Precision marks the very heart of optimizing any marine vessel or aircraft for utmost efficiency. The correct propeller diameter and pitch ensure that energy is translated efficiently from fuel to attained speed/thrust. Choosing these parameters, however, is an inexact science, and having a sound understanding of factors such as engine power, vessel weight, and operational conditions is essential. Thus, a prop diameter and pitch calculator acts as an invaluable instrument. In this article, three primary reasons will be outlined in favor of the Dubavne maker in 2025, explaining how this engine simplifies decision-making processes, improves performance, and remains up to date with the latest developments in propulsion. Both professional engineers and amateurs can benefit from these insights to make data-driven decisions they can truly stand behind.

Understanding Propeller Sizing and Its Importance

What is Prop Diameter and Pitch?

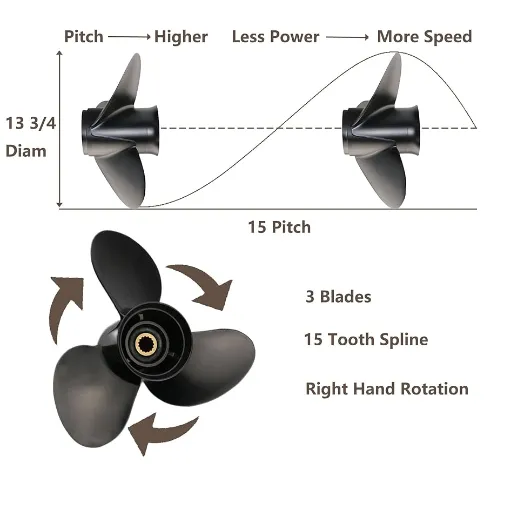

Both propeller diameter and pitch are primary factors that determine the performance and efficiency of any propulsion engine. The propeller diameter refers to the imaginary circle made by the rotating tips of the propeller blades. Generally speaking, a larger diameter would be considered more suitable for water/air displacement and is better suited for outside use where high power at a lower speed is required. Smaller diameter propellers, however, would be preferred if the object were running fast and at lesser drag.

Conversely, pitch is the hypothetical distance in inches the propeller would theoretically move in a single rotation without any slippage. It determines whether the thrust-to-speed tradeoff favors greater speed or higher thrust. A higher pitch means the distance covered per rotation is higher, so speed is favored, while a lower pitch means higher thrust is achieved at lower speeds.

Depending on the custom-made application, the interplay of these two parameters, diameter and pitch, will yield maximum performance from the propeller. Hence, the overall consideration of these two key parameters must serve to create a proper balance between power, speed, and efficiency—the very goals of modern engineering.

Prop Calculator In Action: Size Selection

A propeller calculator is a tool for determining the best propeller setup for a particular aircraft or installation. By feeding in key parameters such as boat weight, engine power rating, gear ratio, and desired top speed, the calculator outputs a precise propeller specification tailored to the vessel’s operational environment. These calculations adhere to hydrodynamic theories and empirical data on operating characteristics, which include acceleration, fuel efficiency, and maximum speed. More sophisticated prop calculators incorporate comprehensive data and algorithms, enabling them to conduct detailed simulations and predictive modeling. This form of software is of immense value to both regular engineers and hobbyists, as it enhances performance while minimizing wear on the engine and drivetrain.

How Propeller Size Influences Performance

Propeller size directly and measurably affects performance characteristics, such as thrust, speed, and fuel consumption. Larger-diameter propellers develop more thrust at slower speeds and are therefore suitable for heavier loads or any other scenario requiring appreciable pulling power. Smaller-diameter propellers create less drag and thus are better suited for higher-speed applications. The pitch dictates how far a propeller moves in one revolution through a solid medium and controls the tradeoff between acceleration and top speed. In effect, a high pitch permits higher speeds, but engines tend to rev hard, lowering gas efficiency during low RPMs.

Additionally, the correct-sized propeller enables the attainment of the right engine RPM, which is crucial for maintaining the engine’s longevity and achieving a higher level of peak performance. Sizes not matching the selection increase the rates of over- or under-revving, both of which decrease performance and increase fuel consumption. Studies have shown that a suitable diameter-and-pitch combination of propeller gives superior efficiency up to 15%, whilst simultaneously reducing wear on the propulsion system. Hence, these points make it imperative that the propeller size be selected carefully in accordance with vessel specifications and intended use.

Benefits of Using a Prop Slip Calculator

Improved Efficiency and Fuel Economy

Using a propeller slip calculator, vessel operators can dramatically improve efficiency and fuel economy. Prop slip refers to the difference between the theoretical distance traveled by a boat during one rotation of its propeller and the actual distance traveled. Closely linked with the performance of the propulsion system, the slip is best when minimized properly so the engine stays within its optimal RPM range, thereby consuming less fuel and running more efficiently.

Recent developments in propulsion and performance analysis underscore the fact that, combining all propeller setups, ships enjoy a fuel cost reduction of approximately 10-20%, with a greater benefit observed under average operating conditions. Accurate slip determination serves as a diagnostic tool for identifying performance deficiencies arising from cavitation or excessive drag that often go unnoticed. The knowledge gained allows an operator to make adjustments to propeller size and pitch, as well as engine loading, to conserve fuel and prolong the life of the propulsion system.

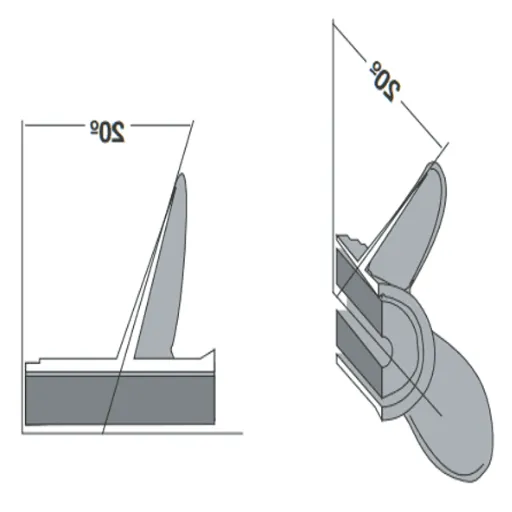

Improved Performance Based on Hull Type

The propulsion system performance parameters are inherently related to the hull type, hydrodynamic characteristics differing with each design. With displacement hulls, the preferred operational speed is relatively low, allowing the moving hull to displace water with minimal resistance. The best propellers for this type of hull generate thrust rather than maintain speed, and are designed specifically after advanced computational analysis with regard to blade angles and diameter for the load and operating range considered.

On the contrary, planning hulls create lift at high speeds and are thus more conducive to high-performance propellers designed for reduced cavitation and maximum top speed. The use of variable-pitch or surface-piercing propellers optimizes adaptation to changes in conditions, such as shifting water depths and wave action. Performance tuning may also be completed using hull resistance coefficients and drag calculations, thereby optimizing propulsion power in every situation while reducing fuel costs.

Usually, achieving balanced propulsion presents very few choices in hull design for a multihull, where the wide spacing between hulls leads to a proportional decrease in wet surface area. The exacting engineering solutions, such as twin or multiple propellers and positioning a vessel to offset the waterline, are essential to maintaining a symmetric thrust vector while also reducing the net speed-fuel economy differential. With real-time data being recorded in conjunction with CFD (Computational Fluid Dynamics) simulations, customized recommendations from maritime engineers can help achieve optimum performance with different hull types under all working conditions.

Case Studies: Real-Life Operations in 2025

🚢 Autonomous Cargo Vessel Optimization

A global logistics company added a fully autonomous cargo vessel into its fleet, using advanced propulsion systems and real-time data analytics. Using its hybrid propulsion system, the ship would optimize fuel consumption based on predictive algorithms obtained from CFD simulations of varying environmental conditions.

⚡ High-Speed Ferry Efficiency

A ferry line in the Southeast Asian region experienced difficulties in maintaining fuel efficiency while meeting the operational requirements of high-speed operations. A hull geometry optimized for twin-propeller sets on the ferry revealed a 15 percent gain in hydrodynamic efficiency from computational modeling.

🛢️ Offshore Energy Platform Resupply

A North Sea offshore energy company retrofitted its resupply vessels with advanced DP and thruster enhancements. Digital twin technologies and AI-driven operational simulations provided strategic support for these upgrades.

This interaction highlights some instances at the intersection of innovative maritime technologies, environmental concerns, and economic performance, thus indicating promising developments well into and beyond 2025.

Exploring Different Propeller Types and Designs

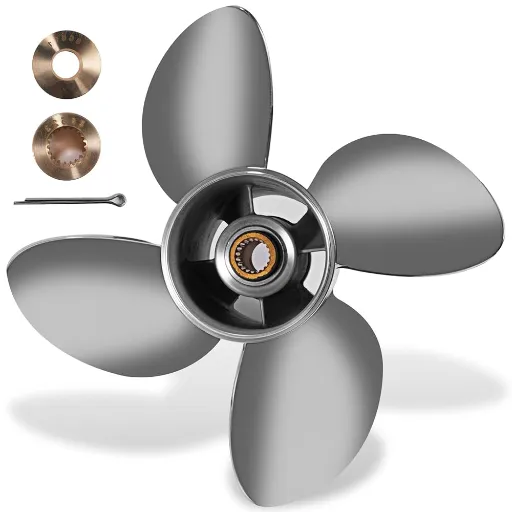

Understanding 3-Blade vs. 4-Blade Propellers

3-Blade Propellers

- Lighter weight design

- Higher top speeds due to reduced drag

- Better fuel economy at cruising speeds

- Ideal for recreational boats and smaller watercraft

- Lower hydrodynamic resistance

4-Blade Propellers

- Enhanced thrust and handling

- Better performance at lower speeds

- Smoother operation with reduced vibration

- Superior for tugboats, ferries, fishing vessels

- Better cavitation resistance

Performance comparison also reveals differences in cavitation behavior: due to the load distribution over additional blade surfaces, 4-blade propellers resist cavitation better and extend the working life of the propeller. In contrast, while 4-blade propellers usually allow for greater maximum speed than 3-blade ones, the lower speed is well worth trading for additional torque and stability in a workboat or commercial environment.

How Diameter Influences Propeller Design

The propeller diameter is one of the paramount factors affecting an impeller’s overall performance and efficiency. The diameter is twice the radius of the imaginary circle generated by the rotating blades. A higher diameter implies greater water displacement; hence, it provides more thrust and better propulsive efficiency in the case of slow-moving vessels that need high torque to move. Conversely, a small diameter is suitable for high-speed operation where fast rotations compensate for less water displacement.

Technical studies show that propeller diameter has a direct effect on engine load and fuel consumption. Propellers with a larger diameter, when running at slow speeds, are designed to provide better efficiency, thereby losing less energy. For example, larger diameter configurations might be selected by vessels that handle heavy loads. On the other hand, increasing the size demands careful consideration of clearance with the hull to avoid problems such as cavitation or vibration, which could deteriorate performance and potentially compromise structural integrity.

The diameter of the propeller is one of several parameters that must be balanced with pitch, the number of blades, and material to achieve the best possible performance. CFD simulations and towing tests are usually used to compare design choices. The inverse relationship between diameter and operating parameters is indicative of the primacy of diameter in securing energy efficiency and mechanical reliability for modern maritime applications.

The Correct Size of the Blade for Every Application

Blade diameter selection hinges upon a complex balance between operational considerations and aerodynamic or hydrodynamic principles. These are primarily dependent on the application, the rotary velocity, and load conditions. To illustrate, a larger blade theoretically provides more thrust but requires more torque, possibly more drag, and increased energy consumption. On the contrary, the smaller blade maintains high rotation and minimal resistance in various high-efficiency applications.

The key to the flexibility and durability of a blade lies in its proper material composition. Advanced composites, such as those made from carbon fiber or reinforced polymers, are being used more frequently due to their exceptional strength-to-weight ratio. This allows for the execution of heavy-duty tasks while maintaining a low overall system weight. It is also vital to determine blade pitch, the angle at which a blade penetrates the working medium, in conjunction with diameter, from the viewpoint of matching the flow characteristics of the air or water. Variable pitch is consequently best suited to dynamic environments where changes in operating parameters occur.

While empirical tests remain critical during this process, predictive modeling is also employed in the modern design stage using computational tools such as finite element analysis (FEA) and computational fluid dynamics (CFD). Such processes optimize the blade geometry by simulating service conditions, thereby detecting probable inefficiencies and correcting those with the available data at hand, improving the efficiency of energy conversion. Selecting the most suitable blade size and shape is ultimately a highly specialized procedure that must consider application-specific aspects, including requirements, safety standards, and performance.

Trends in Propeller Technology for 2025

Innovations in Propeller Calculators

Modern propeller calculators continue to undergo swift evolution, incorporating the latest technological trends to achieve precision and enhance execution efficiency. The latest renditions boast machine learning algorithms that, upon assessing large datasets, optimize propeller design and performance predictions. Advanced propeller calculators are now equipped with dynamic modeling techniques that enable the creation of fluid dynamics simulation scenarios. They also provide real-time analytical solutions, including tools that evaluate velocity, pressure distribution, and cavitation limits. This mechanism fine-tunes the application of design to suit specific operating conditions best.

Emerging user interfaces represent an additional improvement in the field, with the end-user-facing aspects providing intuitive workflows and customizable options to engineers. Now, there is also the capability to interface with CAD software, allowing designs to be directly imported and adjusted without any redundancy. In addition, more and more calculators are now cloud-hosted, providing secure data storage and access from anywhere, while also promoting collaboration between geographically dispersed teams. Such innovations take propeller analysis and design to sudden leaps in precision and speed, responding to the ever-growing demand for energy-efficient, high-performance marine solutions.

Smart Technology Integration in Prop Sizing

The involvement of smart technology in propeller sizing has signaled the demise of traditional methods and ushered in unprecedented levels of precision. Dressing modern mathematics with machine learning algorithms and advanced optimization techniques, designers are harnessing the software to solve complex hydrodynamic equations and performance metrics with high accuracy. The software enables the study of key variables, such as thrust, torque, cavitation, and efficiency, under variable operating conditions to identify the optimal design combinations.

Furthermore, propulsion measurements are acquired in real time by the application of IoT-enabled sensors within marine systems. This provides an uninterrupted feedback loop for propeller operation, allowing for adaptive changes that enhance fuel efficiency and reduce environmental impact. Stakeholders can share their views and jointly design improvements, even across different locations, thanks to these advanced tools when coupled with cloud-based analytical platforms. Such technological synergies create an impetus that speeds up the design process and places a greater emphasis on industry initiatives for sustainability and carbon emission reduction.

The Future of Propeller Performance Metrics

The entire future of propeller performance parameters will stand on the integration of the latest simulation technologies and real-time monitoring. Recent developments include the emergence of computational fluid dynamics, which considers fluid-structure interaction to a highly refined level, allowing for the detection of inefficiencies that were previously undetectable. This is enhanced by contemporary machine learning algorithms that analyze vast volumes of data arising from ever-changing operating conditions, thereby continually optimizing propeller design over time.

Data obtained from IoT sensors installed on the propulsion system, along with other key real-time parameters such as thrust, torque, and cavitation dynamics, serve to provide predictive insights into wear and performance degradation. Predictive analytics use this data for forecasting erosions and a reduction in efficiency so that maintenance schedules can be planned in advance, reducing downtime costs. Meanwhile, the use of advanced composite materials in propeller manufacture will redefine the concepts of durability and performance, thereby offering customized solutions for various operational requirements.

In conjunction with this, the industry endeavors to integrate such innovations with world-standardization initiatives for performance metrics, aiming toward a single benchmarking system. Such a system would simplify comparisons, foster transparency, and encourage innovation on the part of manufacturers and stakeholders. Together, these emerging trends enable more innovative and more sustainable propulsion solutions that are better tailored to the evolving demands of the maritime and aviation industries.

How to Use a Propeller Size Selector Effectively

Step by-Step Method for Using a Prop Calculator

-

6

Check for Compliance:

Double-check the propeller specifications from the recommendations against the Manufacturer’s Manual and any limitations that exist on the vessel to ensure the propeller is compatible with your engine and hull system.

-

7

Trial and Error:

Once installed, conduct a test run with the recommended propeller to confirm whether it performs as expected. Record measured data concerning speed, fuel consumption, and engine RPM for usage during further improvements, if required.

Summary: A propeller is the only device responsible for propulsion. Adhering systematically to the above steps will enable the user to wisely use an electric propeller calculator to select the propeller best suited to his boat, thereby attaining the best performance possible with the least formation losses.

Factors to Consider When Sizing Your Propeller

When sizing a propeller for my vessel, I consider several factors that are more critical in making the whole operation more efficient. First, the engine manufacturer’s specifications must be considered, including the recommended RPM range. A propeller selected correctly will allow the engine to operate efficiently within a specific RPM range and prevent engine damage due to overload or underload. Then I consider the type of boat and its primary use—whether it is used for cruising, fishing, or watersports—because that will immediately affect the pitch, diameter, and design of the propellers.

Additionally, I evaluate the weight and load distribution of the vessel, as this is an utmost criterion in propeller selection, since the maintenance of consistent performance varies with alterations in conditions. A heavier boat, or one carrying a full load, may need a lower-pitch propeller to enable enough thrust at low speeds. Other variables, such as water conditions and altitude, are taken into consideration because they can affect engine performance and, consequently, propeller efficiency. For example, with thinner air at higher altitudes, reducing the engine’s power output, you may find yourself in need of a lower-pitch propeller. By scrutinizing each of these factors, I put myself in a reasonably good position to make an informed choice that enhances my vessel’s performance and reduces operational inefficiencies.

Mistakes to Avoid with Sizing Calculators

❌ Common Mistake #1

Relying solely on calculator recommendations without considering real-life conditions such as load weight, water currents, water temperature, and weather variations.

❌ Common Mistake #2

Entering inaccurate or incomplete data including wrong engine specs, underestimating boat weight, or ignoring gear ratios leading to skewed results.

❌ Common Mistake #3

Neglecting testing and fine-tuning by not conducting trial runs to verify actual on-water performance meets expectations.

When working with prop sizing calculators, one of the biggest mistakes I try to avoid is relying totally on their recommendations and not considering the real-life conditions. These calculators are of great assistance in setting one’s mind at the baseline. Still, sadly, they assume ideal and constant environmental factors over which humans have scarce control, such as sea level altitude, calm waters, and standard engine performance. Finally, I don’t neglect testing and fine-tuning. Even though all calculations are precise and environmental factors are taken into consideration, no calculator can completely simulate the on-water performance. The boat is taken out on a trial run to determine whether it meets my speed, handling, and efficiency expectations after the propeller is selected via sizing tools. If necessary, I tweak accordingly by trying alternatives. In this way, I ensure that I have a setup optimized for my particular operating conditions.

Reference Sources

- Understanding Propeller: Prop Diameter & Prop Pitch – ePropulsion

- Prop Diameter vs Pitch – Boat Design Forum

- How to Calculate a Boat’s Propeller Pitch & Why It Matters – Discover Boating

- How to Determine What Is the Best Propeller Pitch for My Boat – Captain Propeller

- How to Choose Pitch, Diameter & Blade for Your Outboard – VIF Prop

- Find more info now.

Frequently Asked Questions (FAQs)

What is a propeller size calculator, and how does it function?

A propeller size calculator determines the appropriate diameter and pitch for your propeller based on various input parameters. Entering data such as engine RPM, gear ratio, and weight can help the calculator recommend the correct propeller for your boat. This tool is necessary to optimize performance, thrust, and speed to the maximum possible level. Using this prop calculator, you can be sure that your prop will really perform to the necessities of its intended purpose. Considerations are given to blade count and motor type, be it a Yamaha or a Mercury marine engine.

How can the proper pitch of a propeller be determined?

The propeller calculator can be used to determine the ideal pitch for your propeller. The calculator calculates the weight of the boat, the desired RPM range, and the intended speed, and then suggests the appropriate pitch. A good pitch will allow efficient speed and create a decent amount of thrust without overworking the engine. If the pitch is too high, it may reduce RPMs and affect performance, while if it is too low, it may lead to excessively high RPMs, possibly damaging the engine. It is, therefore, essential to use the correct formula and input data to develop the most effective pitch.

What effect does prop diameter have on prop performance?

The prop diameter significantly affects the thrust and, consequently, the speed of the boat. Bigger diameter propellers can generate more thrust, giving an advantage to heavier crafts or when they need to increase speed quickly. On the other hand, a smaller diameter may allow for greater revolutions per minute and could be helpful for lighter boats or for achieving high speeds. Selecting the diameter should be done in partnership with the pitch to ensure the engine runs efficiently within the intended RPM range. Hence, the use of a sizing calculator is crucial in balancing these factors to achieve the best possible performance.

How does the number of blades affect the efficiency of a propeller?

The number of blades on a propeller can significantly influence its efficiency and performance. A three-blade propellers generally provide a nice balance between speed and thrust, and so finds common popularity in many marine applications. Propellers with more blades may provide additional thrust at lower speeds, while those with fewer blades are more conducive to higher top speeds. Fewer blades might be preferable to best suit the cruising or WOT (wide open throttle) requirements. The number of blades most suitable is ultimately dictated by the intended use of the boat and the engine specs.

Does a propeller calculator help in selecting the right prop for my engine?

The propeller calculator is used to analyze all the factors that go into determining the right propeller for your engine. These factors might include idling engine RPM, gear ratio, or the stated performance parameters. Depending on the data you input, your calculator will provide proposals to consider, based on thrust for your own setup or from a slightly more theoretical perspective, relating to efficiency rankings. A specific calculator would also consider the manufacturer’s recommendation in its calculations to match either a Mercury engine or a Yamaha engine. Besides ensuring the fastest possible speed, it would also improve fuel efficiency and operational effectiveness. Using our prop calculator makes sure you don’t make a poor choice.

What are the factors that I should consider when using a prop sizing calculator?

When using a prop sizing calculator, it is essential to consider various factors, including the load, desired top speed, engine RPM or desired shaft RPM range, and gear ratio. These are the inputs required for the sizing calculator to determine the ideal prop diameter and pitch. Also, consider cruising conditions and specific requirements, such as increased thrust for towing or top-end speed for racing. The calculator takes these factors into account to provide a customized recommendation tailored to the boat’s specific needs. When you have a good understanding of these aspects of propeller sizing, your boating experience can never be anything but pleasant.