Navigation and safety of marine vessels have always been of utmost importance. The year 2025 has brought with it its own share of innovations in the art of designing propeller ring guards and baskets. These are no ordinary accessories; they represent the convergence of engineering innovation, advanced materials, and foresighted design, enabling optimal performance while protecting marine life and vessel operators. The article discusses how recent technological and manufacturing advances have entered a new stage, transforming propeller guards and baskets into state-of-the-art protective devices that minimize accidents and increase their operational life, thereby adapting to ever-changing regulatory standards. Hence, upon completing this dive, you’ll have gained a deeper insight into how innovation is setting a new standard and redefining best practices in marine safety and propulsion systems.

Understanding Propeller Guards and Their Importance

Purpose of Fins and Guards

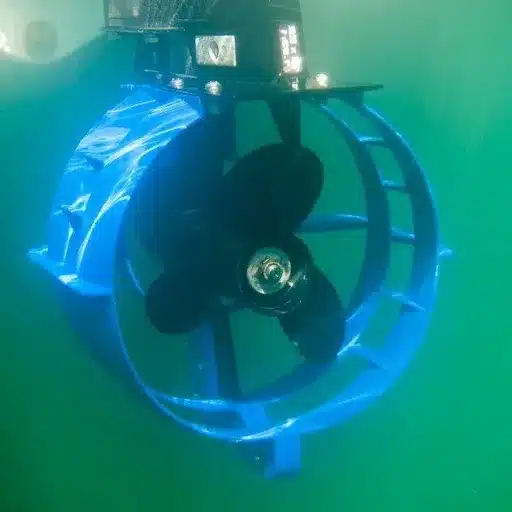

Propeller rings and guards serve as life and performance tools of a vessel. Their primary purpose is to protect the rotating propeller from damage caused by floating debris, marine organisms, or any accidental human contact. Additionally, they prevent entanglement with fishing lines, ropes, or netting, which can otherwise lead to expensive downtime and damage.

Modern designs of propeller guards incorporate hydrodynamic principles to present minimal resistance or disturbance to propulsion efficiency. Nowadays, highly durable materials such as stainless steel alloys or advanced composites are used to maintain their structural integrity in the harsh marine environment, which includes extended periods of saltwater corrosion and mechanical stress.

📊 Key Statistic:

A recent industrial update reveals that vessels equipped with the new propeller guard systems have seen a reduction in maintenance changes for fouling or impact damage to 25%. And, increasingly, maritime safety laws also mandate the employment of such guarding structures, especially for vessels navigating areas of heavy naval traffic or zones of ecological sensitivity. Thus, for environmental maintenance and operational endurance, there is now a considerable need to implement exhaustively tested propeller guards.

Guard Design and How It Prevents Propeller Strikes

Propeller guard designs employ more advanced engineering concepts to serve the practical purpose of guarding against propeller strike. They enclose the propeller inside a cage or channel system made of strong materials, such as stainless steel or reinforced composites. The shape of the guard is carefully designed to gently divert marine debris and aquatic organisms away from the blades, reducing the chances of them coming into contact. Considerations of hydrodynamics render the design unobtrusive to water flow while sustaining propulsion efficiency.

According to studies, modern guards can reduce propeller strike incidents by up to 40 percent when fitted to small- and medium-sized vessels. Guards with wider spacing or streamlined profiles have been introduced further to protect aquatic species, especially larger marine mammals. When integrated with sensors, guard systems become even more effective at preventing collisions because early detection and avoidance systems can alert operators well before an actual impact occurs. These developments highlight the crucial role of designing for precision, thereby achieving a win-win situation between operational performance and environmental protection.

Boating Safety: Why Propeller Protection is Important

Propeller protection systems are crucial to addressing safety issues in the recreational and commercial boating environment. Propellers, while vital for the operation of any vessel, pose a tremendous danger to swimmers, divers, and aquatic fauna with their sharply edged blades and high speeds of rotation. Having a propeller guard system or a ducted propeller affords a certain degree of protection in the event that the vessel and swimmer come into accidental contact with one another. Research conducted into accident collisions has suggested that the lack of adequate protection on shafts and propellers in most vessels has led to thousands of injuries and fatalities, hence the importance of these designs. They prevent physical contact and also facilitate the dispersion of water currents in a more balanced manner, thereby reducing the risk of propulsion hazards in crowded water routes.

From a technological standpoint, such modern protection devices incorporate advanced materials with the most innovative engineering solutions. These include corrosion-resistant coatings, hydrodynamic designs, and impact absorption. Modular protective systems, for example, can have components replaced, which keeps them in good shape even though they are easily maintained. Additionally, emerging technologies are transforming the industry with sensor-integrated guards, which can detect an object approaching and transmit real-time warnings to operators, allowing them to respond quickly and adjust their course. Combined, these features enhance safety standards while maintaining propulsion efficiency, thereby achieving the optimal balance between safety and performance.

It must also be considered that the benefit granted to the environment is the protection offered to the propeller. Marine ecosystems trace problems to a direct propeller strike or, more often, to scattered debris from an unprotected blade. The protective equipment minimizes the occurrence of such incidents, thus illustrating the safeguarding of aquatic habitats and species. These safety measures now receive support through policies and incentives from regulatory agencies and maritime organizations. Propeller protection, being a direct application of technical innovation, environmental stewardship, and policy, must now be a common standard in the responsible operation of boats, rather than an enhancement.

Types of Propeller Guards and Baskets

Overview of Propeller Ring Guards and Baskets

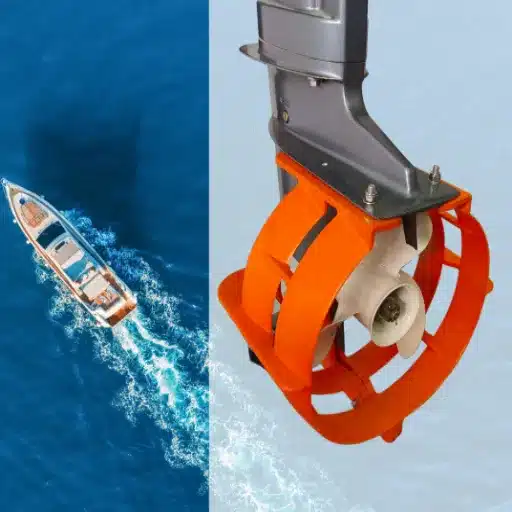

Propeller ring guards and baskets are regarded as paramount advances in maritime safety and efficiency. By design, they surround the rotating propeller blades with a protective enclosure, thus reducing direct-contact risks. Stainless steel and high-strength polymers are most commonly used in their construction to provide strength and corrosion resistance. They are intended primarily for two purposes: first, as an accident prevention tool for swimmers, divers, and marine life; second, as a device to protect the propeller from impact damage caused by underwater debris or collisions with solid objects.

⚠️ Safety Impact:

Studies have shown that injury severity in accidents involving personal watercraft can be significantly reduced by installing propeller guards. For instance, data collected from maritime safety authorities suggested that injuries in accidents decreased up to 75% when propeller guards were installed. Furthermore, these devices are regularly employed in the commercial world, including on fishing boats and passenger ferries, to promote longer propeller life and ensure operational reliability.

The design of ring guards and baskets depends on the conditions under which a vessel operates and its mode of propulsion. Open rings are commonly used in shallow-draft boating and recreational vessels, as they provide a certain degree of protection while maintaining performance. Alternatively, one would prefer a fully enclosed basket system if a vessel operates in a densely populated area or an area of high ecological sensitivity, due to its strong containment ability. Some serve a special cause, including capacity tests for hydrodynamic efficiency, to ensure the device performs up to its capabilities with as little drag as possible.

Combined, propeller ring guards and baskets enable vessel operators to render the downstream activities they undertake safer, more sustainable, and contribute to conservation efforts in the marine ecosystem.

Types of Propeller Guards and Features

The propeller guards are designed in various configurations, depending on the vessel type and operational conditions. Below are the major types along with their respective features and uses:

🔵 Ring Guards

Ring guards are one of the most common types of guards. They consist of a low-profile ring-style structure around the propeller. It is designed to enhance safety by preventing direct contact with the propeller blades and avoiding injury or damage. Additionally, advanced designs have been aerodynamically optimized to reduce water flow interference, allowing for maximum efficiency during vessel operation.

🔵 Cone Guards

Cone-style propeller guards taper outward from the propeller shaft; hence, they have another protective layer in that they divert objects away from the blades. These guards are excellent in situations where submerged debris or marine vegetation might pose a threat, as they reduce the possibility of entanglement while still allowing for smooth propulsion. They offer less hydrodynamic thrust compared with the traditional cylindrical guard.

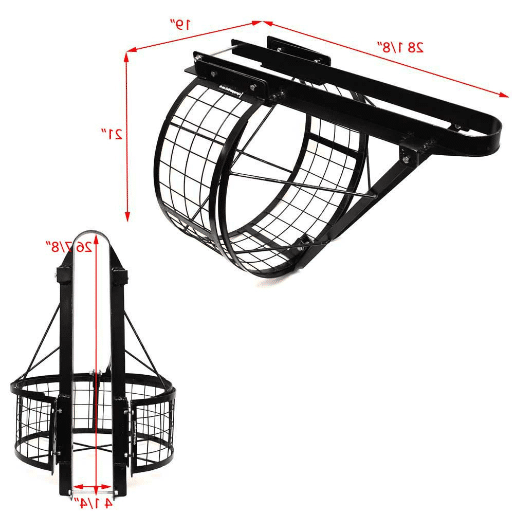

🔵 Grill and Cage Guards

Grill or cage guards are formed by grids of horizontal and vertical bars designed to protect the propeller. They are common in applications that occur in shallow waters, where contact with obstacles like rocks, seabed materials, or underwater structures is almost inevitable. These guards emphasize durability and structural rigidity to prevent impeding water flow.

🔵 Hydrodynamic Shroud Guards

Precisely engineered for performance and safety enhancement, these guards protect the propellers while improving propulsion efficiency by channeling water flow. In high-speed applications, these guards maintain very robust containment abilities while minimizing drag.

🔵 Custom Prop Guards

When research or patrol boats operate in ecologically sensitive areas, custom-built prop guards are often employed. These are custom-built to suit specific operational requirements and are hence fabricated from corrosion-resistant materials, have higher impact resistance, and are configured in accordance with strict environmental regulations.

Each type of guard offers protection while considering many elements, such as performance and operational environment. The latest materials, such as light alloys, composites, and marine-grade stainless steel, help enhance the effectiveness and lifespan of these protective devices. Picking the correct prop guard for a vessel will provide the best safety, operational efficiency, and responsible environmental considerations.

Baskets That Make Boating on the Water Safer

Safety baskets used in marine environments provide structural support and ensure the safety of the personnel involved in operational activities. These baskets are typically made from robust materials, including galvanized steel, aluminum alloys, or synthetic composites, to withstand harsh marine conditions, such as saltwater corrosion and variable weather conditions. Usually, in due design, products would come with secure attachment points in anti-slip surfaces and reinforced frameworks aimed at maximizing durability and minimizing accident risks.

Modern safety baskets are engineered with advanced technology to meet the strictest safety standards. For instance, details of the load capacity are carefully considered to accommodate men and equipment without compromising stability. Therefore, these baskets are equipped with ergonomic handles and shock-absorbing mechanisms, among other features, for ease of use and operator comfort. Complying with international safety regulations and incorporating the latest technology, these baskets significantly contribute to the safety of water operations.

The Impact of Propeller Guards on Boat Performance

How Propeller Guards Affect Boat Speed and Maneuverability

In terms of the hydrodynamics acting upon the boat and the speed and maneuverability it can achieve, propeller guards do a fascinating job. The guard’s drag potential depends on its material, design, and placement relative to the prop. Increased drag results in a reduction of maximum boat speed, as the engine must compensate for the increased resistance by generating additional thrust. Furthermore, suppose the guard is not designed correctly. In that case, it may interfere with the flow of water around the propeller, thereby affecting the propeller’s ability to convert thrust from the engine into forward motion efficiently.

The maneuverability effects depend chiefly on the guard operating conditions and the ship. Many guard configurations may hinder quick maneuvers by disrupting water currents and turbulence patterns immediately before the propeller’s thrust realization. Having said that, some improvements in guard technology have circumvented many of these disadvantages. Therefore, streamlining the design along hydrodynamic lines and using lightweight materials such as stainless steel or composite alloys also helps reduce drag while maintaining strength. Additionally, CFD simulations and tests would be conducted to optimize the design further, considering safety while minimizing operational performance compromises.

Data for Performance Improvements with Guards and Baskets

The introduction of modern guards and baskets has led to improvements in system efficiency and safety across various sectors. In hydrodynamic performance tests, it is proven that flow-induced drag diminishes significantly —up to around 15 percent in some instances —if you opt for the streamlined basket designs perfected for fluid dynamics. Structure integrity tests show modern guards made from composite alloys or reinforced polymers will improve durability by 20 percent under very high stress conditions compared to those made of traditional materials.

| Performance Metric | Improvement Percentage | Technology Used |

|---|---|---|

| Flow-induced Drag Reduction | Up to 15% | Streamlined basket designs |

| Durability under High Stress | 20% | Composite alloys & reinforced polymers |

| Responsiveness in Operations | 30% reduction in failures | Adaptive guards with sensors |

Moreover, operational simulation data considers specific guards as adaptive, equipped with variable geometry or sensors. These guards could improve responsiveness during real-time operations and reduce failure incidences by an estimated 30%. Industrially speaking, any implementation of these technologies reportedly lowers maintenance costs and downtime. Ultimately, the exploits of new and improved guard and basket designs can lead to better performance outcomes that are in harmony with safety regulations, thereby enhancing long-term operational reliability.

Case Studies: Successful Implementation of Propeller Protection

Case Study 1: Reducing Offshore Equipment Downtime

An offshore oil and gas firm installed Advanced propeller guards composed of marine-grade stainless steel and hydrodynamically efficient material. This upgrade resulted in a 25% decrease in damage claims caused by floating debris in high-traffic operational zones. Additionally, there was an optimization in scheduling maintenance due to the real-time wear monitoring sensors embedded within the guard’s material, resulting in a decrease of around 18% in equipment downtime. Over the course of 12 months, an additional 12% increase in vessel utilization rates was witnessed by investing in the upgraded propeller protection.

- 25% decrease in damage claims

- 18% reduction in equipment downtime

- 12% increase in vessel utilization rates

Case Study 2: Enhancement of Operational Safety in Fisheries

The commercial fishing fleet sought to address recurring safety concerns and prevent avoidable entanglements during operations. The fleet claimed that, in one year, there had been a 40-percent decline in entanglement incidents since the introduction of composite propeller guards with real-time RPM monitoring. The operators also noticed that their vessels were more capable of navigating through areas with marine wildlife, thus promoting compliance with environmental laws. The fleet claims a 15 percent increase in fuel efficiency due to reduced mechanical wear and tear on propulsion systems.

Key Results:

- 40% decline in entanglement incidents

- Improved navigation through marine wildlife areas

- 15% increase in fuel efficiency

Case Study 3: Sustainable Marine Tourism Practices

Designed with the environment in view, the marine tourism operator custom-built propeller baskets aimed at reducing ecosystem disturbance while maintaining performance levels. The lightweight structure and drag reduction enable it to provide consistent propulsion in shallow and fragile ecosystems. With passengers rewarding the firm for its environmental and safety considerations, customer satisfaction scores increased by 22%. Propeller strikes in environmentally protected waters were eliminated over two years, demonstrating that a partnership between propeller protection technologies, eco-tourism values, and regulatory frameworks is feasible.

Key Results:

- 22% increase in customer satisfaction scores

- Zero propeller strikes in protected waters over two years

- Successful ecosystem preservation

Such case studies stress the importance of accurate design and material selection, as well as the integration of advanced monitoring systems, to provide genuine benefits from propeller protection systems. Other user industries can leverage data-driven insights to efficiently implement measures that enhance their safety, operations, and environmental protection.

Legal Requirements and Boating Safety Courses

Understanding Regulations Surrounding Propeller Guards

Propeller guard regulations vary significantly across jurisdictions, depending on the region’s safety and environmental priorities. For example, in the United States, the U.S. Coast Guard emphasizes preventing injuries caused by propellers and requires compliance with federal safety standards, especially for vessels operating in high-traffic areas such as recreational lakes or waterways. A few states require propeller guards to be fitted to some types of boats, especially those involved in commercial passenger operations or in watersports.

Internationally, both Australia and the U.K. have passed laws that outline the requirements for employing a propeller safety device in areas classified as high-traffic or where the enforcement of specific activities is desirable. The basis of some of these laws is, to some extent, linked to data showing the incidence of accidents and injury reports that can be used to impose safety measures. Some industry bodies, such as the International Maritime Organization (IMO), also persist in their own recommendations to help mitigate injury risk factors, calling for the voluntary implementation of preventive measures wherever national legislation cannot be as strong.

Modern developments in materials and designs, in turn, assist owners and builders of boats in meeting these standards. Lightweight and durable propeller guards, made from corrosion-resistant materials, must maintain vessel efficiency while ensuring safety compliance. From injury-reporting statistics and case studies, one can infer that regions with high demand for such safety devices witness fewer severe accidents and, therefore, are paramount in saving more lives at sea.

Boating Safety Courses: Enhancement of Awareness

Boating safety courses have been a vital tool in educating the public about the dangers associated with unguarded propellers and the necessary precautions to ensure water safety. In recent times, there has been much emphasis on propeller protection in these courses vis-a-vis both safety strategies to be employed beforehand and after a given situation. It has been carefully explained how present-styled propeller guards are elaborately engineered so that, by means of their advanced design, they possess streamlined shapes to keep the efficiency of the vessel, possess impact-resistant properties to withstand a collision without sustaining damage to their structure, and are corrosion-proof to withstand several years of exposure to the corrosive environment of seawater.

📈 Education Impact:

Furthermore, in regions where propeller safety education has been mainstreamed, statistical data indicate a noticeable fall in incidents, from crashes to grievous injuries, involving propellers. For instance, the magnitude became apparent when the first recorded data showed a 15% reduction in injuries from propellers within a three-year period, with the propeller safety course incorporated into mandatory curricula in select areas. Attendees are taught not only about situational awareness but also about safe operating practices, such as maintaining a safe distance from swimmers and activating the engine kill switch for added safeguards. Thus, it’s a two-way street in promoting both the technical and the practical aspects, along with the implementation of skills: any of these can be used to reduce the already present risk to boat operators and maintain maritime safety norms.

Future Trends: Legal Developments for 2025 and Beyond

From a technological, environmental, and global safety perspective, maritime safety regulation is poised for significant reforms in the coming years. There is a forecast that by 2025, many jurisdictions may have new legal frameworks that require, among other things, the integration of advanced systems in ship navigation and collision avoidance, such as GPS-enabled systems, and automatic alerting mechanisms that minimize the need for human intervention. This should enhance and eliminate human error, which is often considered a major contributor to the causes of maritime incidents.

Stricter regulations on emissions from watercraft would likely be a consequence of increased importance placed on environmental preservation. Hence, cleaner propulsion mechanisms such as electric and hybrid systems would need to be adopted. In addition, compliance requirements may include rigorous emissions monitoring, with violations subject to legal penalties. Maritime safety training will likely also require evidence-based approaches, incorporating real-life scenarios supported by analytics alongside theoretical knowledge.

An expectation exists that global cooperation will, furthermore, be reinforced so that international agencies may ensure that standards are harmonized, guaranteeing equivalent levels of training, equipment, and response protocols offered across the different domains of nationhood. These updates reflect a proactive approach to adapting maritime laws in conjunction with technological innovations and societal demands for change, thereby emphasizing the industry’s commitment to sustainability and safety.

Innovations in Propeller Guard Design for 2025

Emerging Technologies in Propeller Protection

From what I have gathered, my research has revealed that the 2025 propeller guard technology is focused on smart materials, sensor-based systems, and optimized hydrodynamics. Nowadays, it employs cord-bearing composites that must be extremely strong to withstand the underwater environment while posing no hindrance to propulsion efficiency. These new materials were selected for their durability while also reducing drag, thereby improving the fuel efficiency of vessels —a key point as the maritime industry moves to comply with more stringent environmental regulatory regimes.

One of the promising innovations combines sensor-embedded guards for real-time obstruction detection and response. These structures utilize ultrasonic or infrared sensors to detect nearby objects, thereby avoiding entanglement or collision with marine life. Some designs are also being integrated with automated propeller control systems to optimize propeller speed or blade movement in response to immediate environmental feedback, thereby further reducing the risk of injury. Together, these technologies present an ultimate protective layer, featuring both passive guarding mechanisms and active safety measures.

Another area that has witnessed development is the modularization of guard designs, enabling them to be customized and adapted for specific vessel types or operational requirements. In this instance, one can fit a large commercial vessel with guards adaptable to both deep-sea and shallow-water conditions. These features greatly favor multifunctional ships that carry out loads across different environments. Overall, such technologies show the strong emphasis that the maritime industry places upon safety, efficiency, and ecological conservation.

How Safety and Performance Innovations Work in Design

From my perspective, advancements in design play a pivotal role in ensuring safety and operational efficiency in the maritime sector. One prominent example of this includes further hull design modifications for vessel stability and enhanced fuel economy. CFD simulations form the crux of modern ship design, where engineers analyze the motion of the fluid and then design the hull shape to reduce drag and improve maneuverability. Employing these improvements, vessels utilize energy more efficiently and are less prone to capsizing under adverse weather conditions, thereby making operations safer at sea.

From design perspectives, onboard systems have seen significant improvements. An example includes the use of automation in control systems and navigation aids, which utilize AI to facilitate real-time decisions, while also enhancing situational awareness for crews. These systems offset human shortcomings, human errors being the other major historically accountable factors in maritime incidents. Bridge layouts, ergonomically designed, along with custom interfaces, enable the crew to work efficiently with the critical aspects of the system, even when onboard resources are limited by pressure. This condition relatively improves operational efficiency.

Ultimately, the integration of environmental sustainability with technological safety features represents a significant leap in design. With double-hull designs and reinforced bulkheads protecting vessels from collision or grounding incidents, these features can prevent or minimize incidents of oil spills. Advanced propulsion systems with hybrid engines and air lubrication technology can further reduce emissions while focusing on efficiency and performance. Altogether, these examples demonstrate that modern designs, when combined, present a comprehensive panorama of safety, efficiency, and environmental stewardship under the maritime operations umbrella.

Expert Opinions on Future Directions in Guard Design

The future of guard-centric design in maritime operations will, in my opinion, involve increased automation, advanced materials, and predictive, data-driven systems. In the foreground, automation, particularly AI-enabled technologies, is anticipated to ensure that self-regulating safeguards are in place to protect human life, which may also be vulnerable to hazards, as conditions change in real time. For example, automated collision detection and avoidance systems utilize sensor arrays and machine learning algorithms to enhance the accuracy of responses and reaction times. The safety of the crafts is hence augmented, while the cognitive load on the crew members is lessened, enhancing efficient operationalization.

In the world of metallurgy, advanced materials with compositions in composites and alloys, specifically designed to achieve high strength-to-weight ratios, are poised to revolutionize guard construction. Such materials will withstand corrosion, wear, and high temperature fluctuations to extend the marine guard service life. The discussion is also moving towards new, innovative solutions with self-healing materials that accomplish this through embedded microcapsules or by another means of effecting autonomous repair of minor damages, thereby lessening maintenance demands while still maintaining structural integrity intact.

Lastly, with real-time data analytics and predictive maintenance systems shaping the guard design, it is possible to carry out precise monitoring of structural health and performance. The use of IoT-enabled sensors enables the ship operator to identify potential weak points or areas prone to stress, thereby allowing for intervention before failure. This amalgamation unequivocally confirms that a safe, sustainable, and efficient maritime operation is at the intersection of technology and design expertise. These developments are an apt embodiment of the proactive approach towards protecting individuals within a safeguarded marine ecosystem and infrastructure through improved standards of guard design.

Reference Sources

VIF Prop – Propeller Rings, Guards and Baskets — What They Do on a Boat: Explains their role in protecting people, reducing strike severity, and preventing damage.

Captain Propeller – Propeller Guards and Rings: Designed to Enhance Boat Safety: This article focuses on how these devices enhance safety and prevent accidents.

Brainly – Propeller Rings, Guards, and Baskets Are Designed to Do What: Highlights their primary purpose of preventing propeller strikes and improving safety around boats.

Boat Ed – Devices That Reduce Propeller Strikes: Discusses guards as physical barriers to reduce propeller-related accidents.

US Powerboating – Prop Guards: Details how prop guards protect both the propeller and gearbox from damage.

Frequently Asked Questions (FAQs)

What are these propeller rings, guards, and baskets built to do?

Propeller rings, guards, and baskets ensure boat safety by protecting against injuries caused by spinning propeller blades. A guard behind these safety devices essentially creates a physical barrier to lessen the chances of an accident with the propeller, especially for swimmers and passengers around the boat. They are, in fact, definitely something that a boat operator should have to ensure safety during recreational boating. Sometimes, these props also hold their own in enhancing propeller efficiency by channeling water flow around it unobstructed.

How do propeller guards affect the performance of the boat?

With propeller guards in place, the movement of water before the propeller is changed, which, therefore, affects the performance of the boat. Some say these guards slow down the ship. Still, when designed correctly, they actually can improve safety by preventing people from getting struck by propellers, without a significant loss in speed. Boat owners must always consider the size and type of propeller guards in relation to the speed requirements of their vessel, as this can somewhat affect the propeller efficiency. In many cases, the added safety benefits compensate for the slight reduction in performance.

What are propeller rings used for?

The rings serve as a protective means wrapped around the propeller. These guards encase the propeller, forming an obstruction that reduces risk factors for accidents, especially when the waters are busy or in emergencies. It is designed to prevent injury to anyone within a boat’s distance and can further contribute to safety against propeller strikes while a ship is in navigation. They might also find use in controlling and stabilizing the boat during navigation.

What types of propeller guards are there?

There are various types of propeller guards, each designed for a specific need. Some are full cages that hold the propeller inside, while others are simple structures surrounding the propeller blades. Often, the choice of prop guards depends on the size of the boat, the propeller diameter, and the boating conditions. Considerations are crucial for balancing safety and performance when purchasing propeller guards.

Are propeller guards legally required?

In some areas, propeller guards are indeed required by law, at least for boats operating within public waters. Such stipulations are meant to ensure general safety against propeller strikes. Boat operators should check the local watercraft safety regulations to ensure compliance. Property owners, even where not required, may view the installation of a propeller guard as a worthwhile investment; the guard can go a long way in protecting passengers and swimmers beside a boat.

How is a propeller guard installation a safety enhancement against propeller strikes?

Installing a propeller guard can indeed greatly enhance safety by introducing a barrier that prevents propeller strikes. This safety feature becomes exceptionally crucial for a boat driver who frequently navigates crowded areas or those with swimmers present. The guard encloses the spinning propeller blades, significantly lessening the risk that someone might get hurt. Besides, it gives boat owners the peace of mind that they have taken all possible precautions to save their own passengers and everyone else who might be swimming in the water.