Any boat owner knows that acquiring the right propeller is a crucial decision to make. This decision will have a significant impact on the boat’s performance and efficiency, as well as the user experience. It may be beyond the reach of many today. Still, when it comes to design and material choices in 2025, stainless steel and aluminum propellers will become the paradoxical choice for the best boat propeller. As we can see, the best boat propeller is the one that can withstand the forces of an aluminum boat propeller. However, for the success of this, other factors will have to be put into consideration as well. This article examines the comparison between aluminum and stainless steel propellers in terms of design, performance, and suitability for various boat applications. Are you looking for increased speed, more years of service, increased economical or effectiveness in the use of fuel resources, then this purpose will be served with this research guide. Moreover, none of this information would make sense without understanding the critical points of effectiveness or performance when changing or modifying specific parameters of the boating craft.

Understanding Boat Propellers

What is a Boat Propeller?

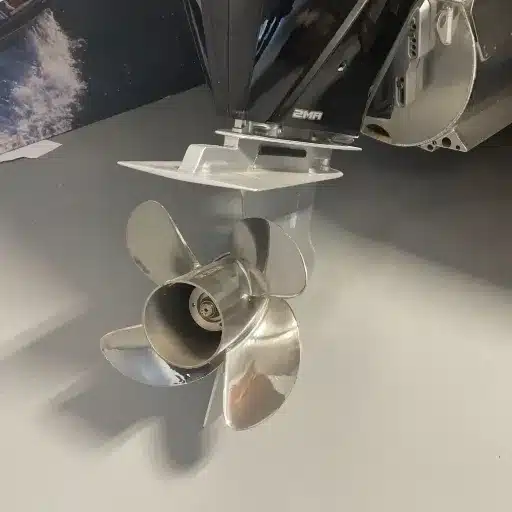

A boat propeller is a crucial mechanical component in marine propulsion, converting rotational energy into thrust to enable the vessel’s movement through the water. Typically manufactured from stainless steel or aluminum, propellers consist of blades designed with specific pitches and diameters needed to match the desired performance perfectly. Design laws create, under the geometry of the blades, a pressure difference in the water that is exploited to propel the boat forward. Types of propellers are available, such as three-blade and four-blade propellers, for differing and specific performance requirements, including outrunning, fuel efficiency, and handling. Additionally, a crucial factor in selecting the optimal propeller Type for optimal functioning is the engine’s horsepower, the boat’s size, and the purpose of its use.

Types of Boat Propellers: Stainless Steel vs Aluminum

Aluminum Propellers

Highly popular due to their price and weight considerations, and are often sufficient for the casual boater. They always perform well under standard situations, especially when considering smaller boats with diminished horse-powered engines.

Stainless Steel Propellers

Noted for their strength and longevity. High-quality propellers of this type would retain their shape under higher torque, resulting in improved efficiency and speed.

Each type can meet some needs or others. Yet, these types of propellers tend to wear faster when faced with abrasion-related impacts, or even in a rough sea environment. Stainless steel propellers are exceptional in terms of accurate handling, making them well-suited for performance-driven boaters or those who use boats in harsh conditions. And while the pros continue, the cons include stainless-steel propellers being more expensive upfront, and repairing or replacing them requires additional money.

It depends on the budget, usage, and, consequently, performance priorities. Aluminum is inexpensive and preferred by those attending occasional parties, whereas stainless steel is suitable for true enthusiasts who demand superior speed, longer life, and better handling under heavy loads.

Importance of Propeller Material for Boat Performance

Speed, fuel economy, and durability-all these parameters are affected by the nature of the propeller. Stainless steel propellers were consistently associated with superior strength, and the design was chosen to increase the acceleration and top speeds. Due to its rigidity, it will not flex significantly under high loads, making it suitable for powerful motors and rough water conditions. Material costs and repair costs must also be considered when making a decision.

Aluminum propellers, on the other hand, remain the cheapest and lightest option that is preferred. Aluminum propellers cannot compare to stainless steel propellers in terms of both durability and performance accuracy. Aluminum is a good choice due to its lower repair costs and ease of replacement. Aluminum and stainless steel were once quite distinct in terms of performance. Some modern methods have reduced these differences, opening options for different boating conditions.

💡 Expert Insight:

Research led by experts shows that the propeller material used directly affects the boat’s fuel consumption, with savings becoming ascertainable over time through an efficient design. For example, an appropriate need for a stainless steel propeller to reduce drag and increase thrust makes it easier for the engine to perform well, thus conserving fuel. With such knowledge of risk and tradeoffs, one can ensure optimal performance and enjoyment on the water, as tradeoffs can vary depending on one’s goal of either cost or speed. The properties of each material must be weighed when striving to find the right balance of efficiency, price, and durability for the operator, whether they are a weekend boater or a performance boater.

Stainless Steel Propellers: Advantages and Disadvantages

Durability and Strength of Stainless Steel Props

Stainless steel propellers are renowned for their exceptional durability and strength, making them a preferred choice for a myriad of watercraft applications. When compared to aluminum props, stainless steel types are more susceptible to physical damage, such as dents and warping, as the craft navigates waters containing debris or with rocky bottoms. Their strength allowed the blades to be designed thin, hence offering greater hydrodynamic efficiency and performance.

Gaining torque and power uphold their structural integrity; therefore, propellers fit nicely on a high-performing boat or bigger vessel. The resistance to flexing offers greater speed and acceleration, allowing for sustained fuel efficiency as the vehicle ages. Marine research indicates that stainless steel props, compared to aluminum ones, last at least five times longer; therefore, making the initial purchase price worthwhile due to fewer replacements in the long run.

🔧 Maintenance Tip:

For long-term use, after proper maintenance, stainless steel props resist corrosion very well, especially in saltwater. Hence, with proper maintenance, such as regular cleaning and anti-corrosion treatments, these propellers will retain their performance and good looks. Boat owners have much to gain from investing in stainless steel if they are seeking a propeller that is dependable and offers high performance, with durability being a top priority.

Performance Benefits for Boat Owners

About rendering unique performance benefits for boat owners in terms of greater efficiency and precision during operation, the category of stainless steel propellers stands undisputed. The sturdiness of their constituting material allows their blades to be made thinner and more hydrodynamic, thereby reducing drag and speeding acceleration. The margin of speed is, therefore, higher, and fuel is saved significantly, making it a more economical resolution in the long term. Stainless steel differs from aluminum in being more rigid; thus, under enormous stresses, it will not flex and will transfer power more consistently and predictably.

But preceding developments always gave a little edge to these attributes. From new blade geometries to pitch variations that enable practical adjustments for optimal performance in diverse water conditions, studies reveal that boats fitted with stainless steel props offer better handling and reduced vibration, translating into enhanced user comfort and overall vessel stability. With such improvements, steel props serve as the first choice for boat owners seeking perfect functionality and long-term value.

Cost Considerations for Stainless Steel Propellers

When evaluating the cost of stainless steel propellers, one must consider the initial investment versus their longer-term benefits. Stainless steel propellers are typically more expensive than aluminum ones, with prices varying depending on factors such as blade design, diameter, pitch, and brand. For example, high-performance boating premium models allow a higher price due to superior engineering and material quality. Nevertheless, the price balance can often be made up by better durability and exceptional performance over time.

Much more stainless steel retains a longer life since it offers better resistance against corrosion, denting, and abrasion, and hence does not need frequent replacements. They age well, diminish in maintenance and replacement cost, making these propellers an affordable choice for the boater who values reliability and performance. Furthermore, the decreased fuel consumption and improved handling attributed to stainless steel propellers may result in operational savings, thereby supporting the acquisition price.

Aluminum Propellers: Advantages and Disadvantages

Affordability and Weight Benefits of Aluminum Props

Generally, aluminum propellers are considered inexpensive and lightweight, and hence tend to be preferred by amateur and recreational boaters. Slightly cheaper than stainless steel propellers, these offer an excellent budget alternative for those looking to weigh their options in terms of cost without compromise on immediate performance. Aluminum props are lighter, further adding to ease of handling, along with quick acceleration, which becomes an advantage, especially for smaller boats or those with low-output engines.

Meanwhile, aluminum as a material can be molded into various designs, making it applicable to and compatible with different types of watercraft. Aluminum propellers, although they may lack durability in some areas compared to stainless steel, are highly repairable, which can be another long-term cost-saving measure. For many boat owners, balancing cost, ease of use, and adequate performance makes aluminum propellers an appealing and practical choice.

Performance Drawbacks Compared to Stainless Steel

While aluminum props are inexpensive and lightweight, they fall short in terms of performance and durability compared to those made of stainless steel. In fact, stainless-steel props are capable of withstanding a much larger beating angle-wise than aluminum ones. They do not deform even under high-stress applications such as going at a higher speed in a rough stretch of water. Conversely, aluminum props tend to flex, especially at higher RPMs, which in turn decreases thrust and efficiency marginally. Having mentioned that, aluminum is also slightly more prone to damage from impact and underwater debris, which reduces its lifespan and reliability when used in a demanding environment.

Above all else, stainless steel propellers offer acceleration, top speed, and improved fuel efficiency due to their rigidity and precise engineering. It is a well-established fact, based on extensive testing and industry qualification, that aluminum props are suitable for casual or recreational boaters. However, they may struggle to maintain optimal performance at high speeds or under the demanding conditions of commercial use. For owners wishing for longevity and performance, stainless steel remains the number-one option, despite being somewhat expensive.

Best Use Cases for Aluminum Propellers

If you would like to opt for a good propeller, aluminum ones are an excellent addition to complement your selection. They are highly affordable, versatile, and easy to handle. On this particular type of propeller, you will find it more suitable for casual boaters who work in calm water conditions or indulge in light-duty activities such as:

- Fishing

- Water skiing

- Casual cruising

- Emergency backup propeller

Cheaper aluminum propellers are appropriate for beginner boats or as a second propeller for backup in an emergency. Elsewhere, aluminum propellers really blossom with moderate power, generally less than 150 horsepower, where running conditions cannot be as violent as those of performance or commercial vessels.

The recent specialization in aluminum alloys has further reduced damage risk, resulting in improved durability and ensuring that products last longer for day-to-day use. Moreover, they are very lightweight and easy to replace, which aligns well with the ambitions of an individual who prefers things to be simple in terms of maintenance and repairability. Aluminum propellers would remain a conventional and cheap system in virtually all casual touch-and-go operations since they cannot compete in terms of strength or performance with stainless steel propellers at speeds or under extremely trying conditions.

Comparative Performance Analysis: Aluminum vs Stainless Steel

Speed and Efficiency Parameters

When speed and efficiency in production are considered, various parameters come into play, including aluminum and stainless steel propellers. The aluminum propellers are suitable for low to medium speeds, offering dependable performance and smooth operation for leisure traffic. In addition, they tend to weigh less, so they promote fuel savings in daily applications. At high speeds, aluminum propellers are expected to perform slightly below those made of stainless steel due to their lower rigidity and tendency to flex somewhat under greater loads.

Conversely, stainless steel propellers can exert higher thrust under demanding conditions, faster off the line, better handling, and fly more efficiently at higher RPMs. Stainless blades, under pressure, hold shape well, reducing drag and maximizing thrust, whether it be for critical performance in competitions or heavy lifting.

For the recreational crowd cruising calm waters, aluminum propellers offer good speeds and efficiency at an affordable rate. In contrast, those seeking the highest performance have chosen stainless steel propellers for improved fuel economy and advanced handling capabilities, which are among their key features.

Handling and Maneuverability

The most critical parameter affecting handling and maneuverability must be the design details and material composition of the propeller. With stainless steel propellers, the flexing possibilities during high RPM are reduced, making them the most responsive and easiest to handle under harsh conditions. This robustness can be particularly handy in performance or tight waterway ventures, where control accuracy is an absolute necessity.

Additionally, some enhancements to blade geometry, including cupping rake adjustments, have improved cornering grip and stability during cornering. Currently, propellers are being designed with these specifications to provide smooth transitions and improved directional control at intermediate speeds.

For the recreational or casual operator, aluminum propellers continue to offer a nice, balanced approach to maneuverability and ease of control, particularly in calm environments. However, those demanding fast response and top-level control, especially on high-powered engines or in rough water, must absolutely be able to justify buying the technologically advanced stainless steel choice.

Case Studies: Boat Owners in Real Life

As a long-standing boat owner, I have experimented with the use of aluminum and stainless steel propellers for various applications, and the results have been quite eye-opening indeed. Initially, I chose aluminum propellers because they were a suitable option for leisurely outings and offered fair performance in relatively calm waters. Being lightweight, inexpensive, and easy to replace, it was a perfect choice when still getting to know the vessel and how it handled. Just as my riding skills in challenging waters had started to develop, and I was pushing the boat to almost new speeds, this propeller began to show itself to be quite prohibitive. There was not enough responsiveness and efficiency when I had to go over the waves, tow a heavy sports tube, or waterski, among other activities.

Eventually, I went for a stainless steel propeller, and it was as if somebody had turned on the light: soaring above the clouds. The apt: one can feel the difference in sharper control and efficiency at high speeds, both of which are immediate. When a stainless steel propeller operates in rougher conditions, so do its performance and durability. My earlier aluminum propeller, however, would have cried for favor! In particular, I cherish the resistance against wear and deformation with time-the thought of shallow water or any unexpected impact damaging my props doesn’t even cross my mind anymore. Of course, the initial outlay was higher, but the benefits achieved over the years made this expense well worth it.

Having said this, the owners have been considerably enhanced by the addition of a stainless steel propeller. New-found handling that is sharper and smoother, and the feeling that all power from the engine is fully employed, are virtues I now enjoy when I am in the water. If the owner is looking for a performance upgrade or can overcome some challenging conditions, then I highly recommend pursuing the upgrade. For me, it is an investment that performs well each time I step on water.

2025 Trends in Propeller Technology

Innovation of Stainless Steel and Aluminum Propeller Design

The modern innovations of stainless steel and aluminum propeller design allow one to achieve the highest measures of efficiency, durability, and performance. Stainless steel propellers underwent severe enhancements with industries to incorporate manufacturing techniques such as precision casting and computational fluid dynamics to optimize the thrust and drag of blade geometries. This meant better fuel efficiency and smoother operation, even under demanding conditions.

On the other hand, aluminum propellers have become lighter and stronger with innovations in alloy composition and surface treatment. Improvements are in place to render aluminum-propellers corrosion-resistant and able to withstand higher torque levels, rendering them an economical yet dependable alternative option for a wide variety of vessels.

Moreover, hybrid designs are melding the best of the two materials to achieve custom solutions, depending on the varying demands of very different types of boating. To put it another way, thanks to these state-of-the-art developments, a boat owner will have the luxury of picking out a propeller tailored exactly to the engine’s need and his or her own operational environment, for maximum punctual performance and longevity of the propeller.

Environmental Impact and Sustainability Considerations

To look into environmental impact and sustainability of the type of propeller choice, I consider it very important to study the materials and manufacturing methods inherent in each possibility, not forgetting to look at long-term performance. For example, from one viewpoint, a stainless steel propeller may offer a long-lasting solution, while on the other, due to the manufacture processes on energy consumption that it requires, may affect sustainability in the negative manner. But on the flip side of the coin, due to its very long life, the initial need for frequent replacements of the propeller, and consequently the need for disposal, is minimized, thereby somewhat lessening the overall waste generated. Aluminum propellers would be preferred in the environmental-friendly respect as they are lighter and highly recyclable whenever disposed of in a well-defined manner.

In my own opinion, hybrid propeller designs seem to be a worthwhile consideration as a means of mixing the advantages of two different materials and limiting their drawbacks. These designs improve efficiency while leaving room for manufacturers to develop with sustainable materials that are less impactful on the environment. With the advent of new production methods, which include either recycled metal or energy-efficient methods, propeller manufacture might also boast an environmentally considerate advocate.

In the final analysis, I consider sustainability in propeller choice as a process that requires the whole. By bringing eco-conscious practices to the forefront-however they may be used, be they material choices, efficient designs, or responsible recycling-a boating enthusiast like myself could get the most performance out of a propeller with the least environmental impact. These efforts serve to protect marine flora and fauna, while at the same time satisfying an increasingly loud call for greener and more sustainable practices in all walks of marine engineering.

Predictions Regarding Boat Propeller Materials in the Future

I believe future opportunities for boat propeller materials lie in sustainable composites and technologies. These include bio-based composites and recycled carbon fibers that are gaining popularity for their compromise on properties against environmental concern: low weight and less carbon footprint. Higher-end nanotechnologies may permit even tougher corrosion-free materials thus rendering longer-lasting propellers that, over time, reduce waste.

There is one more big trend that I predict will be taken up-a 3D printing trend for propeller manufacture. This manufacturing technique further reduces material waste, allowing for higher levels of design intricacy and customization. Combine this with smart materials that adapt to underwater conditions or self-heal, and it becomes even more exciting. These can be used toward the huge push these days to create solutions that are fuel-efficient and performance-oriented, in turn making marine industries both ecologically and cost-wise beneficial.

The future of propeller materials will ultimately be forged from a synergistic set of approaches marrying sustainable practices with technology. Hence, by continuing to emphasize eco-conscious designs while hitting on disruptive innovations, we can design products that perform really well, all while sustaining our oceans in the long term. I am hopeful that, through ongoing research and dedication, we will find groundbreaking solutions that make the marine engineering landscape better.

Reference Sources

-

Prop Bites: How To Choose Between Aluminum and Stainless Steel Props – Discusses the stress tolerance and design differences between stainless steel and aluminum props.

-

Stainless Steel vs Aluminum Prop: What’s the Difference? – Explores cost, repair, and performance differences between the two materials.

-

Stainless Steel vs. Aluminum Boat Propellers – Highlights the trade-offs in weight, impact resistance, speed, and thrust.

-

Stainless Steel vs Aluminum Propellers – Provides insights on pitch adjustments and durability when switching between materials.

-

Aluminium vs Stainless Propeller – A forum discussion with practical experiences and insights on performance differences.

Frequently Asked Questions (FAQs)

❓ What separates stainless steel from aluminum in propeller manufacturing?

The differences between types of propellers, specifically class stainless steel versus aluminum, lie in their materials and the way they perform. Stainless steel is generally more durable, capable of delivering better performance and acceleration under high horsepower demands. The higher resistance to impacts also means hitting obstructions underwater less often, where a sudden deflection might be caused-an obstruction could be anything from a stump to driftwood. Aluminum, meanwhile, is usually considered cheaper and lighter, thus suited to smaller motors or low-horsepower needs; however, the question can be raised just how much performance is lost in terms of top speed and fuel efficiency.

❓ In terms of durability, which of aluminum and steel is better?

Durability-wise, stainless steel definitely tops aluminum. Stainless steel props are stiffer and can take quite a bit of rough play, whereas those made of aluminum are likely to sustain damage if they hit a hard bottom or shallow water. Therefore, boat-owning connoisseurs who prefer longevity and performance opt for stainless steel, as it retains its shape for a long time, even at high speeds. Aluminum props may be cheaper for casual boaters, but they could end up having to be replaced so often that they break even on the starting price.

❓ Are aluminum and stainless steel suitable for shallow water use?

Both aluminum and stainless steel props can be used in shallow water, but their performance can differ significantly from each other. Aluminum props are relatively lighter and somewhat flexible, which makes them easier to manage in low water conditions; however, they tend to deform upon striking an obstacle underwater. Stainless steel ones offer more durability but also require more care during even normal operations to avoid damage. Choosing a stainless-steel prop with thinner blades might therefore present the best compromise between durability and performance for the boater who often traverses shallow waters.

❓ Which one propeller assures better mileage: aluminum or stainless steel?

When discussing stainless steel props, the general understanding is that they provide better gas mileage at high speeds, as this option allows for higher speeds with less drag through the water. This means that, in terms of total fuel efficiency, a stainless steel prop is better, especially with your large outboard, which could use all the horsepower it can get. Conversely, if you wish to go slower, aluminum props might be suitable, as they generate more drag, resulting in increased fuel consumption over time. For boat owners torn between performance and cost, a thorough evaluation of their specific boating needs and conditions will be necessary.

❓ What are the advantages of using a stainless steel prop at high speeds?

There are also several advantages to using a stainless steel prop for high-speed boating, particularly in terms of acceleration and top speed. The stiffer blades of a stainless steel prop allow for more effortless torque transfer from the engine, resulting in improved performance. Moreover, stainless steel propellers typically have a sharper leading edge and a finer trailing edge, which enables smooth water flow and thus reduces drag. This translates to better efficiency, which is an asset in itself for any boater who requires performance above all during high-speed maneuvers.

❓ Can I use a spare aluminum prop if my primary one is stainless steel?

While an aluminum spare could technically be fit when the stainless-steel ones are not, one should always consider the performance implications. It is unlikely that an aluminum propeller can match one in performance, especially with regard to top speed and fuel efficiency. Furthermore, the difference in engine characteristics presented by the two types of props and how they transmit engine torque to the drive shaft could cause issues with boat population. Therefore, it is best to keep the spare props of the same material type to match their handling and performance characteristics.