preparation, for which a technician must have a complete set of the required tools and materials. The critical tools usually involved are torque wrenches for correctly tightening fasteners, multimeters for electrical diagnostics, and measuring tapes calibrated to confirmed standard dimensions. Last, but certainly not least, are silicon-based sealants and relevant applicators for sealing records to prevent leaks or environmental contamination. A fully equipped toolkit should also contain screwdrivers, pliers, and adjustable wrenches in various sizes to accommodate any sudden requirements for parts or adjustments that may arise during the process.

Required Materials

Materials depend on the nature of a particular installation, so that mounting hardware, such as screws, bolts, and washers, compatible with the installation’s specifications may be necessary. One may need to use insulation materials, such as foam or heat-resistant tape, to shield sensitive components from temperature variations or vibrations. Specific installations may require special lubricants or cleaning agents that protect the system’s integrity while aiding smooth operation over time. Including all of this in a checklist of materials before beginning the installation facilitates efficiency and substantially reduces downtime from missing or incompatible items.

Digital Aids for Advanced Installations

Lastly, digital aids such as system calibration devices or software for programming and testing functionalities can be particularly beneficial for advanced installations. For example, testing operational parameters using certified diagnostic tools or software after installation can save time and guarantee that everything is performed according to the standards of its corresponding industry. Equipped with the right tools and materials and a mind entirely focused on accuracy and compatibility, you create the right environment for a reliable, performance-oriented system. Always check all equipment for safety and readiness before entering the installation site.

Maintenance and Care for Outboard Propellers

Tips for Regular Inspecting and Maintenance

Well-maintained outboard propellers are those that are inspected regularly to spot trouble at an early stage. The propeller blades should be scrutinized for dents, cracks, or other physical damage that compromises the performance. Even minor abrasions, such as nicks or bends, could cause vibrations that reduce fuel efficiency, which in turn contributes to engine issues.

Also, check that the propeller hub is tight and free from corrosion. Occasionally, remove the propeller to inspect for fishing lines or debris trapped around the shaft, as these can damage the seals if left in place, eventually leading to expensive repairs. Cleaning away any build-up of marine debris or barnacles will retain the propeller surface integrity, thus maintaining excellent balance.

Regularly applying high-quality lubricants to the propeller shaft helps prevent rust and wear. Moreover, the propeller should be replaced if performance issues occur, irrespective of proper working and maintenance, thereby safeguarding the safety and utility of the outboard system. The more preemptive attention one gives to these maintenance activities, the longer the propeller’s life will go, saving on fuel and preventing unwelcome breakdowns.

Detecting and Rectifying Propeller Damage

Early Detection Signs

Early detection of propeller damage is essential for the ongoing performance and service life of your engine. Begin the inspection by thoroughly examining the propeller for signs of wear: bent or chipped blades may cause vibrations and a loss of efficiency. Listen for unusual sounds and vibrations during operation; these may be clues to the presence of damage, such as internal cracking or deformation, which are not visible to the naked eye.

Check whether fishing lines, debris, or marine growth are wrapped around the propeller shaft, as these obstructions can impair performance and cause overheating in nearby parts. Observe for discoloration or corrosion, as this may indicate prolonged exposure to saltwater or the absence of a protective coating. One should also keep an eye on the speed and fuel efficiency of the boat; if it noticeably deteriorates, it could be the mute victim of some unlooked-for damage affecting propeller performance.

Damage Assessment and Repair

To address damages to a propeller, one must first assess the extent of the damage to determine whether a repair can be done or if the propeller needs to be replaced. Minor damages, such as small nicks and imperfections, can usually be repaired by using a filing tool or by professional service. Replacement is usually the best option to regain optimal performance when significantly bent or broken blades are involved.

To provide extra durability to your propeller, consider upgrading to stainless steel, which offers superior impact and corrosion resistance. Regular maintenance will reveal any cracks or damage, allowing you to repair them promptly and serve safely and efficiently on the water.

Replacement Guidelines for Outboard Propellers

Several particulars must be considered when replacing an outboard propeller to ensure it is in favor of both performance and suitability with your own boat. Essentially, all characteristics considered while selecting a propeller focus on diameter and pitch. The distance between the tips directly affects thrust, speed, and fuel consumption. A lower pitch means greater thrust and less speed; a higher pitch means more speed, but the engine has to work harder, resulting in fewer engine hours.

| Factor | Aluminum Propellers | Stainless Steel Propellers |

|---|---|---|

| Cost | Lightweight and inexpensive | Higher initial cost, better long-term value |

| Suitability | Everyday boating activities | Harsh environments and frequent use |

| Performance | Adequate for recreational use | Superior durability and performance |

| Best For | Casual boating, budget-conscious users | High-performance, commercial applications |

Design aspects of the propeller, such as the number of blades and their shape, can also affect handling and acceleration. For example, three-blade propellers offer excellent top-end speed, while four-blade propellers excel in control and a smooth ride at low speeds.

The propeller must be matched within the RPM range recommended for your engine. Running outside this range will put stress on the engine and may shorten its life and efficiency. Additionally, consider the types of activities you typically engage in, such as waterskiing or fishing, as some propeller styles will be better suited to your needs.

Lastly, during installation, check for damage to all other propeller hardware, including washers, nuts, and cotter pins, and replace as necessary. Regular maintenance on the prop, along with proper installation, will ensure greater performance and longer life for your outboard motor, so you can enjoy safe and fun cruising.

Trends for 2025 in Outboard Propeller Technology

Innovations Propeller Design and Material Basis

The trends for outboard propeller technology in 2025 are expected to focus on design and material development. Designers might consider working on more hydrodynamic propeller shapes, thereby reducing drag and increasing fuel efficiency. This becomes crucial as the boating industry seeks to move towards sustainability and minimize its environmental impact. Additionally, variable pitch propeller designs or modular designs may become popular as they offer the flexibility to adjust the equipment to suit different environmental and performance requirements.

In terms of materials, the trend will lean more towards lightweight composites and advanced alloys, as durability and decreased weight translate into increased performance and efficiency for these materials. The realm of innovative technologies could now be the integrating factor, with sensor embedding within the propeller, allowing for real-time performance and wear monitoring. This way, a data-oriented approach could enable the boating community to maintain and optimize performance ahead of time while improving the longevity and reliability of their equipment.

Environmental Considerations in Propeller Manufacture

In my view, these seem to be groundbreaking elements that could open avenues for both sustainability and performance improvement. In the design of propellers using composite materials, manufacturers can indeed bring significant environmental benefits to the table. From a materials standpoint, most composites use a comparatively lesser amount of raw materials and are less energy-intensive to manufacture than traditional metals, thereby encouraging greener production practices worldwide. Moreover, their longevity contributes to a reduction in waste in the long run.

In other words, the installation of intelligent systems in propellers represents another significant step in environmental evolution. Sensors integrated into the propeller can measure performance in real-time, allowing the user to adjust operations to conserve fuel and curb emissions. Such data-grounded insights guide skippers in tuning their operations to environmental norms without compromising outstanding performance. For example, keeping maintenance proactive with sensor data prevents unwarranted replacements or work, thereby reducing waste.

In the broad program of modern propeller production, such technologies are key to the intersection of technology, sustainability, and functionality, leading to an environmentally friendly marine industry.

Future of Performance: The Smart Propeller Technologies

For me, they are the future of performance in the marine industry. These innovations represent the synergy between cutting-edge technologies and practical applications, providing levels of precision, efficiency, and sustainability not previously seen. Equipped with sensors and real-time data analytics, a smart propeller can respond to changes in water conditions, maximizing performance and minimizing fuel consumption, all while operating with minimal to no human intervention. The intelligent adaptability thus helps improve vessel efficiency while also significantly reducing operational costs and environmental footprint.

I believe that the meaning of intelligent propeller technologies extends beyond mere optimization. Additionally, preventive maintenance is involved, which keeps track of the performance at all times. The technology utilizes this information to predict damages related to performance changes, ensuring that such failures do not occur suddenly. This prevention actually helps extend the equipment’s life and reduce replacements, making it genuinely sustainable. Moreover, when combined with IoT technologies, such propellers can communicate with larger ship systems to facilitate smoother decision-making and thereby enable more integrated operation across the ship.

In my opinion, innovative propeller technologies will form the bulk of tomorrow’s marine propulsion. We are witnessing the industry’s shift toward environmentally conscious, data-driven solutions that balance performance with sustainability. These are not merely innovations driven by efficiency; they are investments in a better, sustainable, and tech-driven marine future, where new technology will serve as a beacon for improved performance and environmental responsibility.

Reference Sources

-

Top Tips in 2025 on How to Install an Outboard Propeller – A detailed guide on proper installation techniques for outboard propellers in 2025.

-

Propeller Maintenance – Boat Maintenance Tips by Mercury Marine – Offers practical advice on inspecting and maintaining propellers to ensure optimal performance.

-

Propeller Maintenance Guide by Yamaha Outboards – Focuses on cleaning, protecting, and maintaining outboard propellers effectively.

-

A Must-Know Guide to Boat Propeller Maintenance by Deep Blue Yacht Supply – Provides simple hacks and tips for regular propeller maintenance.

-

The Hidden Signs Your Boat Propeller Needs Repairs (Expert Guide 2025) – Highlights preventive maintenance plans and repair signs for 2025.

Frequently Asked Questions (FAQs)

What exactly is an outboard propeller, and how does it work?

An outboard propeller is a crucial component of an outboard motor that propels watercrafts; with the help of its blades, it pushes water away from the boat, allowing it to move forward. The use of an outboard propeller has a significant impact on the ship’s performance, including acceleration, top speed, and other key factors. Moreover, depending on the type of design, it can have three or four blades, and the characteristics of its operation change accordingly. When choosing the proper propeller, the pitch, diameter, and material have to be considered. Stainless steel type props are preferred mostly for their durability and efficiency, in contrast to aluminum ones.

How do I select a boat propeller that matches my engine?

Having the correct propeller for your engine means knowing the character of your engine. In fact, horsepower and model form the nature of the engine. Consider what kind of activities you engage in: towing or recreation. These activities also influence your propeller choice. The pitch and diameter of propellers are equally important as they match engine power with the required performance from acceleration to speed. You may want to consult with dealers or use a propeller selection guide that emphasizes your particular application. You could also test different propellers to determine which one gives the best performance and fuel economy.

What are the benefits of stainless steel propellers over aluminum propellers?

Stainless steel propellers offer more advantages than aluminum ones, primarily due to their enhanced durability and performance. They can withstand the harsh marine environment and thus have less likelihood of getting bent or damaged. Stainless steel props are typically the best for acceleration and top speed due to their design and material properties. Advanced designs are available from companies like Solas or Quicksilver, which further improve propulsion efficiency. Although stainless steel props may cost more initially, their long-term benefits and performance gains make them an obvious choice for those seeking dependability and efficiency.

Is there any specific time frame for the replacement of an outboard propeller?

The frequency with which an outboard propeller needs to be replaced depends on usage, material, and the conditions under which the boat is operated. When wear is observed in terms of damage to the blade or the hub, replacement becomes necessary. Making it a point to inspect one’s propeller after a long haul will allow the operator to identify any issues before performance is compromised. Recreational boaters may get by with a prop change every few seasons, whereas commercial users will require more frequent replacements. However, always consult your dealer for advice on the best replacement schedule tailored to your specific application.

Why does pitch matter when selecting an outboard prop?

A propeller pitch determines how far a propeller moves through the water with a single revolution. A higher pitch offers an advantage in top speed but could limit acceleration. On the contrary, a low-pitch propeller would give better acceleration but would restrict top speed. Choosing the appropriate pitch requires knowing what you want from your boat; for example, towing for watersports would require a lower pitch. There are often manufacturers’ guidelines given for pitch selection depending on engine power and boat type, making it easy to choose the best fit for the outboard.

Can someone put a propeller from another manufacturer on an outboard?

Using a propeller from a different manufacturer is possible, provided it is compatible with the outboard motor you have. Factors such as hub design, pitch, and diameter must align with the specifications of your engine for it to perform optimally. Most boaters go for OEM-type props to ensure a perfect fit and performance. On the other hand, brands worthy of mention, such as Michigan Wheel or Yamaha, provide aftermarket parts that can serve just as well as replacements. Always check the compatibility of any new propeller with your motor’s specifications to ensure it will not cause performance problems.