Any boating enthusiast constantly seeks the best propulsion system to augment their on-water exploits, and the age-old debate between propeller systems versus jet systems continues to roll into 2025. With the dawn of new marine technologies, the need to clearly comprehend the differences between these two systems is paramount today than ever.If you are an adrenaline junkie seeking thrills through speed and agility, or just a leisure cruiser pursuing efficiency and control, that decision can truly enhance or detract from your boating experience and satisfaction. This guide will provide the latest insights, innovations, and practical considerations for both prop systems and jet systems, from which you can make an informed choice tailored to your needs. It will be a tour all-around, from performance traits to maintenance, and you shall finally discover that the specific system stands at the top as far as the contemporary boat operator is concerned.

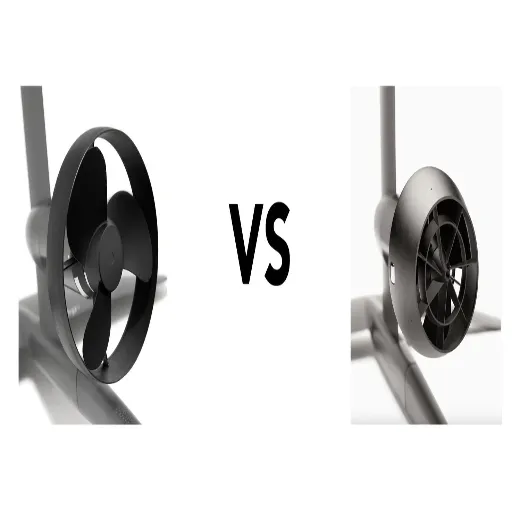

Understanding Boat Propulsion: Jet vs Propeller

How would you define Jet Propulsion?

Jet propulsion defines the expulsion of streams of water through a specially designed nozzle at very high velocity to gain thrust and propel a boat. Unlike the operation of standard propellers, the jet propulsion mechanism involves drawing water through an intake beneath the hull, accelerating it with an impeller, and then releasing it with force to counteract the vessel’s motion when moving forward or reversing. Such systems, because of their nature, work well only in shallow waters where a little risk to the propellers may be had. Jet propulsion provides fast acceleration and maneuverability, making it desirable for high-speed vessels such as jet skis, small powerboats, or commercial ferries.

Key Advantages of Jet Propulsion

- Excellent performance in shallow waters

- Minimizes underwater protrusions for safety

- Fast acceleration and superior maneuverability

- Safer for swimmers and marine life

- Reduced risk of propeller damage from debris

The design also helps minimize underwater protrusions, making it safer for swimmers and marine life to be around. However, maintenance becomes a critical factor, as it involves cleaning debris from the intake and monitoring impeller efficiency. With jet propulsion improving over the past few years in terms of fuel consumption, noise abatement, and performance, a larger spectrum of boating activities is considering it as an option.

What Is Propeller Propulsion?

Propeller propulsion is one of the most commonly used marine mechanisms, providing reliable and efficient thrust to push boats and ships through water. The blades of a propeller are typically four or more in number, attached to a central hub. When the hub turns, thrust is produced by driving a pressure difference between the front and rear surfaces of the blades that pushes the vessel forward.

Propeller Advantages

- Excellent energy efficiency

- Suitable for diverse boat types

- Adaptable to various speeds

- Proven reliability and durability

- Cost-effective maintenance

Propeller Considerations

- Risk of damage from underwater debris

- Cavitation can reduce efficiency

- Less suitable for very shallow waters

- Exposed propeller safety concerns

- Blade wear over time

Propeller propulsion systems excel in energy efficiency and provide a good ride for diverse boats, ranging from small pleasure crafts to huge commercial ships. As they have this adaptability for various speeds, they must be able to perform well when traversing open waters. At the same time, they have some disadvantages, such as the possibility of destruction by underwater debris and the cavitation phenomenon, which reduces efficiency and wears down the blades.

Among modern propeller improvements are those addressing such problems. New systems, such as controllable-pitch and shrouded-propeller types, ensure efficiencies while minimizing noise and vibrations. Material improvements, including composite blades, also extend durability and lessen maintenance requirements. Through these developments, propeller propulsion will always be a strong and evolving candidate in marine engineering.

Functional Organization Differences

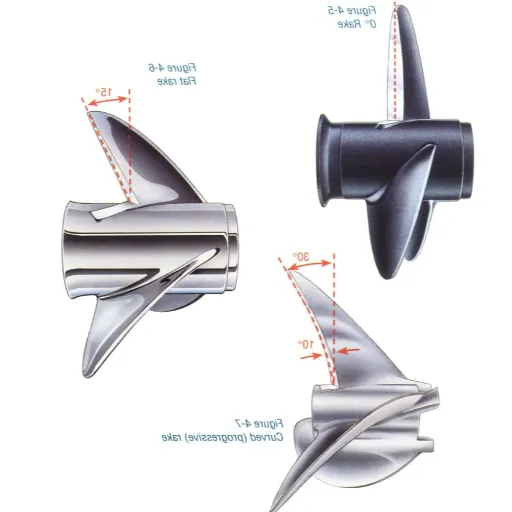

Propeller propulsion systems are highly varied in their designs and applications, each tailored to a specific need in a particular aspect of operational context. Fixed-pitch propellers are simpler in design, thus well known for their reliability and ease of maintenance. For performance adjustments, however, one is at a loss. Conversely, controllable-pitch propellers permit operators to alter the blade angle while in motion, which maximizes thrust at differing speeds and load conditions.

| Propeller Type | Design Complexity | Performance Adjustability | Best Applications |

|---|---|---|---|

| Fixed-Pitch | Simple | Limited | General boating, cost-conscious operations |

| Controllable-Pitch | Complex | High | Commercial vessels, variable load conditions |

| Shrouded | Moderate | Moderate | Quiet operations, research vessels |

| Azimuth Thrusters | Very Complex | Maximum | Tugboats, dynamic positioning |

Further distinctions exist. For example, shrouded propellers promote thrust efficiency and reduce noise; vessels that value quieter operations, above all, research vessels or submarines, are usually favored by them. In contrast, azimuth thrusters are more maneuverable as they can rotate 360 degrees and are, therefore, active on tugboats and dynamic positioning vessels. These improvements in the propeller field, as aided by respect to rituals of a somewhat different nature, demonstrate the multipurpose character of modern propeller technologies, which face every imaginable challenge in marine engineering.

Performance Comparison: Jet Boats vs Propeller Boats

Speed and Acceleration Characteristics

Propelling mechanisms pose speed and acceleration differences between jet boats and propeller boats. Jet boats, which employ waterjet propulsion, are high-speed to accelerate because thrust is generated almost immediately by drawing water into a pump and discharging it at a very high speed. This system also renders the jet boats very nimble, making them best suited for activities like watersports or cruising through shallow waterways with numerous obstacles.

| Performance Factor | Jet Boats | Propeller Boats |

|---|---|---|

| Initial Acceleration | Excellent – Almost immediate thrust | Good – Slightly slower initial response |

| Top Speed | High – Quick bursts of speed | Higher – Better sustained speeds |

| Fuel Efficiency | Moderate – Less efficient at cruising | Excellent – Superior cruise efficiency |

| Best Use Case | Short bursts, shallow water | Long-distance, heavy loads |

Propeller boats, in contrast, operate through the mechanism of traditional propeller-driven systems, which are slightly slower in the initial acceleration phase but manage to deliver better efficiency and attain higher speeds at cruising. The flatter grounds are ideal for preferred long-distance travel or heavy loads, in which steady performance is paramount. Several studies suggest that jet boats have one or the other advantage in sudden short bursts of speed, while propeller boats are better suited for endurance and fuel economy. Such divergence necessitates a careful selection of the appropriate propulsion system based on the actual work requirements and performance objectives.

Handling and Maneuverability

Depending on their handling and maneuverability, jet- and propeller-driven boats exhibit distinct characteristics that enable varying performances in different water conditions. Jet boats are renowned for their exceptional handling, particularly in shallow waterways or areas with obstructions. Their propulsion mechanism pulls water right inside the unit and then thwarts it with great speed so much so that very fine turning and abrupt changes of direction can be carried out. Thus, its use is ideal where agility is required, like in water sports, rescue, or along rivers with tight turns and somewhat unpredictable terrain. Additionally, the absence of an exposed propeller reduces the likelihood of damage, resulting in a smoother ride through waters filled with debris or other boats.

Jet Boat Handling

- Exceptional turning radius

- Rapid directional changes

- Superior shallow water navigation

- No propeller strike risk

- Excellent debris handling

Propeller Boat Handling

- Stable at slow speeds

- Linear, predictable thrust

- Easy docking maneuvers

- Consistent performance with loads

- Reliable in open water

Conversely, stability at slower speeds or in open, calm waters is often afforded to propeller boats. The mechanics generate a somewhat continuous and linear thrust that aids in easy docking or slow cruising maneuvers. The setup of propellers offers a significant advantage over jet boats for larger vessels or those traveling long distances, as their steady maneuvering prowess remains undeterred by varying loads. They may be more agile than jet boats in complex terrain, but propeller boats can be counted on for handling situations where steadiness matters more than razor-sharp response.

In recognizing the above differences, the operators will decide on the kind of boat that best meets their requirements. When considering a boat for a higher speed and quicker turns, the operating environment and use case should be taken into account to ensure a better boating experience. In light of developments in new propulsion options and the need for an appropriate framework that balances agility with stability, a decision can be made accordingly.

Fuel Trends for the Year 2025

While 2025 promises remarkable innovations in fuel-efficient boats, regulatory impetus on one hand and technological advances on the other, waterways are indeed witnessing modern propulsion systems that combine electric and fuel engines from manufacturers for better efficiency without compromising on performance. This dual-power mode slightly reduces fuel consumption while cutting emissions, a step toward sustainability that the world desires. On the other hand, the use of lightweight composites in boat making reduces the boat’s weight, thereby improving its energy efficiency. These improvements matter even more during longer journeys, when savings on even shorter refuel intervals can make a significant difference to the costs.

2025 Fuel Efficiency Innovations

- Hybrid Propulsion Systems: Combining electric and fuel engines for optimal efficiency

- Lightweight Composites: Reducing boat weight to improve energy efficiency

- Smart Energy Management: AI-powered systems optimizing fuel consumption

- Solar Integration: Renewable energy reducing conventional fuel dependence

- Advanced Hull Design: Hydrofoils and air-cushioned structures reducing resistance

A further development that is receiving much attention is the installation of intelligent energy management systems. By working with complex algorithms and feeding real-time data, these systems optimize fuel use in operation. For instance, one of the parametric route map predictions, coupled with load considerations, guides an operator to choose fuel-efficient routes and speeds. Solar energy systems, another renewable source, have come into the limelight for their integration into vessel design to generate some degree of power, thereby lessening dependence on conventional fuel. Another aspect is hull refinement, wherein hydrofoils and air-cushioned structures reduce water resistance, enabling the boat to travel longer distances using less fuel.

With these emerging developments, the year 2025 will offer a range of very green and cost-effective options to owners and operators. Driven by continuous advancements in propulsion technologies, along with improvements in design engineering and energy management systems, the boat industry promises a greener tomorrow. Such improvements translate into operational savings and further help consumers move towards environmentally sustainable solutions.

Maintenance and Durability: Engine Considerations

Jet Engine Maintenance Needs

Jet engines are renowned for their reliability and performance; however, they must also be adequately maintained to operate optimally and safely. Routine inspections may be necessary for highly stressed components, such as turbine blades, compressors, and fuel systems. Turbine blades are subjected to extremely high temperatures and pressures and are prone to wear. Maintenance schedules nowadays include the use of advanced diagnostic tools, such as borescopes, to detect early indications of damage or deterioration, allowing for timely repairs to prevent significant losses.

| Maintenance Component | Inspection Frequency | Common Issues | Diagnostic Tools |

|---|---|---|---|

| Turbine Blades | Every 100 hours | Heat damage, wear | Borescopes |

| Compressors | Every 250 hours | Blade erosion, FOD | Visual inspection, NDT |

| Fuel Systems | Every 50 hours | Contamination, leaks | Pressure testing |

| Intake Systems | After each use | Debris, marine growth | Visual inspection |

Another vital maintenance activity involves inspections for foreign object damage (FOD) and erosion. Particles, debris, or a bird strike may cause engine components to wear out, become less efficient, and possibly suffer long-term damage. Preventative measures, such as cleaning and pre-flight inspections, can significantly reduce these risks. Digital routes, however, are taking this to the next level. Predictive maintenance, powered by AI and IoT sensors, enables operators to gather performance data in real-time, allowing them to detect anomalies early and avoid unplanned maintenance.

Ensuring the durability and efficiency of jet engines relies heavily on a blend of conventional maintenance methods and advanced technologies. By integrating solid diagnostic systems and incorporating predictive analytics, this industry can significantly improve safety, reduce operational costs, and extend the lifespan of these vital components.

Propeller Engine Maintenance Views

In its maintenance, a systematic approach is necessary, including routine checks and advanced technological means. Frequent visual inspections should reveal signs of wear, corrosion, or damage to propeller blades and hubs, as these components typically bear the most significant mechanical stresses during operation. Along these lines, the critical performance parameters, such as blade pitch alignment and vibrations, should be frequently checked to ensure optimal performance and prevent imbalance, which can lead to component failure.

Propeller Maintenance Best Practices

- Visual Inspections: Regular checks for wear, corrosion, and damage

- Vibration Analysis: Monitoring for imbalance and component stress

- Ultrasonic Testing: Detecting cracks and material fatigue

- Proper Lubrication: Reducing friction and extending component life

- Scheduled Replacements: Following manufacturer intervals

Being new to the maintenance technology scene, predicted tools are modern tools that analyze engine performance data and identify problems before they become serious. For example, vibration analysis and ultrasonic testing can secretly find cracks or material fatigue in propeller blades. Machines can also be lubricated effectively to reduce friction, which increases efficiency and extends the life of the components.

Following the recommended maintenance intervals is another critical aspect of propeller engine maintenance. Replacing worn-out components is a good way to keep the system reliable. Therefore, with advanced materials used and fresh designs created, the ability to last has been enhanced, reducing the need for frequent component replacements.

By combining careful manual inspection with state-of-the-art diagnostic and monitoring processes, operators can ensure maximum efficiency and safety of propellers while incurring minimal maintenance costs over time. This integrated approach ensures a fair balance between archaic and modern systems, sustaining performance and reliability in high-demanding operational environments.

Long-Term Durability: Jet Versus Prop Engines

The long-term durability of jet engines versus that of propeller engines is a question that weighs in with some of the most critical factors in practice, operating environment, load stresses, and maintenance. Recognized for being streamlined, allowing for maximum speed operation, jet engines typically take advantage of materials like titanium alloys and ceramic composites to aid resistance to wear, while heat resistance is of greater importance. Those materials extend operational life, especially in applications where jet engines are dominant, such as high-altitude, long-distance operations.

| Durability Factor | Jet Engines | Propeller Engines |

|---|---|---|

| Material Technology | Titanium alloys, ceramic composites | Advanced steel alloys, composites |

| Operational Environment | High-speed, high-stress conditions | Variable loads, mechanical stress |

| Maintenance Frequency | Less frequent, but more complex | More frequent, but simpler |

| Expected Lifespan | 15-20 years with proper maintenance | 20-30 years under favorable conditions |

| Predictive Technology | Advanced AI diagnostics | Traditional + emerging smart systems |

With propeller engines, for example, the ones generally found on regional flights and low-speed operations, there is considerable acclaim for their sturdy construction and simplicity. These engines are subject to more frequent maintenance cycles than jets because they experience mechanical stresses due to vibration and variable workloads. The advancements in lubrication systems and engineering, however, have made these engines stronger, and under favorable operating conditions, propeller engines can function reliably for several decades.

Both engine genres–jet and prop–have profited from the advance of technology. Predictive maintenance, based on real-time data and AI-supported diagnostics, is one example whereby an operator can predict wear and tear ahead of failure, thereby extending the useful life. By utilizing these advanced techniques, operators of jets flying at high altitudes and propeller-driven aircraft working over varied terrains can optimize their performance and operational life according to their specific needs.

Choosing the Right Propulsion for Your Needs

Some of the Great Uses of Jet Boats

Renowned for their versatility, jet boats are high-speed and up to the task of handling adverse environments. These boats can operate in shallow waters, a capability their traditional prop-driven counterparts lack in rivers, lakes, or coastal regions. One of the main advantages of jet propulsion is that it does not allow a risk of propeller damage, and this aspect gains great importance in areas dotted with debris, rocks, or vegetation.

Ideal Applications for Jet Boats

- Recreational Water Sports: Jet boats support water skiing, wakeboarding, and tubing at incredible speeds while performing other adventurous feats

- Shallow Water Navigation: Their shallow draft design allows navigation through narrow rivers and streams where propeller boats cannot operate

- Rescue and Patrol Operations: Tight turning capability is essential when responding to emergencies in hard-to-reach places

- Eco-Tourism: Minimal disturbance to underwater habitats makes them practical for conservation teams and environmental operators

- Rocky or Debris-Filled Waters: No exposed propeller means reduced risk of damage in challenging environments

For recreational use, jet boats support water skiing, wakeboarding, and tubing at incredible speeds while performing other adventurous feats that boats cannot achieve due to their shallow draft design, which allows them to navigate through narrow rivers and streams. Another widespread application of jet boats is in rescue and patrol work, where their tight turning capability is a requirement when responding to emergencies in places hard to reach.

In environmental terms, jet boats pose a lesser threat to aquatic ecosystems compared to regular boats because their propulsion methods minimize disturbance to underwater habitats. That is why they are a practical consideration for eco-tourism operators or conservation teams. When it comes to jet boats, their impeccable reputation stems from the diverse demands placed on them for recreation, professional use, or environmentally conscious efforts.

Ideal Scenarios for Propeller Boats

Propeller-powered boats rank high in terms of efficiency, precision, and adaptability in running waters. Their design is suitable for long-distance travel, offering better fuel economy than jet boats. Hence, any boater or commercial operator whose mind is on cost-effectiveness during these long-distance trips will most definitely opt for propeller boats. Moreover, the propeller boat possesses its capabilities in environments such as lakes, reservoirs, and offshore operations, where water depths are fairly predictable and debris rarely clogs the propulsion.

Ideal Applications for Propeller Boats

- Long-Distance Cruising: Superior fuel economy for extended voyages

- Commercial Operations: Passenger transport, cargo hauling, luxury charters

- Precision Activities: Fishing, scientific studies, harbor navigation

- Deep Water Operations: Lakes, reservoirs, offshore environments

- Heavy Load Transport: Better torque and steady performance under load

In activities requiring steady control at lower speeds, such as fishing, scientific studies, or harbor cruising, these boats demonstrate their greatest strengths. The rudder and propeller enable the ship to be navigated with precision and maneuverability, making it ideal for any challenging task and precise positioning. Additionally, propeller boats are available in various models with distinct features to suit different requirements, including passenger transport, cargo hauling, and luxury charters.

From an economic perspective, the maintenance and repair of a propeller boat are comparatively less complicated and cheaper to carry out, especially in an area with access to skilled technicians and replacement parts. These factors, in conjunction with technological advancements that improve their efficiency and extend their lifetime, render the propeller boat suitable and dependable across many industries and activities.

Future Trends in Boat Propulsion Technology

In current boat propulsion technologies, evolving due to the environmentally friendly nature of the products, the increased need for performance, and direct reductions in operational expenses, the world has witnessed significant developments. One major trend considered here is the adoption of electric and hybrid propulsion systems. What they offer in return are near-zero or low-emission operations, low noise, and fuel savings. The advances in battery technologies, such as lithium-ion and solid-state batteries, make long ranges and short charging times possible, hence rendering this technology workable for many marine uses.

Emerging Propulsion Technologies for 2025 and Beyond

Another change is the deployment of autonomous and innovative technologies within propulsion systems. AI-based systems, along with IoT-enabled components, enable real-time monitoring, predictive maintenance, and optimal fuel efficiency. For instance, smart controls may automatically adjust propulsion output according to environmental conditions to optimize performance and minimize energy waste.

Hydrogen fuel cells are the main point of interest in marine propulsion. This clean energy releases nothing but water and heat into the atmosphere; therefore, it fulfills the demands of sustainability. Pilot projects and research initiatives on hydrogen-powered vessels are paving the way for broader adoption in the coming years, especially for large ships and commercial applications.

Additionally, highly efficient propeller designs and materials contribute to enhanced performance. The latest carbon fiber and composite materials offer propellers that are both lighter and stronger, thereby minimizing drag and maximizing speed. Concurrently, 3D printing is transforming the landscape in propeller manufacturing, enabling custom designs tailored to the specifications of a given boat, thereby introducing an additional level of performance and efficiency.

These advancements speak for themselves about the clear shift into sustainable, intelligent, and high-performance propulsion sectors that are environmentally regulated and serve the boating enthusiast and the industry of today.

Case Studies and Data Analysis

Recent Innovations in Jet Drive Technologies

Jet drive technologies have witnessed significant innovations in recent times, enhancing both performance and sustainability aspects. One such innovation sees the advent of electric and hybrid jet drive systems. Using an all-electric drive propulsion system reduces fuel consumption and carbon dioxide emissions, while maintaining the high-speed maneuverability for which jet drives are renowned. Therefore, by integrating battery technology with conventional propulsion systems, manufacturers can provide an environmentally friendly alternative that complies with strict environmental laws to their credit. This type of system is favored by operators of pristine marine ecosystems and those with established emission control programs.

Key Innovations in Jet Drive Technology

- Electric and Hybrid Systems: Reduced emissions while maintaining performance

- CFD-Optimized Designs: Enhanced efficiency through computational fluid dynamics

- Advanced Materials: Carbon fiber and lightweight alloys for durability

- Smart Monitoring Systems: Real-time performance optimization and predictive maintenance

- Noise Reduction Technology: Quieter operation for recreational and commercial use

Further developments include the refinement of designs through CFD concepts and the enhancement of materials. With the aid of complex simulations, engineers refine the jet drive shape and flow to optimize efficiency, thereby minimizing drag and maximizing thrust. Materials now include lightweight and corrosion-resistant options, such as carbon fiber and advanced alloys, whose durability and commercial efficiency enhance jet drives, making them more cost-effective in the long run. These also help quiet operations, increasing their attractiveness on both recreational and commercial fronts.

Meanwhile, in smart systems for jet drives, the intelligences are integrated for real-time monitoring of performance and predictive maintenance. These systems utilize sensors and onboard diagnostics to optimize propulsion output and alert the user to potential maintenance needs before these issues escalate into urgent matters. Together, these advancements enhance efficiency and reliability, positioning jet drives as modern options in the ever-evolving landscape of marine propulsion.

Case Study: Popular Propeller Boats in 2025

2025 paints a landscape of popular propeller boats shaped by a few notable trends chronicling their timeless interest and innovations. In recent decades, propeller-driven boats, by their very nature, have served both recreational users and commercial purposes, navigating various water conditions with the cast-iron reliability and versatility they require. The manufacturers responded to the call for design enhancements that would promote fuel efficiency and environmental friendliness, with sustainability at the forefront of their agenda. Hydrodynamics, with developments in the wake, are designed to help smooth out the ride and quicken the pace while increasing drag and noise pollution; hence, there is a better satisfaction of user demand for enhanced performance and comfort on water.

| Innovation Category | 2025 Improvements | Benefits | Market Impact |

|---|---|---|---|

| Hybrid Propulsion | Electric motor integration | Reduced emissions, lower noise | High demand from eco-conscious buyers |

| Smart Systems | AI navigation, automated controls | Enhanced safety, better efficiency | Premium market segment growth |

| Advanced Materials | Composite hulls, lightweight design | Better performance, fuel savings | Increased appeal across all segments |

| Hydrodynamic Design | Optimized hull shapes | Smoother ride, reduced drag | Enhanced user satisfaction |

One striking innovation in this field is by way of hybrid propulsion systems for propeller boats. These types of systems reduce fuel consumption, emissions, and noise by combining the use of traditional internal combustion engines with electric motors. Eco-conscious boaters and governmental agencies for marine sustainability were keen buyers of such innovations. Smart navigation and control systems also entered the limelight, providing real-time data and automated controls that improved maneuvering and adaptability to guarantee safety and enhance the user experience.

Ultimately, in 2025, it was demonstrated that propeller boats remained competitively equipped with the latest technologies while still retaining their traditional strengths. These vessels, therefore, continue to appeal to a broad spectrum of watercraft users, from advanced materials to intelligent propulsion and navigation systems, thus emphasizing that even time-tested solutions can evolve to meet the dynamic needs of contemporary times.

The Comparative Data Analysis of User Preferences

From my perspective, user preferences in the propeller boat market have always been influenced by considerations of performance, versatility, and innovation. Latest data from 2008 specify an increasing trend toward tech features, including automatic navigation, green propulsion alternatives, and smart-level safety measures, which are becoming increasingly attractive for a whole generation that appreciates convenience alongside environmental sustainability. For instance, buyers looking for hybrid-electric engine boats or AI-controlled boats are those seeking future-proof solutions that align with broader global trends.

2025 User Preference Trends

- Technology Integration: 45% prioritize innovative features over legacy systems

- Environmental Consciousness: Growing demand for hybrid and electric options

- Smart Features: AI navigation and automated controls highly valued

- Performance vs. Sustainability: Balance between efficiency and eco-friendliness

- Future-Proofing: Investment in cutting-edge solutions

Comparing traditional versus modern-day user preferences reveals significant shifts in the list of priorities. Previous consumers put somewhat more emphasis on durability and affordability, while the modern buyer, depending on a wide array of factors, may place his considerations on efficiency, innovative functionalities, and the user experience itself. Such an adjustment can be attributed to technological enhancements, as well as the increased level of expectations of modern consumers for tools that can ease operations and security functions. Survey findings also indicated that 45% of users, when purchasing new models, tend to prioritize innovative features over legacy systems, showing a strong propensity towards vessels that blend classic reliability with cutting-edge solutions.

Trends in the propulsion industry clearly indicate that the evolutionary cycle of the sector parallels shifts in consumer behavior. The further incorporation of digital marketing and the promotion of green designs emphasizes the delivery of a product that addresses the new market demand, while the legacy trust elements of traditional propeller boats remain respected. This understanding of consumer interests can assist manufacturers and designers in making their product more approachable to certain end-user groups, thereby maintaining these customers’ engagement and satisfaction.

Reference Sources

-

Jet Boat vs Propeller: Key Differences Every Boater Should Know – Buy Propeller

Highlights the advantages of jet boats in shallow waters and tight maneuvering compared to the speed and efficiency of propeller boats. -

Comparing Jet Boats vs. Sterndrive (Prop) Boats – Discover Boating

Discusses the differences in running angles, passenger load adjustments, and sea condition adaptability. -

Jet Boats vs. Propeller Boats: Which is Best for You? – Power Product Systems

Compares top speed, acceleration, and engine power between jet and propeller boats. -

How Much Do You Know About Jet Boats? – Boat Mart

Explores fuel efficiency and engine performance differences between jet and propeller-driven boats. - Find more info now.

Frequently Asked Questions (FAQs)

What are some merits and demerits of jet propulsion as opposed to propeller propulsion?

Jet propulsion systems, for instance, offer several additional advantages, including greater speed and maneuverability, particularly in shallow waters. Conversely, jets tend to suffer from poor efficiency at lower speeds. In contrast, propeller-driven systems tend to be fuel-efficient and provide relatively good torque at low speeds, making them suitable for boats traveling at slow speeds. The decision between jet and propelling systems boils down to the type of watercraft used, where fuel economy is essential, and performance is also crucial. Moreover, hull shape and weight also play possible roles in the overall efficiency of any system.

How is thrust produced in a jet engine as opposed to a prop engine?

Jet engines exert thrust by expelling high-pressure water through the nozzle set at the aft of the vessel to push the ship ahead. Contrarily, propeller-engine systems, often referred to as propeller boats, generate thrust by rotating the propeller attached to the drive system, which pushes water backward. Such differences in thrust generation affect the arrival of the watercraft’s performance stage. The jet engine allows for rapid acceleration and higher top speeds, whereas the prop engine achieves efficiency in cruising speeds, which is highly considered for long-distance travel. Both systems, in general, have their unique advantages and disadvantages, depending on the operational considerations.

How does hull design affect jet and prop power?

The hull design is quite critical to the capability of a jet or prop system to produce thrust. Generally, a well-designed hull yields better efficiency from jet propulsion by allowing a more efficient flow of water to the jet pump, and it also contributes to the generation of thrust in propeller propulsion. Performance boats, for instance, are generally hulls designed for either jet or prop systems to exploit fuel consumption efficiency and speed fully. Also, the interaction between hull and water affects the handling and stability of the watercraft. Choosing the right hull design is the first and most important consideration if the performance of the propulsion system is to be realized.

What exactly is a jet boat, and how is it different from a regular propeller boat?

A jet boat is a watercraft that is propelled by a jet drive system. The engine forces water outwards through the jet pump to build thrust. Conversely, a traditional propeller boat uses its propeller to push water backward, giving it thrust. Compared to propeller boats, jet boats typically have the advantage of shallow drafts, allowing them to navigate through relatively shallow water. However, normally, propeller boats are more fuel-efficient and less expensive when cruising at lower speeds. The final choice between a jet boat and a propeller boat depends on the intended use, performance requirements, and the nature of the water.

What is the fuel economy advantage of jet engines over propeller engines?

Fuel economy for jet and propeller engines differs significantly, primarily due to the state of operation. Prop engine fuels generally perform better at cruising speed and hence, they would be chosen for a high-economy, long-distance trip. When speed is considered, jet engines may rank higher in performance and acceleration, but their fuel consumption increases with an increase in velocity. Furthermore, other aspects also contribute to fuel economy, including throttle rank, hull design, and the vessel’s weight. The purpose of considering fuel economy and, hence, minimizing fuel costs varies depending on the engine selected for your boat.

Could the jet engine be more fuel-efficient than the prop engine?

In some scenarios, jet drives may confer unique advantages, but most of the time, they are comparatively less crude than propeller drive systems, especially at lower speeds. Jet drives are suitable for shallow waters and fast acceleration; however, if the conditions are not optimal for their operation, they will suffer greater inefficiency. Prop drive systems with efficient propellers usually retain the best fuel economy and can generate higher torque at lower speeds. The choice for installation is determined by the specific requirements that any watercraft will be asked to fulfill; thus, speed, fuel consumption, and the type of water disturbances it will face are considered. Each efficiency depends on the requirements that the specific design will provide.