Boat propellers can be thought of as the unsung heroes of marine travel, converting rotary energy into thrustful forward motion with such exactitude. Killing off such a romantic image puts into perspective how few truly appreciate the science behind the generation of thrust by these components and the power vessels of all sizes that move through the water. Whether you’re an avid boater, an engineer, or simply curious about the mechanics of propulsion, we’ll reveal to you the plethora of concepts that make boat propellers so effective. From hydrodynamics to the very shape of the blades, here are the five primary considerations that influence the generation of thrust by boat propellers. By the end of this, you will have developed an appreciation for the fascinating interplay between physics and engineering that enables boats to navigate rivers, lakes, and oceans.

Understanding Propeller Mechanics

How Propeller Design Influences Thrust Generation

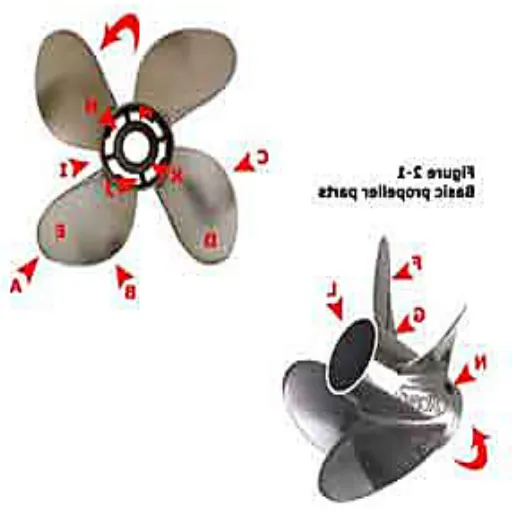

The propeller design is extremely pivotal in establishing the thrust and efficiency offered by any boat. One key factor that influences propeller design is blade pitch, which refers to the angle or lead angle imparted to the propeller blades. The higher the pitch, the faster the boat can go, as more water is displaced in a single rotation. At the same time, the high pitch requires so much more engine power. Therefore, a lower pitch gets better acceleration and is ideal for towing or slower-speed operations.

Blade Count Effects

The number of blades is another critical factor. While three blades are most common for propellers because they provide the right balance of speed and efficiency, a four- or five-blade variation will grant smoothness and thrust advantages at lower speeds or in choppier waters. More blades could spell marginally compromised top-end speed due to drag effects.

Diameter Considerations

The diameter or the total size of the propeller obviously plays a role in defining its performance. When the diameter is larger, more water is pushed back, making it suitable for heavier vessels. Conversely, when the diameter is smaller, the thrust required is for lighter or faster boats.

Material Properties

This is where the properties of the materials come into play, affecting durability and performance. Aluminum propellers cost less and are lighter than stainless steel propellers, but they offer less strength and performance, albeit at the advantage of a significantly reduced upfront cost.

In conclusion, innovations in cupped blade edges and variable geometry types are available for thrust optimization. Cupping provides extra grip in the water, thereby enhancing its efficiency even during speed changes or sharp turns. Variable geometry is less popular, but it provides adaptive control that depends on operating conditions to improve fuel efficiency and overall performance. The two elements illustrate the marriage between engineering precision and thoughtful design, complementing boat propeller functionality.

Efficiency of Blade Shape for Propellers

One of the most critical elements of blade geometry is its influence on the overall performance and efficiency of a propeller. This particular aspect is perhaps best explained by considering the blade pitch, which dictates how far a boat can travel in one revolution of the propeller. Higher-pitch blades are suitable for speedboats, providing much thrust at fewer revolutions, whereas lower-pitch blades offer more torque for heavy loads or towing applications. Furthermore, the rake angle of the blades, which is the angle at which the blades tilt away from the hub, also adds to water flow and thus performance. A high rake angle provides high lift and reduced drag, which significantly benefits high-speed vessels or those navigating through choppy waters.

| Blade Configuration | Speed Performance | Vibration Level | Load Handling | Best Application |

|---|---|---|---|---|

| Fewer Blades | Higher potential speed | Increased vibration | Moderate | Racing boats, speed applications |

| More Blades | Moderate speed | Reduced noise/vibration | Superior load handling | Cruising, heavy-duty applications |

Blade count is another factor in this respect. Those with fewer blades generally have the potential for greater speed but come with increased vibration. In contrast, more blades produce much less noise and vibration, resulting in smoother operation and better load-handling capability. A combination of superior materials, such as carbon composites or stainless steel, further enhances the effectiveness of blade shape, facilitating the creation of thin, strong, and efficient profiled shapes that optimize hydrodynamic inducement and reduce resistance. Propeller designers thus realize that by integrating all factors, such as pitch, rake, and material innovation, they can continue to maximize efficiency and ensure that the vessel is always at its peak performance in all conditions.

Material Choices and Their Performance Implications

In the materials, the nature determines how well a propeller will do in its service. Copper-based alloys are considered the best materials for marine applications due to their excellent corrosion resistance in seawater environments, allowing for long life and efficient service. They also allow the blades of the propeller to be finely shaped, resulting in excellent hydrodynamic performance.

Stainless steel would then be a much better choice for vessels that move quickly or craft working under severe conditions due to its strength and durability. Its wearing resistance, stemming from the presence of abrasive particles in the water, serves to prolong the life of the propeller even in adverse environments. However, with its higher cost and weight compared to copper alloys, this may favor material selection, especially for small vessels.

Titanium is emerging as yet another innovative material in propeller design. Due to its lightweight nature, which offers a greater strength-to-weight ratio, a titanium propeller saves fuel and reduces the strain on the propulsion system. Corrosion and biofouling inhibition by it lessens maintenance. Considering titanium’s promising performance parameters, its cost is only a limiting factor for specialized applications, such as naval or research vessels.

On the other hand, new material advancements, such as composites, are also emerging for lightweight propellers with complex blade geometries. The combination of high stiffness and low weight allows the designer to pursue a highly customized blade shape for peak efficiency. Hence, further research and development in this area will likely yield significant advances in achieving an economical, durable, and highly performing compromise among the available materials.

On the other hand, careful consideration of the vessel type, operating conditions, costs, and performance objectives is necessary when selecting the material for a propeller. Materials science keeps marching on, and so propeller technology continues to develop in tandem to meet the challenges of modern-day maritime operations.

The Propeller Propulsion System Explained

Components of a Boat’s Propulsion System

A boat’s propulsion system is an arrangement of components designed to provide thrust and propel a vessel effectively through the water. The major components, along with their functions and importance in contemporary propulsion systems, are elaborated below:

Propeller

The propeller is central in converting the rotational energy of the engine into thrust. Usually, propellers are made of stainless steel, aluminum, or composite materials. The design of the propeller is intricately linked to the vessel’s design, factoring in its function and intended use. Modern hydrodynamic models helped change the blade shapes, enhancing the fuel efficiency and inhibiting cavitation.

Engine

The engine is the primary component of any propulsion system, responsible for imparting mechanical power to the system in support of propulsion. An engine could be inboard or outboard, with the sterndrive type also possible. The fuel type for the engine also varies, depending on whether the engine is diesel, petrol, or electric. Currently, most electric and hybrid engines are advocated due to their lower emissions and environmental impact.

Shaft

The propeller shaft imparts turning force from the engine to the propeller. The shaft should resist very high torque transmitted to it and withstand the corrosive conditions of the sea, and must be manufactured from robust materials such as stainless steel or titanium. It should be very precisely aligned and drilled to minimize vibrations and maximize efficiency.

Transmission

This adjusts speed and torque from the engine to meet the needs of propellers. Today’s transmission systems typically employ innovative gear ratios and electronic management systems, enabling smooth gear changes with adaptable performance output tailored to varying water conditions.

Control Systems

Control systems enable operators to control the propulsion systems. These systems may range from the rudimentary throttle control to the complex electronic interfaces that convey real-time performance data. The introduction of digital throttle and shift systems is evidence of innovation that is making things more responsive and convenient for the operator.

Bearings and Seals

Bearings and seals ensure smooth operation and prolong the life of the propulsion systems. Bearings reduce friction on the shaft assembly, while the seals prevent leakage and ingress of water into the components. Today’s high-performance seals utilize advances in materials and design to provide longer life and maintenance intervals.

Cooling Systems

An efficient cooling system must be in place to prevent overheating in the engine and other vital components. Almost all modern propulsion systems utilize water pumps and heat exchangers to maintain an optimum operating temperature, ensuring reliable performance in the presence of strenuous operating conditions.

Exhaust Systems

The exhaust system confines gases produced during the engine’s combustion and expels them outside the propulsion system and the interior of the boat. In compliance with environmental regulations, modern designs frequently incorporate noise reduction features and emission control technologies.

Steering Mechanisms

Steering mechanisms enable the steering system to control the direction of the propulsion system’s thrust when it is thrusting. It may include the rudder for fixed inboard systems or the turn provided by outboard-and-sterndrive systems. Hydraulic and electric steering systems gave excellent control and greatly reduced operator effort.

Each of these would constitute the fundamental side of the propulsion-actuation system operation. With continuous development in materials and technologies, today’s propulsion systems are more efficient, safer, and environmentally friendly, meeting the evolving demands of the shipbuilding industry.

How the Propeller Works with the Engine

It is a thing of beauty: a perfect outlet for the merging of mechanical and hydrodynamic principles. The engine provided power to the drive shaft, which in turn rotated the propeller. The moment the propeller arrives, it converts the transmitted energy into thrust and pushes the vessel forward. Continuously modernizing engines are equipped with many advanced functionalities, such as variable speed control, allowing for real-time adjustments to propeller performance aimed at achieving maximum speed and fuel efficiency.

Hence, the very foundation of interplay would be the application of electronic throttle control, torque specification, and so on. Hence, with examples, the direct injection system in the engine closely matches the power demand of a propeller at high speed, thus making the engine-propeller system as efficient as possible. Blade ware arises. With its swept or low-drag profile, it works in conjunction with the engine to reduce cavitation and increase thrust production. Hence, the engine-propeller is a hybrid system in close coupling to produce cruise propulsion with less fuel consumption and emissions.

Understanding Gear Ratios and Their Effect on Thrust

Considered the efficiency and working of a propulsion system go hand-in-hand with alteration of gear ratios. Since these maintain the ratio of the rotational speed of the engine and propeller, they govern the thrust produced and hence work on the system. The lower the gear ratio, such as for a given arrangement, may allow the propeller to rotate at a lower speed but at maximum torque, and such conditions are required for heavy, loud vessels demanding high thrust at low speed. In contrast, a high gear ratio would speed up the propeller where speed is needed more than pure thrust.

Such a motor system, equipped with suitable advanced design features, ensures, among other aspects, precision-accurate materials in its construction and has an optimum design configuration that causes the least power loss due to friction. Studies have shown that appropriate gear ratios can lead to a 15 percent improvement in fuel efficiency while maintaining thrust performance at variable operational loads. Dynamic control systems may also provide for the adjustment of gear ratios in real-time, meaning factors will be considered if the water current varies or there is a change in the vessel’s weight; accordingly, the system will automatically take measures to ensure the propulsion system remains at its highest efficiency. These advancements underscore the importance of informantness by understanding and developing gear ratios that optimize thrust and energy utilization.

Factors Influencing Propeller Performance

Significance of Propeller Diameters

The propeller diameter is of utmost importance, as it significantly affects the performance and efficiency of a vessel’s propulsion system. Larger diameters usually mean more water is displaced, therefore, offering more thrust and more fuel economy at lower speeds. On the flip side, smaller diameters are often preferred for high-speed applications, as every bit of drag must be minimized.

Large-diameter propellers require less rotation to produce the same amount of thrust, thus preventing wear and tear on the engines and avoiding cavitation. Research, for instance, shows that ships that optimize diameter and blade area ratio experience smoother operation and higher service life. On the other hand, physical considerations, such as hull clearance or operating conditions (shallow waters or high currents), must be taken into account; hence, a balanced approach is necessary. By considering the vessel’s purpose, weight distribution, and the possible loads it must carry, selecting the correct diameter consequently plays a significant role in enhancing performance and sustainability.

How Pitch Affects Thrust and Speed

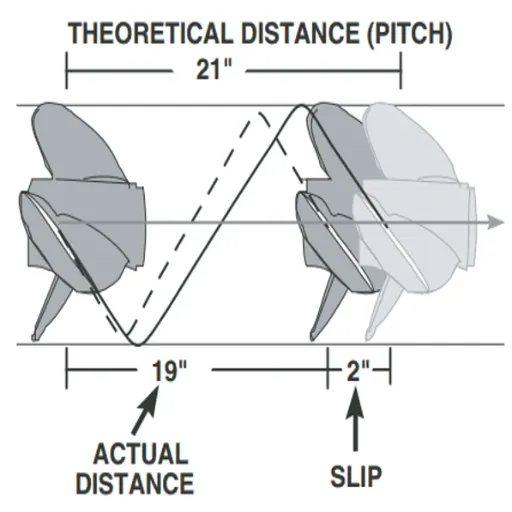

The angle of a propeller, or its pitch, is the distance a propeller would travel forward in one full rotation, assuming no slippage, and plays a critical role in determining thrust and speed. A higher pitch theoretically allows greater forward movement with a single rotation, allowing the vessel to reach higher speeds at a lower RPM. This means, however, that a greater amount of motor power would be required, potentially reducing system efficiency and placing stress on it if the propeller were being used in unsuitable conditions.

A lower pitch, by contrast, offers more thrust at lower speeds, thus providing faster acceleration and better performance under heavy loads or high-resistance situations, such as towing or navigating rough water. Finding the extremum balance between pitch, thrust, and speed is necessary. Over-pitching can overload an engine, resulting in reduced performance and possible wear. Meanwhile, under-pitching allows for unnecessarily high RPMs, which consume energy but do not yield any gain in speed. By adhering to the correct pitch setting, aided by modern performance analysis tools, one can ensure that prop efficiency is well optimized for the expected operational profile of the craft.

Environmental Factors Affecting Thrust Generation

Thrust generation is primarily influenced by environmental conditions that affect the performance and efficiency of propeller systems. Water density is a significant factor, since it varies according to salinity, temperature, and pressure. Generally speaking, denser and cooler water provides greater efficiency in thrust; warmer and less saline conditions would have the opposite effect, reducing it.

Another essential consideration is currents. Against a strong current, the effective thrust of a vessel is reduced, thereby increasing the power needed to maintain desired speeds. Conversely, a favorable current assists propulsion, thereby optimally saving energy consumption. Hence, wave patterns create situations in which resistance alters, thus continuously interfering with the thrust. When the waters are calm, thrust application becomes steady, while a rough sea would threaten it.

The thrust efficiency can be hindered because marine growth and fouling increase drag and reduce the smoothness of water flow across the hull and propeller surface. Cleaning the hull and propeller, and applying an advanced coating, helps to avoid this problem, ensuring maximum vessel performance. Similarly, wind speed and direction, as well as the resistance created by this on the vessel’s superstructure, will affect the overall efficiency.

If vessel operators consider these environmental effects and utilize necessary modern measurement devices, they will be able to properly adjust propulsion parameters for optimal thrust generation, improved energy consumption, and reduced wear on propulsion machinery.

Case Studies on Propeller Efficiency

Performance Analysis of Various Propeller Designs

Advanced marine propulsion technologies have emphasized the necessity for custom propeller designs that enable a vessel to perform at its optimum capability. An exhaustive comparison of fixed-pitch, controllable-pitch, and ducted designs reveals their individual strengths and mutually exclusive advantages. Being simple and hence highly durable, fixed-pitch propellers are still considered very useful, especially in vessels in which the load remains constant. Nevertheless, they lose much of their advantage if operated under variable speeds.

A controllable-pitch propeller (CPP) is more adaptable, as it can vary the angle of the blades to meet operational requirements, thereby optimizing fuel efficiency and maneuverability under changing environmental conditions. For instance, studies on medium-sized cargo vessels have found that CPPs are approximately 12% more energy-efficient under variable loads than their fixed-pitch counterparts.

Regarding ducted propellers, this design incorporates nozzles around the blades to direct thrust, yielding slightly better performance at low speeds. They are analyzed as useful in tugboats and other craft requiring substantial thrust in restricted waters. According to field data, a ducted propeller is capable of providing a thrust increase of up to 20% under low-speed conditions, making it suitable for use in high-resistance operations.

From these performance parameters, an operator may thus proceed to configure the propulsion system suitable for the operational requirements, thereby ensuring energy conservation and environmental protection in the various maritime applications of the ship, of whichever nature.

Lessons Learned from Marine Engineering Innovations

Marine engineering has continually evolved to address issues such as energy efficiency, environmental awareness, and operational reliability. One very important lesson emphasizes the necessity of CFD modeling so that these considerations are integrated into the design loop. Those simulations will help engineers understand fluid flow, configure hull designs, and enhance hydrodynamic performance to reduce drag and fuel consumption.

Another important fact about the Ocean Engineering world is how hybrid propulsion systems combine diesel engines with battery storage and fuel cells. Data revealed that hybrid propulsion systems could reduce fuel consumption by 30% while also reducing greenhouse gas emissions, thus solidifying a step toward global decarbonization. This approach signifies the increasing convergence of classical marine engineering with contemporary energy storage technologies.

Considering alternative fuels such as LNG, ammonia, and hydrogen has provided a wide range of crucial insights. LNG has been accepted due to its cleaner combustion profile, as it reduces SOx emissions by 100% and NOx emissions by 85%. In turn, future fuels like ammonia and hydrogen will provide long-term sustainable options. Such innovations will need to be realized alongside improvements in storage and safety protocols, thereby underlining the importance of systems thinking.

Predictive maintenance tools include incidents, transforming the management of vessels. Utilizing IoT sensors and AI analytics, operators can monitor engine health in real-time, foresee potential failures in advance, and minimize downtime. This foresight enables the optimization of maintenance schedules and extends the life of critical components.

Over time, the industry recognized the benefits of collaboration among various stakeholders across different domains, including shipbuilding, classification societies, research, and policymaking, to accelerate innovation. Based on this premise, the two parties in the marine sector would share their data and align their goals to work together toward advancing technologies that cater to both economic and ecological demands. Therefore, lessons learned in marine engineering evolve over time, thereby preparing for an efficient and sustainable future.

Future Trends in Propeller Technology

Emerging Materials and Their Potential Benefits

I consider the new materials in propeller technology to be full of opportunities for transforming the marine industry. To this effect, lightweight composites—such as carbon fiber-reinforced polymers — are starting to show promise in reducing the weight of vessels and improving fuel efficiency. New-age materials help reduce operational costs and also drive demand for environmentally friendly solutions. Their strength-to-weight ratio offers durability, while corrosion resistance will keep maintenance costs down, almost for free; hence, these composites act as a boon to the modern propeller design.

Meanwhile, galvanizing interest in the partnership of materials with shape-memory and bio-inspired materials. Shape-memory alloys impart adaptive functions, enabling propellers to alter their shapes under variable operating conditions for optimum performance. Such bio-inspired materials imitate natural designs found in aquatic creatures for reducing noise pollution and improving hydrodynamics. If anything, these innovations are a direct response to the industry’s desire for quieter vessels that consume less energy yet satisfy the demands of strict environmental regulations.

One should understand the utilization of advanced materials as the key factor in designing the next generation of marine propulsion. With investments in research programs, the marine industry can adopt these technological developments, finding solutions to key issues such as fuel consumption, greenhouse gas emissions, and high operating costs, while competing at the highest levels. Furthermore, propeller technology will combine material science and design innovations to develop more innovative and environmentally friendly vessels.

Thrust-Improved Propeller Design Advancement

From my standpoint, advances in propeller design have always been motivated by the other side of the law: increasing efficiency or making them environmentally friendly. One of the major changes has been the development of the blade geometry optimization processes, where state-of-the-art tools of CFD, Computational Fluid Dynamics, are utilized to model the fluid interaction with utmost accuracy. By optimizing parameters such as pitch, surface area, and curvature of the blade, thrust can be increased, and drag, coupled with cavitation, can be significantly reduced. Such factors, working together, improve the overall efficiency of propulsion. Since these forces are reduced, wear and tear are also less significant, thereby increasing the lifespan of the propellers.

In addition to this, the incorporation of novel composite materials into propeller design is indeed remarkable. These materials, such as carbon-fiber-reinforced polymers, serve as lightweight yet robust alternatives to traditionally employed metals. They are beneficial as they bring higher performance levels by providing less resistance to rotation, thereby improving corrosion resistance in tough marine environments. When these groundbreaking advancements in materials are combined with innovative design concepts, such as adjustable pitch propellers or biomimetic designs inspired by nature, we can make a significant impact on the field of marine propulsion. By embracing these unconventional technologies, the marine industry has taken significant steps toward developing green and efficient solutions.

Predictions for 2025: The Next Propeller Systems

In my opinion, 2025 is going to be a pivotal year in the evolution of propeller systems, thanks to the advancements in materials and intelligent technologies. Another more important change that I expect is the widespread adoption of smart propellers fitted with sensors and systems for real-time monitoring. This would enable vessels to adjust continuously in response to environmental conditions, achieving optimum performance and fuel efficiency while minimizing operational costs. With such capabilities, shipping administrators will be able to achieve far better navigation accuracy and comply with stringent regulations concerning emissions and sustainability.

Another exciting advancement in AI and ML is in propulsion design and control. Learnt from large datasets and through predictive algorithms, propelled systems shall adapt their functioning proactively to varying conditions, such as water currents or load demands. This adjustment will increase the lifespan of propeller components while also significantly saving energy. In conjunction with novel materials like graphene composites, which are known for being lightweight yet strong, these AI-driven propellers will set new hallmarks of efficiency and reliability in the marine industry.

Thus, I believe that biomimetic designs will have become trendy by 2025. Propellers can take on shapes and functions inspired by sea creatures, such as whales and dolphins, to achieve some degree of hydrodynamic efficiency or to minimize cavitation effects. Biologically inspired developments such as these, along with complementary integration of renewable energy through wind-assisted propulsion, will go a long way toward greening maritime activities. All of these achievements, when taken together, can provide the basis for advancing tomorrow’s propulsion systems, which in turn lead to a sustainable marine environment.

Reference Sources

-

Propeller Thrust – NASA

Explains how spinning propellers create pressure differences to generate thrust. -

How Do Boat Propellers Work – Deep Blue Yacht Supply

Discusses the conversion of engine power into thrust through propeller torque. -

How Does a Ship’s Propeller Work? – Maersk Training

Details how pressure differences on the blade surfaces generate forward motion. -

Propellers | How Things Fly – Smithsonian Institution

Compares how propellers create thrust in water and air, explaining the mechanics. -

Propeller – Wikipedia

Provides an overview of how propellers generate thrust to propel boats and aircraft. - Click here to read more.

Frequently Asked Questions (FAQs)

Can you explain how thrust is created at the blade?

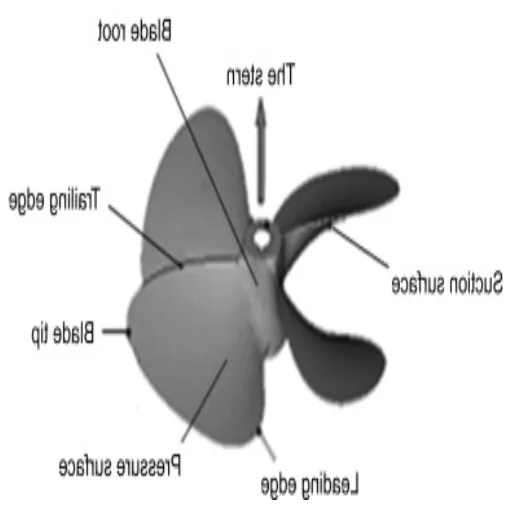

Thrust at a blade is created because of the spinning of the propeller and the resulting pressure difference between the front and back surfaces of the blade. When it spins, it pushes water or air backward, creating an opposing force that pushes the boat forward. This is akin to how a wing works in the air. The angle of attack of the blade affects the thrust created. The selected blade angle essentially strikes a compromise between optimizing efficiency and maximizing thrust. Additionally, the blade shape and size significantly determine the propeller’s efficiency in displacing the fluid.

How does a propeller shaft affect the thrust?

A propeller shaft acts as the connecting member between the engine and the propeller, transferring the rotational energy to the propeller blades. This means that as the propeller shaft rotates, it allows the propeller blades to either move across water or air, creating thrust. However, the efficiency of the propeller shaft must be considered, as losses therein directly translate to losses in the thrust produced by the propeller. An efficient shaft ensures that all the available horsepower is applied to turning the propeller, generating the required pressure differentials that carry into the effectiveness of the thrust system, which in turn pulls the boat forward.

What effects does the angle of attack impose on the exerted propeller thrust?

The propeller blade angle of attack is an angle formed between the propeller blade chord and the direction of incoming fluid flow. Because of this, the angle has the potential to significantly alter the thrust a propeller produces. Increasing the angle of attack generally increases the pressure difference across the propeller disk, thereby increasing thrust. However, if the angle is too high, drag may become dominant and cavitation might occur, thereby becoming harmful to thrust. Hence, one must set the angle of attack such that maximum thrust is generated with little turbulence and losses. This tradeoff is indeed the base of an efficiently working propeller.

What is the role of propeller diameter in thrust creation?

Another factor in propelling thrust elaborates on the propeller diameter. A larger diameter of a propeller allows for a greater area of propeller blades to act on the water or air, enabling more thrust to be generated by the larger diameter. For a vessel that requires much power, a vessel with a larger diameter deflects a greater amount of fluid backward, and there is a greater thrust in the forward direction. However, a greater diameter requires that the horsepower be sufficient to rotate the propeller at an effective speed. Therefore, a proper match between the propeller diameter and the engine, as well as the vessel’s intended use, can achieve the best performance.

How can spinning propellers set pressure differences?

While somewhat simplified, a propeller can be considered an actuator disk set that creates thrust by establishing a pressure difference between its upstream and downstream sides. As the blades pass through the water, they make a low-pressure region behind them and a high-pressure zone in front, causing water to flow from the high-pressure region toward the low-pressure one. It is this pressure differential that generates thrust, driving the vessel forward. The degree of efficiency of this pressure system depends on the blade form, speed of rotation, and, of course, the medium in which the propeller operates. It is essential to understand this concept when optimizing a propeller propulsion system.

What forces exist that form the thrust produced by the propeller?

Thrust is generated by different forces acting on the propeller blades as they rotate. The action of the propeller is such that it imparts a backward momentum to the water or air; with equal and opposite reactions, the body is propelled forward. The thrust bearing supports these thrusts and the smooth working of the propeller rotation. This thrust, called forward thrust, results from the power exerted by the propeller on the air or water behind it. The balance of forces, including lift and drag, determines the performance and capability of the propeller propulsion system.