The marine industry is undergoing significant transformation under the influence of technology and the growing demand for sustainability. At the heart of this evolution are ship propeller manufacturers who are redefining efficiency, performance, and environmental responsibility. By embracing the best of engineering, materials science, and design principles, these visionaries ensure that the propellers are created with minimal adverse effects on the ecosystem while optimizing fuel consumption. This paper provides an insight into the world of ship propeller innovation in 2025, along with some of the manufacturers leading this charge. Find out how these companies are furthering the cause of marine transportation by providing answers to the multi-dimensional needs brought about by the rapidly changing world.

Understanding Marine Propeller Design and Manufacturing

Key Elements of Propeller Design

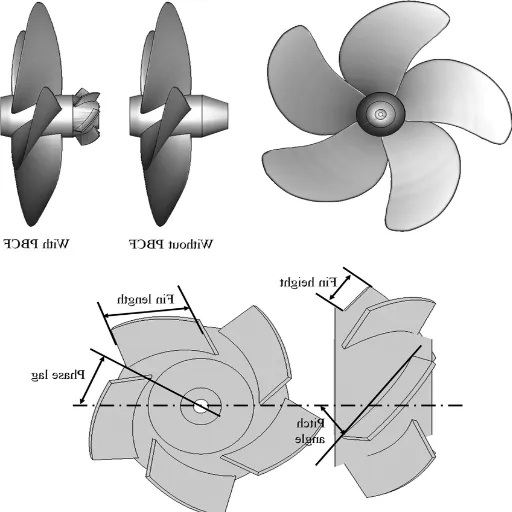

The design of a modern marine propeller utilizes advanced engineering techniques to achieve optimal performance, durability, and efficiency. Hydrodynamic efficiency remains the crucial factor that attempts to ensure an equal power conversion of the engine to thrust without loss of energy. Designers now study the flow of water around the propeller using CFD simulations-the idea being to reduce drag, turbulence, and cavitation.

Material selection has a significant impact on the longevity and serviceability of the propeller. One of the common materials considered by manufacturers is the nickel-aluminum-bronze alloy, as it resists corrosion and fatigue to a perfect measure while being strong under marine conditions. Further advancements in composite material technology are introducing lighter materials, which consequently make the propeller more fuel-efficient without sacrificing durability.

Another critical aspect in propeller manufacturing is blade geometry, considering pitch angle and skew, as well as curvature. Each is chosen to meet the specific requirements of the vessel in terms of speed, load capacity, and operating conditions. Advanced technologies, such as additive manufacturing and CNC machining, facilitate blade customization, offering performance advantages and long-term reliability.

Environmental Design Considerations

In recent years, environmentally friendly processes have also influenced propeller design. Low-noise profiles and energy-saving ducts are two features designed to reduce ecological footprints by minimizing underwater sound pollution while increasing fuel transport efficiency. These elements, together, form the blueprint for next-generation propellers that satisfy both technological and environmental needs.

Innovations in Marine Propeller Manufacturing Techniques

- Additive Manufacturing (3D Printing): The rapid development of manufacturing techniques opens the door for improving efficiency, durability, and environmental aspects. Among the most potent innovations in the manufacturing field is the introduction of additive manufacturing (3D printing), concerning exact and more complex designs that, until now, could not be achieved through traditional means. By minimizing material wastage and reducing production times, this approach makes the entire manufacturing process more sustainable and cost-effective.

- CAD and Simulation: On the other hand, CAD, in tandem with simulation, enables manufacturers to design blade geometry and predict its behavior under simulated conditions before the final production stage. Such aerodynamic and hydrodynamic modifications work to lessen drag and therefore increase fuel efficiency.

- Composite Materials: Composite materials are also used in the advancement of propellers. Using composites of carbon fiber and other advanced alloys will impart strength while significantly reducing weight. The corrosion resistance of these materials is excellent, as is their resistance to wear and abrasion. They also guarantee resistance to aging from marinating.

- Automation and Robotics: Finally, robot manufacturing systems have incorporated automation into tasks such as finishing, polishing, and quality inspection, thereby streamlining the production of propellers. These ensure precision enhancements without human error, thereby improving both their reliability and performance.

These and other innovations have collectively been molding marine propellers with the latest manufacturing techniques to achieve efficiency, durability, and a sustainable character.

Trends in Boat Propeller Technology for 2025

Impending Trends in Propulsion Systems

Key Technology Trends for 2025

- Hybrid Systems: Combining traditional combustion engines with electric propulsion

- Advanced Hydrodynamics: Superior designs to reduce drag and energy usage

- AI and IoT Integration: Real-time monitoring and predictive maintenance

- Alternative Fuels: Hydrogen and biofuel adoption

- Noise Reduction: Electric motors for environmentally sensitive areas

By 2025, propulsion systems will incorporate novel technologies, ensuring higher efficiency, reduced pollution, and improved performance. Hybrid systems are increasingly being accepted by manufacturers and consumers alike since they combine the traditional combustion engine with electric propulsion. This bimodal technique, which optimizes fuel use and reduces emissions, aligns with broader global sustainability objectives.

Another standing trend is the implementation of superior hydrodynamic designs to achieve a better course through water and reduce drag on the motor system, resulting in less energy being utilized. Simultaneously, noiseless electric motors are being developed with respect to performance and environmental emissions considerations, particularly in areas under stringent noise emission regulations.

Innovative propulsion systems are gaining momentum, including those employing artificial intelligence and IoT technologies. These systems enable real-time monitoring of working conditions, predictive maintenance, and adjustments to propulsion based on those conditions. For commercial and recreational vessels, this technology is essential to streamline operations, reduce costs, and minimize downtime.

Another trend that supports the development of green technologies is the use of alternative fuels, such as hydrogen and various types of biofuels. Clean and sustainable alternatives for powering vessels are now in demand due to increasingly stringent emissions regulations being implemented worldwide.

Besides stringent environmental norms placed by various governing authorities, continuous technological advancements go hand in hand in propelling the evolution of propulsion technology. Hence, the emphasis on hybrids, innovative technology, hydrodynamics, and alternative fuels continues to take the marine industry to the forefront of environmental challenges.

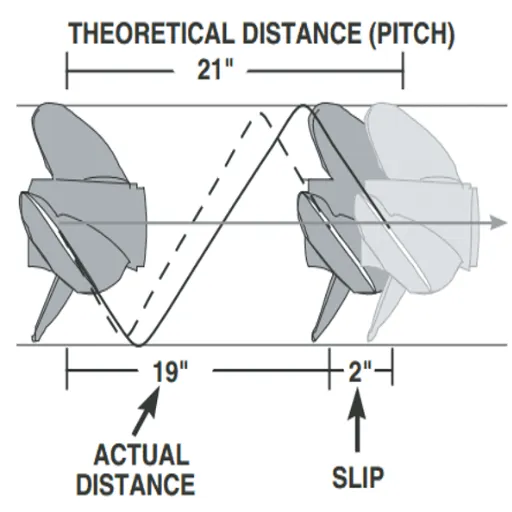

Variable Pitching in the Propeller: A Study

A critical consideration in modern marine engineering is the use of variable pitch propellers. Whereas fixed-pitch propellers do not provide operators with the option to adjust a blade angle for optimal propulsion in relation to speed or load conditions, variable-pitch propellers are adjustable in angle. This improves overall operational efficiency in terms of fuel consumption, minimizes operator costs, and adheres to environmental regulations, which are strictly enforced at present.

Insofar as high maneuverability is needed by vessels operating with precision, these vessels include ferries, naval ships, and offshore supply vessels. It also enables the vessel to accelerate, decelerate, or reverse without compromising the speed of its engines, allowing for greater control in challenging seabed conditions. Moreover, over the last decade, automation and real-time monitoring systems have been integrated into modern variable pitch systems to provide operators with detailed performance data, upon which decisions can be based to further optimize operations.

From an environmental perspective, variable pitch technology reduces emissions by optimizing propulsion to maximize energy efficiency. In conjunction with advancements in lightweight materials and hydrodynamic blade designs, these systems can arguably pave the way toward greener maritime transportation. Variable pitch propellers, thereby, remain integral to modern propulsion-system consideration where sustainability and cost-cutting methods are paramount.

Performance Impact of Sharrow Technology

Sharrow Technology Benefits

Efficiency Improvement: Nearly 9% greater efficiency at cruise speeds

Reduced Cavitation: Minimal energy loss and maximum thrust efficiency

Cost Savings: Lower fuel expenses and operational costs

Environmental Impact: Improved sustainability through efficient water flow

Sharrow technology has significantly transformed propeller design through its unique tip geometry placement, resulting in minimal energy loss and maximum thrust efficiency. Less cavitation means better propulsion performance, longer system life, and in general, better performance in Sharrow propellers compared to what is familiar with older designs. Because it facilitates efficient water flow distribution on the blades, this design saves on fuel expenses, having the second-largest effect on operational costs and improving sustainability. Field tests have proven that vessels equipped with Sharrow propellers can achieve nearly 9% greater efficiency at cruise speeds, marking a significant difference in performance and environmental benefits. It all goes to show that Sharrow technology truly stands at the forefront of creating greener and more affordable maritime alternatives.

Leading Ship Propeller Manufacturers to Watch

Industry Leader Overview: The Veem Precision Propeller Company

When discussing the giants of the ship propeller manufacturing sector, Veem comes to mind, thanks to its innovations and commitment to outstanding performance. Veem manufactures high-quality, precision-engineered propellers for commercial vessels and luxury yachts. Their state-of-the-art manufacturing process leverages modern metallurgical expertise and proprietary CNC technologies to deliver superior quality and hydrodynamic performance. Beneath these USPs lie fuel efficiency, reduced vibration, and durability that the maritime sector rates very highly.

An interesting phenomenon in the industry is associated with modular propeller design, as exemplified by the designs by Yanmar or Schottel. The design enables easier repair and maintenance while also modifying performance expectations for various vessel types. Likewise, companies like Rolls-Royce implement digital twin technology, which simulates and refines propeller performance before the construction phase, thereby streamlining operational efficiency and performance while minimizing environmental impact.

Their ability to utilize modern materials for manufacturing and design, combined with sustainable practices, provides the competitive edge to these industry leaders. Additionally, their substantial investment in research and development is shaping the future of marine propulsion systems. Performance and sustainability go hand in hand, and they remain key drivers for transformation in the marine industry.

Comparative Analysis of Custom Vs. Standard Propellers

| Aspect | Custom Propellers | Standard Propellers |

|---|---|---|

| Performance | Enhanced thrust and efficiency | General-purpose performance |

| Fuel Efficiency | 10-15% increase | Standard efficiency |

| Cost | Higher initial investment | Lower initial cost |

| Availability | Longer lead times | Readily available |

| Maintenance | Reduced maintenance needs | Standard maintenance |

The process of choosing between custom and standard propellers is a crucial one involving tradeoffs between performance, efficiency, and cost in marine applications. Custom propellers are made with individual vessels in mind, taking into consideration hull design, engine power, and operational requirements. The customized design typically yields enhanced thrust, reduced fuel consumption, and improved performance. Industry data indicate that vessels equipped with custom propellers achieve a 10-15% increase in fuel efficiency compared to ships constructed with standard propellers.

On the other hand, although expensive, they are intended to meet precise performance and efficiency requirements. In other words, they are designed and engineered to meet specific customer needs. On the other hand, standard propellers are mass-produced, making them available at relatively low prices from the perspective of operators with rather general propulsion requirements. While lacking the precision optimization of custom designs, they are more readily available, with hopefully shorter lead times and a lower initial investment. These features make them best suited for smaller operations or vessels where any such advanced customization may not be economically feasible.

Another very important differentiating factor will come from the long-term operational benefits. Custom propellers can significantly reduce maintenance due to their improved cavitation resistance, quieter operation, and enhanced durability, resulting from their specific parameters and advanced engineering. These advantages commonly allow these options to compensate for the high price paid by offering less maintenance and somewhat assured extended durability.

Ultimately, the decision between custom and standard propellers is determined by operational objectives, budget constraints, and performance requirements. In terms of fuel efficiency and sustainability, a credible case can be made in favor of custom propellers; price and availability remain focused on standard options. This mixture further illustrates how marine propulsion technology continues to evolve in response to the industry’s varying requirements.

New-age Innovative Approaches

Emerging players in marine propulsion are leveraging cutting-edge technology and data-driven dynamics, seeking to disrupt traditional practices. One partially recognized approach involves another class of advanced materials, including lightweight composites and corrosion-resistant alloys, which offer enhanced service life and improved vessel efficiency. They further provide focus on hybrid propulsion systems to compound electric and fuel propulsion in order to respond to the pressing need for a sustainable and energy-efficient solution as environmental regulations are getting stricter.

Another major trend is the adoption of digital twin technology and AI-driven analytics for optimizing propeller design and its performance. By simulating actual real-world effects on their products, companies can perfectly adjust them to specific operational environments, minimizing trial-and-error and achieving maximum aggregate performance measures. Most entrants are also pushing the envelope in manufacturing processes by using 3D printing for rapid prototyping and scaled production, thus reducing lead time and costs without compromising accuracy.

These technological advancements are supported by strategic partnerships with research institutions and maritime bodies, enabling the sharing of insights that, in turn, accelerate innovation. Regardless of the environment, these combined factors highlight how agile new entrants can be, while carving out their space as road-openers in a highly competitive market.

Challenges in Marine Propeller Performance

Understanding Cavitation and Its Effects on Efficiency

Cavitation Impact on Performance

Efficiency Loss: Up to 20% reduction in propeller efficiency

Noise and Vibration: Increased operational disruption

Surface Erosion: Damage to propeller blade surfaces

System Performance: Overall propulsion system degradation

Cavitation is a phenomenon that occurs when vapor bubbles form within a liquid due to rapid changes in pressure. Such bubbles typically form around the surfaces of marine propellers operating at high speeds or under heavy loading conditions. As the bubbles collapse, this shock wave may erode the surface of the propeller blades, drastically reducing the efficiency of the entire propulsion system.

There are greater noise levels and vibrations due to this phenomenon, which further hinder the smooth sailing of marine vessels. According to recent studies, cavitation can reduce propeller efficiency by up to 20% in severe scenarios, requiring urgent attention to proper design and performance optimization of propellers.

Nowadays, a range of computational fluid dynamics (CFD) tools is being applied in the design of propellers to predict and mitigate cavitation effects. Strategies such as blade shape optimization and the installation of erosion-resistant materials serve to maximize durability and ensure energy conservation. These solutions are particularly significant at higher standards of fuel consumption and environmental friendliness, as they cater to the growing demand for green maritime transport.

Addressing Common Performance Issues in Boat Props

To achieve maximum efficiency and reliability when investigating performance problems in propellers, several key factors must be considered. Cavitation is a highly possible issue where vapor bubbles develop in the propeller blade area due to a rapid decrease in pressure. Erosion occurs due to cavitation, resulting in a reduction of efficiency and an increase in vibration. Proper blade surface condition and correct pitch and diameter specifications must be maintained to combat it.

Ventilation is another common underwater problem that occurs when air is sucked into the propeller blades, typically resulting in thrust loss. Incorrect trim settings, damaged blades, and an ill-fitting propeller and engine specifications of the boat may be the causes. Frequent checkups and re-angling of the outboard motor, or opting for a more suitable propeller design, will minimize ventilation efficiently.

Also, at improper RPM ranges, the performance of a marine vessel will clash with one another. Installing a propeller that cycles within an engine’s design RPM range will help save fuel and reduce the engine’s stresses. New materials and coatings for propellers are introduced, which improve wear and tear resistance, thereby benefiting their lifetime and functionality.

By understanding these common performance problems and implementing precision-engineered solutions, we can reduce fuel and other long-term operational costs, making the entire industry more sustainable and environmentally friendly.

Future Solutions to Enhance Propeller Efficiency

Emerging Efficiency Solutions

- Smart Adaptive Systems: Real-time data analytics and machine learning

- Biomimetic Design: Nature-inspired blade shapes and surfaces

- Advanced Materials: Carbon fiber-reinforced composites

- Energy Harvesting: Micro-hydroelectric generation systems

Emerging technologies and the concomitant innovative methodologies appear to significantly increase propeller efficiency for maritime operations. However, one promising avenue remains the concept of intelligent and adaptive propulsion systems. Such a system utilizes real-time data analytics and machine learning algorithms to monitor the propeller’s performance and dynamically adjust thrust according to varying operating conditions. For example, speed, load, and water currents may be some of these conditions.

The other comes in the form of advanced biomimetic design applications. Inspired by the humpback whale and fish, researchers seek to design propeller blades with unusual shapes, grooves, or even somewhat compliant surfaces. Their goal is to reduce cavitation, enhance hydrodynamics, and decrease noise pollution while improving fuel consumption.

The orientation toward sustainable materials is gaining momentum. Engineers are investigating lightweight yet rigid composites, such as carbon fiber-reinforced polymers, which are resistant to the corrosive environment of the sea while lowering the vessel’s weight and drag. Through the integration of energy-harvesting systems, such as micro-hydroelectric generation within the propeller structure, the vessel can capture and reclaim energy lost during normal operations, thereby improving its efficiency and environmental sustainability.

By implementing such solutions, the industry takes a crucial step toward addressing environmental concerns and making informed, long-term decisions that lead to cost reductions and operational excellence. These futuristic technologies clearly point toward an excellent vision for more innovative and environmentally friendly propulsion systems.

Successful Implementations of Advanced Propellers

Real World Applications of High Performance Marine Propellers

In my experience, high-performance marine propellers have lived up to their name in a few remarkable real-world applications. For instance, in maritime affairs, with better propeller designs engineered from superior materials, fuel consumption has been minimized, even with an overall enhancement in vessel efficiency. Commercial shipping companies have implemented such technologies to comply with stringent environmental regulations, such as those set by the IMO, which call for a reduction in carbon emissions. Hence, the shift has not only helped lessen the environmental impact but has also closed the cost-ability gap for large-scale operations.

Another approach I can think of is in the yachting and recreational boating sectors, where very-high-performance propellers enable smoother, more stable navigation. Speed and maneuvering must be jointly optimized for these vessels, all without compromising fuel efficiency. Modern designs of propellers formulated to an individual vessel’s specifications provide a delicate balance between performance and sustainability and are hence embraced by both environmentally conscious owners and manufacturers.

In offshore wind or deep-sea exploration, on the other hand, advanced propellers are on top-of-the-line instrumentation that allows precise positioning and operational stability. Dynamic positioning systems utilize propeller technologies to maintain the vessel’s stability in ever-challenging conditions, combining safety and operational precision. Real-world scenarios bring to life the potent applications of high-performance marine propellers across different sectors of the marine industry.

Comparative Performance Metrics of Different Propeller Types

| Propeller Type | Thrust Efficiency | Energy Consumption | Noise Levels | Cavitation Resistance |

|---|---|---|---|---|

| Fixed-Pitch Propellers | High under set conditions | Optimal for simple routes | Moderate | Moderate |

| Controllable-Pitch (CPP) | Adaptable | Reduces energy waste | Quieter | High |

| Ducted Propellers | Best for high-thrust work | Efficient at low speeds | Medium | Enhanced |

| Propeller Pods | Highly effective | Energy-efficient | Very low | Good |

| Surface-Piercing | High-speed vessels | High energy input | Higher | Less resistance |

The various metrics that measure the efficiency, reliability, and suitability of propellers for maritime work include thrust efficiency, energy consumption, noise levels, cavitation resistance, and environmental considerations. Presented above is a comparative evaluation of these aspects with the common propeller types.

With such metrics evaluated, the operator can ensure that propellers are set in line with operational parameters, depending on efficiency or environmental considerations. Yet, this dynamic acceptability of propeller types continues to advance marine engineering, enabling it to meet the requirements of modern navigation and its sustainability.

Lessons Learned in Terms of Recently Installed Marine Propulsion Systems

From recent projects in marine propulsion, I have learned that integrating advanced technologies is vital to achieving operational efficiency and environmental sustainability. For example, during the design phase of propulsion systems, CFD was used to gain accurate insight into propeller performance. Real-world conditions were simulated to design a propeller that reduces cavitation and increases overall hydrodynamic efficiency, thereby saving fuel and reducing emissions. This practical application of advanced tools has driven home the point that technology is an enabler for sustainable innovations in the maritime sector.

Basically, another vital lesson has taught us about multidisciplinary teamwork. The ability to communicate effectively among naval architects, engineers, ship operators, and environmental scientists appears to be critical for achieving a balanced approach to performance versus compliance with international emissions regulations. Such collaboration promotes the sharing of knowledge for developing tailor-made solutions alongside hybrid propulsion systems and energy-efficient hull designs. Each project has further cemented the importance of working together to develop ideas and the evolution of the propulsion systems in the right direction towards operational requirements and on the regulation agenda that keeps changing.

On the other hand, I have realized that stakeholder engagement at the beginning of a project is crucial to ensure the success of propulsion upgrades or new system installations. The engagement of operators and crews has yielded insights into practical considerations, such as maintenance and operability, while there may be a strong focus on technical considerations in design. Equally vital, it strives to ensure that the solutions implemented meet not only technical requirements but also align with the day-to-day practicalities of maritime operations, with a strong commitment to achieving better results in practice.

Reference Sources

-

2025 EMP Propeller Catalog – Engineered Marine Products: Highlights new propeller lines with advanced features and compatibility.

-

How Leading Boat Propeller Manufacturers Are Innovating in 2025 – Captain Propeller: Discusses key innovations shaping the maritime industry in 2025.

-

CJR Propulsion: A leading UK-based manufacturer known for precision-engineered propeller and sterngear packages.

-

Marine Propeller Market: Trends, Innovations, and Future – IDST: Covers advancements by companies like Caterpillar, MAN Energy Solutions, and Hyundai Heavy Industries.

-

Marine Propeller Companies – Top Company List – Mordor Intelligence: Lists top manufacturers such as Wärtsilä, Hyundai, Mitsubishi, Schottel, and Nakashima.

- Find more info now.

Frequently Asked Questions (FAQs)

What types of propeller designs are offered by marine propeller manufacturers?

Typically, marine propeller manufacturers provide a range of options, from fixed-pitch and variable-pitch designs to custom solutions tailored for special applications. They may utilize modern techniques, such as CFD (computational fluid dynamics) analysis, to design the most hydrodynamically efficient propellers. Another choice they may offer manufacturers is the type of material used, such as stainless steel propellers or aluminum bronze, to enhance the performance and longevity of an installation. Design and manufacturing are performed with utmost care and expertise to meet the stringent tolerances required for marine performance.

How do boat owners select the right boat propeller for their vessel?

The type of boat, engine specifications, and other desired performance characteristics should determine the selection of boat propellers. Propellers may thus be designed for use with outboard or inboard engines. The performance of a boat depends significantly on its pitch, diameter, and blade configuration. Once, there were five blades, or just one stainless steel blade, which was one of the other options. The net profit or an overall propeller needs to maximize fuel efficiency and performance, taking into consideration the expected operating conditions, such as displacement and maximum speed. A consultation with a producer of marine propulsion equipment will be of paramount assistance.

What is cavitation concerning a marine propeller?

In the increased water flow, the pressure drops below the vapor pressure around a propeller. Bubbles form and collapse violently, causing damage to the propeller blades. Cavitation significantly changes the performance and lifespan of a propeller. Practitioners avoid cavitation by taking zealous measures to create a propeller that minimizes adverse effects, such as modifying the blade rake and contour. Therefore, it is essential to recognize cavitation to ensure that a propeller maintains optimal propulsion performance while minimizing noise and vibration problems. Due to maintenance and inspection, these measures may also help mitigate cavitation-related issues.

What materials are commonly used in the manufacturing of ship propellers?

The materials chosen for the ship propellers are generally stainless steel, aluminum bronze, and manganese bronze, each having its own advantages. Propellers made of stainless steel are strong and resistant to corrosion, making them suitable for high-performance applications. Aluminum bronzes are often favored because of their wear resistance and ability to withstand harsh marine environments. Manganese bronzes fall somewhere in between, offering a balance of strength and corrosion resistance suitable for various marine applications. Another factor to consider regarding the use of these materials is the consumption of fuel, durability, and, consequently, performance. Hence, these considerations are of utmost importance for manufacturers and boat owners.

What is the function of CNC machining in the manufacture of propellers?

In manufacturing, CNC machining is an integral part of propeller testing and maintenance; therefore, attention is paid to each propeller set regarding precision and consistency. By being fully CNC machined, each blade of the propeller is carefully created with specific instructions for optimal performance. In this way, manufacturers can tighten tolerances and create intricate designs that would otherwise be too difficult to manufacture using older methods. CNC machining further enhances the capacity to manufacture custom propellers, integrating variable designs to meet particular vessel needs to improve performance and fuel efficiency. Hence, CNC technology serves as a path for innovation in marine propellers.

How do marine propeller manufacturers ensure optimum performance?

Marine propeller manufacturers ensure that they achieve the highest levels of performance by utilizing advanced design techniques with high-quality materials and rigorous testing. Computational fluid dynamics (CFD) is often used to simulate and analyze propeller performance under different conditions, allowing for design changes that improve performance and efficiency. Moreover, they utilize fully CNC-machined components with tight tolerances, essential for a well-balanced operation. The propellers are regularly tested to ensure the highest level of fuel economy and vibration level, meeting all industry standards and customers’ expectations. Manufacturers innovate and focus on performance, thereby creating high-quality products that complement marine propulsion systems.

The Future of Marine Propulsion is Here

Leading ship propeller manufacturers are driving the industry forward with innovative designs, advanced materials, and sustainable technologies. From AI-powered systems to biomimetic designs, the marine propulsion landscape in 2025 promises enhanced efficiency, reduced environmental impact, and superior performance across all vessel types.