Long before propellers entered the realms of thoughts or theories, the boating industry was quite simply a fact in the world. With efficiency, sustainability, and performance at the forefront of discussion in modern times, new-age ideas are set to challenge the entire perception of propulsion in marine vessels. From unconventional materials to CNC programs and operational codes, the process of propeller manufacturing has reached an unprecedented level of precision and performance. This article explores the modern breakthroughs in propeller design that promise to improve boating efficiency, reduce environmental impact, and satisfy the rapidly evolving needs of a fast-trending market. Get ready to meet the innovators paving the way toward a more streamlined and sustainable marine future!

Understanding the Propeller Manufacturing Process

Kinds of Propellers and Their Uses

Each propeller is designed in varying configurations to suit the different types of vessels and working conditions. They are generally split into two categories: fixed-pitch and controllable-pitch propellers. Fixed-pitch propellers, typically manufactured in a single piece of material, are sturdier and less expensive, making them favorable for vessels with constant operating conditions. Examples of such vessels may be cargo ships and recreational boats. The adjustable blades of controllable-pitch propellers, on the other hand, allow optimization under varying conditions, offering flexibility for ferries, icebreakers, or naval ships.

In another classification, consideration is given to blade configuration and material: the choice of three blades represents a compromise between efficiency and maneuverability, while the four- or five-blade designs allow for quieter operation with less vibration. Hence, high-performance propellers for competitive marine sports are made from exotic materials such as titanium alloys to increase strength-to-weight ratios and aerodynamic efficiency.

A new age of propeller technologies aims to optimize efficiencies and harmonize with environmental considerations. For example, CFD simulation tools are being used to further evolve blade shape for the best flow characteristics through water. Further, hybrid designs with energy-saving fins or ducts around the propeller have demonstrated a decrease in fuel consumption and emissions, in line with sustainability goals. This innovative approach is a testimony to how the different types of propellers and their uses keep evolving to cater to the needs of the world’s marine industries.

The Role of Marine Propellers in Boating Efficiency

Marine propellers’ performance depends mainly on their design and materials. In modern times, the detailed optimization of the geometry of the propeller blade, aimed at reducing cavitation and maximizing thrust, is possible with advanced computers and numerical methods in fluid dynamics. Research has found that by properly designing the blades, thrust efficiency can increase by as much as 10-15%, resulting in reduced power aggregation and operational costs. Modern marine propellers are mostly made from materials such as high-strength alloys or composites that offer greater durability and corrosion resistance, especially in a harsh marine environment. Besides technical improvement, these features are accompanied by ease of maintenance, making them one of the highest contributors to modern-day sustainable boating applications.

Steps in the Propeller Manufacturing Process

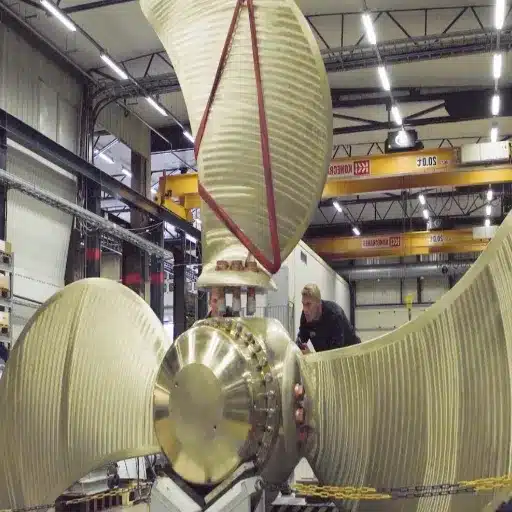

There are various steps in propeller manufacturing to confer on it all the properties required by modern-day applications in terms of performance, durability, and sustainability. The key steps include:

1. Design and Simulation

Planning and designing require significant work in this phase, employing advanced computational analysis tools to set aircraft geometry. The design engineer tests the hydrodynamic performance, thrust efficiency, and cavitation resistance of the propeller using simulation software.

2. Material Selection

The materials to be chosen may be of superior quality, such as bronze alloys or composite fibers, depending on the environment in which they will work. It should be robust, corrosion-resistant, and able to withstand fatigue because marine conditions tend to be harsh on any body.

3. Casting or Forging

The raw material is fashioned into a rough shape of the propeller either by casting, whereby the molten metal is poured into molds, or forging, where the metal is shaped under compressive forces. Composite materials might require very precise layering and curing processes.

4. Machining

After this rough shaping process, CNC machining is used to procure the final dimensions of the propellers, according to the exact blade angle and pitch specified in the design phase. This step is highly essential for performance efficiency and vibration-free operation.

5. Balancing and Testing

Next comes the rigorous balancing of the final propeller to eliminate vibration during operation. Non-destructive testing methods are used to spot any concealed defects or stress points, such as ultrasonic or dye penetrant inspection.

6. Finishing and Coating

To protect against ambient conditions, the surface is coated with an anti-fouling or corrosion-resistant layer. Polishing imparts smoothness to the surface, minimizing drag and hence increasing efficiency.

Each stage requires a high level of technicality and quality control to produce a propeller that performs at the highest level under the demands of modern marine and sustenance transport.

Advanced Techniques in Propeller Manufacture

Innovative Blade Design and Technology

Modern propeller manufacturing techniques strive to push the frontiers of blade performance and ultimate efficiency. CFD simulations are extensively used to fine-tune the blade geometry, allowing a precise analysis of water flow and minimizing cavitation. Whereas adaptive pitch systems allow blades to change their pitch depending on speed and load conditions, this enhances propulsion efficiency in all operating environments. The other important innovation introduced in marine propeller technology was the incorporation of lightweight composite materials like carbon fiber to reduce the overall weight while retaining structural integrity. These innovations align with the industry’s drive for sustainable ships, where reduced fuel consumption and emissions are essential parameters without compromising performance.

Composite Materials in Marine Propeller Manufacturing

Composite materials like carbon fiber and GRP have brought in a revolutionary transformation in Marine Propeller manufacturing. These materials, unlike other conventional materials, have a high strength-to-weight ratio, making them very strong and durable with corrosion resistance, which makes them unsuitable for marine environments. Carbon fiber props are especially lightweight, hence fuel-efficient, allowing vessels to achieve higher speeds with minimum energy consumption.

Moreover, the shaping of these composite propellers is being done with maximum precision due to advanced manufacturing methods like resin infusion molding and 3D printing, which ensure highly optimized hydrodynamic performance. Since composite materials are flexible, manufacturers can design propellers to resist fatigue and cavitation damage better, thus having a longer working life. In turn, such innovative materials, combined with equally innovative manufacturing techniques, are enabling the maritime industry to devise more efficient and sustainable designs for propellers.

Casting and Molding for Precision

Casting and molding have transformed the manufacturing of high-precision mechanical components in shipping, whereby manufacturers design intricate designs that are sturdy and economically realized with respect to wastage of materials, hence efficiency and accuracy. The more complex molding processes, alongside investment casting and injection molding, allow the design of complex geometries that conform to stringent functional criteria. The use of high-quality materials suitable for service conditions, such as the assembly of composite resins or advanced alloys, guarantees final articles with the highest mechanical strength and corrosion resistance. Thus, through modern casting and molding technologies coupled with stringent quality assurance programs, industries can produce components with unmatched precision, further enhancing innovations and reliability demanded by critical applications.

Hartzell Propeller: A Case Study in Innovation

The History of Hartzell Propeller

In fact, the company was founded in 1917 by Robert Hartzell in Piqua, Ohio. Hartzell’s partnership with the aviation pioneer Orville Wright pushed him to begin a manufacturing plant for carved wooden propellers that served the ever-growing demands of the aviation industries. Historically, this gave way to an image of innovation and fine engineering.

With the passage of time, Hartzell developed into a world leader in the manufacture of aircraft propellers. After transitioning from wooden propellers to aluminum alloys in the mid-20th century, the company could deliver greater performance and wear resistance. In the 1970s, Hartzell, aiming to set the pace, was among the first to explore and embark on advanced composite propeller manufacturing. These light-weight composites offered a better performance environment, thus serving as a template for modern propeller designs.

Even today, Hartzell Propeller remains at the forefront of aviation technology, manufacturing cutting-edge propellers used in general and business aviation, as well as in the military. Through sustained innovation, testing, and a commitment to excellence, Hartzell has essentially built a name for itself in aviation as a trusted partner for every pilot worldwide, guaranteeing reliability and efficiency.

Recent Innovations Impacting Performance

Hartzell has pursued continuous improvement in technology to keep pace with the changing demands of present-day aviation. An exhibition of this includes lightweight composite blades, designed using a novel carbon-fiber material to reduce weight while maintaining strength. These blades increase fuel efficiency on the one hand but enhance the aircraft’s performance in terms of noise and vibration reduction on the other. Then there is the extended-blade-lifecycle technology, which reduces maintenance costs and increases the interval between overhauls, giving great economic value to the operators.

Another big step is the introduction of aerodynamic refinements through CFD to improve thrust and efficiency of blade design. Another of Hartzell’s inventive systems is the intelligent monitoring process that enables pilots and maintenance teams to monitor parameters in real-time, ensuring the system operates at peak levels and allowing for early detection of any abnormal states. The innovations testify to Hartzell’s commitment to creating new solutions for better aircraft performance, sustainability, and operational reliability.

Customer Feedback and Real-World Applications

Hartzell Propeller Systems has been widely acclaimed by pilots, aircraft technicians, and aircraft owners. Clientele have indeed talked about fuel efficiency improvement, decreased noise levels, and how these upgrades contribute to a more pleasurable flying experience. For example, operators of small commercial aircraft report huge savings as a result of the optimized blade design, while private pilots praise the smooth operation and reliability.

In practical applications, Hartzell technology has been shown to affect various sectors of aviation. On the other hand, in regional air services and agricultural aviation, a wide array of propellers has been installed in a versatile and challenging environment, ensuring satisfactory performance under various conditions. For instance, the propellers provide the best performance in extreme conditions found in high-altitude airports or areas with humid climates. These practical renditions have consistently justified Hartzell’s ongoing commitment to engineering innovations, which focus on the changing needs of the aviation industry.

Inspection and Quality Control in Propeller Manufacturing

Importance of Quality Assurance in Marine Propellers

The quality check is an essential aspect of manufacturing marine propellers because they are subjected to harsh conditions during loading and use by marine vessels. Properly manufactured propellers give high performance, fuel efficiency, and safety of the ship. This manufacturing involves stringent processes, including the proper selection of materials, modern casting methods, and comprehensive inspections to detect any defects or inconsistencies that may occur. To cite, non-destructive testing, such as ultrasonic or radiographic inspection, helps identify weaknesses in the structure without damaging the propellers.

Furthermore, adherence to international standards and certifications such as ISO 484 for propeller tolerances stresses the importance of adhering to strict quality criteria. Improvements in CAD and CFD have increasingly contributed to refitting propellers for different marine environments. Focusing on quality at each production stage will ensure durability and minimize potential maintenance in operational commercial or recreational vessels.

Methods for Inspecting Propeller Blades for Defects

Inspection of propeller blades is one of the essential operations to ensure the safety and performance of marine vessels. One such technique is one of visual inspection, wherein blades are closely checked for any surface cracks, pitting, or corrosion, using magnifying glasses or other optical aids. UT is also highly effective, using sound waves to detect internal flaws such as voids or fractures inside the blade material. Another widely used method is dye penetrant testing (DPT) to detect surface defects. This technique involves placing liquid dye on the surface of the blade and watching for any dye penetration into cracks under ultraviolet light.

Radiographic testing (RT) uses X-rays to provide a detailed view of the inner structure of the blade, revealing even the slightest defects. MPI works well in spotting surface and near-surface defects in propellers made of ferromagnetic materials. The methods, coupled with modern diagnostic tools and the latest developments in non-destructive evaluation technologies, offer exhaustive and reliable assessments, ensuring propeller blades meet arduous operational standards before being put to use.

Trends of Inspection Technologies of the Future

Future inspection technologies are characterized by highly advanced automation, artificial intelligence, and real-time data analytical capabilities, integrated to ensure higher precision and efficiency. Patterns and anomalies detected by machine-learning algorithms might otherwise go unnoticed through traditional methods, enabling predictive maintenance and early detection of defects. Robotics is transforming inspection by providing access to hard-to-reach areas and reducing human intervention in potentially hazardous environments.

In industries such as aviation and marine, remote inspection tools using drones and ROVs are becoming more popular. They offer the advantage of rapidly surveilling large areas with high precision, thus reducing downtime and operational costs. Furthermore, AR is emerging as a potent tool meant for training inspectors and assisting in real-time diagnostic analysis during inspections.

Other factors for consideration are related to sustainability, as more industries are developing inspection methods that consume less energy and produce less waste. Non-contact inspection techniques, such as ultrasonic and laser sorts, are increasingly being adopted for the non-invasive solutions they offer to meet strict environmental regulations. Generally, the intersection of AI, robotics, and green practices will reshape inspection technologies over the next few years.

2025 Trends Shaping the Future of Propeller Manufacturing

Emerging Technologies and Their Potential Impact

When I muse about the future of making propellers, I believe any emerging technology will cause a sea change in advancements. One of the major ones is the increasing usage of additive manufacturing, also known as 3D printing. This allows for highly customized and precise propeller designs while minimizing waste during production. It facilitates rapid prototyping and shortens development cycles, allowing manufacturers to test and refine propeller designs more quickly. Moreover, the use of lightweight and yet durable materials like carbon composites and titanium alloys is increasingly common. These materials contribute towards an energy-efficient system while upgrading the overall performance and durability of propellers in a hostile environment.

Another innovative development is the manifestation of AI and machine learning in propeller design and production. Through predictive modeling and analytics, manufacturers simulate different performances of propeller designs under various conditions before their physical production. Finally, factories are using AI to support quality control, making inspections more accurate and allowing defects to be found more easily early in the manufacturing process. Further efficiencies can be realized through reduced downtime and higher productivity.

The effects of automation and robotics cannot be overlooked. Automated systems, in their current form, aptly perform very complex machining procedures with a high degree of accuracy, hence increasing productivity. Robotic arms and automated assembly systems are also working to lessen human error and labor costs. When complemented with sustainable practices such as energy-efficient manufacturing and circular economy-based models, these technologies pave a green and bright future for propeller-making. I believe it is these emerging technologies that will change the industry and keep alive our spirits for innovation and sustainability.

Sustainability and Eco-Friendly Manufacturing Practices

While sustainability in manufacturing has been a significant focus as we strive to minimize environmental degradation and meet high industry standards, eco-friendly processes have come into the limelight. Sustainable measures mean less waste, less consumption of resources, and greater compatibility of industrial processes with global efforts to counter climate change. For one, solar and wind energy are renewables that can be harnessed to power production units and thereby reduce carbon emissions. And with these new high-tech recycling approaches to recycle raw materials, we can also shift to building a circular economy where waste is reused or repurposed instead of just being thrown away. These measures prevent environmental degradation while ensuring business sustainability in the long run.

Innovative technologies make environmentally friendly manufacturing possible and scalable. Gunduz and Yalcinbaloglu emphasize the highest production mechanization processes utilizing AI and machine learning to conserve energy and minimize material waste. Another example would be using predictive analytics to foresee maintenance issues, eliminating all prevailing downtimes and extending the lifetime of equipment. 3D printing has helped reduce surplus materials by allowing components to be made with great precision, resulting in almost negligible or zero waste. I am sure that adopting such technologies would embody our commitment to sustainability and our responsibility to future generations.

Looking ahead, the manufacturing industry must set sustainability apart from high-grade quality. This entails research, partnerships, and greener technologies on the one hand, while supporting policies that promote green manufacturing on the other. Working together to promote industrial growth aligned with planetary well-being is establishing a legacy of innovation and environmental stewardship for the years ahead.

Market Insights: The Demand for High-Performance Boat Propellers

Depending on my study, the demand for top-quality boat propellers is influenced by a handful of factors: advances in marine technology, an increasing interest in recreational boating, and the constant demand for fuel-efficient solutions. In the present day, boaters want propellers that offer maximum speed and agility, along with high efficiency, yielding excellent performance while reducing environmental impact. An increasing array of water sports and leisure activities, along with the luxury yacht market, are additional considerations that drive manufacturers to innovate and satisfy myriad customer needs.

Another equally worthy factor to consider for demand is the growing push for the maritime industry to institute environmentally friendly practices. High-performance propellers, designed hydrodynamically, consequently reduce fuel consumption and emissions, aligning with the spirit of all global initiatives aimed at combating climate change. Additionally, by using advanced materials like stainless steel and novel designs such as adjustable pitch propellers, the life expectancy of the products has been maximized while maintaining versatility in application. As commercial vessels focus on efficiency and reliability, the need for more advanced propeller systems broadens the market opportunity further.

In the high-performance boat propeller market, demand is expected to grow steadily, as consumers and enterprises emphasize performance, sustainability, and economic feasibility. Companies that embark on research and development to provide innovative yet customized solutions will be well-positioned to capitalize on this burgeoning need.

Reference Sources

- •Exploring the 2025 Trends in Composite Propeller Manufacturing – Discusses advancements in materials and aerodynamic designs for propellers.

- •ASTM AM CoE Joins Digitally Enabled Efficient Propeller Project – Focuses on smart, cyber-physical systems for propeller performance monitoring.

- •World-leading Consortium Launches Digitally Enabled Efficient Propeller Project – Highlights additive manufacturing and digital twin technology in propeller innovation.

- •Redefining Propulsion: Greg Sharrow at REINDUSTRIALIZE 2025 – A video presentation on how the Sharrow Propeller is revolutionizing propulsion.

- •2025 Propeller Buyer’s Guide – Covers new developments in propeller designs for various aircraft, which may have parallels in marine applications.

- Find more info now.

Frequently Asked Questions (FAQs)

How is a boat propeller manufactured?

The first step in the manufacturing of a boat propeller is the design of the propeller by the use of computer-aided design (CAD) software. After the design for a particular propeller is finalized, manufacturers find a way to make a mold for casting or machining the propeller. Aluminum may be chosen; stainless steel propellers could be used, or even composites like carbon fiber, depending on the properties they want to enhance, such as durability and lighter weight. The raw material will then be converted into a rough form, followed by polishing, inspection, and dimensional checking. Eventually, finishing processes will come about to ensure performance and aesthetics.

How do machines cut the propeller blades?

Propeller blades are made through advanced machining processes to maintain precision and quality. It usually involves milling operations with a 5-axis machine, wherein the material is cut away to form the blades correctly. The complex geometry and profile of the propeller can therefore be obtained to improve its efficiency. Once machined, the blades go through inspection, often via a CMM (Coordinate Measuring Machine), to ascertain dimensional accuracy. Polishing and finishing processes follow to enhance surface quality and minimize vibration during running.

What are the common materials employed in propeller manufacture?

See below for some of the common materials used in propeller manufacture: aluminum, stainless steel, composites of fiberglass, and carbonfiber. Aluminum propellers are light, corrosion-resistant, and hence suitable for various marine applications. Stainless steel offers more strength and durability, which is needed in high-performance vessels. Composite propellers provide a good compromise between weight and strength and are more commonly used in aviation and in high-speed boats. Each of these materials has its benefits; thus, the selection is often more dependent on the application and the desired properties.

What is an important aspect to consider in propeller design, which would be pitch?

The pitch of a propeller is one of the most significant factors determining its overall efficiency and performance. An observed definition states that it is the distance that a propeller would theoretically travel forward in one complete revolution if moving in a slip-free condition. A high-pitch propeller is designed for use in fast applications, while a low-pitch propeller favors acceleration and handling of a load. Since the pitch can heavily affect the performance of the prop, speed, and fuel efficiency, it is one of the very first considerations in the engineering process. Therefore, manufacturers calculate pitch very carefully to suit their end use and engine specification.

How are inspection processes used in making a propeller?

Inspection is essential for manufacturing a propeller-type part, as it determines whether the product meets quality and safety standards. In this stage, several inspection techniques such as visual inspection, dimensional checks, and non-destructive testing methods are followed to detect defects and irregularities. The use of automated inspection tools such as CMM ensures very high accuracy in measuring certain critical dimensions. Therefore, this thorough inspection increases the propeller’s reliability and reduces the possibility of failures during operation, ensuring it optimally serves its intended marine or aviation application.

What are the various advantages of composite material in the construction of a propeller?

Composite materials indeed offer several advantages for propeller applications. Being light and strong, they efficiently perform the task without imposing an unnecessary load on the moving vessels and aircraft. Their resistance against corrosion and fatigue prolongs the lifespan of the propellers in different environmental settings. Lastly, composite propellers can be molded into unusual shapes in a way that results in more lift and less vibration. The possibility of designing such materials to meet exact performance specs allows manufacturers to continue advancing propeller technology.