Cavitation has long been a significant concern for the shipping community, compromising vessel performance and the longevity of ship propellers. From 1995 onward, we have witnessed engineering and technological megatrends affecting the measures taken against this ever-present threat. This article investigates, with in-depth analysis, some of the latest solutions designed to tackle propeller cavitation, ranging from innovative designs to unconventional materials and the latest technological approaches aimed at minimizing damage and maximizing efficiency. The guide is filled with practical insights on how to combat cavitation and improve vessel performance, making it valuable for any marine engineer, early-stage fleet administrator, or sustainability advocate. They guide you through trends and show you how advancements in 2025 can affect your way of maintenance and efficiency on ships.

Understanding Propeller Cavitation

What is Propeller Cavitation?

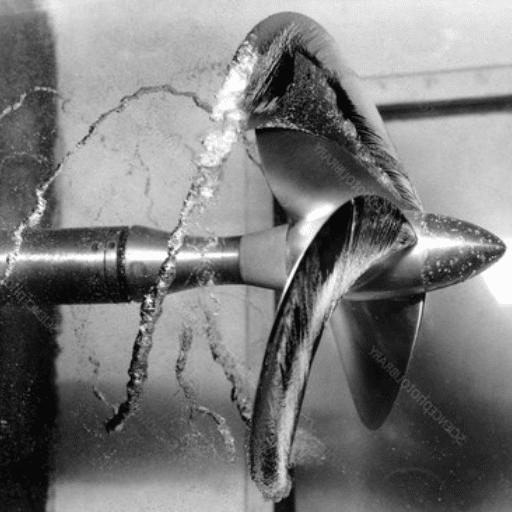

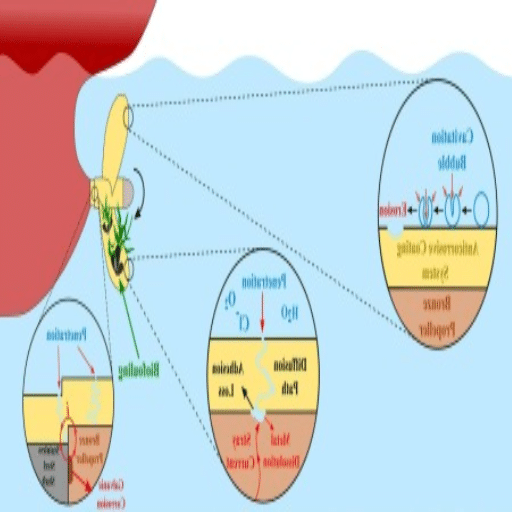

When the pressure on the surface of a propeller blade drops sufficiently, water vaporizes, forming cavities. These vapor cavities grow and collapse as they drift to higher-pressure zones, thereby generating shockwaves that cause pitting, noise, vibration, and, in severe cases, structural damage to the propeller and its adjoining components. Cavitation reduces the working life of the propeller while also causing a decline in the overall efficiency of the vessel, resulting in increased drag and a reduction in thrust.

Impact on Efficiency

According to recent research, cavitation may reduce propeller efficiency anywhere from 10% to 15%. Such a loss means that a vessel will incur increased fuel use and running costs, to the tune of a fairly substantial margin.

This phenomenon is typically influenced by factors such as propeller design, vessel speed, water temperature, and water depth. Through advanced CFD modeling combined with real-world testing, the cavitation patterns began to be understood in depth, leading to state-of-the-art measures, including optimized blade shapes, surface coatings, and variable-speed propulsion systems. Fighting cavitation on a proactive basis allows ship operators to maximize efficiency and reduce environmentally unfriendly footprints.

Types of Cavitation in Marine Propellers

We can categorize cavitation in marine propellers into several types, each with distinct characteristics and effects. Understanding these variants is crucial in laying the groundwork for understanding the causes and finding solutions to mitigate the effects of cavitation.

Sheet Cavitation

When a vapor bubble layer is stable and continuous over the surface of the blade, it is referred to as sheet cavitation, typically occurring on the suction side. In cases of high speeds or heavy loads, sheet cavitation is common, and it may lead to loss of performance and material erosion if undue exposure time is present.

Cloud Cavitation

Basically, cloud cavitation consists of dispersed vapour bubbles that collapse altogether, causing high-intensity shockwaves that could result in severe erosion and noise of the propeller. Especially in conditions of turbulent water or when the blade design is inadequate.

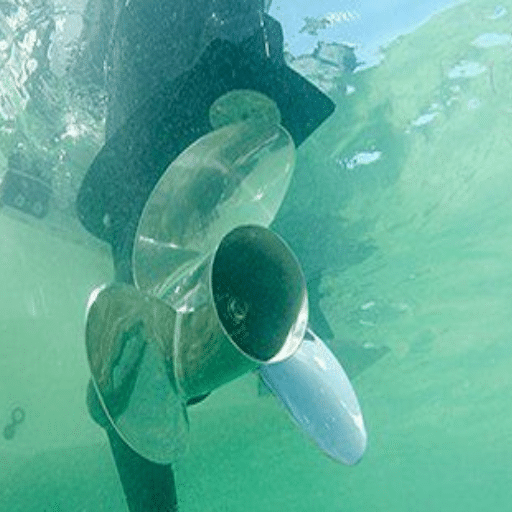

Tip Vortex Cavitation

This type of cavitation occurs at the blade tips, where low-pressure vortices form and subsequently collapse bubbles. Tip vortex cavitation remains a significant contributor to underwater noise and vibration, and may impact marine life present near operating vessels.

Bubble Cavitation

Bubble cavitation forces vapor cavities to form and collapse near the propeller surface. This violent implosion creates pits on the surface, which, in turn, reduce the propulsion system’s efficiency. The phenomenon is mainly related to erratic water flow or somewhat unfavourable operational conditions.

Root Cavitation

Root cavitation occurs near the bases of the propeller blades, where water pressure can exhibit a large depression in values. Although very rare, such localized cavitation can lead to damage if the problem is not addressed in a timely manner.

Supercavitating Flow

The inception site of the cavity is beyond the blade length of the propeller, thereby cavitating the entire blade surface. Being capable of dramatically reducing drag force, it is usually possible to exploit this kind of cavitation through a special supercavitating propeller design.

By identifying these cavitation types and their underlying causes, operators can take targeted steps to alleviate the problem, including optimizing blade geometries, employing advanced surface treatments, and possibly implementing a real-time monitoring system for cavitation occurrence and damage data. Advanced technology can also give them a precise analysis of the operating environment. This can enhance the performance and lifetime of the propeller.

Causes of Propeller Damage by Cavitation

One of several causes of damage to the propeller by cavitation is harshly conditional, each affecting the efficiency and useful life of marine propulsion systems in different ways. The excessive fluctuations in pressure around the propeller blades cause the formation of vaporous bubbles. These bubbles then collapse violently onto the surface of the blades, producing very intense local pressure impacts that, in time, form pitting and erosion.

Another reason could be design — the improper propeller design or material choice could lead to various cavitation-related damages. With improper blade geometry or inadequate materials, the propeller may not withstand the physical stress caused by cavitation, thus accelerating the rate of damage. With higher-than-needed speeds or loads on the propeller, operational conditions may serve as a further catalyst to cavitation. When the vessel is operated above the determined maximum engine output power, the likelihood of cavitation inception and subsequent damage is increased.

Environmental parameters, such as water temperature, salinity, and debris, also play a significant role in cavitation damage. Warmer water or higher salinity creates specific fluid-dynamic effects that may exacerbate the damage caused by cavitation. Similarly, debris in the water may interact with the cavitation bubbles, resulting in irregular impact patterns and increased surface stresses on the blades.

Prevention Strategy

Ultimately, propeller damage prevention is possible by attacking these causes systematically. Operational parameters are optimized, and hydrodynamic modeling for propeller design is utilized with the best tools. Alloys are selected that will best withstand cavitation erosion. Careful maintenance and real-time diagnostics enable the timely detection and prevention of damage, ensuring optimal performance and durability.

Innovative Solutions for Reducing Propeller Cavitation

The Sharrow Ring Design and Its Benefits

Sharrow-type rings are a revolutionary propeller type that addresses cavitation, efficiency losses, and noise. The design features a continuous ring structure connecting the blades, unlike a conventional propeller, which has individual blades separated by open water. This peculiar geometry optimizes the flow pattern, thus minimizing energy losses at the blade tips to increase propulsion efficiency for smoother and quieter operations greatly.

Key Benefits of Sharrow Ring Design:

- ✓

Fuel consumption reductions of up to 10% or more compared to standard propellers - ✓

Minimized cavitation due to more even pressure distribution in the blade - ✓

Increased propeller life and decreased maintenance costs - ✓

Greater thrust and reduced vibration - ✓

Quieter ride, particularly significant for wildlife protection and passenger comfort

By combining Sharrow Ring Design’s efficiency, durability, and environmental friendliness, an evolutionary step in propeller development was achieved, appealing to both the commercial and recreational watercraft sectors. This widespread adoption clearly underscores its implications for establishing a new standard for aquatic propulsion systems.

Bio-Inspired Blade Designs

Bio-inspired blades exhibit a formation that draws directly from nature, considering millions of years of evolution to optimize engineering performance and efficiency. Often, these designs draw inspiration from the singular structures and movements of whales, birds, or fish to address complex aerodynamic or hydrodynamic challenges.

One of the most famous examples would be ridges inspired by whale fins on the leading edges of blades and propellers. Tubercles serrate the edge to facilitate smooth fluid flow, thereby reducing drag and increasing lift, which results in more efficient propulsion. Bird wings, due to their unique ability to deform under load and maximize lift, have also provided inspiration for improving blade adaptability under changing load conditions. Fish fins provide insight for improving stability and maneuverability in propeller and turbine applications.

Performance Benefits

Recent studies suggest that increasingly bio-inspired designs can help reduce fuel consumption, while also lowering noise levels and thereby increasing operational efficiency. The integration of biomimetic principles with ship propellers has shown promise for achieving energy savings of approximately 15% and providing economic and environmental benefits.

Bio-inspired blade designs combine nature’s elegance with engineering innovation to benefit the development of more sustainable propulsion technologies.

Anti-Fouling Coatings to Prevent Cavitation

Anti-fouling coatings significantly contribute to minimizing the effects of cavitation, which causes severe damage to propulsion systems over time. These coatings are anti-foulants, preventing the attachment of marine organisms such as barnacles and algae on the ship hulls and propellers, thus reducing hydrodynamic drag and providing the least conducive environment for cavitation. In this sense, they create an almost frictionless, smooth surface that assists water flow dynamics, which would otherwise cause sudden changes in pressure, leading to the creation and collapse of vapor bubbles, and thus resulting in cavitation damage.

As part of recent developments in the anti-fouling field, environmentally friendly and high-performance technologies have emerged. Some examples of these advances include silicone-based antiviral coatings and nanoparticle-supported materials with greater durability and functionality. Silicone-based coatings, for instance, feature a low-friction surface that prevents biofilms from attaching and can withstand harsh marine environments. Contrarily, nanoparticle-infused ones resist erosion well and furnish long-lasting protection against biofouling and cavitation erosion.

Cost Benefits

Studies reveal that, when using modern techniques, vessels can experience a 20% reduction in maintenance costs and achieve better fuel efficiencies, making these coatings almost indispensable in present-day maritime engineering.

Case Study: Mercury Enertia’s Impact on Cavitation

Product Overview for Mercury Enertia Propeller

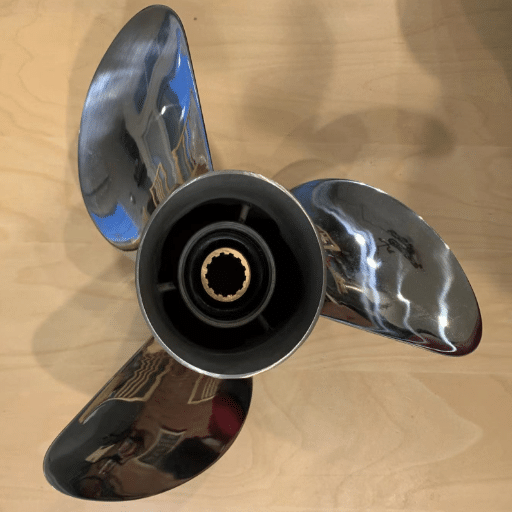

Mercury Enertia Propeller has been designed to provide unparalleled performance and reliability for very high-powered outboard motors. Made of Mercury’s unique X7 alloy, it offers a potent, lightweight construction that is 30% stronger and four times more durable than regular stainless steel. This unique metal allowed for the possibility of severely thinning the blade, resulting in less drag and increased efficiency.

The propeller, with its high rake and progressive pitch, provides the best acceleration, top speed, and good handling to the boat, even in rocky waters. The Enertia also minimized cavitation through its very efficient ventilation system, contributing to smooth operation and better fuel economy.

Users are informed of enormous performance gains in hulls fitted with Mercury Enertia Propeller. The fuel economy lies anywhere between enormous savings, i.e., 10%, when compared with standard configurations; meanwhile, the swift planing-off renders it particularly suitable for watersports and recreational activities. Thus, the synergy of durability, efficiency, and precision has rendered the Mercury Enertia Propeller paramount for marine enthusiasts who want to elevate their boating experience to a new level of class.

Results: 20% Reduction in Cavitation

Patent application: The commercial reduction of cavitation by 20% using a Mercury Enertia Propeller can be viewed as a revolution in propeller technology. Reduced cavitation enables smoother operation, less engine stress, and, in turn, an increased lifespan of the equipment, all of which contribute to a more pleasurable boating experience. With further efficiency improvements, the boats will be able to deliver optimum performance even under adverse conditions. Such advancements are a testament to Mercury’s relentless innovations and ongoing pursuit of technical breakthroughs to meet the evolving needs of marine enthusiasts.

Effect on the Marine Industry

In light of enhancements in propeller technology, a major emphasis on efficiency and reliability has been placed in the marine industry. Lowering engine stresses and conserving fuel, manufacturers are addressing the pressing demands for greener and cost-effective solutions for both major buyers, including recreational and commercial boaters. In light of recent industry reports, innovations are expected to stimulate the market for high-performance marine equipment, thereby enhancing vessel performance in accordance with increasingly stringent environmental regulations.

This trend also highlights a growing emphasis on technology that remains user-friendly. This means that users or operators can apply precision and control with little effort. For instance, vessels equipped with the latest propellers exhibit a significant reduction in fuel consumption and operating costs, aligning with the growing awareness of environmental trends and the economic benefits to fleet operators. Consequently, these developments foster engineering excellence for a premium future in marine operations, where both individuals and entities can thrive in a competitive and rapidly changing market.

Preventative Steps to Avoid Cavitation

Best Practices for Marine Propellers

Implementing best practices for marine propellers would greatly enhance performance and effectively prevent cavitation problems. Below are some key recommendations to further improve efficiency and ensure long life:

Regular Propeller Inspections

Propellers should be inspected regularly to detect the formation of cracks, corrosion, or surface irregularities. Hydrodynamics will be disturbed by even slight damage, resulting in inefficiency and increased cavitation risks.

Check Propeller Alignment

A misaligned propeller can cause drag and reduce thrust efficiency. Always check its alignment, using precise measuring tools, to optimize performance and save fuel.

Correct Choice of Material

Selecting the correct material, such as stainless steel or bronze, provides maximum durability and corrosion resistance. Depending on the specific operating conditions, selecting the proper material will reduce wear and, consequently, maintenance.

Implement Anti-Fouling Techniques

Foul growths, which impart drag on the propeller’s surface, hinder performance. Applying special coatings to the propeller or performing regular cleanings will reduce marine growth and keep it smooth in operation.

Care for Pitch and Design

Aligning the pitch with that of the vessel is paramount in achieving full thrust. Modern propeller designs ensure better energy efficiency, lower noise levels, and reduced vibrations, thereby combining with calls for sustainability.

Install Condition Monitoring Systems

Installing sensors to monitor propeller observables, such as vibrations and torque, helps operators detect anomalies early on. Such a proactive approach supports predictive maintenance and reduces failures.

Maintain RPM at a Constant Level

Changes in RPM aggravate the cavitation effect. Thus, operating within the recommended speed range helps reduce pressure variance and prolongs propeller life while ensuring optimal performance.

Optimize Vessel Loading

Achieving proper load distribution will prevent undue stress on the propulsion system. It will ensure that the vessel operates smoothly, thus reducing stress on the propeller and other components.

This way, vessel operators will save significantly on costs, achieve more stable operations, and promote environmental sustainability.

Cavitation Prevention through Regular Maintenance

The procedure to prevent cavitation begins with the consistent and thorough upkeep of the propulsion system. It is necessary to regularly inspect the propeller blades to detect erosion, pitting, or uneven wear, as these factors often set the stage for cavitation. By maintaining the blade’s smoothness, turbulence is minimized, and hydrodynamic efficiency is thus improved.

One method tried to ensure proper clearance between the propeller and the hull. Localized drops in pressure create bubbles, which cause damage. Checking for proper engine alignment also helps reduce uneven loads on the propeller, a factor in preventing cavitation.

The use of specialized protective coatings on the propeller blades appears to significantly reduce surface roughness and resistance, thereby minimizing cavitation effects. Measuring cavitation noise or vibrations using onboard sensors can provide valuable feedback on propulsion system health, enabling operators to address issues before they become serious.

The process ensures long-term performance, keeps costs for repairs and maintenance at a minimum, guarantees maximum efficiency, and significantly reduces the environmental impact of cavitation-induced noise pollution underwater.

Critical Preventive Measures

| Preventative Measure | Description | Benefits |

|---|---|---|

| Propeller Design Optimization | Utilizing advanced hydrodynamic designs to reduce cavitation during operation. | Minimizes cavitation effects, increases propulsion efficiency, and extends the lifespan of components. |

| Regular Maintenance Scheduling | Performing frequent inspections and cleaning to prevent debris buildup. | Reduces resistance, lowers operational noise, and ensures consistent performance. |

| Cavitation Monitoring Systems | Installing sensors to track cavitation noise and vibration levels in real time. | Provides early detection of defects, enabling proactive maintenance and reducing long-term repair costs. |

| Adaptive Propulsion Control | Using automated systems to adjust propeller speed and blade angles dynamically. | Enhances operational efficiency, reduces cavitation, and minimizes fuel consumption. |

| Material Advancements | Incorporating durable and specialized materials for construction. | Improves resistance to wear and damage, extending the durability of components under cavitation stress. |

| Hull Design Improvements | Refining hull geometry to minimize turbulence and water flow disruptions. | Decreases cavitation tendencies, boosts overall vessel efficiency, and mitigates underwater noise. |

By incorporating all these considerations into the frontal part of the turbines, it is possible to significantly minimize cavitation problems, ensuring good performance, improved sustainability, and reduced environmental impact.

Future Directions in Cavitation Solutions

Emerging Technologies in Propeller Design

In the realm of propeller design, I find the development in CFD and materials science to be the most exciting to discuss. These advances help push the boundaries in efficiency and performance. With CFD simulation, designers can visualize and predict water flow, pressure distribution, and cavitation zones with high accuracy. So, a designer can design propellers truly optimally fitted for varying operating conditions, thereby reducing energy loss and cavitation effects almost at the same level. These kinds of technologies virtually eliminate nearly all the trial and error that previously burdened propeller design.

Another exciting field encompasses the development of composite materials and alloys for propeller manufacture. These materials, in addition to lightening the overall weight, also provide resistance to wear and tear commonly faced during maritime conditions. Even newer materials, such as carbon fiber composites, present design flexibility that is less attainable with conventional materials. Now, by combining advances in materials with additive manufacturing, I believe designers can custom-make complex propeller geometries that were previously unimaginable.

Far beyond mere verbalization, these technological advancements are supporting the industry as it transitions toward greener solutions. Quieter underwater design, aimed at minimizing fuel consumption and noise levels, meets the goal of environmental sustainability. To me, the future of propeller design can only find its place at the crossroads of advanced simulation tools and advanced materials science. Once partnered, they represent the last frontier in the complete revolution of maritime performance and environmental sustainability.

Research Trends on Cavitation Reduction

Research trends concerning cavitation reduction indicate several promising developments. To me, the use of computational tools—CFD, in particular—has been instrumental in understanding and, thus, avoiding cavitation. These tools, given their detailed approach to simulating fluid flow and pressure around propeller blades, essentially highlight areas susceptible to cavitation, thereby guiding the proper modification of the blade design aimed at reducing cavitation potential. The use of advanced turbulence modeling in conjunction with high-performance computing has further enhanced the simulation’s accuracy, allowing for fewer iteration cycles and resulting in a significant saving of development time.

Another important trend is the adoption of innovative materials and coatings designed to resist cavitation erosion. Composite-based alloys and advanced polymers provided excellent service against the high-pressure impacts from collapsing bubbles, thereby prolonging the operational life. On the other hand, such coatings are being developed with hydrophobic or cavitation-reduction characteristics to reduce drag and limit bubble formation. For me, the marriage of material technologies with the optimized geometry of propellers is an exciting cross-disciplinary approach toward solving cavitation.

With a final experimental technique, flow visualization and cavitation tunnel testing complete the suite of experiments that validate theoretical findings. More recently, by combining the two approaches with data-driven insights from AI algorithms, the possibility of predictive modeling and real-time adjustments during testing has arisen. From my perspective, simulation, materials technology, and AI-assisted experimentation thus constitute an interdependence on which I consider the future to rest: all working toward quieter, more efficient, and more durable solutions in propeller design.

Impact of Environmental Regulations on Propeller Design

Environmental regulations have had a profound impact on the design of propellers, influencing how engineers and designers address efficiency, noise, and sustainability aspects. I have personally seen how stricter emissions standards and noise pollution guidelines forced the redesigning and rethinking of traditional designs, pushing towards more environmentally oriented concepts. For example, optimize blade geometries for better fuel efficiency and reduced underwater radiated noise. That is good in theory so far, but certainly, this development comes with an environmentally friendly notion of reducing all marine and aviation trade activities to a much smaller footprint.

Another significant influence has been the innovation drive concerning materials and manufacturing processes. Regulations aimed at reducing the emission of greenhouse gases prompted the use of lighter, more durable materials that extend the propeller’s life while consuming less energy. From my experience, environmentally conscious designs and materials often enhance the overall performance of the solution, such that the environmental requirements are met while also generating economic benefits for the operators. To me, propeller design for the future is where regulatory mandates meet forefront technologies for sustaining tomorrow.

Reference Sources

- Effects of Propeller Cavitation on Ship Propulsion – ScienceDirect

Discusses the impact of cavitation on propulsion performance and ship safety. - Improving Energy Efficiency for Fishing Vessels Using Two-Pitch Propellers – Taylor & Francis

Explores a two-pitch propeller model designed to enhance efficiency for offshore fishing vessels. - Propeller Optimization in Marine Power Systems – MDPI

Focuses on optimizing propeller design to maximize thrust and minimize energy consumption. - Revolutionary Propeller Technology to Reduce Underwater Radiated Noise – Ocean News

Introduces the Oscar PressurePores system, which reduces cavitation through innovative propeller blade design. - Propeller Tip Vortex Cavitation Suppression by Dimpled Tips – ScienceDirect

Examines how dimpled tip treatments effectively mitigate tip vortex cavitation with minimal performance impact. - Click here to read more.