The boat effect of being thrown astride waters on the power of the propulsor, the outboard propellers are literally cast as the heart of an efficiency- and fun-growing boating experience. It is worth noting that, with the rapid changes in technology being witnessed, the landscape of outboard propellers in 2025 takes into consideration the new advancements and fresh dilemmas that boating enthusiasts face. This article discusses what lies beyond the contemporary state-of-the-art, providing details and offering tips; it should be essential knowledge for each boater seeking top performance, fuel economy, and durability. Whether you are already a learned navigator and pro in the field or a willing but unblemished newbie to the world of boating, you shall come out having learned how to benefit from the present trends and innovations in making every moment on water worth your while. So stay with us as we put forward the selling points of outboard propellers and, in fact, how you undertake the daunting task of selecting one for your craft.

Understanding Outboard Propellers

Definition and Function of a Propeller

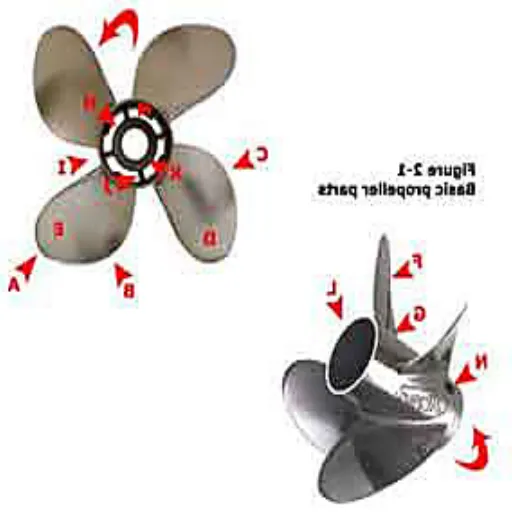

The term “propeller” in boating refers to a mechanism that converts rotational power from the engine into thrust, which is then used to propel the vessel through the water. Generally made of aluminum, stainless steel, or other metals, the propeller has blades that are angled and shaped for efficient working. These blades push water, exerting high-pressure force on one side while low-pressure force works oppositely from the other, thus creating thrust.

Modern Propeller Advantages

- Efficiency Enhancement: Cupping, pitch optimization, and special coatings

- Performance Gains: Improved speed, fuel efficiency, and wear resistance

- Fuel Economy: Up to 20% improvement when properly matched

- Smoother Handling: Better overall vessel control and stability

Modern advances in outboard propeller technology allow for greater efficiency and customization. Features such as cupping, pitch optimization, and special coatings enhance speed, fuel efficiency, and wear resistance. It is established that around a 20% improvement in fuel economy can be realized by properly matching a propeller to an outboard engine and boat type, and handling is also much smoother. The buyer’s market encompasses a range of options, from three-blade to five-blade propellers with variable pitch. The choice of propeller depends on the particular need, whether it is leisure, fishing, or high-speed competition.

Types of Outboard Propellers

Different designs of outboard propellers are available to suit various boating activities and performance needs. Some of the most common types are:

Three-Blade Propellers

The excellent balance of speed and efficiency makes a three-blade propeller ideal for general-purpose boating. Providing the highest speed possible, they are particularly suited to light boats or applications that require high performance, and are considered a choice by ordinary people because of their ability to serve all purposes.

Four-Blade Propellers

With high thrust and smooth operation, these four-blade propellers are ideal for cruising boats, often used in fishing or watersports. Better acceleration, improved handling on choppy waters whilst cruising, and better fuel consumption at cruising speeds are the four characteristics.

Five-Blade Propellers

For smoothness, balance, and maximum efficiency, the five-blade propellers are favorites among high-speed enthusiasts or watercraft that require better control at variable speeds. They help cut vibrations to an extreme level and do a superior job when high horsepower is involved.

Cupped Propellers

These propellers have a blade with a special curvature for extra grip on water. This reduces the slipping effect and is best for boats operating in choppy waters or during sharp maneuvers. Cupped propellers are also said to contribute to better gas mileage.

High-Performance Stainless Steel

While stainless steel propellers emphasize endurance and speed, they remain superior in durability and performance compared to aluminum. They excel in situations of high stress, such as competitions or navigating waters laden with debris, thereby offering a better trade-off between speed and power.

Selection Factors

When selecting a propeller, several factors come into play: blade material, pitch, and diameter. A low pitch provides more torque, which is necessary for handling heavy loads or towing, while a high pitch promotes speed. Hence, matching the right kind of propeller to the engine specifications and the intended usage of the craft leads to optimal performance and a delightful boating experience.

Boat Performance: The Importance of Propeller Diameter

The propeller diameter is the most crucial criterion for optimizing a boat’s performance, as it directly affects the amount of thrust produced and its efficiency. This term refers to the measurement across the circle formed by the path of the propeller’s blades as they rotate. The larger the diameter of a propeller, the more thrust it can produce; hence, slower vessels, such as trawlers or heavy-load carriers, tend to use propellers with diameters on the larger side. Small-diameter propellers are primarily utilized for faster boats, where speed and higher RPMs are preferred.

| Diameter Size | Best Applications | Performance Characteristics | Ideal Vessel Types |

|---|---|---|---|

| Large Diameter | Heavy loads, towing, steady propulsion | Higher thrust, better water contact, reduced slippage | Trawlers, cruisers, work boats |

| Small Diameter | High speed, racing, quick acceleration | Higher RPMs, faster acceleration, increased top speed | Racing boats, lightweight craft, sport boats |

Researchers state that matching the propeller to engine specifications and hull type provides smooth operations and less cavitation, which could slowly erode efficiency and cause damage. Hence, for example, a cruiser boat designed to achieve the best fuel economy might want a slightly larger propeller diameter because it would reduce slippage, allowing for greater contact with the water. Racing would require smaller diameters, which would provide faster acceleration and higher top speeds for performance applications. Selecting the right diameter can help owners improve propulsion efficiency, reduce fuel consumption, and make boat rides more enjoyable.

Choosing the Right Boat Propeller

Factors to Consider: Diameter and Pitch

The diameter and pitch of the boat propeller operate in harmony to directly influence performance, efficiency, and the user’s experience. The propeller diameter is the distance across the circle that its rotating blade tips trace out in the water and is a chief factor in water displacement. Larger diameters provide better thrust and are preferred for heavy boats or applications requiring steady propulsion over an extended period. Smaller diameters eventually make the boat speed up and accelerate more, thus suited for a lightweight craft or a sport activity.

Diameter Effects

- Larger Diameter: Better thrust for heavy boats

- Smaller Diameter: Higher speed and acceleration

- Water Displacement: Chief factor in propulsion

- Application Match: Must suit boat weight and use

Pitch Characteristics

- Higher Pitch: Favored for speed applications

- Lower Pitch: More torque for towing/hauling

- Engine Balance: Prevents overworking the engine

- RPM Range: Maintains efficient operation

Pitch is the distance a propeller would move in one complete revolution if it were to move without slipping. Higher-pitch propellers would be favored by boats that require speed, while those of lower pitch would provide more torque or pulling power, which is necessary for towing or hauling heavy loads. The diameter has to be well balanced with the pitch so that the engine can be properly maintained and not overworked, or an efficient engine RPM range can be achieved. It is believed that, depending on the type of boat, engine power, and water conditions, matching these dimensions will result in improved fuel efficiency and extended engine life.

With these considerations in mind and following trusted guidelines or manufacturers’ recommendations, boat owners can ensure that their choice of propellers best suits their individual needs and boating aspirations.

Effect of Rake and Cup on Performance

The performance, efficiency, and handling of a propeller vary with its rake and cup. The rake angle, or the degree the blades tilt backward toward the shaft, is of significant consideration. By increasing the rake angle, the bow of the boat can be lifted more, which is beneficial for hulls that require a lot of lift or boats being operated in rough waters. For small-rake-angle ships, on the other hand, it is a matter of enhanced stability and easy performance in calmer waters.

Rake and Cup Effects

Rake Angle Benefits

- Higher Rake: Lifts bow, ideal for rough waters and hulls requiring lift

- Lower Rake: Enhanced stability and smooth performance in calm waters

- Hull Compatibility: Must match specific vessel design requirements

Cupping Advantages

- Enhanced Grip: Reduces cavitation for efficient operation

- Speed Benefits: Higher speeds at same RPM through reduced slip

- Thrust Increase: Better water contact and displacement

- Ventilation Reduction: Improved performance in challenging conditions

In cupping, the propeller blades have a slight concavity or an exaggerated “lip” at the edge. This design enhances grip and reduces cavitation, allowing the propeller to make closer contact with the water for more efficient operation. Furthermore, cupping allows a propeller to reach slightly higher speeds for the same engine RPM, as it reduces slip and increases thrust. For example, a heavily cupped propeller is best for speed; the cupping reduces ventilation and helps in water displacement during actual operation.

Since rake and cup act together to give a boat the very design requirements for maximum performance, high rake and differently aggressive cupping might be the balance between speed and control on fast boats. On the other hand, for boats that are nearly always carrying heavy loads or are primarily designed for rough waters, the blend may opt for a moderate rake and slight cupping for enhanced stability and efficiency. Picking rake and cup settings accurately, based on manufacturer specifications and some expert advice, will allow the boat to excel at whatever it wants to do.

Stainless Steel vs Aluminum Propeller

Is it crucial to understand the particular characteristics that differentiate stainless steel and aluminum propellers before effective powers and gains can be offered for your wooden boat? Being perhaps the best-made prop, it is durable and well-suited to withstand stress with stainless steel propulsors. Due to such strength, blades can be manufactured thinner, thereby increasing the efficiency of propellers by reducing drag and improving top speed. Stands excellently against deformation under extreme stress, making it ideal for mighty engines and high-speed applications. This panoply of strength comes at a cost, both in initial development and potential repairs due to the rigidity of this metal.

| Feature | Stainless Steel | Aluminum |

|---|---|---|

| Durability | Excellent – withstands extreme stress | Good – suitable for moderate conditions |

| Weight | Heavier but allows thinner blades | Lighter overall construction |

| Cost | Higher initial and repair costs | Cost-effective and easy to repair |

| Performance | Reduced drag, improved top speed | Satisfactory for moderate speeds |

| Applications | High-performance, powerful engines | Recreational, shallow/debris areas |

| Blade Design | Thinner, more efficient design | Thicker blades, slight drag increase |

Conversely, aluminum propellers make a cost-effective option that recreational boaters have generally accepted. While they are not as durable as stainless steel ones, aluminum, being lighter, can quite satisfy all moderate-speed demands. They also offer the more advantageous option of being inexpensive and easy to repair in case of damage, a selling point for the average boater who may find themselves plying shallow or debris-littered waters. Aluminum blades, on the other hand, might end up being thicker, causing slight drag and affecting high-performance scenarios.

Selection Guide

Competent selections between stainless steel and aluminum propellers depend on various factors, such as your boating style, budget, and performance requirements. If you are looking to consider your money for the long run and want an absolute performing build, stainless steel propellers could be the best solution for high-performance or heavy-duty applications. Aluminum propellers remain an efficient and versatile solution for casual or lightweight applications. Weighing these factors should ensure that your choice of propeller complements the boat and the purpose for which you are using it.

Analyzing Propeller Specifications

Understanding Propeller Size and Its Effects

Propeller size affects the performance, efficiency, and handling of boats and is characterized by the name diameter plus pitch. Diameter refers to the total width of the propeller’s circle while rotating. Pitch refers to how far the propeller will travel forward in one complete rotation. A large-diameter propeller delivers greater thrust and is typically used in heavier boats or at slower speeds. High-pitch propellers are meant to travel faster, but to a certain level, they reduce acceleration and load-handling capacity.

Diameter Impact

- Total width of propeller circle

- Large diameter = greater thrust

- Best for heavier boats

- Ideal for slower speeds

Pitch Effects

- Forward travel per rotation

- High pitch = faster travel

- Reduces acceleration capability

- Limits load-handling capacity

Performance Balance

- Engine power consideration

- Boat weight matching

- Intended use optimization

- Efficiency maximization

Selecting diameters and pitches depends on engine power, weight, and the boat’s intended use. For instance, having less pitch might increase acceleration and towing power, which would be beneficial for water sports. Conversely, more pitch could serve well for achieving top speed in light crafts. Another critical element is the size of the propeller in relation to the engine power; a mismatch causes undue stress on the engine, thereby reducing fuel efficiency and engine lifespan. Careful consideration of the above factors will offer smoother and more custom experiences with the boat.

Number of Blades: All You Need to Know

The number of propeller blades plays a vital role in determining a boat’s performance and handling traits. Generally, boat propellers come with three or four blades, each serving a distinct function. The three-blade propeller is usually favored for achieving efficiency and speed, with recreational boating and lighter loads being prime candidates. The thrust and handling of a four-blade propeller are superior to those of its counterparts, which benefits larger boats for water sports or in choppy conditions, allowing them to maintain consistent power.

Blade Count Characteristics

Efficiency and speed focus, recreational boating, lighter loads

Superior thrust and handling, larger boats, choppy conditions

Seventy-three data points reveal the trend: Four-blade propellers are more fuel-efficient at these midrange speeds because the engine is not exerting significant strain on those long trips. For some time, perhaps, blade design meant that performance differences were stark, thus limiting one’s choice. However, improvements in blade design have rendered these differences mostly negligible, allowing consideration to be given to one’s specific needs. Perhaps a boater should consider the number of blades in conjunction with what he or she values most about boat performance and enjoyment.

Matching Propeller with Type of Boat

The proper propeller selection for your boat begins with remembering how propeller characteristics match the vessel’s type, size, and purpose. For smaller boats, such as pontoons or PWCs, three-blade propellers are best suited for achieving greater speed and agility on the water. Larger boats for cruising or towing, such as cabin cruisers and ski boats with four blades, typically find more thrust below and a gentler touch in return above.

| Boat Type | Recommended Propeller | Material Choice | Key Benefits |

|---|---|---|---|

| Pontoons/PWCs | Three-blade propellers | Aluminum (cost-effective) | Greater speed and agility |

| Cabin Cruisers | Four-blade propellers | Stainless steel (durability) | More thrust and smooth operation |

| Ski Boats | Four-blade propellers | Stainless steel (performance) | Enhanced towing capability |

| Heavy-Duty Work | Variable (application-specific) | Stainless steel (strength) | Maximum durability and efficiency |

Furthermore, the propeller’s composition in the materials used imparts great significance here. Aluminum propellers attract a large group of buyers due to their relatively reasonable prices, coupled with sturdy performance under recreational conditions. In contrast, for heavy-duty work, stainless steel propellers are required due to their strength and efficiency in demanding conditions. Considering the size of your vessel, pattern of usage, and performance requirements, you can ensure its propeller is efficient in terms of fuel consumption, engine performance, and ease of navigation.

Trends and Innovations in Outboard Propellers for 2025

Emerging Technologies in Propeller Design

Consequently, propeller technology continues to evolve in response to the needs related to sustainability, efficiency, and durability. Major advances include the use of 3D printing in propeller manufacturing. This innovative manufacturing process enables the design of highly customized propellers that precisely meet narrowly defined specific performance criteria. Complex geometries are realized that enhance hydrodynamics and minimize manufacturing waste, presenting an environmentally friendly approach.

3D Printing Technology

- Highly customized designs

- Complex geometry realization

- Enhanced hydrodynamics

- Minimized manufacturing waste

- Environmental friendliness

Lightweight Composites

- Advanced carbon fiber materials

- Lighter and stronger construction

- Superior corrosion resistance

- Freshwater and saltwater suitable

- Enhanced durability

Variable-Pitch Systems

- Real-time adaptability

- Navigation optimization

- Fuel savings enhancement

- Engine life extension

- Performance optimization

CFD Design Tools

- Computational fluid dynamics

- Pre-manufacture verification

- Design modification capability

- Reduced prototype costs

- Faster research-to-market cycle

The second great leap is that of lightweight composites. By doing so, advanced composites such as carbon fiber are used to manufacture propellers that are much lighter and stronger. They are good corrosion-resistant materials compared to metals; hence, this makes them ideal in both freshwater and saltwater situations.

Variable-pitch propeller systems have gained popularity because they enable real-time adaptability during navigation. These touchless variable pitch propellers adjust the propeller blade setting/speed to optimize performance according to varying conditions during transit, thereby assisting in fuel savings or prolonging engine life.

Computational fluid dynamics (CFD) design tools have been applied, allowing the designer to verify and modify the propeller design before committing it to actual manufacture. This simulation technology minimizes faulty designs and additional expenses associated with prototype production, enabling a quicker research-to-market cycle with designs that are inherently efficient. With all these new developments, we are looking at a future where outboard propellers will perform efficiently while emitting fewer pollutants.

Data-Driven Insights on Boat Performance

Nowadays, most boating technology centers on achieving optimum efficiency, safety, and performance through data insight. Using advanced sensors, telemetry systems, software analytics, and real-time data, engineers and manufacturers can obtain valuable insights into fuel efficiency, engine capacity, hull resistance, and navigation patterns. Therefore, IoT-enabled systems can help boat owners remotely monitor the boat’s performance parameters, allowing for anticipated maintenance, as opposed to end-of-programming methods, thereby reducing downtime.

Data-Driven Benefits

- Advanced Sensors: Real-time monitoring of critical parameters

- Telemetry Systems: Remote performance tracking and analysis

- IoT Integration: Connected systems for predictive maintenance

- Historical Analysis: Performance prediction under various conditions

- Efficiency Optimization: Reduced fuel consumption and emissions

Moreover, these computational models, aided by historical performance datasets, detail the predictions of a boat’s behavior under various conditional scenarios, such as rough seas or high velocities. These data approaches assure optimum reliability of vessels, while promoting sustainable practices through reduced fuel consumption and emissions. As such, the marine industry continues to metamorphose to suit the ever-changing modern standards of performance.

Successful Propeller Upgrades

Upgrading a propeller is a crucial step in improving marine performance and efficiency. It is a new application featuring modern design, utilizing innovative materials such as composites and high-strength alloys to enhance durability and resistance to corrosion. Customized blade shapes and precise adjustment of blade pitches improve thrust and minimize cavitation and other harsh operations, thus increasing energy efficiency.

Upgrade Performance Results

- Noise Reduction: Five-blade propellers dramatically reduce noise and vibrations compared to three-blade models

- Fuel Efficiency: Up to 20% reduction in fuel consumption documented

- Speed Enhancement: Increased cruising speeds with reduced engine loads

- Smoother Operation: Improved onboard environment and comfort

- Sustainability Focus: Enhanced efficiency, reliability, and functionality

Five-blades, for instance, dramatically reduce noise and vibrations as opposed to three-blades, thereby providing a smoother onboard environment. Moreover, the performance analyses conducted before and after these upgrades provide real data, proving enhancements such as increased cruising speeds, reduced engine loads, and up to a 20 percent reduction in fuel consumption. The overall goal of such upgrades is to promote sustainability, with a focus on efficiency, reliability, and functionality.

Maintenance and Care for Outboard Propellers

Maintenance Tips to Improve Longevity

To maintain the performance of outboard propellers, I typically employ a few simple yet effective measures to ensure they function optimally in the long run. First, an inspection of the propeller for any damage is carried out, including dents, cracks, or bent blades. Any small imperfection can reduce performance, increase fuel consumption, and compromise effectiveness. Additionally, ensuring the prop is well cleaned after every use in salty water, as well as removing marine debris such as algae or barnacles, helps prevent corrosion.

- Regular Damage Inspection: Check for dents, cracks, or bent blades that can reduce performance and increase fuel consumption.

- Saltwater Cleaning: Clean thoroughly after every saltwater use and remove marine debris like algae or barnacles to prevent corrosion.

- Shaft Inspection: Periodically check propeller shaft for fishing lines and debris that could damage seals and become costly.

- Lubrication and Security: Keep propeller well-lubricated and securely fastened to shaft to prevent unnecessary wear and tear.

- Hardware Inspection: Remove and inspect hardware condition, checking if prop nut or washers need replacement.

I inspect the propeller shaft for fishing lines and other debris periodically; they could damage the seal and, in the long run, become very costly. Furthermore, I keep the propeller well-lubricated and secure it tightly to the shaft to prevent unnecessary wear and tear. Sometimes I even take it off and inspect the hardware condition, checking to see if the prop nut or washers need any kind of replacement.

For optimal performance, I do not hesitate to consult the manufacturer’s manual or a technician, especially right before the high-usage season. Routine maintenance prolongs the life of my propeller, improves fuel efficiency, and guarantees smooth, reliable operation. Protecting this vital asset is easy with just a little bit of care and attention.

Typical Troubles and Their Cures

The primary common damage to my propeller is caused by debris like fishing line, seaweed, or rocks. This might cause chips, dents, or bends in the blades, thereby reducing performance and increasing vibration. Any semblance of a difference in sound or vibration from my propeller prompts me to inspect it immediately. Minor damages are addressed by me using a file to smooth rough areas and remove entangled debris with minimal force. On the other hand, severe damages call for professional repair or outright replacement of the propeller to maintain maximum operational efficiency.

Debris Damage

Causes: Fishing line, seaweed, rocks

Symptoms: Chips, dents, bent blades, vibration

Solutions: File rough areas, remove debris carefully, professional repair for severe damage

Saltwater Corrosion

Causes: Saltwater exposure over time

Symptoms: Pitting, surface corrosion

Solutions: Fresh water washing, anti-corrosion spray, routine maintenance

Installation Issues

Causes: Improper installation, loose hardware

Symptoms: Performance issues, potential loosening

Solutions: Regular checks, proper tightening to manufacturer specs

Saltwater environments also see corrosion problems. Over time, saltwater exposure would cause pitting or corrosion on the metal surface of the propeller, thereby affecting its performance. To prevent this, I usually wash the propellers with fresh water after every use and then apply a coat of anti-corrosion spray. I also watch for early signs of wear and promptly address any corrosion that arises during routine maintenance to prevent further deterioration.

Lastly, performance issues could also arise due to improper installation or loose hardware. I have learned that it is essential to regularly check whether the propeller is securely attached and that the nut is tightened to the manufacturer’s specifications. Loose fittings may not only hinder smooth operation but also increase the risk of the propeller coming loose during use. Being attentive to these common problems and addressing them in advance will prolong the life of my propeller and keep it running smoothly on water.

Seasonal Care for Optimal Performance

Seasonal maintenance ensures propellers are in optimal operating condition for the finest possible performance throughout the year. Among the preparations needed for any boating season is a thorough inspection of the propeller for signs of damage, including dents, cracks, and wear on the conveyor. Any of these instigates severe imbalances that, in the end, will lower performance and might severely damage the engine. The propeller is cleaned as a critical step to prevent the growth of any organisms that tend to colonize it, including marine growth, and to prevent corrosion.

Seasonal Maintenance Schedule

Pre-Season Preparation

- Thorough damage inspection

- Complete cleaning process

- Marine growth prevention

- Corrosion assessment

Winterization Process

- Complete cleaning and inspection

- Protective coating application

- Hardware replacement as needed

- Proper dry storage setup

Winterizing my propeller is a crucial part of preparations for the colder season. First, I give it a thorough cleanup and then apply a protective coat, such as an anti-corrosion spray, to prevent rust and other deterioration during storage. While I’m at it, I check for any problems that the seasonal changes might have aggravated and replace worn-out parts, such as propeller nuts or washers, to avoid inconveniences when the new season begins. Storage is just as necessary as all of the above: the prop needs to be stored in a dry and secure area, such that it cannot be damaged by freezing temperatures or prolonged disuse.

By maintaining my propeller throughout the seasons, I prolong its life and ensure a better boating experience. Proper maintenance ensures the propeller is running at optimum performance, improving fuel efficiency and reducing the likelihood of costly repairs. It gives me mental peace, allowing me to cherish my time on the water with my equipment in its prime state.

Reference Sources

-

How to Choose the Right Yamaha Outboard Propeller – VIF Prop: A comprehensive guide on selecting Yamaha outboard propellers, focusing on performance and efficiency.

-

How to Choose the Right Mercury Outboard Propeller – VIF Prop: Offers insights into Mercury outboard propellers, including blade types and their impact on speed and fuel efficiency.

-

Propeller Guide – Propeller Depot: A step-by-step guide to selecting the right propeller for your outboard engine.

- Find more info now.

Frequently Asked Questions (FAQs)

What is a propeller, and how does it affect performance in boats?

An outboard propeller is a crucial component of any boating motor, providing thrust to the boat through the engine’s power. The design of propellers–their pitch and diameter– means acceleration and top speed of the ship. The proper propeller will ensure that maximum performance and fuel economy are achieved, with the boat operating within its recommended RPM range. Learning basic information about props, such as whether they are made of stainless steel or aluminum, will help in selecting the correct one.

How does one act to choose a propeller for his boat?

Selecting the best propeller requires considering several factors, including the type of boat, the desired performance, and the engine’s power. The pitch and diameter of the propeller determine acceleration, and hence how the ship reaches its top-end speed. There is also a choice of the number of blades; for example, four-blade propellers provide more thrust and smoother operation. Ideally, the propeller should be suited to the boat specifications and the recommended WOT RPM range for best performance.

What is propeller pitch, and why is it important?

Propeller pitch refers to the distance a propeller would theoretically travel in one complete turn, measured in inches. If the pitch is set high, theoretically, it provides for a higher top speed; however, if it is too high for the engine’s power, it will induce acceleration problems. A lesser pitch can increase acceleration and hole shot, but it would then reduce the top speed. Boaters well understand that the mix between pitch and diameter is the key to achieving a balance in particular performance applications.

What are the advantages of using stainless steel pumps?

There are several performance advantages that a stainless steel propeller has over its aluminum counterpart, including strength, efficiency, and acceleration. Due to its strength, stainless steel propellers don’t bend easily and can take in more horsepower. This would be a good choice for high-performance marine applications. A stainless steel propeller is typically manufactured to more advanced designs that reduce drag and increase the speed of the boat, featuring cupped blades or a rake profile. While generally more expensive, the higher price may be worth it for serious boaters due to the design and durability factors.

What effect does the number of blades on a propeller have on its performance?

The number of blades on a propeller can have a significant influence on the behavioral pattern of a boat. Three-blade propellers are the most commonly designed because of their balance of speed and fuel efficiency. A four-blade propeller will increase thrust and acceleration, especially at lower boat speeds. With more blades, the propeller can generate higher lift, which is beneficial for watersports or handling heavier loads. More blades will also cause higher drag, so keeping in mind what your boat is primarily destined for will help in selecting the number of blades.

What exactly is propeller diameter, and how does a smaller or larger diameter affect my boat’s speed?

A propeller has a diameter measured across the circle created by the ends of its blades. In other words, the diameter plays a crucial role in determining boat speed and efficiency. If the diameter is large, more thrust can be produced, which is suitable for heavy loading or towing. The smaller diameter, on the other hand, could maintain high RPMs and increase speed. The diameter should also be selected to suit the engine’s power and the recommended RPM for operation, thereby avoiding problems such as over-revving. Match the right prop size to your boat specifications, and enjoy increased performance and fuel economy.