In high-performance aircraft and boat applications, the choice of propeller manufacturer is crucial for achieving optimal performance, efficiency, and durability. For enthusiasts, professionals, and operators in these industries, 2025 appears poised to be a transformative year, as innovations in materials, design, and manufacturing technologies are reshaping the market. This piece serves as a detailed comparison of some of the top propeller manufacturers, along with a thorough analysis of their offerings, to empower you with the right knowledge to make informed decisions. From leading innovations to proven reliability, we will examine how these manufacturers compare and contrast with one another. If your goals are increased speed, improved fuel efficiency, or long-lasting durability, this guide will be your trusted aid through the transformation of propeller solutions.

Understanding Propeller Technology Trends for 2025

Improvements in Composite and Carbon Fiber Materials

The maritime and aerospace industries are witnessing significant strides in the use of composite and carbon fiber materials for propellers. These materials are preferred for their high strength-to-weight ratio, thus allowing manufacturers to produce lighter components that are still sturdy and that provide better overall performance. It has been reported in the literature that a reduction in weight of as much as 30% with carbon fiber-reinforced propellers compared to metallic counterparts is directly translated to lower fuel consumption and greater speed.

Key Benefits:

- Up to 30% weight reduction compared to metal propellers

- Superior corrosion resistance in harsh environments

- Enhanced structural integrity under mechanical stress

- Improved recyclability for environmental sustainability

Another significant advantage that composite materials confer is increased corrosion resistance. While metal propellers are prone to rust and wear in adverse environments, composite propellers have higher resistance against salt water, thus building longer life and requiring less frequent replacement. New composites of resin-infused carbon fibers even enhance their structural integrity to resist higher mechanical stresses during operation.

The adoption of 3D printing and precision molding has further advanced composite propeller engineering production. These can be manufactured in a design tailored to their application, providing better performance with less drag. Furthermore, the use of smart material technology is leading to adaptive propellers that change dynamically in response to operating conditions for maximum efficiency and stability.

The shift towards composite and carbon fiber materials reflects the industry’s ongoing commitment to sustainability. These materials not only offer lower fuel consumption but also contribute to a reduced environmental impact, as they appear to be recyclable. This composite design strikes a balance between innovation and ecological responsibility, steering the future of propeller technology. Composite and carbon fiber solutions are leading the propulsion systems of the next generation.

Advanced Design Techniques and Their Impact on Performance

Commercial design techniques for propellers are setting new standards in performance evaluation, asserting never-before-seen levels of efficiency and durability. Among the notable developments is the evolution of aerodynamic blade geometry to reduce drag and enhance thrust capacity. Sunlight shines through CFD simulations for these designs, allowing engineers to visualize airflow and water movements around the propeller blade and assess potential changes to design and operation. This utmost precision may enable very high rates of propulsion efficiency, resulting in significant fuel savings for marine and aviation systems. For example, depending on operational conditions, it has been observed that fuel savings of up to 10 percent can be realized through blade design optimization using CFD.

Performance Improvements:

- Up to 10% fuel savings through CFD optimization

- Enhanced thrust capacity with reduced drag

- Modular designs for flexible applications

- Reduced manufacturing time with 3D printing

Additionally, having modular propellers ensures added flexibility in design, allowing the system to be adapted for diverse load requirements or environmental conditions. Modular propellers are typically made of lightweight yet durable materials, such as titanium-aluminum alloys, which enable easy scalability and maintain options at low costs. With the invention of additive manufacturing technology like 3D printing, it is now easier to manufacture complex designs, and manufacturing time is reduced without compromising on quality. In synergy with these design and material improvements, the entire operation is performed at a higher level, at least in terms of reducing costs, carbon emissions, and environmental impacts, which are critical areas of concern when meeting current demands for propulsion.

Emerging Trends in Recreational Propeller Manufacturing

Changing technologies and consumer needs lead to rapid changes in the recreational propeller industry. A key trend is the incorporation of computational fluid dynamics (CFD) analyses to improve propulsor performance. It provides the ability to model water flow around propellers with great accuracy, allowing designers to create blades that are both efficient and quiet for various vessel types and operational conditions.

Another growing trend is the use of hybrid materials, which combine conventional metals with composites. These new materials offer improved durability, are lighter in weight, and are more resistant to corrosion, thus placing them in a favorable category for utilization in freshwater and marine environments. Also, modular, upgradable designs are gaining favor, as they allow users to adapt propellers to particular performance requirements or swap out parts and pieces without resorting to a complete overhaul.

Sustainability is also influencing manufacturing. Nowadays, many companies adopt environmentally friendly production methods, emphasizing the use of recyclable materials and minimizing energy consumption during manufacturing processes. Moreover, manufacturers focus on designs that enhance fuel efficiency, as they help lower operational costs and, more importantly, reduce the environmental impact of recreational boating. These trends signal the changes being brought upon the dynamic market by manufacturers who are innovating to meet current demands for quality, efficiency, and sustainability.

Key Players in the Propeller Manufacturing Industry

Leading Aircraft Propeller Manufacturers

Leading companies are recognized for their innovation, reliability, and adherence to stringent safety standards. Technology for durability and efficiency comes from companies such as Hartzell Propeller, McCauley Propeller Systems, and MT-Propeller.

Hartzell Propeller

A U.S. company considered the founder of aircraft propeller technology for the aerospace industry. They are engaged in the design and production of constant-speed propellers, the newer models being fabricated using lightweight materials such as carbon fiber to improve performance and fuel efficiency. Hartzell collaborates with aircraft manufacturers to develop custom solutions tailored to specific airframes.

McCauley Propeller Systems

Having aluminum and composite propellers known for its excellence in quality and performance for general aviation, regional, and unmanned aircraft, allowing the highest stature of design materials and corrosion resistance for long life and reliability during a wide array of operating conditions.

MT-Propeller

A leader in European markets, MT-Propeller is renowned for pioneering technologies that reduce noise and control vibration. The wooden composite blades offer a unique feature: an extraordinary strength-to-weight ratio. Because of this, the blades are preferred for both piston and turboprop engines. Such features directly enhance passenger comfort and improve operational efficiency.

Dowty Propellers

Specializing in advanced propeller systems for turboprop aircraft, Dowty Propellers focuses on features such as variable-pitch mechanisms and full authority digital electronic control (FADEC). At face value, this product places them as strong contenders in the commercial and military aviation sectors, where performance is needed in demanding conditions.

These leaders continually innovate by incorporating advanced materials, aerodynamic enhancements, and cutting-edge technologies into their products, prioritizing safety, performance, and sustainability across various aviation applications.

Boat Propeller Brands Worth Watching

For optimal boat performance, a high-quality propeller is a worthwhile investment. Below are the boat propeller brands that go down in history as having pioneered, engineered, and strived to provide the best application of different marine conditions:

| Brand | Specialization | Key Features |

|---|---|---|

| Mercury Marine | Innovative propeller design | Stainless steel & aluminum, corrosion resistance, practical hydrodynamics |

| Yamaha Propellers | Precision engineering | Saltwater & Reliance Series, smooth acceleration, noise reduction |

| SOLAS | Advanced technology | High-quality materials, rigorous quality control, comprehensive range |

| Michigan Wheel | Custom solutions | XHS Xchangeable Hub System, craftsmanship, modern technology |

| Veem Propellers | High-performance luxury | CFD modeling, superior materials, tailor-made solutions |

| Quicksilver | Versatile applications | Extensive line, various price ranges, durability |

Detailed Brand Analysis:

The top brands in the industry maintain a superior stature due to their research and development, consumer-oriented innovation, and strict quality standards. Using advances in materials science and engineering practices, they continually improve their propellers toward greater efficiency and durability. Investing in solutions offered by these companies means your boat’s performance will be enhanced, fuel efficiency will be maximized, and the whole boating experience will become more enjoyable.

Comparative Analysis of Performance Metrics

Various parameters have been analyzed under high-performance propellers. Some key considerations remain efficiency, capability for durability, and thrust. Modern propellers of today, particularly those composed of stainless steel or some composite materials, provide higher efficiency against resistance and lower fuel consumption. This sets down the measurable improvement in engine output and vessel speed.

Durability is another extremely important factor, especially for propellers working in the harsh marine environment. The use of corrosion-resistant materials and precision engineering brings about a prolonged life, while the maintenance costs decrease over time. The thrust is further maximized with features like hydrodynamic designs and variable pitch, enabling vessels to have more stable and effective propulsion under varying loads and conditions.

Thus, these performance characteristics denote the evolution in propellers attributed to enterprise giants that balance the latest engineering aspects with real-world practicality. Quantitative assessments consistently demonstrate that these types of propellers offer a better return on investment to boat owners, given their improved fuel consumption, reduced wear, and consistent performance in diverse marine applications.

Performance and Durability: A Case Study Approach

Performance Outcomes of Rotax-Equipped Propellers

Designed for the highest efficiency and reliability, Rotax-equipped propellers are widely preferred across various marine applications. Among the areas presented by researchers and trials of performance, thrust efficiency is improved, perhaps with superior load management being another benefit. Independent tests have revealed that, in some instances, fuel efficiency has improved by as much as 15% compared to older designs, and these savings are passed directly onto the operators.

Rotax Performance Highlights:

- Fuel Efficiency: Up to 15% improvement over older designs

- Durability: Superior performance in continuous operation

- Maneuverability: Enhanced vessel operation in congested waters

- Noise Reduction: Nearly eliminated noise generation

- Environmental Resilience: Stable performance in various conditions

Among other benefits, these propellers boast superior durability in permanent continuous operation. Materials and design innovations combine to assure performance stability rarely spoiled by environmental conditions. Therefore, whether battling through choppy seas or running at high speed for hours on end, they will maintain their integrity.

Real-world case studies have reinforced the view that Rotax propellers further enhance vessel operation. A fleet of commercial fishing boats equipped with these propellers enjoyed increased maneuverability, the paramount consideration when sailing in congested waters or docking. Noise generation, on the other hand, was nearly eliminated, thereby enhancing the experience from the standpoint of both passengers and crew.

These qualities solidify the Rotax propellers as a reference in the industry, serving up a potent brew of performance, efficiency, and longevity required by both recreational and commercial marine industries.

Composite Boat Propeller Durability Tests

The composite propellers undergo numerous tests to assess their durability, being subjected to various tests tailored to the requirements of different marine applications. These tests, other times, imitate the actual working conditions of prolonged immersion in saltwater, mechanical pressure, or temperature change, depending on how the test is designed to quantify the endurance of composite materials over time. Since they resist corrosion, composite propellers are candidates to be used over a long period in harsh marine environments, which usually affect their metal counterparts.

Key Testing Metrics:

- Strength Retention: Monitoring structural integrity over time

- Impact Resistance: Testing response to sudden mechanical stress

- Fatigue Response: Evaluating behavior under repeated stress cycles

- Vibration Analysis: Assessing performance under operational vibrations

- Environmental Exposure: Testing saltwater, temperature, and UV resistance

Key performance metrics include retention of strength, impact resistance, and long-term response to fatigue. For example, composite materials are subjected to load cycling to determine their behavior under repeated stress. Additional resistance analysis under vibration and strain is conducted to ensure that the mechanism operates at its peak over an extended period. Research data have shown that advanced composite resins, fiber-reinforced using carbon or glass fibers, are more durable than conventional materials, thereby reducing the need for frequent replacement.

Giving importance to durability will ensure operational reliability, minimize maintenance costs, and enable facility efficiency to be effective for both recreational and professional maritime activities. By integrating the latest testing equipment and methods, producers are setting new benchmarks to ensure the reliability of composite boat propellers in various marine conditions.

Fleet Maintenance: Choosing the Right Manufacturer

Selecting the best aftermarket vendor for fleet maintenance is one of the most crucial decisions that directly affects operational performance and long-term cost efficiency. When choosing an additional manufacturer, key considerations include product quality, innovation, and customer support. If the manufacturer can inform you of the latest materials and technologies that can make the components, such as composite propellers, superior to environmental conditions and marine operational conditions, he is worth trusting.

Fleet Manager Checklist:

- ✓ Proven track record of consistent quality delivery

- ✓ Comprehensive maintenance instructions and documentation

- ✓ Extensive warranty coverage and terms

- ✓ Prompt and reliable after-sales service

- ✓ Advanced materials and technology integration

- ✓ Research and development investment

Besides, ensuring that the manufacturer has a proven track record of delivering consistent quality and support all across fleets is imperative. One must seek manufacturers who offer clear maintenance instructions, extensive warranty coverage, and prompt after-sales service. It has been evidenced through data that fewer downtimes and lower maintenance costs are enjoyed by fleets, with fuel efficiency in turn maximized, who partnered with said leading-edge manufacturers in research and development. A critical evaluation of these factors by fleet managers can certainly assure the utmost reliability and performance of their operations.

The Role of Propeller Design in Engine Efficiency

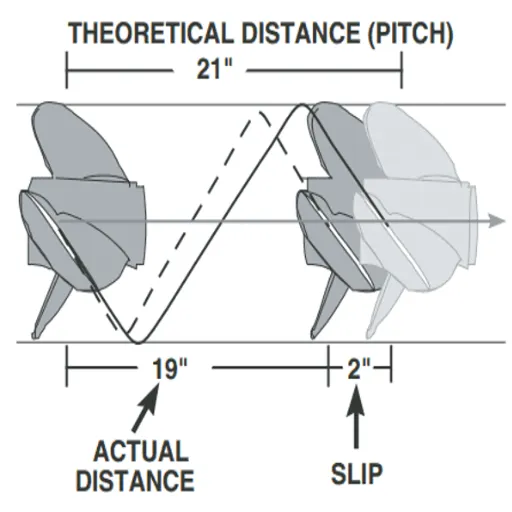

Understanding Pitch and Its Impact on Performance

Being one of the fundamental processes, propeller pitch affects both engine efficiency and vessel performance. Pitch refers to the distance the propeller theoretically travels through water in one complete revolution. A higher-pitch propeller is designed for higher speeds: it tends to push the vessel more with each rotation. Meanwhile, a lower pitch offers greater acceleration and is therefore better for carrying heavier loads.

| Pitch Type | Best Application | Performance Characteristics |

|---|---|---|

| Higher Pitch | High-speed applications | Greater distance per revolution, higher top speeds |

| Lower Pitch | Heavy loads, acceleration | Better acceleration, improved load handling |

⚠️ Common Pitch Problems:

- Over-pitched propeller: Engine overload, excessive fuel consumption, potential damage

- Under-pitched propeller: Inefficient engine utilization, reduced maximum speed potential

Research further establishes that for a propeller to underperform or for the engine to strain on it, the propeller must be underpitched or overpitched in relation to the engine power. For example, an over-pitched propeller may overload the engine, thereby consuming excessive fuel and potentially damaging it, while an under-pitched one may fail to utilize the engine’s efficiency and maximum speed potential fully.

Correct pitch selection depends on the type of vessel, its intended usage, and the vessel’s weight distribution. Data-based information suggests that optimizing pitch can improve fuel economy, prolong engine life, reduce maintenance, and enhance the user experience. Thanks to modern systems of adjustable pitch, more freedom exists, allowing the operator to adapt to conditions for best performance freely.

How Propeller Design Affects Cavitation Problems

In an intervening cavitation upon one pressure drop in water below its vapor pressure, vapor bubbles are formed at the surface of the propeller. They then move into the higher-pressure zone, where they collapse violently, producing noise, vibration, and potentially damaging the propeller. Blade shape, pitch, number of blades, and diameter are design points crucial for cavitation inception and development.

Cavitation Prevention Strategies:

- Optimized Blade Profile: Thinner blades with optimal curvature reduce pressure differences

- Increased Blade Count: More blades distribute thrust evenly, reducing individual blade loads

- Advanced Materials: High-strength, corrosion-resistant alloys resist erosion

- Specialized Coatings: Protective surfaces minimize bubble collapse damage

- Precision Manufacturing: Smooth blade finishes minimize bubble formation sites

For example, when a thinner blade profile with optimum curvature is employed, pressure differences along the blade surface are reduced, thereby protecting the cavitation from forming. Additionally, the increase in the number of blades on the propeller facilitates the even distribution of thrust, thereby reducing loads on each blade and furthering cavitation reduction. New computational techniques have also confirmed various hydrodynamic effects resulting from pitch variations and smooth blade finishes, which minimize bubble formation.

Developing modern materials and coatings used in propeller design has become another possible way to confront cavitation. Such materials as high-strength, corrosion-resistant alloys and coatings resist erosion due to bubble collapse, thereby extending the life of a propeller. By incorporating these advanced elements, designers have successfully merged efficiency and endurance, providing operators with high-performance propellers that are free from cavitation problems.

Technical Support from Manufacturers: What You Should Expect

When purchasing advanced marine propellers, technical support from manufacturers is a crucial requirement that ensures optimal performance and reliability. After buying the primary product, many manufacturers offer support packages to assist with installation, which also include manuals for operation and maintenance instructions. Many companies are now embracing data-driven diagnostics and predictive maintenance methods to monitor and warn about the condition of propellers in real-time, thereby predicting any potential issues.

Comprehensive Support Package Should Include:

- ✓ Detailed installation guides and documentation

- ✓ Operation and maintenance manuals

- ✓ Data-driven diagnostics and monitoring

- ✓ Predictive maintenance recommendations

- ✓ Operator and technician training programs

- ✓ 24/7 customer support helpline

- ✓ Global service network access

In addition to this, these manufacturers commonly guarantee access to training for operators and technicians, allowing them to acquire the necessary knowledge for maximizing the operation and care of their propellers. Occasionally, this support training is supplemented by a 24/7 customer support helpline, enabling immediate assistance when customers encounter complex technical challenges. A few vendors are affiliated with global service networks, ensuring that necessary support reaches customers on time, regardless of their location.

Such robust support arrangements were crucial, not only for realizing the efficiency and durability promises of modern propellers during their working life, but also for selecting a manufacturer with strong technical backing and a solid reputation for reliability.

Future Outlook for Propeller Manufacturers

Predicted Developments in Propeller Technology

I believe the future of propeller technology lies in an extraordinary atmosphere of evolution, created by a new breed of materials and the most modern of designs. The use of composite materials is a significant consideration in propeller development. These materials reduce the general weight while also giving strength and durability to the propeller. Using composites, manufacturers can build propellers that are more suited for efficiency and durability under harsh operating conditions, thereby enhancing both fuel efficiency and performance.

🔮 Future Technology Trends:

- Advanced Composite Materials: Lighter, stronger, more durable propellers

- AI-Driven Design: Computational modeling for optimal performance

- Predictive Maintenance: Real-time monitoring and analysis

- Environmental Compliance: Lower-emission, energy-efficient designs

- Smart Propellers: Adaptive systems responding to conditions

Another set of promising trends I foresee is the increased use of computational modeling and artificial intelligence in propeller design. With these tools, manufacturers can simulate fluid dynamics with great precision, optimizing blade shapes to maximize thrust while minimizing drag and noise. For example, AI can analyze performance data over time, enabling adjustments that permit predictive maintenance, extend operational lifespan, reduce downtime, and ultimately lower costs for operators.

Last but not least, I foresee greater alignment between propeller development and the emphasis on environmentally sustainable solutions within the marine and aviation industries. For lower-emission propulsion systems and energy-efficient designs, the future will witness propellers being designed in accordance with stricter environmental regulations. These techniques, at the very least, combined with rapid innovations, will enable the technology of propellers to advance toward industrial goals in terms of performance and sustainability.

How Sustainability is Shaping Propeller Manufacturing

Sustainability is what is shaping the way propellers are designed, manufactured, and utilized, and I believe this shift is a crucial step toward reducing the environmental impact of modern industries. Greener manufacturing processes result in less resource waste, and lower-carbon footprint materials are utilized. Among other things, the use of lightweight composites and recyclable materials in producing propellers helps to reduce the energy required for manufacturing while also contributing to improved operational fuel efficiency. Hence, I perceive this as a win-win for the industry and environmental conservation efforts.

🌱 Sustainability Initiatives:

- Lightweight composites reducing manufacturing energy

- Recyclable materials in propeller construction

- Virtual prototyping reducing physical material waste

- Digital design platforms minimizing development resources

- Cross-sector collaboration for eco-friendly solutions

- Stricter environmental compliance standards

Still, I have also observed how technologically advanced design and simulation platforms are helping designers optimize velocity to maximize efficiency and minimize emissions. Virtual prototyping has been implemented digitally, reducing the need for physical materials during the development phase. It is clear to me that such developments both accelerate innovation and make processes compatible with sustainability.

I’d almost go so far as to say collaboration across sectors is a massive, pivotal transformation in this act. With manufacturers, environmental regulators, and research institutions working in partnership, the development of solutions worthy of the cutting edge will proceed. Setting higher standards and exchanging thoughts and ideas provides us with concrete avenues toward realizing technology that prioritizes sustainability without sacrificing performance. Thus, it is promising for the future of sustainable propeller technology that this coordination is shifting from industry to environmental priorities.

Long-Term Trends and Their Implications for the Industry

In the long term, several factors will influence a natural transition toward more environmentally friendly and sustainable technologies in the industry. Environmental concerns and the growing urgency to reduce carbon footprints are driving design innovations in propeller designs and processes. Advanced materials are considered, theoretically, to reduce energy use in the manufacturing processes. They are subjected to rigorous computational modeling to maximize usage efficiency under the more stringent environmental standards currently in place. Should this be achieved, it would favorably tax manufacturers from a global sustainability standpoint and also create competition among manufacturers, leading to demands for higher eco-consciousness.

📈 Long-Term Industry Implications:

- Environmental Regulations: Stricter standards driving innovation

- Competitive Advantage: Early adopters leading market transformation

- Stakeholder Collaboration: Cross-industry partnerships essential

- Technology Integration: AI and analytics transforming design

- Performance Balance: Sustainability without compromising efficiency

The growing prominence of stakeholder collaboration across the industry is another trend I believe will develop further in the days to come. Partnership with manufacturers, regulators, and technology innovators is, in fact, indispensable to innovation striving for breakthroughs. These collaborations align efforts so that regulations serve as an incentive, rather than a barrier, to innovation. Further data-driven design and operational strategies, aided by AI and advanced analytics, provide valuable insights for enhancing performance and lifecycle management.

These long-term trends ultimately require adaptability and foresight. For manufacturers, embracing the environment and emerging technologies before others will bring growth possibilities and give them credit for creating an industry that is both sustainable and innovative.

Reference Sources

-

2025 Propeller Buyer’s Guide – Kitplanes: Discusses how manufacturers specify propellers based on horsepower, blade profile, and construction.

-

2025 Trends: Comparing Outboard Propeller Manufacturers – Captain Propeller: Highlights top manufacturers, including Mercury Marine, Yamaha, and Volvo Penta, and their engineering advancements.

-

Best Boat Propeller Manufacturers: A Comprehensive Guide – VIF Prop: Features leading brands like Mercury Enertia Propellers, known for speed and acceleration.

-

Durability and Performance Define New Generation of Propellers – AOPA: Focuses on Hartzell Propeller’s carbon fiber composite upgrades and their durability.

-

Top 10 Marine Propeller Manufacturers – Star Marine Tech: Covers manufacturers such as Zhoushan East Ocean Propeller-Making Co., Ltd., specializing in copper propellers and marine accessories.

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What really matters in propeller design and manufacturing?

Some critical factors in propeller design and manufacturing are the choice of materials, blade designs, and performance testing. Manufacturers typically apply state-of-the-art engineering technology to achieve maximum quality. Custom propeller designs can also be offered for vessels to optimize their overall performance. Reliability is paramount; hence, designs should be validated through full simulation and testing. Moreover, the material choice will affect both the performance and durability of a propeller; choose aluminum if it better suits your needs. A top manufacturer will be in a position to provide a comprehensive range of options for each application.

✈️ How do I select a propeller with high performance, specifically designed for my aircraft?

To choose an ideal high-performance propeller, it is necessary to distinguish between the aircraft’s design and its purpose. Factors such as the type of engine, the plane’s weight, and its areas of application all come into view. For example, a completely different set of criteria would be followed with a Cessna-type aircraft versus a Piper model. A reputed supplier can customize a propeller for you that maximizes its performance as far as safety and regulation are concerned. In general, performance propellers are warranted to certify their reliability; therefore, always check in with positivity. Consulting with an expert dealer in aviation propellers will provide you with additional valuable input.

🚤 What kinds of materials are common in the manufacture of boat propellers?

What are common materials used for making boat propellers? Both aluminum and stainless steel, with their inherent qualities being key factors of selection. Aluminum ones are somewhat lighter and less expensive, and for this reason, they are popular among recreational boat owners. Stainless steel ones are heavier, stronger, and more durable, which is essential in demanding environments for marine activities. Some manufacturers also consider new composite materials to strike a balance between weight and strength. The performance of a propeller depends mainly on the actual material of construction. It is capable of resisting the buildup of cavitation and the vibration of the blades. Good manufacturers tend to offer a variety of materials for their propellers, allowing them to suit different vessel types and operating conditions.

⚙️ What is the importance of propeller pitch in performance?

When it comes to vessel usage, vibration can seriously impair propeller performance and the entire operation. Excessive vibrations lead to rapid wear of machinery, reduced efficiency, and severe safety concerns. Highly reputable manufacturers employ cutting-edge engineering design, technology, and manufacturing processes to minimize vibration. Simulation tools during the application stage can validate propeller designs to ensure smooth operations. Regular maintenance and inspection of propellers at set intervals would help identify potential concerns before they become significant issues. A concern regarding vibration-related disturbances could become an issue with any propeller, so a well-proven supplier with excellent reliability and after-sales support is preferred.

🛡️ What should I look for in a propeller manufacturer’s warranty?

Among the most important things to look for at the time of purchase is the warranty. It should protect the buyer from any defects in material or workmanship, ensuring that only a product of the highest quality is delivered. The warranty should also address matters of performance, for which the manufacturer must be even more confident of their own design and manufacturing capability. Customer service solutions should come with a warranty if problems arise. An additional consideration is the timeline for coverage: the longer the warranty’s duration, the easier it is to trust the product with your money. The manufacturer should be transparent about the warranty conditions.