When your boat begins to lose performance, it is usually the initial warning sign that trouble lies below the surface, such as propellers spun, a lower unit damaged, etc. So keep your vessel efficient and satisfied with higher speeds and lower fuel consumption, which can be achieved with little frustration. The good news is that smooth sailing is just around the corner. In this compilation, we will walk you through the entire diagnosis, repair, and prevention of these common issues. Even as we explore how to identify the signs of a spun prop and move through a few lower-unit repair tips, the ultimate goal is to retune this poor yet so much fun vessel into one that watches the sunsets at noon. Please don’t be shy; even you Indies could use an article on boat maintenance! Stay with us as we delve into expert tips, workable fixes, and must-have tools to get out on the water as quickly as possible.

Understanding the Spun Prop and Lower Unit Mechanics

What is a Spun Prop and How Does It Affect Performance?

It is called a spun prop when the rubber hub inside your boat’s propeller is damaged or disconnected from the propeller’s outer casing. This typically occurs due to wear and tear, a sudden impact, or when the engine is overloaded. When this issue occurs, the engine may send power to the propeller inefficiently, resulting in a complete loss of performance from the propeller.

Key Performance Indicators:

- Excessive engine revving without increasing speed

- Reduced acceleration

- Poor fuel mileage

For instance, a good propeller pushes the boat smoothly and utilizes the available power at an optimum rate, reaching the desired speed and efficiency. In contrast, a damaged prop might cause you to end up stranded or incur costly repairs.

In simple terms, the lower unit, consisting of the gearbox, shafts, and propeller, would bear the brunt of the effects of a spun prop. This would lead to continuously stressing the engine and the lower unit, and eventually, the two may develop mechanical problems if no timely intervention is made. Vigilant inspection and maintenance, in addition to fitting high-quality components, will protect against such occurrences and ensure optimal performance.

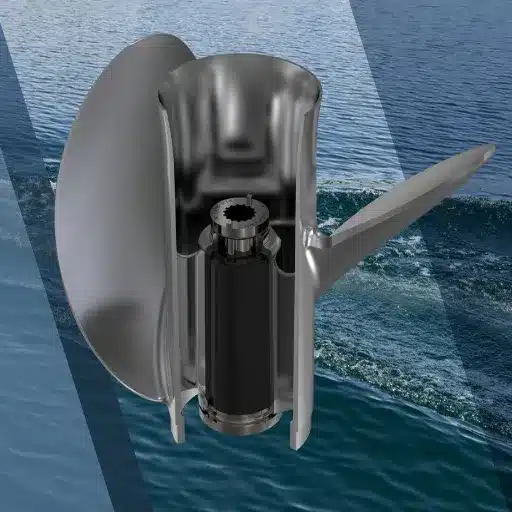

Overview of the Lower Unit Parts and Accessories

The lower unit of a marine engine serves as a critical conduit between the engine and the body of water, facilitating transmission and propulsion. It is composed of several interdependent parts, each of which is crucial for optimal operation.

Primary Components:

- Driveshaft: Runs from the engine to supply power

- Gearbox: Converts rotational motion for effective propeller driving

- Propeller: Provides thrust by pushing water away

Critical Features:

- Lower Gearbox: Protects internal gears from external elements

- Seals & Gaskets: Keep enclosure watertight

- Water Pump: Circulates water through cooling system

⚠️ Maintenance Checklist:

- Look for possible wear on the seals

- Check the propeller for damage or warping

- Detect signs of contamination in the gear oil

Keeping the lower unit in optimal condition not only improves the engine’s performance but also prevents significant repair expenses and downtime in the long run.

The Prop Hub’s Role in Efficient Boating

Conversion of engine power to movement of the boat through water is carried out by the propeller system, of which the prop hub is a paramount part. Energy loss occurs if these hubs and propellers are not suitably designed and harmonized. The result is a smooth operation and efficient fuel consumption.

With the advent of new technologies in the field, the development of improved materials and designs has been pursued to reduce vibrations, enhance durability, and improve performance. For elastomer-type hubs, such as the ones that absorb shock from sudden impacts or torque fluctuations, the best possible protection is ensured for the rest of the drivetrain against damage.

Next to the engine work, prop hub selection should be efficient for that engine and that specific boat. Evidence suggests that a mismatched prop hub could result in considerable performance loss, including a reduction in top speed and increased fuel consumption, which are essentially two key parameters.

The next necessity would be to inspect for wear signs, such as cracks or deformations, periodically, so that the prop works as intended. Leveraging new advances in prop-hub design within everyday practice promotes not only efficiency but also curtails the environmental footprint through reduced fuel consumption and emissions.

Diagnosing a Spun Prop or Lower Unit Issue

Common Signs of A Spun Hub or Propeller Issue

A spun hub or propeller problem will be evident in the boat’s performance, as felt by the operator. One of the most common signs of this problem is an abrupt loss of speed and power, which contrasts with high engine RPMs being recorded by the tachometer. This happens because the hub, which serves as a rubber-cushioned link between the propeller and propeller shaft, has lost its grip, causing it to slip under load.

🚨 Warning Signs to Watch For:

- Abrupt loss of speed and power with high engine RPMs

- General lack of acceleration or difficulty attaining plane

- Strange vibrations or abnormal engine notes

- Propeller flailing in the water without effective thrust

Another telltale sign is a general lack of acceleration or difficulty in attaining plane, where the slipping hub unwillingly interferes with the transfer of energy from the engine to the water. You might feel strange vibrations or hear an abnormal engine note as the propeller flails in the water or even in trying to engage with the thrust in vain.

💡 Inspection Tip:

Remove the propeller and look for melted rubber fragments or pronounced wear around the hub. Early detection and addressing the problem begins to safeguard your boat, allowing it to continue performing safely and efficiently, thus avoiding further damage to the drivetrain components.

Diagnosis Procedure Step-Wise

Identifying Symptoms of a Spun Hub

Observe the boat. Symptoms such as loss of thrust with a sudden increase in RPMs, which do not correspond with speed, or slight vibration can all indicate a problem with a spun hub. Take note of any changes in the engine’s behavior, as these will help narrow down the issue significantly.

Perform a Propeller Slip Test

Mark a line with a waterproof marker on both the propeller hub and on the propeller shaft. Run the boat at low throttle for a short while and then shut the engine down. If the marks are no longer aligned, this is clear evidence of a spun hub.

Look for Damage on the Propeller Hub

Carefully remove the propeller and inspect the hub for visible wear or damage. Signs of a spun or failing hub include melted rubber, cracks, or debris on the surface. These checks should be complemented by inspecting the blades for any related damage.

Check for Proper Fit and Connection

Ensure the propeller is seated correctly and securely fitted onto the shaft. Any loose-fitting may contribute to slippage that can mimic the symptoms of a spun hub. Inspect the condition of the splines and ensure they are not overly worn.

Controlled Testing

Once you have adjusted or repaired, try in controlled conditions with moderate throttle levels. Monitor other performance metrics, such as speed, RPMs, and vibration levels, to assert that the issue has indeed been resolved.

🎯 Result:

In this manner, systematically proceed to diagnose spun hub type issues and implement remedies to ensure the boat is at peak performance before it is delayed, allowing time for mechanical failure to be addressed. Acting quickly will reduce potential downtime and possibly defend the drivetrain from getting damaged even further.

Making Use of Yamaha Tools for Precise Diagnosis

Yamaha has developed a broad assortment of specialized diagnostic tools to make troubleshooting outboard engines easier and more effective. The Yamaha Diagnostic System (YDS) kit, for instance, enables direct interfacing with the engine’s ECM to extract vital information such as fault codes, engine hours, and performance parameters. These data sets can help determine the existence of either mechanical or electronic problems.

YDS System Capabilities:

- Direct ECM interfacing for fault code extraction

- Engine hours and performance parameter monitoring

- Real-time component testing (fuel injectors, ignition systems, sensors)

- Step-by-step evaluation processes

Incorporating these tools into your diagnostic routine can enable quick testing of components such as fuel injectors, ignition systems, and sensors. For instance, the YDS software can monitor engine parameters in real-time, enabling you to conduct an analysis specifically tailored to the operation itself. Following a step-by-step evaluation process, the tools can eliminate trial-and-error methods and reduce repair time, thereby keeping recreational and commercial crafts running at full capacity.

Repair Techniques for a Spun Prop or Lower Unit

Repairing or Replacing: When to Make the Decision

Choosing between repairing and replacing a spun prop or lower unit depends on factors such as the extent of damage, cost, and the long-term functionality of the component.

✓

When to REPAIR

- Less severe damage

- Wear on propeller blades

- Slightly spun hub

- Seal or bearing issues in lower unit

- Cost-effective re-hubbing option available

✗

When to REPLACE

- Heavy structural damage

- Seriously bent or cracked propeller

- Compromised structural integrity

- Repair costs exceed replacement costs

- Internal lower unit damage

Operational Considerations:

- Commercial vessels: Replacement ensures less downtime and peace of mind

- Recreational users: Minor repairs may suffice depending on usage intensity

- Budget considerations: Factor in long-term durability and maintenance costs

This factor is crucial for achieving optimal performance and preventing more significant mechanical issues.

How to Fix a Spun Prop Hub

If the performed operation interrupted the spinning propeller hub, the resulting unfavorable impact on the boat’s performance would be caused by the inability to feed power from the engine to the propeller smoothly. Should you face such an issue, follow these steps to fix the problem:

Identify the Symptoms of a Spun Prop Hub

Be sure you have a spun hub before proceeding. Common signs include slipping at high RPMs, a lack of thrust, and the engine revving without much corresponding momentum. Inspect the propeller and hub for visible damage or excessive wear.

Remove the Propeller

Remove the propeller from the shaft safely and securely. Take a wrench, loosen, and remove the prop nut, washer, and cotter pin if any. Slide the propeller carefully to position it correctly over the hub assembly.

Inspect the Hub Assembly

Inside the hub, examine the rubber insert for any damage or misalignment. Such is the case in a spun hub, where noticeable wear or deformation is evident in this area. It is time to repair or replace the hub if the rubber is found to be deteriorated or has been removed from the housing and has come loose.

Replace the Hub Insert

If the hub is replaceable, depending on your propeller design, a new rubber hub insert can be pressed into place. Hub repair kits, compatible with various propeller models, are available in many marine supply stores. Use a hydraulic press or take the hub insert to a local shop that can install it for you.

Rebalance the Propeller

With new hub inserts installed, the propellers should be carefully balanced to prevent vibrations that can cause damage to your engine and drivetrain. This can either be done professionally or by yourself, using a propeller tuning tool if you have one.

Reinstall the Propeller

Place the propeller on the shaft, ensuring all other components are in place, including the washer, locking device, and nut. The prop nut should then be firmly tightened to the manufacturer’s prescribed torque to prevent it from wobbling during operation or, worse, slipping off.

Test Your Repairs

A water test should be conducted under normal operating conditions immediately after the propeller is installed, and observe if the problem persists. If smooth acceleration is restored to the boat and power is accurately transferred, then the repair is deemed successful.

🔧 Important:

Getting a spun prop hub repaired promptly will prevent further mechanical failures and ensure dependable boating performance. Proper maintenance and prompt repairs can save time and avoid costly downtime.

Essential Tools for Lower Unit Repairs

A just lower-unit repair requires the tools that will put it there with precision, ease, and long-term service. Some of the tools a marine technician or a DIY enthusiast must consider having are:

🔧

Propeller Wrench

Specialized wrench designed to remove and install the propeller safely, preventing damage. Find one that accommodates various sizes of propeller nuts for added versatility.

📊

Gearcase Pressure Tester

Helps identify leaking seals and gaskets of the lower unit under pressure. Essential for preventing water ingress into the gearcase and potential severe internal damage.

⚡

Torque Wrench

Essential for final production stage bolt-fastener-tightening according to manufacturer specifications. Prevents over-tightening or under-tightening issues.

🛢️

Marine Grease

High-quality, water-resistant grease for lubrication areas such as seals, prop shafts, and bearings to prevent corrosion and ensure smooth operation.

🔄

Seal Puller and Installer Kit

Essential for installation or removal of seals in limited gearcase space. Prevents damage during seal replacement, which can create functionality issues.

⚙️

Bearing Carrier Puller

Required for disassembling the lower unit and servicing internal parts such as gears and shafts. Enables quick and safe removal without damaging surrounding parts.

🚰

Drain and Fill Pump for Gear Oil

Designed for standard gear oil maintenance tasks. Facilitates smooth and clean draining and filling of oil in the lower unit.

📖

OEM Repair Manual

Original equipment manufacturer manual offering diagrams and instructions tailored specifically for your outboard motor or sterndrive.

🔍

Inspection Mirror and LED Flashlight

Essential for inspecting parts deep inside the lower unit. Strong illumination helps identify cracks, wear, or other issues not visible at first glance.

🔒

Thread Locker Compound

Marine-grade formulation prevents screws and bolts from loosening over time due to vibration or high-speed operations.

💡 Investment Tip:

Such tools will ensure that your lower-unit repair is complete and reliable. Good tools are an investment; they make your marine equipment last longer and help you recover the downtime lost due to improper maintenance or half-hearted repairs.

Choosing the Right Spare Prop and Hub Kits

Factors to Consider When Selecting a Spare Prop

When choosing a spare prop for your marine vessel, several key factors demand your attention to ensure it performs to your liking and will adequately service your boat or ship.

🔧 Material Selection

- Aluminum: Lightweight and inexpensive

- Stainless Steel: More demanding but efficient at higher cost

📐 Dimensions

- Pitch: Affects boat speed and fuel consumption

- Diameter: Impacts engine performance

- Always refer to engine manufacturer’s instructions

⚙️ Blade Configuration

- Fewer blades: Provide more top speed

- More blades: Improve acceleration and cruising experience

🌊 Water Conditions

- Shallow water requires specialized props

- Debris-filled water needs stress-resistant designs

- Consider typical operating environment

🎯 Compatibility Check:

Another thing to check is the gear ratio compatibility and snug fit of the prop with your hub kit. By considering these aspects, you enhance the boat’s performance and its long-term reliability.

Recommended Spare Prop and Hub Kits for 2025

Choosing the spare prop and hub kits for 2025 is one of the most crucial steps one can take to enhance performance and durability under varying boating conditions. Below are some high-performance kits to cover all needs:

Mercury Spitfire X7 Propeller and Flo-Torq Hub Kit

| Material: | Stainless steel for enhanced strength |

| Design: | Aggressive four-blade design |

| Compatibility: | 75-150 HP mid-sized outboards |

Why Choose It:

Top-rated fuel efficiency and minimal vibration make it suitable for long-haul trips. Perfect for water sports enthusiasts and serious boaters.

Yamaha Reliance SDS Propeller and SDS Hub Kit

| Material: | Aluminum with corrosion-resistant coating |

| Design: | Three blades with SDS technology |

| Compatibility: | 150-300 HP Yamaha high-thrust outboards |

Why Choose It:

Shift Dampener System (SDS) reduces noise while offering excellent handling for fishing and recreational crafts.

Turning Point Hustler Propeller and MasterGuard Hub Kit

| Material: | Reinforced aluminum at economical price |

| Design: | Vented design for maximum ventilation |

| Compatibility: | 40+ HP outboards and sterndrives |

Why Choose It:

Budget-friendly choice that perfectly marries cost with dependable performance in fresh and salt waters.

BRP Evinrude RX4 Stainless Steel Propeller and Hub Kit

| Material: | Highly polished stainless steel |

| Design: | Four-blade design for firm grip |

| Compatibility: | 200-300 HP large outboards and sterndrives |

Why Choose It:

For top-tier customers requiring top performance and robust load handling capabilities in real-world environments.

🎯 Selection Guidelines:

Each of the kits selected here excels in providing extra thrust, robustness, and overall improvement in boating performance. When selecting your spare propeller kit, consider the normal load or horsepower rating required at speed, as well as the water conditions in which your boating adventure is set to take place. Investing in a trusted spare kit can prevent unexpected breakdowns and keep your boating days smooth throughout the year 2025.

Comparisons Between Yamaha Propeller Choices

When comparing Yamaha-propeller options, performance characteristics should always be measured against the actual boating needs in terms of speed, fuel economy, and handling ability. Yamaha offers an extensive range of propellers for various applications, with a strong emphasis on high-quality materials and precision engineering.

| Comparison Factor | Stainless Steel | Aluminum |

|---|---|---|

| Strength | Superior strength and durability | Lighter weight but less durable |

| Performance | High-horsepower boats, excellent acceleration and top speeds | Light loads and recreational boating in calmer waters |

| Cost | Higher investment | More economical option |

| Best Use | Performance applications, harsh waters | Recreational use, calm conditions |

🏆 Performance Series

- Reliance Series: Mid-range boats with good speed and fuel economy

- Saltwater Series II: Enhanced corrosion resistance for harsh saltwater environments

📐 Size and Pitch Options

- Lower pitch: Better acceleration for towing activities

- Higher pitch: More maximum speed capability

- Multiple diameters available for specific requirements

🚀 Unique Features and Innovations:

Shift Dampener System (SDS): Yamaha integrates design and engineering innovations into its propellers. The SDS significantly reduces vibrations and noise, providing a smooth ride through gear changes. This is particularly desirable for frequent boaters, as comfort is the top priority.

Based on the evaluation of these factors and their adjustment with your boating specifics, Yamaha’s entire range of propellers thus guarantees an optimum solution for performance. Depending on whether the use is recreational or commercial, a propeller has a direct bearing on your actual water experience, efficiency, and fulfillment.

2025 Trends in Boat Propeller Technology

Design Innovations for Performance Upgrades

The very act of innovating in propeller technology is shaped by the development of new materials and engineering techniques suitable for achieving enhanced performance and efficiency.

🧪

Advanced Materials

- Lightweight composite materials

- Reduced overall weight while maintaining strength

- Enhanced durability and longevity

- Improved fuel efficiency capabilities

🖨️

3D Printing Technology

- Advanced hydrodynamic modeling

- Precision blade design and manufacturing

- Minimized drag and maximized thrust

- Smoother operations and greater maneuverability

⚙️

Variable Pitch Propellers

- Real-time blade angle adjustment

- Optimal thrust under varying water conditions

- Reduced engine wear and tear

- Enhanced adaptability and performance

🔇

Noise Prevention Features

- Integrated noise-reduction technology

- Quieter and more comfortable boating environment

- Enhanced user experience

- Reduced environmental noise impact

Emerging Technologies in Lower Unit Manufacturing

This field evolves with the emergence of new materials, better engineering, and greater innovations in automation.

🔬 Advanced Materials

Composites and alloys that improve durability while reducing weight. These materials extend the life of the lower units by protecting them from adverse marine environments.

🤖 Manufacturing Automation

Automated assembly processes ensure accurate construction with minimal human error, resulting in superior performance and reliability of components.

🖨️ 3D Printing Integration

Revolutionizes prototype development, allowing for quicker iterations and cost-effective testing of designs with new geometries for enhanced hydrodynamics.

📡 Smart Sensors & IoT

Integration of smart sensors and IoT components provide real-time performance data and facilitate predictive maintenance for enhanced performance.

🎯 Future Impact:

These technologies contribute to enhancing performance while presenting insightful data that allow a boatman to fine-tune their engine for environmental friendliness and fuel conservation.

Environmental Considerations in Propeller Manufacturing

When protecting the environment during propeller production, attention should be paid to adopting sustainable and eco-conscious practices throughout the entire manufacturing process.

♻️

Sustainable Materials

- Sustainable or recycled metals (aluminum, stainless steel)

- Composite materials from renewable sources

- Reduced natural resource depletion

- Lower carbon footprint from raw material extraction

🏭

Waste Reduction

- Precision machining for efficient material use

- Scrap metal recycling programs

- Minimized landfill waste

- Energy-efficient plant operations

🔄

End-of-Life Sustainability

- Design for repair and reuse

- Recyclable component construction

- Extended propeller lifespan

- Reduced demand for new manufacturing

🌱

Green Energy Integration

- Renewable energy in manufacturing

- Energy conservation in machine operations

- Reduced carbon footprint

- Environmentally conscious production

🌍 Environmental Commitment:

By employing environmentally conscious processes in propeller construction, manufacturers aim to ensure a greener future for the marine industry while meeting performance demands and customer expectations.

Reference Sources

-

How to Fix a Spun Prop Hub: Permanent and Temporary Fixes – Propeller Propeller: A complete guide covering DIY hacks and professional replacements for fixing a spun prop hub.

-

How To Replace A Spun Hub On A Boat Prop – Salt Strong: A video tutorial by Capt. Mark “Hollywood” Johnson on effectively replacing a spun hub.

-

How to Diagnose and Deal with a Spun Hub – Mercury Marine: Explains how propeller hubs protect lower-unit gears and how to address failures caused by age, heat, or impact.

-

How to Diagnose and Fix a Spun Prop: Protect Your Lower Unit – Captain Propeller: Offers step-by-step instructions to identify and repair spun prop issues while protecting the lower unit.

-

What Causes a Spun Prop Hub? – Boating Magazine: Discusses causes of spun prop hubs and options for repair, including professional services and costs.

- Click here to read more.

Frequently Asked Questions (FAQs)

How do you diagnose a spun prop hub?

Diagnosis of a spun prop hub entails several steps. First, you want to see if the propeller spins freely when the engine is in gear; this is a typical symptom of a failed hub. When the engine revs up without the boat moving, this usually implies slipping of the prop on the hub.This should also be an inspection of wear on the prop shaft and the rubber hub. Try to turn the prop and see if it engages correctly. If you suspect you have a spun hub, it will help to post on a boating forum and solicit advice from other boat owners.

What should I do if my lower unit gets locked?

If the lower unit is not engaging, it may be due to an issue with the shift cable or the gearcase. The first step would be to verify that the throttle works perfectly. If the engine revs up but the boat does not move, then the prop may have spun or the coupler might have failed. Check the driveshaft and gears for signs of damage. At times, the problem may be as simple as having insufficient gear oil, so ensure your lower unit is well lubricated. Get a mechanic if you are not confident enough to do a check yourself.

If the lower unit is not engaging, it may be due to an issue with the shift cable or the gearcase. The first step would be to verify that the throttle works perfectly. If the engine revs up but the boat does not move, then the prop may have spun or the coupler might have failed.

Check the driveshaft and gears for signs of damage. At times, the problem may be as simple as having insufficient gear oil, so ensure your lower unit is well lubricated. Get a mechanic if you are not confident enough to do a check yourself.

Can I replace only the prop hub?

Yes, the prop hub can be replaced if it is damaged. Many boat owners, however, favor an interchangeable hub system, which means that replacing a propeller does not involve buying another one. When installing the new hub, check to see if the prop blades are damaged. The blades should be in perfect condition for maximum performance. It is best to use a new rubber hub for proper engagement. If you are uncertain, a good prop shop should be visited for advice; it will inform you which spare prop and hub kit will best suit your needs.

Yes, the prop hub can be replaced if it is damaged. Many boat owners, however, favor an interchangeable hub system, which means that replacing a propeller does not involve buying another one. When installing the new hub, check to see if the prop blades are damaged.

The blades should be in perfect condition for maximum performance. It is best to use a new rubber hub for proper engagement. If you are uncertain, a good prop shop should be visited for advice; it will inform you which spare prop and hub kit will best suit your needs.

How does the prop spin when the gear is engaged?

Usually, a spun prop occurs when the rubber hub, which connects the propeller to the driveshaft, wears out. This slip occurs when the rubber wears out at higher RPMs. Cavitation, excessive throttle, or improper propeller installation can exacerbate the problem. When the propeller no longer pushes forward, diagnosing the fault quickly is necessary. Regular maintenance and inspections are the best way to prevent a spun prop. If you have a spun prop situation, the best recommendation is usually to replace the hub.

Usually, a spun prop occurs when the rubber hub, which connects the propeller to the driveshaft, wears out. This slip occurs when the rubber wears out at higher RPMs. Cavitation, excessive throttle, or improper propeller installation can exacerbate the problem.

When the propeller no longer pushes forward, diagnosing the fault quickly is necessary. Regular maintenance and inspections are the best way to prevent a spun prop. If you have a spun prop situation, the best recommendation is usually to replace the hub.

How to detect if there is damage to my propeller and hub?

Visually inspect each blade of the prop for nicks or bends to determine if the propeller and hub are damaged. A prop turning freely while in gear may point to a spun hub. If you hear unusual noises or feel vibrations when running the boat, those are indications that the boat has suffered damage. Check for spline wear, and check that it responds to the driveshaft engagement. Any signs of trouble will warrant a trip to the prop shop for a professional evaluation. Regular checks can maintain your propeller and hub in good working order.

Visually inspect each blade of the prop for nicks or bends to determine if the propeller and hub are damaged. A prop turning freely while in gear may point to a spun hub. If you hear unusual noises or feel vibrations when running the boat, those are indications that the boat has suffered damage.

Check for spline wear, and check that it responds to the driveshaft engagement. Any signs of trouble will warrant a trip to the prop shop for a professional evaluation. Regular checks can maintain your propeller and hub in good working order.

What do I do if I have to replace my prop?

If you need to replace the prop, consider purchasing a new hub and propeller kit to ensure compatibility. It is essential that the prop meets the specifications of your boat, diameter, and pitch. For any doubts, a boating forum or a prop shop can be invaluable. When installing a new prop, ensure that you inspect the prop shaft and lower unit to avoid any future problems. After installation, run tests at several RPMs to ensure everything performs well. Regular upkeep of the prop and hub will ensure longevity and maximize the boats’ enjoyment.