When it really comes down to it, the propeller is nearly the most crucial part when it comes to getting the maximum power from the boat. Hence, a right choice of propeller will allow Suzuki owners to enjoy a smoother ride, better consolidation of fuel, and, overall, better handling and speed. The options are many and confusing, and this might just feel like another attempt at navigating uncharted waters in finding the best Suzuki propeller to put on your boat in 2025. This guide is meant to ease that task! We will examine the various factors, including material, pitch, and the specific requirements for the type of boat, so you can make an informed choice that suits your needs and boating lifestyle. Whether you want all the technically possible speed or the most cost-effective and hardened propeller for your scenario, this article will fill you in on all you have to know for an improved boating experience.

Understanding Suzuki Outboard Propellers

What makes a Suzuki Outboard propeller special?

Suzuki outboard propellers, due to their innovative engineering and precision craftsmanship, enable them to serve any water transport need. Efficient fuel consumption and performance are key features in the design of these propellers, which provide thrusters and speed to the boat, further enhancing the feeling of a smooth ride. The materials used, including stainless steel and alloys, ensure maximum durability even in extreme marine weather conditions.

Key Performance Features:

Low-speed effectiveness and handling are the key attractions of Suzuki propellers and systems, making them a perfect choice for anglers, recreational boaters, and professionals alike. Other pitch and blade geometries are specifically designed to reduce cavitation and vibration, making propulsion quieter and requiring less resistance while cruising on the water. The result of a combination of technological advancements and high-quality manufacturing envisions an ideal compromise on power, control, and efficiency, demanded by any modern perspective.

Why Choosing the Right Propeller Is So Important

Choosing the right propeller for a boat is crucial to maximize performance, fuel efficiency, and the entire boating experience. The size, pitch, and material of the propeller all have direct impacts on how one’s engine interacts with water, affecting speed, handling, and even maneuverability. For instance, a propeller with a higher pitch may result in greater top-end speed but less low-end power, which is undesirable for towing or water sports. Conversely, materials such as aluminum and stainless steel have different advantages. Aluminum propellers are lightweight and comparatively inexpensive, while stainless steel offers better performance and durability in harsh conditions.

Fuel Economy Impact:

Research has suggested that a good propeller match can improve fuel economy by as much as 20 percent, further proving the propeller’s stance on cost and environmental responsibility. By taking into consideration all these issues and focusing on individual boating needs, you will obtain the proper setup for power and precision on the water.

Overview of Types of Suzuki Propellers

Suzuki propellers cover a broad arena to suit all kinds of boating needs, from efficiency and durability to performance. Designed and manufactured with innovative materials and designs, these propellers can offer maximum efficiency on the water. The main types of Suzuki propellers and their notable features are:

Aluminum Propellers

Aluminum propellers are primarily recognized for their lightweight construction and affordable price tags. These represent compelling choices for casual boaters looking for a fun time at a reasonable price. They are not as durable as stainless steel; however, under most operational scenarios, aluminum propellers will serve their purpose in maintaining speed and efficiency. Maintenance stands as a foremost factor in increasing their lifespan.

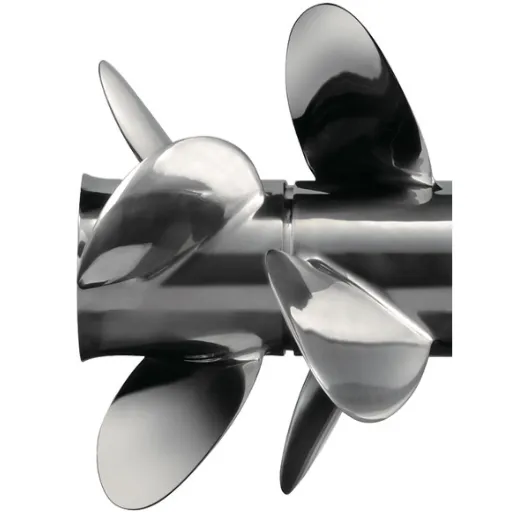

Stainless Steel Propellers

Designed to withstand the harsh marine environment, stainless steel propellers offer the greatest strength, abrasion resistance, and corrosion resistance. They provide precise thrust, allowing for better acceleration and higher top speeds compared to aluminum. They cost the most upfront, but it is an investment that pays off for the boating enthusiast seeking a propeller that will work reliably and efficiently to the utmost.

Four-Blade Propellers

Suzuki’s four-blade propeller models cater to the needs of users who require stability and control, especially in rough waters or for towing applications such as wakeboarding. The extra blade in the water produces more grip, thrust, and better holding ability of the boat. These propellers lend themselves to power the application at the reduced speed range and provide consistent power delivery.

Three-Blade Propellers

Known for their versatility, these propellers offer a good compromise between speed and efficiency. They are geared toward a variety of boating activities, particularly those focused on top speed and fuel economy. The smooth design caters to quicker acceleration and swifter handling in calm waters; hence, it is favored among general-purpose users.

Specialized Propellers

Suzuki also offers propellers of a specialized nature, such as those designed for high performance, saltwater applications, or fuel-saving efficiencies. Weedless variants are functional in shallow or debris-laden waters, while high-thrust ones support heavier vessels or those operating under load. By employing a propeller tailored to its specific needs, further optimization of the setup can be attained toward the objective in question.

Propellers are produced in various diameters and pitches for each type to provide propulsion tailored to the boat model, engine power, and purpose. Depending on the type and specification chosen, they offer greater fuel efficiency, a smoother ride, and unparalleled durability at sea for boat owners. Timely maintenance, inspection, and general care only guarantee it lasting performance, making Suzuki propellers a very worthwhile option in any marine operation.

Choosing the Right Propeller for Your Suzuki Outboard

Factors to Factor in When Selecting a Propeller

Choosing the right propeller for your Suzuki outboard engine involves considering several critical factors to maximize the boat’s performance and efficiency. Here are some that should be considered:

| Factor | Description | Impact on Performance |

|---|---|---|

| Material Type | Aluminum vs. Stainless Steel options | Affects durability, cost, and performance levels |

| Pitch & Diameter | Distance propeller moves water per revolution | Determines speed vs. acceleration characteristics |

| Number of Blades | Three-blade vs. Four-blade configurations | Influences smoothness and handling |

| Operating Conditions | Water depth and environmental factors | Affects propeller size requirements |

| Engine Specifications | Horsepower and maximum RPM ratings | Ensures optimal engine performance |

| Load & Application | Boat weight and intended usage | Determines pitch requirements |

Material Selection Considerations:

Material Type:

Propellers can be made of either aluminum or stainless steel, each with its own set of advantages. Aluminum propellers are lightweight, inexpensive, and ideal for cruising around. Stainless steel propellers are far more durable and offer better performance, making them suitable for use in heavy-duty or high-speed applications.

Pitch and Diameter:

The pitch and diameter of a propeller greatly influence today’s speed and cost of work. The pitch is the distance that the propeller theoretically moves the water in one revolution, and the diameter is the width of the circle in which the propeller blades rotate. The greater the pitch, the greater the speed, with a reduction in acceleration. Conversely, the low pitch provides strong thrust and exemplary handling at low speeds, or at power somewhat less than the rating. It is crucial to select a propeller that matches the horsepower of your boat engine and its intended use for optimal performance.

Number of Blades:

The Number of blades affects the manner in which a propeller cuts through the water. A three-bladed propeller will travel faster but may vibrate at high speeds, whereas a four-bladed propeller offers smoother operation, better handling, and improved fuel economy.

Operating Conditions:

Check the operating environment in which your boat is mainly used. For example, shallower waters require propellers with a smaller diameter, whereas those working in deeper and rougher waters require propellers designed for stability and strength in variable conditions.

Engine Specifications:

Always consider the specifications of your Suzuki outboard engine, particularly its horsepower and maximum RPM (Revolutions Per Minute). This ensures that the chosen propeller does not strain the engine or reduce overall performance, thereby aligning with the manufacturer’s suggestions.

Load and Application:

The weight the boat carries and the manner in which it is used are among the factors for propeller selection. Boats with heavier loads would require lower-pitch propellers to ensure uninterrupted power delivery, while speedboats or recreational crafts would prefer high-pitch propellers for faster performance.

Considering the above factors during decision-making guarantees that the Suzuki propeller you choose perfectly matches your requirement for a safer, more efficient, and enjoyable time on the set. Continual testing and tweaking of your propeller setup ensure it runs at peak performance to suit your needs.

The Basic Understanding of Propeller Pitch and Diameter

Both the pitch and diameter of a propeller constitute major factors that work in contrast to influence boating performance, fuel efficiency, and handling. The pitch is referring to the distance the propeller would move forward in one revolution if it were not slipping. More pitch means faster speed, but it demands higher power from the engine, while less pitch provides better acceleration and good off-road handling.

In contrast, the diameter denotes the total width of the circle produced by the propeller blades in rotation. Higher diameters can push out more thrust and are usually implicated for heavier vessels or those working under a load. In contrast, those with smaller diameters are implicated for lighter crafts that need faster response time and greater speed.

Performance Balance:

Finding the right balance between pitch and diameter is key, as their direct relationship affects engine RPM (revolutions per minute) and fuel efficiency. For instance, an incorrect pitch literally takes the most strain out of the engine if the RPM is too high, or conversely, it requires the least strain on the engine capacity if the RPM is too low. Likewise, a diameter that does not correlate well may produce the least-receiving response and the least thrust.

The manufacturers provide details on the recommended range of pitch and diameter, which vary by engine model and method of use, allowing for fine-tuning of the craft’s performance. Choosing the correct values for your propeller ensures better fuel economy, a smoother ride, and an entirely enjoyable boating experience, whether you’re fishing, cruising, or engaging in watersports. Regular modifications and constant checks, along with an understanding of interrelations, will keep your craft in its optimal potential.

How to Match Your Suzuki Outboard Motor with the Right Prop

Propeller selection for a Suzuki outboard motor is a crucial step in achieving optimal performance, efficiency, and durability. The process involves narrowing down the options to consider engine power, boat size, weight, and intended use. Considering all of these will greatly enhance your boating experience and ensure your motor is working at its fullest potential.

Matching Process Steps:

- Know Prop Pitch and Diameter: A propeller pitch refers to the distance the propeller moves through the water with one revolution, while the diameter measures the width of the circle the blades produce. High-pitch propellers are generally used for activities requiring speed, such as waterskiing; whereas a lower pitch delivers a stronger thrust prop, suitable for heavy loads or towing. Similarly, an appropriate diameter is chosen to suit your motor’s horsepower and the design of your boat.

- Match Prop Material to Your Needs: Propellers are typically made from either aluminum or stainless steel. Aluminum props are more economical to purchase and lighter in weight, making them best suited for casual boaters. Stainless steel propellers are stronger and perform much better when subjected to stress during high-demand activities like offshore fishing. Choose the option that suits you better according to your needs and budget.

- Account for the Type of Boating Activity: Different activities require varying propeller sizes. The cruising guys would prefer a prop that offers fuel efficiency at mid-range RPMs. Fishermen may want the king of steady trolling speed. For various watersports, such as wakeboarding, a prop offering great acceleration is a necessity.

- Consider Engine RPM and Performance Figure: Every Suzuki outboard motor has a recommended range of operation, typically specified in the owner’s manual. Select a propeller that can bring the motor up to the higher range of its recommended RPM for peak performance and without working the engine too hard. Check your tachometer frequently to ensure that the propeller matches your motor.

- Test and Fine-Tune the Selected Propeller: Performance in a propeller differs with water conditions, altitude, and load variations. An on-water test evaluation of the chosen propeller is needed to assess its performance under practical application conditions. Changes in speed, fuel consumption, and the responsiveness of motors to these changes should be observed and adjusted as needed to better suit the operator’s particular style of boating.

By factoring these elements in and tailoring your propeller selections to your specific requirements, you can achieve the perfect combination of performance and efficiency. Proper maintenance and occasional adjustments can further extend the life and reliability of not only your propeller but also your Suzuki outboard motor, granting you ample worry-free boating time.

Material Options: Aluminum vs. Stainless Steel Propellers

Aluminum Propellers

Advantages:

- Low cost and affordability

- Lightweight construction

- Easy to handle and install

- Good for recreational boating

- Easier and cheaper to repair

- Wide variety of sizes available

For several reasons, aluminum propellers remain the most popular among Suzuki owners. Among the most attractive considerations is its low cost. Aluminum propellers are an economical option for recreational boaters or those with a budget already under strain. Although priced relatively low, they still offer reliable performance for boats moving at moderate speeds and in less arduous situations.

Since aluminum is lightweight, these propellers are much easier to handle, install, and replace when needed. This helps to reduce the torque exerted on the outboard engine, resulting in smoother operation and improved fuel economy during normal usage.

Durability also makes aluminum propellers a practical choice. While these cannot withstand the brute strength exerted by stainless steel propellers, an aluminum prop can sustain several bumps and minor abrasions in common everyday usage, especially in lakes and rivers with minute debris. They can be more easily repaired or replaced when damaged, at a lower cost. Modern aluminum propellers, however, are coated with corrosion-resistant finishes for extended life in freshwater.

Stainless Steel Propellers

Advantages:

- Maximum durability and strength

- Superior corrosion resistance

- Better acceleration and top speeds

- Thinner, more efficient blade design

- Long-term cost effectiveness

- Enhanced fuel efficiency

The most durable and maximally efficient ones for the outboard motor are stainless steel propellers, which marine enthusiasts favor. These propellers are designed to resist corrosion and wear, even in unforgiving environments such as saltwater, thereby increasing their longevity in heavy-duty applications. Their robust build allows the use of comparatively thinner blades, thereby improving hydrodynamics while minimizing drag and enhancing speed and fuel handling.

Steel’s strength also enables more precise cutting of blade design, further improving thrust and acceleration. Stainless steel propellers typically last much longer and provide greater efficiency. Although the initial price may be higher, they will undoubtedly prove worth the investment over time, especially for heavy-duty use or high-speed boating applications.

Durability vs. Cost Efficiency

🛡️ Durability Analysis:

Speaking of durability, stainless steel propellers are the industry’s favorite due to their resistance to wear, corrosion, and impact. This durability is particularly effective against rough seas, for instance, in a saltwater environment, where aluminum and composites lose this property at higher degradation speeds. Research shows that, between aluminum and stainless steel, the latter maintains its structural integrity for up to five times longer, making it suitable for long-term utilization.

💰 Cost Efficiency Analysis:

From the point of view of cost efficiency, stainless steel propellers may appear more expensive initially, but in reality, companies that consider the longer lifespan and fewer repairs or replacements find the costs to be less in the long run. Many boat owners believe there is significant value in achieving consistent performance and fuel efficiency, which can also contribute to a higher resale price when considering stainless steel blades. This makes stainless steel the preferred option for those who believe in both longevity and total cost of ownership when making a marine investment.

Trends in Outboard Propeller Technology for 2025

Innovations in Propeller Design and Performance

Propellers for outboard motors experienced some developments in 2025, driven by an emphasis on fuel efficiency, durability, and maneuverability. Materials science has made possible the use of composite materials that strike a balance between being lightweight and incredibly strong; these materials reduce wear and tear while maintaining the highest standards of performance. Instead of employing traditional trial-and-error, engineers are now applying hydrodynamic modeling to design blade shapes that reduce drag while increasing thrust. Such designs not only achieve the best fuel economy, but also provide smooth acceleration and handling.

2025 Technology Highlights:

Innovative technology is making waves with the incorporation of sensors and data analytics for real-time monitoring of their performance. This grant helps boat owners monitor maintenance, adapt to water conditions, and cruise along at peak efficiency with minimal manual interference. Variable-pitch propellers are increasingly within the hands of recreational and professional shipping interests, allowing them to fine-tune their performance across various speed ranges.

Recent trends tend toward environmentally friendly designs that minimize adverse impacts, such as propellers that reduce wake turbulence and noise pollution. Builds upon this ongoing request for marine technology with an environmental conscience, thereby establishing a fair playing field for a future in which good performance must be pursued in tandem with ecological responsibility.

Eco-Friendly Materials and Sustainable Production

The use of basic raw materials and sustainable production processes is slowly altering the marine industry. Manufacturers are increasingly turning to biodegradable composites, recycled metals, and marine components made from durable polymers that do not generate waste or environmental hazards. Natural fibers, such as flax and hemp, are incorporated into composites to form lightweight and strong parts, offering a greener alternative to traditional fiberglass. Other sustainability-promoting processes include the use of energy-efficient machinery and minimizing waste during production stages.

Sustainable Innovation:

Moreover, old ships are being converted into new ones, and materials are recycled instead of being discarded in landfills, a circular-economy approach being adopted by some boat builders. This reduces the extraction of raw materials and extends the life cycle of existing resources. By coupling these developments with other certification standards, such as ISO 14001 Environmental Management, companies themselves become independent front-runners in sustainable marine technology, all while being pressured by the confounding rise in regulatory overreach and consumer demand for green practices.

These advances indicate not only how sustainability has come to the forefront of the maritime sector but also how it is working hand in hand with the industry to maintain performance criteria, offering a reasonable trade-off for environmental gains.

What to Expect: Smart Propeller Technologies

Innovative propeller technologies are rapidly revolutionizing the maritime industry, as they augment efficiency, reduce fuel consumption, and alleviate environmental impact. These are innovations involving advanced materials, intelligent control systems, and adaptive designs. To illustrate, high-strength alloys and composites are being used in propeller constructions to provide durability while reducing weight. Adaptive pitch control systems have been shown to increase propulsion efficiency, as they adjust the angles of the blades in real-time based on actual operating data. Additionally, IoT-enabled sensors embedded within propellers can accurately measure performance metrics, enabling predictive maintenance interventions with minimal downtime. By combining these technologies, vessels achieve lower carbon emissions and superior operational performance, thereby conforming to sustainability efforts across the industry.

Essential Propeller Hardware and Maintenance Tips

Key Propeller Hardware Components for Suzuki Engines

There are a few critical elements that I pursue for top performance and durability when it comes to some propeller hardware components for Suzuki engines. The most important thing, I feel, is the actual material of the propeller. Suzuki propellers are generally manufactured in either stainless steel or aluminum. Stainless steel offers greater strength, corrosion resistance, and improved performance at higher speeds, whereas aluminum is more cost-effective and suitable for lighter work. The choice of material should depend on factors such as the engine’s horsepower, the type of vessel, and the vessel’s intended usage.

Critical Hardware Components:

- Hub System: Suzuki hubs feature rubber inserts to absorb vibrations and protect the engine and propeller from damage in the event of an impact

- Pitch and Diameter: Significantly impact engine speed and performance characteristics

- Material Selection: Choice between stainless steel and aluminum based on application needs

The other major item all boats have in common is the hub system. Suzuki hubs feature rubber inserts to absorb vibrations and protect the engine and propeller from damage in the event of an impact. It is good practice to inspect this hub for wear and tear to ensure proper functioning of the system and thus avoid expensive repairs overseas. Additionally, the pitch and diameter of the propeller significantly impact the engine speed and the engine itself. Suzuki offers a wide range of propeller sizes, enabling users to best match the configuration to their specific needs, whether for towing, cruising, or increased speed.

In contrast, I always recommend propeller maintenance to ensure the propeller’s longer life and optimal performance. This includes periodic inspections for dings, cracks, and other signs of damage that could affect the boat’s operation, performance, or fuel consumption. A well-maintained propeller will not only boost up Suzuki engine performance but also maximize fuel capacity and allow for a smooth ride. Tracking down these few matters and keeping routine maintenance in check ensures that you can confidently uphold the Suzuki engine as a reliable and top-efficiency machine.

Maintenance to Extend Propeller Life

For propeller life extension and maintenance, a few crucial maintenance practices are undertaken to maintain efficiency and durability. First, I perform regular inspections of the propeller. This includes any signs of wear, such as nicks, dents, and rust. If these occur, the efficiency of the propeller decreases and can further damage it. The sooner I can catch minor issues early, the less likely I am to need expensive repairs or replacements down the line.

Essential Maintenance Steps:

- Regular Cleaning: After cleaning it every time I use it, especially if I take it out and break it on salt water, I make sure the propeller is clean. Salt buildup will initiate corrosion. Keeping it clean with fresh water could prevent that.

- Lubrication: It is worth having a little movie grease on the action from time to time to reduce friction and resist rust, resulting in a more enjoyable and smooth operation.

- Debris Removal: Occasionally, removing the propeller to check for fishing line or debris wrapped around the shaft is another essential step that should not be skipped.

- Proper Operation: Finally, I always try to avoid running the engine in shallow or debris-filled waters and make sure I have got the appropriate size and type of propeller for my Suzuki engine in use.

All of these prophylactic actions, coupled with regular maintenance and care, help extend the propeller’s life while ensuring maximum engine performance. By taking care of my propeller, safe and smooth boating remain my yearly jollies.

When to Change Your Suzuki Propeller

When evaluating my Suzuki propeller for replacement, one must keep track of its general condition and performance. If there are visible signs of damage, such as cracks, chips, or bent blades, it is probably time to replace the propeller. Such defects can unbalance the propeller, thereby reducing its efficiency and putting more strain on the engine. On the other hand, I keep an eye on any changes in the boat’s performance, such as difficulty reaching top speed, unusual vibrations, or increased fuel consumption. Such signs may indicate an aging or damaged propeller.

| Warning Sign | Indication | Action Required |

|---|---|---|

| Visible Damage | Cracks, chips, bent blades | Immediate replacement |

| Performance Issues | Difficulty reaching top speed | Evaluate propeller condition |

| Unusual Vibrations | Propeller imbalance | Professional inspection |

| Increased Fuel Consumption | Reduced efficiency | Consider replacement |

| Material Wear | Aluminum vs. stainless steel aging | Monitor and replace as needed |

Another key consideration I ponder when it comes to my propeller is the material. Aluminum propellers, while inexpensive and lightweight, are more prone to damage, and I may need to replace them sooner if I frequently encounter debris or shallow waters. Stainless steel propellers would then become worthy if I need durability; still, they can also require gears after a very long time. Most of the time, I observe wear and tear on my propeller and attempt to resolve it before it becomes a bigger problem.

I want to maintain a good balance between performance and preventative care. By swiftly acting at the first signs of damage or inefficiency, my engine is safer, my experience better, and malfunctions are avoided. Having an extra propeller aboard is always a good idea, just in case something happens that could jeopardize my boating time.

Reference Sources

-

How To Choose The Right Propeller For Your Boat? – Suzuki UK

Offers insights into Suzuki stainless steel and aluminum propellers, highlighting performance and durability. -

Suzuki Propellers—Selecting the One That’s Right for You – PartsVu

Discusses how to choose propellers based on boat load and usage, with tips for optimizing speed and efficiency. -

How to Choose the Right Prop for Your Suzuki Outboard – AZ Big Media

Reviews key factors for selecting the ideal propeller for a smooth boating experience. -

How to Choose the Perfect Suzuki Outboard Propeller – Captain Propeller

Explains the differences between 3-blade and 4-blade propellers and their suitability for various boat types. -

Suzuki Outboard Boat Propellers – Propeller Depot

Provides a Propeller Guide to help narrow down options based on specific Suzuki outboard engines. - Find more info now.

Frequently Asked Questions (FAQs)

❓ What is the best Suzuki outboard propeller for 150-300 hp engines?

Selecting a Suzuki outboard propeller for 150-300 hp engines involves considering options that strike a balance between pitch and diameter to achieve optimal performance. Stainless steel boat propellers tend to be the more popular choice due to their superior friction and efficiency properties. A 3-blade prop would provide better thrust and acceleration, while 4-blade configurations would increase top speed and torque. Select the specifications that match your Suzuki motor as closely as possible for optimal performance. OEM options are also great for primary fitment and compatibility.

❓ How should I choose the correct propeller for my Suzuki outboard motor?

Choosing the right propeller for your Suzuki outboard requires consideration of several factors, including the motor’s horsepower, its intended use, and the boat’s size. A 3-blade aluminum prop fits many smaller Suzuki outboards. The larger ones, though, prefer a stainless steel prop with more pitch for speed. The diameter of the propeller is also a consideration, as a greater diameter means better thrust, while a smaller diameter provides better acceleration. A marine specialist will help you determine what’s best for your particular Suzuki outboard engine.

❓ What are the benefits of a stainless-steel propeller for Suzuki boats?

The advantages afforded by stainless steel propellers to Suzuki boats include greater durability and performance compared to aluminum ones. Hence, these are thrust- and efficiency-oriented propellers, which would bring about improved acceleration and top speed for the boat. Then, since they care less about wear and tear, debris can act as a very effective medium in many marine scenarios. Furthermore, stainless steel propellers would indeed come at a hefty price, but if you are a serious boater, the long-term benefits and reduced maintenance would surely justify the investment.

❓ Aluminum propellers are suitable for use on my Suzuki outboard engine, right?

Yes, aluminum props can be used on the Suzuki outboard engine, and they are generally preferred for smaller engines, such as the Suzuki 35-65 hp models. Aluminum propellers are inexpensive and provide good performance for recreational boating. However, they would not be as durable or efficient at higher speeds or under heavy loads as stainless steel options are. Selecting the right pitch and diameter is crucial for achieving optimal engine performance and preventing excessive wear.

❓ What is the difference between a high- and low-rake propeller for Suzuki outboards?

The rake of a propeller is the angle between the blades and the hub. The high-rake propellers are designed to provide good thrust in rough water, but they can also generate thrust at high speeds. On the other hand, low-rake propellers are well-suited for acceleration and can provide improved handling at low speeds. Depending on your Suzuki outboard horsepower and boating activities, you may want one over the other. Consider how the design of the propeller will affect the performance of your boat in various marine conditions.

❓ What maintenance tips should I follow for my Suzuki propellers?

Your Suzuki propellers must undergo maintenance to ensure long-term performance. Periodically inspect the blades for damage, particularly nicks or bends, and replace them as needed. The hardware of the propellers, including the hub and fittings, should be kept in optimal working condition for optimal performance. Also, rinse it with fresh water if it has been in contact with salt water to prevent corrosion. Protection will create longevity for aluminum and stainless steel propellers and keep them working well for your Suzuki outboard motor.