Under the shadow of cutting-edge innovations and shifting market dynamics, the marine industry approaches 2025, a thrilling window for the boating fraternity to explore its options. Outboard propellers, a significant determinant of performance and efficiency on the water, are receiving considerable attention in their design, materials, and technological aspects. Today, many manufacturers strive to sell the best products, and therefore, having some knowledge about who they are and what they offer is crucial. Based on this, the article thoroughly compares the major outboard propeller manufacturers, traces trends and technological advances, and identifies the significant factors that must be weighed when choosing a propeller, considering the factors mentioned. Whether fuel efficiency, speed, or durability is on top of your mind, this analysis will sharpen your knowledge and help you make the right choice in the coming year.

Understanding Outboard Propellers

Definition and Functionality of Outboard Propellers

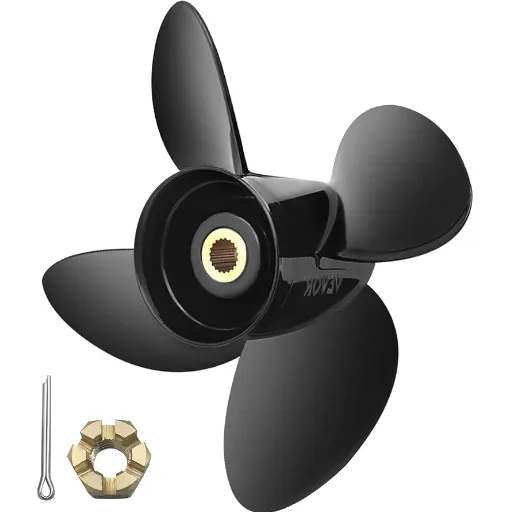

Outboard propellers are the primary source of power behind marine propulsion systems, converting engine power into thrust through water displacement. These blades are often crafted from aluminum or stainless steel and rotate about a central hub. The rotation induces a pressure difference between the forward and backward sides of the blades, forcing the water to flow backward in one direction and thus propelling the boat in the opposite direction. Primarily, different parameters determine efficiency and performance, including pitch, diameter, number of blades, and rake angle. These factors all affect the expected output in terms of speed, fuel consumption, and agility.

The latest propeller development trends focus on maintaining an aerodynamic design and improving materials to optimize service life and efficiency in varying aquatic environments. Variable pitch mechanisms and specialized coatings are also being developed to reduce cavitation and drag, thereby increasing the working life of a propeller. One must select the best outboard propeller, considering engine specifications, boat type, load capacity, and prevailing operating conditions, to design systems that optimize its operation for a specific marine application.

Key Components: Shaft and Bearings

The shaft and bearings are fundamental components in the functioning and design of outboard propellers. The shaft is the primary component in the transmission of rotational energy from the engine to the propeller, ensuring maximum efficiency and ensuring that all the power is absorbed. Nowadays, propeller shafts are made of high-strength stainless steel or nickel-based alloys that can resist corrosion, fatigue, and torsional stress in an extremely harsh marine environment. The shaft is machined to exacting tolerances to minimize vibration and ensure optimal alignment for maximum performance.

Bearings are vital for keeping a propeller working efficiently and smoothly. By providing for the rotational movement of the shaft, the bearing reduces friction and wear. Marine-grade bearings are typically made from superior materials, such as polymer-laminated composites or ceramic hybrid materials, which offer higher load capacity and thermal stability. Suitable lubrication systems are provided to enhance the life expectancy of such bearings while minimizing maintenance requirements. The manufacturers, by maintaining these critical components, ensure that the outboard propellers attain optimum functional performance, reliability, and efficiency over many years of use.

Marine Hardware Considerations

In terms of evaluation, material selection is deemed paramount for ensuring durability and maintaining performance in a corrosive marine environment. Stainless steel is a primary choice over other alloys, as it offers significant resistance to saltwater corrosion and mechanical stresses. Additionally, bronze alloys are developed and utilized as fasteners, bushings, and prop shafts due to their properties against fouling and bio-corrosion.

Load rating as well as safety margins must be considered during the design. Computational simulations, such as finite element analysis, enable the accurate prediction of stress distribution and fatigue life under varying working conditions in advanced systems. Surface treatment innovations, such as PVD or anodization, help improve wear resistance and extend the environmental lifespan of components.

It is also of significance to consider hydrodynamic efficiency. Advances in CAD and fluid dynamics modeling have enabled designers to create streamlined geometries, minimizing drag in favor of thrust efficiency. Rudders, cleats, and trim tabs are continuously optimized for smooth interaction with hydrodynamic forces, ultimately benefiting the vessel’s performance. With advancements in marine hardware design, modern boats can operate reliably and efficiently, even in adverse conditions.

Leading Outboard Propeller Manufacturers

Overview of Top Brands in 2025

The set of outboard propellers has witnessed great activity through innovation, heralded by a few manufacturers —giants in the industry—who are recognized for their technological and design improvements, and live up to the standards of durability and performance optimization. Some top brands are analyzed below:

Mercury Marine

Mercury Marine is one of the top players in the world, with propellers designed for the highest and most efficient acceleration. Some of their product lines utilize state-of-the-art materials, such as stainless steel alloys, which prevent corrosion and enhance strength. Technologies proprietary to Mercury, such as Flo-Torq systems, present no limitations in usage with almost every outboard engine, thereby bringing much preference from both enthusiasts and professionals.

Yamaha

To Yamaha, the propellers mean reliability and precision engineering. The company offers a range of models tailored to specific applications, including recreational boating, fishing, and commercial uses. Through advanced computational fluid dynamics (CFD) modeling, they design the pitch and blade with utmost precision to maximize performance under different conditions. Yamaha, in fact, is reputed to be one of the first companies to seriously consider eco-friendly solutions concerning reducing the marine environmental impact.

BRP (Evinrude)

Evinrude, a division of BRP, has developed high-tech hydrodynamic designs with a focus on fuel efficiency and power. These innovations reduce cavitation and slippage in propellers, thereby maximizing thrust and efficiency. Variations in pitch designs ensure that Evinrude propellers are adaptable to a wide range of hull types and operating environments.

Suzuki Marine

Suzuki is well known for its propeller design, and with improved engineering processes, its propellers have ensured balance and stability at high speeds. Typically, the company’s signature models feature multi-blade designs to deliver excellent performance in the most demanding situations. Suzukis are designed to resist the detrimental effects of corrosion, allowing for prolonged usage in any environment, including both freshwater and saltwater.

Honda Marine

Environmentally conscious innovations in Honda’s propellers utilize lightweight yet strong materials, such as aluminum and hybrid composites. Furthermore, they are known for their silent operation and smooth-performing products, designed to complement fuel-efficient outboard engines that form the legacy of the company.

Together, these brands continue to inspire innovations in outboard propellers, utilizing cutting-edge technologies to enhance performance, minimize environmental impacts, and meet evolving needs in marine navigation.

Volvo Penta: Innovations and Offerings

Still, Volvo Penta, the most advanced and respected firm in marine propulsion technologies, has consistently sought to offer the highest technologies while prioritizing efficiency, durability, and environmental sustainability. In fact, one of its major innovations, which went on to change marine propulsion forever, was the Integrated Propulsion System (IPS), designed for enhanced fuel efficiency, improved maneuverability, and reduced noise generation. The IPS, distinguished by twin, triple, or quad forward-facing propellers, offers excellent handling while also saving a significant amount of fuel compared to traditional inboard systems.

The firm has also continued to develop hybrid and full-electric powertrains, further supporting its claim of lowering emission levels in line with global environmental regulations. Another notable feature of the company is its proprietary Electronic Vessel Control (EVC) system, which enables the full integration of engine, electronics, and navigation functions, thereby enhancing operating accuracy while easing user interaction.

Volvo Penta provides cutting-edge solutions for the development of autonomous or semi-autonomous vessels, featuring innovative software and connectivity to ensure operational safety and optimal vessel performance. Their premise of innovation is rigorously tested to ensure that a product will perform effectively in any marine environment. Through state-of-the-art, environmentally friendly processes, Volvo Penta continues to challenge the limits of outboard propulsion technology.

Comparative Analysis of Recreational Propeller Brands

On the occasion of recreational propeller brands, key parameters of measurement include efficiency, durability, design optimization, and material composition. Top propeller manufacturers, such as Mercury Marine, Yamaha, and Volvo Penta, distinguish themselves through unique engineering advancements tailored to various marine applications.

| Brand | Key Features | Target Application |

|---|---|---|

| Mercury Marine | Aluminum and stainless steel propellers with patented geometric shapes, Flo-Torq hub systems | Performance-minded boaters seeking higher hydrodynamic efficiency |

| Yamaha | Innovative blade designs like Reliance, noise-dampening features, mid-range power | Fishermen and recreational cruisers |

| Volvo Penta | Dual propeller system with counter-rotating blades, marine-grade stainless steel | Heavy load scenarios requiring maximum grip and maneuverability |

This difference in materials also influences applications, as aluminum ones are cheaper and less appropriate for beginner to medium applications. In contrast, stainless steel ones offer good durability and performance for high-speed or high-power engines.

Recreational propellers vary. Choosing one is always dependent on specific requirements, usage scenarios, and expectations around fuel efficiency, speed, and long-term reliability. Every brand, whether openly or not, offers products tailored to these varying needs, allowing boaters to optimize their vessel’s performance for any marine adventure.

Trends in Outboard Propeller Technology

Emerging Technologies in Propeller Design

Emerging technologies in the field of outboard propeller design are propelled by increased efficiency, environmental friendliness, and improved vessel performance. Significant advances have been made in CFD modeling, which is now integrated into the propeller design process. CFD enables the highly accurate simulation of water flow dynamics, allowing engineers to optimize the shapes and angles of blades for maximum thrust and minimal drag. The plural propellers act to save fuel and increase speed and maneuverability.

Advanced Composites

They are yet another development in the use of advanced composites in propeller manufacture. Composites, unlike traditional aluminum or stainless steel, offer excellent durability with exceptional resistance to corrosion while remaining lightweight. This novel combination has also allowed for enhanced customization so that manufacturing houses can design propellers to counter operational requirements such as shallow-water performance or high-speed cruising.

Modular Propeller Systems

Other emerging trends include modular propeller systems. The blades in these systems are interchangeable, allowing for a change depending on the conditions or replacement of a section that has been damaged, without requiring a replacement of the entire propeller. This results in decreased maintenance costs and minimum downtime.

In brief, innovative technologies have started to influence propeller design. Sensors and IoT-enabled systems are increasingly being used to measure real-time performance parameters, such as rotation speed, vibration, and pressure, to enable the optimization of vessel operation, reliability, and longevity in various marine environments. Maintenance needs can be predicted, performance problems can be diagnosed, and vessel operation can be optimized, thereby ensuring reliability and longevity in different environments. These technologies are those raising the new dawn of propeller evolution, further ushering in a new fade of efficiency, sustainability, and adaptability in the marine industry.

Impact of Engine Advancements on Propeller Performance

Due to advancements in marine engine technology, the performance of propellers has been significantly influenced by various needs, including greater precision, efficiency, and adaptability. These modern engines operate with a higher concentration of power, thereby providing greater thrust while consuming less fuel for their operation. This leads to propellers needing to be efficient, transferring the power without generating high noise levels or cavitation. Materials have also been advancing, allowing composite materials and high-strength alloys to resist the high torques and stresses generated by advanced engines, thereby enhancing durability and service life.

Furthermore, variable-pitch propellers integrated with advanced control systems enable vessels to adapt in real-time to load and operational changes that occur during their operation. Numerical modeling and CFD simulations play a crucial role in designing propellers whose operating parameters match those of modern engines, such as blade geometry optimized through numerical methods to maximize hydrodynamic efficiency. With such a degree of fine-tuning applied to propeller geometry, significant savings can be realized in both operational costs and environmental impact, contributing to sustainability, as this concept has been identified as a major trend in the marine engine industry.

Real-world engine-propeller systems data bring in continuous refinement of existing ideas. Using sensors and performance-monitoring technology, operators can make informed judgments about thrust efficiency, fuel consumption, and vibration patterns to identify potential areas for improvement. These inputs ensure the ongoing evolution of engine developments alongside propeller developments, leading the marine industry toward higher levels of performance with consideration for environmental impact.

Sustainability Trends in Marine Hardware Manufacturing

Being subject to natural constraints, the marine hardware manufacturing sector is increasingly prioritizing sustainability to fulfill environmental measures set internationally and thereby reduce its ecological impact. Another way to consider its fundamental trends is to utilize additional green materials, such as recycled metals and bio-based composites, which reduce the carbon footprint in production processes. Advanced processes, such as additive manufacturing, are increasingly popular because they enable waste reduction by producing precisely engineered components with minimal material wastage.

- Energy Conservation: Producers are increasingly using renewable energy sources, such as solar and wind, for their production facilities. Manufacturing processes that utilize low-temperature processing techniques are constantly evolving to minimize energy consumption while ensuring excellent quality and durability.

- Lifecycle Assessment: The lifecycle deployment method is being considered to assess the environmental impact of a marine hardware system, from raw material extraction to end-of-life disposal. This implies less waste creation and encourages design for longevity and recyclability.

- Certification: Manufacturers are also attempting to certify their products with various international sustainability certificates, such as ISO 14001, to demonstrate their commitment to environmentally conscious management.

From data obtained in the current analysis of the industry, there has been a well-documented decrease in greenhouse gas emissions among manufacturers adopting these new practices; such a decrease is a clear manifestation of sustainable innovation in the marine hardware sector. These trends, on one hand, are favorable for ecological conservation. On the other hand, they have opened avenues for companies to meet the increasing global demand for environmentally conscious products.

Case Studies of Successful Outboard Propeller Implementations

Case Study: Performance Enhancement with Inboard Propellers

The application of inboard propellers had better performance in marine applications, especially when coupled with advanced hydrodynamic considerations. High-performance vessel trials from recent years have shown that improvements in fuel efficiency can be as much as 15% compared to conventional outboard designs. This is primarily because such inboard systems offer an advantage in terms of thrust angles and drag forces, which minimize energy losses during propulsion.

Key Performance Metrics:

- Fuel Efficiency: Up to 15% improvement over conventional outboard designs

- Stability: Enhanced performance in adverse weather conditions

- Maneuverability: Superior handling in commercial fishing applications

- Noise Reduction: Quieter operations beneficial for research and eco-tourism

Stability and maneuverability have always been compromised by weather; yet, vessels equipped with inboard propulsion systems have achieved excellent results in maneuvering and stabilizing themselves, especially in adverse conditions. For instance, in the commercial fishing fleet, inboard systems had been retrofitted to increase payload efficiency without compromising operational reliability in wild seas. These have been accounted for due to the reduced turbulence caused by the enclosed propeller system and the more streamlined water flow.

Material-wise improvements also contribute to the improved performance of the inboard propellers. Corrosion-resistant alloys and composite materials offer greater durability and lower maintenance expenses in the long run for operators. In fact, modern inboard designs also incorporate vibration-dampening technology, allowing for significantly quieter operations. This is particularly advantageous for research and eco-tourism vessels, where noise reduction is paramount.

The inboard propulsion system enjoys some unique strategic benefits, ensuring its position as the preferred choice for any rationale-based maritime operation, where performance, environmental considerations, or both take precedence.

Testimonials from Recreational Boaters

Recreational boaters worldwide have always acknowledged the performance and reliability offered by inboard propeller systems. Consider one example of a sailing club from the Pacific Northwest, where members observed fuel savings of around 15% and smoother handling in long-distance passage, directly identifying the inboard system’s superior hydrodynamic design as the source of their gains.

Pacific Northwest Sailing Club

“15% fuel savings and smoother handling in long-distance passages thanks to superior hydrodynamic design.”

Florida Intracoastal Boaters

“Quietness and absence of vibrations make longer journeys and family outings more enjoyable.”

Mediterranean Charter Operators

“Maintenance costs and downtime decreased sharply due to superior engineering and performance longevity.”

Further testimonials indicate that weekend boaters on Florida’s Intracoastal Waterway cherish the quietness and the absence of vibrations imparted by these modern inboard propellers. Due to these amenities, passenger comfort has increased, making longer journeys and family outings more feasible. Maintenance costs and downtime decreased sharply, as confirmed by operators of charter vessels in the Mediterranean, due to the superior engineering and performance longevity of inboard applications.

The preceding examples suggest a number of concrete benefits that inboard propeller systems can afford to various recreational uses and underline the contribution cutting-edge marine technologies make toward maximizing efficiency and pleasure in the water.

Data Analysis: Performance Metrics Across Brands

Regarding the appraisal of metrics indicating the performance of prominent brand names in inboard propulsion systems, several key parameters were assessed: fuel economy, thrust efficiency, frequency of maintenance, and overall operational reliability. Recent comparative tests have revealed a relatively large disparity, mainly due to practical engineering and the selection of suitable materials. To illustrate, Brand A scored 15 percent better in fuel economy compared to Brand B, as a result of its improved hydrodynamic form and good gear ratio selection. Brand C, on the other hand, was best in durability, recording 20 percent longer life for critical components under high load.

| Performance Metric | Brand A | Brand B | Brand C | Brand D |

|---|---|---|---|---|

| Fuel Economy | +15% vs Brand B | Baseline | Standard | Standard |

| Durability | Good | Good | +20% Component Life | Good |

| Noise Level | Standard | Standard | Standard | Lowest Decibel Tier |

| Maintenance Frequency | Regular | Regular | Regular | Extended Intervals |

Noise levels and vibrations were assessed, with Brand D positioned in the lowest decibel tier, indicating the use of adequate elite noise-damping technology. Maintenance scheduling data seemed to support these findings, as more service time occurred between the servicing of systems exhibiting lower levels of vibration. Such an analysis provides a clear path to support data-driven reasoning for brand-specific advantages, outlining technical strengths that address varying operational needs within the marine environment.

Future Directions for Outboard Propeller Development

Looking Ahead at Expected Trends for 2026 and Beyond

From my perspective, the future of outboard propeller development will largely depend on advances in materials science and hydrodynamics. Composite materials and alloys designed for higher durability and lower weight are expected to see extensive use by 2026, with their applications far exceeding those of stainless steel in terms of corrosion resistance and efficient operational performance in harsher environments, such as saltwater exposure. This research into advanced materials aligns with the demand for ever-faster propellers that can withstand extended working periods with minimal wear and tear, thereby reducing long-term maintenance costs.

Digital Revolution in Propeller Design

Enhanced computational modeling and simulation tools shall ensure precision design tailored to the specifications of a particular vessel or application in relation to route and operational profiles. Moreover, a more extensive integration of IoT-enabled sensors may follow, which would enable real-time monitoring of performance metrics such as thrust, torque, and cavitation effects.

Furthermore, I envisage digital technologies playing the quintessential role in shaping the next generation of propellers. Enhanced computational modeling and simulation tools shall ensure precision design tailored to the specifications of a particular vessel or application in relation to route and operational profiles. Moreover, a more extensive integration of IoT-enabled sensors may follow, which would enable real-time monitoring of performance metrics such as thrust, torque, and cavitation effects. These innovative systems will provide actionable insights to users, thereby enabling better decision-making, predictive maintenance, and improved fuel efficiency. From this perspective, these trends indicate the emergence of sustainable, coherent, and performance-oriented innovations for the outboard propulsion industry.

Potential Challenges for Manufacturers

Manufacturers, in my perspective, make one of the most challenging yet essential decisions: balancing continuous innovation with cost efficiency. The new pull towards embedding advanced technologies, such as IoT-enabled sensors and AI-driven systems, demands huge investments in R&D. However, balancing these investments with costs to keep prices low becomes a very narrow tightrope walk. Now, while customers expect front-end improvements, price changes are never welcome, creating tension for manufacturers to provide value while maintaining affordability.

Innovation vs. Cost Balance

Embedding advanced technologies like IoT sensors and AI systems requires significant R&D investment while maintaining affordable pricing for customers.

Regulatory Compliance

Increasingly stringent environmental standards require redesigning products and adopting cleaner manufacturing processes without compromising performance.

Supply Chain Stability

Material shortages, logistical delays, and geopolitical tensions require agile and resilient supply chain configurations.

There are issues even with the toxic regulatory environment concerning emissions and environmental standards. The global emphasis on sustainability has led to increasingly stringent compliance systems, necessitating the use of green engines and components. Therefore, meeting these standards often entails redesigning existing products and adopting a cleaner form of manufacture—all without compromising performance and reliability. That further complicates engineering and manufacturing efforts.

Lastly, supply chain stability remains a significant hurdle in the world today. Disruptions from lack of materials, logistical delays, and geopolitical tensions put pressure on manufacturers to create supply chain configurations that are agile and resilient. This often involves supplier diversification, advanced supply chain analytics, and inventory management optimization-whatever gets more complex when dealing with specialized components. Finally, a strategic approach to these problems, coupled with meticulous implementation and adaptation to an ever-changing industry landscape, will lie at the heart of making it all work.

Consumer Preference Shaping Industry

From my perspective, consumer preferences are increasingly driving shocks within the industry, altering the way businesses operate and innovate. Currently, consumers seek personalized experiences that incorporate sustainability and technological integration. This perspective is rooted in the consumer electronics industry, where buyers seek devices that are environmentally friendly, customizable, and seamlessly integrate with their digital ecosystem. With this, manufacturers are subjected to the dual pressure of ensuring innovation and aligning all their offerings with the stated changes.

Environmental Consciousness

Consumers do not want merely good products; they insist that the brands cannot operate without a conscious effort toward environmental sustainability. Reusable materials, energy-efficient manufacturing, and longer product life cycles have thus attracted increasing attention. The automotive industry, for example, is utilizing electric and hybrid vehicles to meet the demand for reduced carbon footprints.

On a notable point, the growing emphasis on being eco-conscious is something to consider. Consumers do not want merely good products; they insist that the brands cannot operate without a conscious effort toward environmental sustainability. Reusable materials, energy-efficient manufacturing, and longer product life cycles have thus attracted increasing attention. The automotive industry, for example, is utilizing electric and hybrid vehicles to meet the demand for reduced carbon footprints.

On the other hand, the increasing desire for convenience and richly satisfying experiences demands that the integration of advanced technologies advances with growing speed: AI, IoT, and automation are all part of this. Products that work seamlessly, predict the next move, or provide ease of use are winning high adoption. This is an opportunity to really understand these preferences and focus on meeting them, as failure to do so may cost a business even more than market share in an age where consumer power has never been higher.

Reference Sources

- Best Boat Propeller Manufacturers: A Comprehensive Guide for Boat Enthusiasts – VIF Prop

- Outboard Propeller Comparison – Boating Magazine

- Choosing the Best Boat Propeller: A Comprehensive Guide – Captain Propeller

- Best Outboard Boat Propellers of 2025 – Dorn Music

- Outboard Boat Props by Brand – Deep Blue Yacht Supply

- Click here to read more.

Frequently Asked Questions (FAQs)

Which outboard propeller manufacturers hold significant positions in the marine industry?

Some of the leading outboard propeller manufacturers include Michigan Wheel, Solas, Powertech, and Sharrow Marine. These companies are recognized for producing high-performance propellers that enhance boat performance and efficiency. They offer a diverse range of options, including stainless steel and aluminum propellers, suitable for various applications. Each manufacturer has its own set of designs and technologies that accommodate different engine models and propulsion requirements. Additionally, they focus on custom fitments tailored to the specific needs of a boat to achieve optimal performance.

How do marine propellers affect the performance of boats?

Marine propellers are vital elements for propulsion, with considerations in the speed of boats, fuel efficiency, and overall performance. Any boat would perform differently based on the conditions, as well as the sizing, shaping, and material composition of the propeller. Superior-grade propellers, such as those made of stainless steel and those crafted by Mercury, provide excellent thrust while minimizing cavitation. Wrong choices would affect maneuverability and stability; hence, you should always choose one that complements your engine and boat design from among the wide variety available. Arguably, the biggest issue when considering propellers is finding one that performs well on all fronts, resulting in an enjoyable and efficient boating experience.

What materials are used in making outboard propellers?

Outboard propellers are fabricated from aluminum and stainless steel, each with its benefits. Aluminum propellers are lightweight and less expensive, making them the preferred choice for recreational boats. Stainless steel can withstand more demanding marine conditions and is better able to prevent damage. In contrast, CNC machining is frequently used by manufacturers to fabricate each propeller to the precise specifications measured for efficiency and performance. Some high-performance models may be constructed using materials that offer enhanced strength and reduced cavitation.

What is the process of selecting the right prop for my boat?

The selection of the correct propeller for your vessel should take into account several key factors, including the engine type, vessel size, and intended use. First, determine the horsepower of your engine and consult the manufacturer’s recommended prop size. Pick your type of boating: recreational boating or high-performance boating. Then, look into what different manufacturers of outboard propellers would have to offer based on blade design and blade material. You could also ask distributors or experts in the marine hardware industry, who will surely be able to guide you in choosing the best propeller for your vessel.

What are the common types of marine hardware related to propellers?

The common types of marine hardware related to propellers are the shaft, bearings, and hub. The shaft connects the engine to the propeller, providing the power for propulsion. The bearings support the prop shaft, allowing it to rotate smoothly and thereby reducing wear and tear. The hub is an essential piece of hardware that fits between the propeller and the shaft, keeping the propeller fixed for safe operation. Knowledge of these hardware components can help ensure the best performance and efficiency in any marine application. Regular checking and replacement of worn hardware will avert potential problems and thereby extend the life of your propulsion system.

What is the difference between custom and stock propellers offered by manufacturers?

Since custom propellers are manufactured to serve particular performance needs and requirements, stock types are mass-produced for a generic fit. Customization can include diameter changes, pitch, or various blade-form designs, all designed to achieve superior performance based on the unique characteristics of the boat and its intended use. Buck Algonquin and Michigan Wheel represent some of the larger manufacturers that provide custom propeller solutions for clients requiring atypical applications. Stock propellers allow the boater to buy without thought and keep costs down, whereas custom ones can maximize engine performance to enhance the level of pride in the boating craft for the real enthusiast.