Understanding boat and ship terminology and elements is essential for effective maintenance and communication among boating enthusiasts and professionals. Among these components, the propeller, which takes engine power and transforms it into thrust to move a boat, is one of the most essential yet misunderstood parts. But what exactly do you call the propellers on a ship, and why does their design and operation matter? So, in this complete guide, we will try to clear up the term “propeller,” highlight its importance to a vessel’s performance, and integrate those into a larger picture of boating mechanics for the year 2025. Whether a seasoned sailor or an entry-level mariner, this article will provide you with insights into a broader horizon about this vital component and its application in modern boating.

Understanding the Boat Propeller

Boat Propeller: Definition and Function

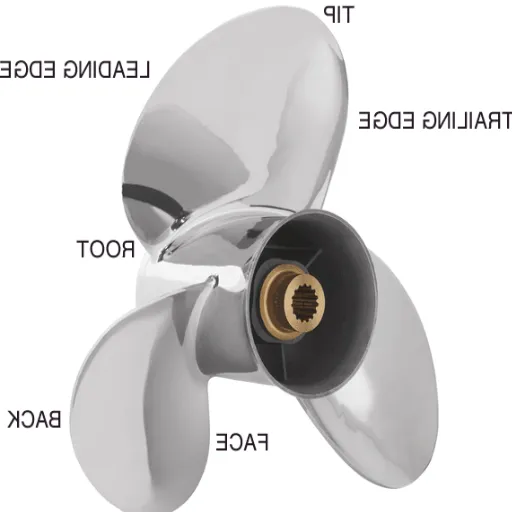

A boat propeller is a mechanical device that converts mechanical rotational energy into thrust, enabling an object or vessel to move through water. It does so by a set of blades, usually three to five, carefully pitched to effect slight differences in water pressure during rotation, which thrusts in the direction opposite to that of blade movement and hence pushes the boat forward or backward, depending on the direction of rotation.

Modern Propeller Technology

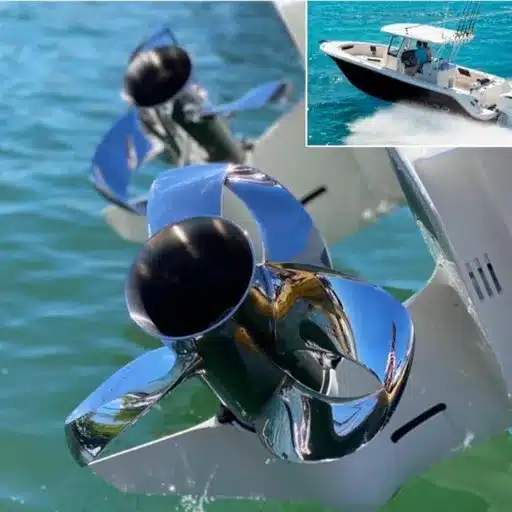

Modern developments in propeller technologies emphasize the use of specific materials, blade design, and operation to suit their respective applications. Stainless steel and aluminum, for example, are commonly employed materials as they offer durability and resistance to corrosion, which are extremely important factors in the maritime environment. More specifically, the diameter, pitch, and blade design of a propeller are calculated in accordance with the power of the engine and the performance requirements of the particular vessel. Larger-diameter propellers, for example, might provide much thrust at slow speeds and hence can be used for heavy vessels, whereas smaller high-pitch propellers can offer faster speeds with less drag for lighter crafts.

Modern designs, through fluid dynamics computations and advanced manufacturing techniques, strive to reduce cavitation, improve fuel efficiency, and enhance maneuverability. Propellers are designed to enhance propulsion while maintaining stability and efficiency in various operational conditions, thereby playing a pivotal role in modern marine engineering.

Distinctions Between Propellers and Impellers

| Aspect | Propellers | Impellers |

|---|---|---|

| Design | Open blades for propulsion | Enclosed in casing |

| Function | Generate thrust through water/air | Enhance fluid pressure/flow |

| Application | Vessels, airplanes, drones | Industrial processes, pumps |

Although both propellers and impellers are key components in fluid dynamics and propulsion systems, they vary in design, function, and typical application. Typically, propellers are used in situations that require propulsion through water or air, and by virtue of their rotation, they create thrust by moving fluid in a given direction. With characteristic open blades, they are often found on vessels, in airplanes, and on a few drones.

Impellers are located inside a casing; therefore, they can enhance the pressure of the fluid or the flow in a system. These machines draw in fluid through the inlet and, using rotational energy, force it outward at a higher velocity or pressure through the outlet. Impellers essentially facilitate fluid motion within a confined space, whereas propellers primarily generate linear motion.

Engineering demands can also be a striking differentiator between the two. Propellers are designed to meet the varying propulsion demands of their operating speeds, taking into account blade pitch and cavitation characteristics. Impellers are constructed with pressure head and flow rate requirements of industrial processes in mind. For instance, centrifugal pump impellers have particular vane configurations that are engineered hydraulically for optimum pump curves and operational stability.

From a materials perspective, impellers often require coatings and wear-resistant adaptations depending on the abrasive or corrosive nature of the materials being processed, whereas propellers are generally designed to reduce drag and increase durability in open conditions. These components are tailored to specific applications in fluid mechanics, emphasizing engineering and operational efficiencies, with inherently different sets.

Importance of the Propeller in the Performance of the Boat

⚡ Performance Impact Statistics

Studies reveal that a larger mismatch between a propeller and, hence, poorly tuned operation would result unfavorably in terms of fuel economy, with a loss of up to 10-15% directly due to operational costs.

The propeller is a crucial piece of equipment that generates a hydrodynamic force, significantly affecting the performance of boats in terms of efficiency, speed, and maneuverability. Propellers convert the rotational energy of the engine into thrust, which is the forward or backward movement of the vessel, depending on the direction of rotation. The design and material do govern the hydrodynamic behavior. The pitch, diameter, number of blades, and rake angle are carefully considered to calculate speed and torque while mitigating cavitation to enhance efficiency and minimize wear on the part.

For instance, any increase in the diameter of the propeller improves thrust and favors heavy vessels, but with the loss of speed at the top end. The pitch of a propeller determines how far a boat moves with one of its turns. A greater pitch equals a faster boat, while a lower pitch makes one better at accelerating and carrying loads. With advances in CFD and materials science, it is now possible to produce high-performance propellers that enjoy better corrosion and wear resistance, as well as have blade geometries optimized for peak efficiency. Other advancements, such as the variable-pitch propeller, enable operating conditions to be changed in real-time, thereby improving adaptability and performance under varying loads.

In the choice and maintenance of the propeller, precision is necessary to achieve good fuel economy and save the engine from unnecessary stress. Consequently, all modern branches of marine engineering emphasize the fundamental principle of initially selecting the propeller, as well as the expectation of regular checks or replacements based on the results, to maximize the vessel’s operational performance.

Types of Boat Propellers

Differences Between Fixed- and Variable-Pitch Propellers

✅ Fixed-Pitch Propellers

- Advantages:

- • Inexpensive to manufacture

- • Easy to maintain

- • Simple to repair

- • Straightforward design

Best for: Constant speed and load conditions

⚡ Variable-Pitch Propellers

- Advantages:

- • 15-20% fuel savings

- • Better efficiency

- • Improved maneuverability

- • Dynamic blade adjustment

Best for: Tugboats, ferries, naval vessels

Being the most common form of marine propeller, fixed-pitch propellers consist of blades that are attached to the hub at a fixed angle. A fixed-pitch marine propeller is inexpensive to manufacture, easy to maintain, and simple to repair due to its straightforward design. In situations where speed and load are relatively constant, FPPs work very well. On the other hand, when the speed and load vary, the propeller design does not permit adjustment; hence, the propeller may become inefficient under varying conditions.

Unlike fixed-pitch propellers, variable-pitch propellers allow for adjustments to blade angles during operation, providing better efficiency over varying speeds and load requirements. VPPs can change blade pitch dynamically, thereby saving 15 to 20 percent on fuel compared to fixed-pitch alternatives, and this becomes more evident in vessels with varying operational profiles. Furthermore, these vessels benefit from the variable pitch system, as it offers improved maneuverability, which is particularly beneficial for tugboats, ferries, and naval vessels. That said, these propellers tend to be more expensive in terms of installation and maintenance due to the complex mechanisms involved, coupled with the advanced control systems required.

Each type of propeller has distinct uses in marining, and the choice of type between them mostly depends on the associated operational profile, cost, and performance required. Continued developments in material technologies and control methods have significantly improved the efficiency and lifespan of both fixed- and variable-pitch propellers, thereby maintaining their relevance in modern marine engineering.

Material Types: Aluminum, Stainless Steel, and Composites

The choice of propeller material in maritime applications is crucial, as it significantly influences the performance, lifespan, and cost of a product. Each material has its advantages, which suit specific conditions and requirements of vessels.

🔧 Aluminum Propellers

Aluminum: Aluminum is ideal for making smaller recreational and light-duty vessels due to its lightweight nature and relatively low cost of casting. Although considered somewhat susceptible to corrosion in certain wash areas, particularly in saltwater environments, aluminum propellers are often coated for protection. The comparative lightness of aluminum puts less stress on engines, offsetting the sluggishness of FPP; however, aluminum propellers tend to wear easily in conditions involving substantial impacts or heavy loadings.

⚡ Stainless Steel Propellers

Stainless Steel: In terms of strength, sturdiness, and corrosion resistance, stainless steel outshines aluminum and is therefore suitable for applications in high-performance environments and commercial vessels. The density being higher than that of aluminum allows for thinner blades, thereby achieving excellent hydrodynamic efficiency and higher speeds. Although expensive in terms of its pricetag, stainless steel is one of the best long-lasting materials that does not deteriorate when coming into contact with debris, thus able to endure testing operational conditions.

🌟 Composite Propellers

Composites: Composite materials are a modern innovation in propeller technology, typically comprising reinforced plastic polymers combined with carbon or fiberglass. Composite propellers present an advantage in terms of corrosion resistance and the capability of managing operational demands moderately, whereas they are known for their durability and lightness. Usually, composite designs include modular blade systems wherein individual components can be replaced at a relatively cheap cost, with speed. At least in the present day, the composites may not fully equal stainless steel in sheer strength, but a range of applications for composites has developed under environmentally friendly and flexible considerations.

The choice of materials should be subject to the vessel’s use-case scenario, wherein considerations are given to cost, performance, and environmental impact. The continuous development in alloys and composite engineering thus pushes the performance boundary of these materials.

Selecting the Right Propeller for Your Vessel

Determining the proper propeller for a boat requires a detailed evaluation of some crucial criteria. These include propeller size, material, pitch, and the number of blades, which can directly affect speed, handling, and fuel economy.

🎯 Key Selection Factors

📏 Diameter and Pitch:

A diameter is the overall size of the propeller, which somehow dictates how much water is pushed with each rotation. Larger diameters are typically more suitable for heavy vessels, as they provide greater thrust. Pitch is the distance, in inches, that a propeller moves forward through the water in a single rotation. A propeller with a high pitch may produce greater speeds, but with higher power requirements for the engine. A lower pitch allows for faster acceleration and is ideal mainly for towing or fighting against strong currents.

🌟 Number of Blades:

Propeller blades generally range from three to five. The fewer the blades are, the higher the speed, and the less the drag. The greater the number of blades, the smoother the performance; less vibration requires stability and comfort, which complement purposes such as cruising or fishing.

🔧 Material Selection:

Propeller materials significantly impact both equipment performance and function. Stainless steel is a superior option in terms of durability and performance, particularly in terms of speed and efficiency. Aluminum, being much lighter, less costly, and easier to repair, is typically acceptable for casual use.

⚠️ Cavitation and Ventilation Prevention:

Correct selection can also help prevent problems associated with cavitation, such as lower water pressure, which can create vapor pockets that begin to erode the propeller. Conversely, wrong installation may cause ventilation, where air is sucked into the propeller blades and reduces propeller efficiency.

Selecting a prop also needs to consider these factors, including engine capacity and the weight of the boat, as well as the intended use of the ship. In the instance where an impeller is chosen correctly, this would always serve to maintain engine output power and actually increase fuel efficiency and overall satisfaction on the water.

The Role of Propellers in Personal Watercraft

Boat and Personal Watercraft Propeller Comparison

Boat and PWC impellers differ significantly in design and scope of functionality, tailored to fulfill their specialized operational requirements and propulsion methods. Boat propellers are typically open, multi-blade systems that convert rotational energy into thrust, propelling watercraft forward. They work well in various water conditions but are more susceptible to damage due to debris or shallow water environments. These propellers depend upon the proper selection of blade pitch and diameter, as well as the material of construction, to suit the engine of the boat and the manner of intended applications, so that they find uses in almost every sphere adjacent to water transport, from recreational boating to commercial transport.

However, personal watercraft utilize impeller systems enclosed within a steel shaft running in a jet pump housing, which suck in water to pressurize and expel water at tremendous velocity for thrust. Due to their protected design, one can be used safely when maneuvering at high speeds in shallow waters or in areas laden with debris. Acceleration and maximum speed are primarily dependent on impeller pitch and the internal pump’s dimensioning.

With a design focus on generalization and load assignments, the boat propeller contrasts with the compact and high-powered designs of PWC impellers. This highlights the need for diverse solutions in marine propulsion systems tailored to specific operational criteria and environmental factors.

Effect of Propeller Designs on Personal Watercrafts’ Performance

The propeller design for personal watercraft has undergone several changes over the years in an effort to meet the demand for increased efficiency, speed, and responsiveness. Stainless steel and composites have replaced old, low-grade aluminum because they offer greater strength and corrosion resistance, and can withstand higher operating pressures. This change has favored the design of fragile, aerodynamic blades, resulting in less hydrodynamic drag and, consequently, improved performance.

🔬 Advanced Design Analysis

Accurate analysis reveals that an aggressive blade geometry based on rake angle, cup, and diameter directly influences acceleration, thrust, and top-end speed. For example, an increase in blade pitch increases speed by displacing more water, but decreases initial acceleration if the pitch is too high. Increasing the number of impeller blades alters the flow of water, making it smoother but slightly reducing the maximum speed.

Historically, there has been a period of research addressing the role of computational fluid dynamics (CFD) in modern propeller design processes. Using CFD tools, engineers can predict cavitation zones, analyze flow efficiency, and improve a blade design to reduce energy losses. Such precision enables PWC impellers to generate maximum thrust for every given waterway, from calm lakes to choppy seas.

Further evidence suggests that improvements in impeller ducting and pump casing designs have all contributed to thrust enhancements, reduced vibration, and, consequently, better rider control and comfort. These innovations drive advances in the propeller industry for PWC, pushing performance boundaries with reliability and durability in harsh working conditions.

2025 Trends in Personal Watercraft Propeller Technology

🚀 Cutting-Edge Innovations in 2025

- 1

Advanced Composite Materials: Integration of carbon fiber-reinforced polymers for high tensile strength and low weight, contributing to propeller longevity and preventing deformation under extreme conditions. - 2

3D Printing Technology: Additive manufacturing enables highly customized propeller designs with complex geometry impossible through conventional methods. - 3

Real-Time Monitoring Systems: Integration of sensors gathering data on blade stresses, rotational speed, and water flow dynamics for predictive maintenance.

In 2025, the evolution of PWC propeller technology will pursue a data-driven and performance-based approach. This thoughtful approach involves integrating innovative materials into propeller designs. Therefore, a variety of composite materials are used, aiming for high tensile strength and low weight, with carbon fiber-reinforced polymers being one such option among many. These materials contribute to the overall longevity of the propeller, preventing it from deforming in the face of extreme conditions, such as highly accelerated magnitudes or water of differing density. In addition, the use of corrosion-resistant alloys imparts a longer life, given the saltwater environment, which is of particular concern to recreational watersports and professional watercraft.

The application of additive manufacturing (3D printing) techniques in propeller production is another emerging trend. The very idea applied here enables manufacturers to produce highly customized propeller designs with complex geometry, which is impossible to achieve through conventional methods. Advanced designs, such as flow-optimized blade shapes and variable pitch configurations, are now being custom-designed for the exact specifications of individual crafts, yielding significant benefits in thrust efficiency and drag reduction. Better fuel economy and more optimized performance are direct effects of such measures, while sustaining the design for a pollution-friendlier environment.

Ever since modernity took hold, propeller technology has been increasingly affected by digitalization. Real-time monitoring systems are increasingly being integrated into the higher-end models of PWC as a standard feature. These systems gather essential data, such as stresses on the blades, rotational speed, and water flow dynamics, to assess wear and alert operators to required maintenance. Backed by advanced hydrodynamic simulation software, manufacturers can then further optimize blade designs during the research and development stage. It is this perfect fusion of state-of-the-art materials and fabrication methodologies with the spirit of digital innovation that marks a new era in technology concerning PWC propellers, catering perfectly to the industry’s requirements of top performance, eco-friendliness, and end-user safety.

Basic Parts of a Boat and Their Functions

Overview of Different Parts of a Boat

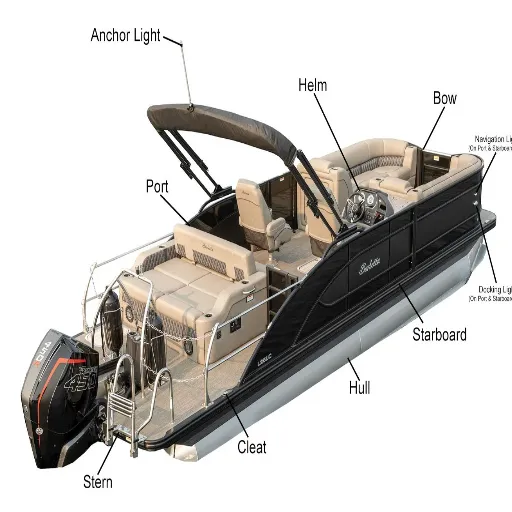

The anatomy of the boat can be categorized into various basic sections depending on the principal function to be considered, such as functionality, stability in response to navigation, or safety in navigation. The hull is the body of the boat that provides buoyancy to carry the weight of the vessel and its cargo while it rolls steadily over a thin medium of water. Plate hulls are typically categorized as displacement, planing, or semi-displacement, depending on their structural design and the water force acting against them.

⚙️ Essential Boat Components

- 🚢 Hull: The body providing buoyancy and carrying capacity

- 🛤️ Deck: Flat horizontal surface for passengers and cargo

- ⚖️ Keel: Underwater plane providing stability and direction

- ⚡ Propulsion System: Propeller, motor, or engine for movement

- 🎯 Rudder: Steering mechanism at the stern

- 💡 Navigation Lights: Safety lighting for visibility

- 💧 Bilge: Lowest hull area with drainage pumps

A deck is the flat horizontal plane of the boat over which passengers move or across which cargo may be loaded. Deck measures various fittings, including cleats, handrails, and/or storage lockers. At the pinnacle of its list of functions, the keel acts on an underwater plane to provide stability, control, and direction for sailboats as they resist lateral forces imposed by wind.

Another critical component is the propulsion system, which typically comprises a propeller, outboard motor, or inboard engine, depending on the type of boat. This system converts energy into thrust, propelling the vessel forward or backward. Rudders, commonly fixed at the stern, are responsible for the steering mechanism by manipulating water flow past the stern.

Navigation lights cast their glow for greater safety, marking the boat’s position, movement, and activity, especially during periods of reduced visibility. Finally, the bilge identifies the lowest location inside the hull where water can accumulate, often equipped with bilge pumps for drainage when necessary. These components collectively emphasize functional efficiency to ensure smooth operation under varying maritime conditions.

How the Propeller Coordinates into the Whole Boat Design

🔄 Propeller Integration System

The propeller is a crucial element of a vessel’s propulsion system, transforming the power generated by the engine into actual thrust and thus propelling the boat through the water. From its shape to its size and material, everything is meticulously designed to optimize performance for the vessel’s intended purpose, which may include speed, cargo loads, or fuel consumption.

For example, the number of blades, pitch, and diameter are decided so that a balance is drawn between thrust and drag. A large propeller with steep pitch will provide significant thrust, making it suitable for heavy-duty or industrial vessels. In contrast, smaller propellers that spin faster are better suited for fast, lightweight boats.

Material construction plays a significant role. The other common materials are stainless steel, which brings durability and corrosion resistance, and aluminum, which offers a lightweight and low-cost option. Manufacturers can also employ advanced hydrodynamic testing methods, whereby they design propellers to reduce cavitation —a phenomenon that occurs due to rapid changes in pressure —enhancing fuel efficiency and reducing vibrations. The propeller, incorporated into the larger boat design, works in conjunction with other system components, including the gearbox, rudder, and hull design, to ensure smooth and fuel-efficient maneuvering in terms of overall operational performance.

Maintenance for Propellers and Other Boat Components

📈 Maintenance Benefits

By statistical evidence, routine maintenance can lead to an increase in the default efficiency of a vessel by between 10 and 15%, thereby causing a lesser chance of mechanical failure and an extended operational duration.

Regular maintenance of boat propellers and other boat components is essential for optimal performance, longevity, and safety. Propeller inspections should be a standard practice, especially for signs of damage such as bent blades, cracks, or excessive wear, as these can significantly impact thrust efficiency and fuel consumption. Cleaning the propeller is required to remove any marine growth and debris that may obstruct its hydrodynamic performance. Additionally, polishing the propeller surface increases its resistance to corrosion and cavitation, particularly in saltwater environments.

🔧 Essential Maintenance Tasks

- ✅ Propeller Care: Regular inspections, cleaning, and polishing

- 🔧 Lubrication: Gearbox and rudder system maintenance

- 🚢 Hull Maintenance: Structural integrity and antifouling treatments

- ⚡ Electrical Systems: Wiring and battery connection inspections

- 🌊 Cooling Systems: Flushing and inspection to prevent overheating

Greasing and lubrication systems must be regularly maintained with greases specified by the manufacturers to reduce friction and prevent component breakdowns, such as the gearbox or rudder. The hull needs to be routinely checked for structural integrity by all means, as well as for fouling, with antifouling treatments applied if necessary to discourage the growth of marine organisms that could cause drag and reduce efficiency. Electrical systems, comprising wiring, battery connections, and the like, require periodic inspections to ensure reliable operation under varying marine conditions. In contrast, the fuel and cooling systems require adequate flushing and inspections to prevent clogging and overheating.

A comprehensive set of maintenance checklists tailored to the specific needs of each boat model needs to be established in the highest interest of maximizing performance and safety during operation.

Future Trends in Boating and Propeller Technology

The Propellers for Cutting Edge Design and Materials

As engineering advances propellers, the focus is placed on superior efficiency, green technology, and enhanced durability. Novel propellers are introduced with biomimicry based on natural phenomena, such as those found in whale fins and fish tails, to optimize hydrodynamic performance and reduce cavitation. Under these conditions, designs have more thrust and efficiency, especially when high-speed operations are required.

🔬 Revolutionary Material Innovations

🧬 Biomimicry Designs

Inspired by whale fins and fish tails for optimal hydrodynamic performance

🏗️ Composite Materials

30-50% weight reduction while maintaining strength

⚛️ Nanomaterials

Surface treatments to reduce friction and wear

🖨️ 3D Printing

Complex geometries for custom-made propellers

Material development is a vital issue in propeller technology. Traditionally, stainless steel and aluminum have been the dominant choices. However, composites and carbon fiber are entering the scene due to their lightweight properties, corrosion-resistant nature, and higher fuel efficiency. Studies reveal that composite propellers can offer weight reduction of up to 30-50% while maintaining strength. Meanwhile, nanomaterials applied to the surfaces of propellers diminish friction and wear, thus enhancing propeller life.

Another significant step towards evolution is the emergence of 3D printing and other additive manufacturing methods for producing relatively complex geometries for custom-made propellers, which were previously unachievable by conventional means. These advancements enable precise adjustment of propulsive properties to desired operational characteristics, thereby achieving significantly improved vessel performance.

The drive towards electric and hybrid technology has rendered the role of fixed-pitch propellers obsolete. Hence, engineers are already considering variable-pitch and contra-rotating propellers for better performance in such propulsion systems. From now on, stronger regulatory pressure for greener technology will inform material selection and energy-saving propeller designs, which will become the standard in the maritime industry.

Environmental Considerations in Propeller Design

🌱 Eco-Friendly Design Priorities

- ⚡ Energy Efficiency: Advanced blade geometry and pitch optimization to reduce fuel consumption and emissions

- 🔇 Noise Reduction: Designs that minimize cavitation noise harmful to marine life

- ♻️ Sustainable Materials: Recyclable materials requiring less energy to manufacture

Environmental concerns in propeller design emphasize minimizing the environmental impact of maritime operations. Optimization of the propellers’ efficiency to reduce fuel consumption thus mitigates the release of greenhouse gases. A highly efficient design, such as one with advanced blade geometry and pitch optimization, enables the vessel to experience less resistance, resulting in reduced energy consumption and emissions. Additionally, CFD simulation tools can be utilized to refine these designs by simulating the flow of water around the propeller and identifying areas that require performance enhancement.

Another factor I consider is the reduction of underwater noise pollution. Cavitation noise is just too loud and might be injurious to marine life. Adopting these lines, I try to choose designs that reduce cavitation intensity, either through novel blade shapes or other means, such as materials that dampen sound vibrations. Also under this heading is the matter of using long-lasting, sustainable materials to manufacture propellers. Choosing materials that are recyclable or that require less energy and materials to manufacture would consider the environment during the product’s life cycle.

A delicate yet necessary balancing act in the modern propeller design environment is that of operational requirements versus environmental responsibility. By embracing modern technologies and sustainable design principles, we envision propeller systems that satisfy both regulatory requirements and ecological conservation objectives.

Data on Propeller Efficiency and Boat Performance in 2025

📊 2025 Performance Statistics

🚀 Efficiency Gains

15%

Hydrodynamic efficiency improvement with CFD simulation

⛽ Fuel Savings

↓

Reduced fuel consumption and emissions

📱 Smart Tech

📊

Real-time monitoring and optimization

According to the latest data from 2025, the increased efficiency of the propeller has significantly impacted the overall performance of the boat. Designing modern propellers with the help of CFD simulation may improve hydrodynamic efficiency by up to 15% compared to designs from previous decades. Thus, with this increase in efficiency, fuel consumption also decreases, thereby reducing emissions in compliance with strict environmental regulations. On the other hand, the development of materials, including lightweight alloys and composite materials, helped provide durability and performance in differing operational conditions.

With smart technology integrated into propulsion systems, further optimizations in boat operations are afforded. Now, propeller systems have incorporated real-time monitoring; embedded sensors notify instantly about blade efficiency, cavitation potential, and structural vibrations. This information can be effectively utilized to dynamically adjust performance parameters, aiming to optimize energy use and minimize wear. At any rate, these advances have enabled vessels to sustain top speeds while also prioritizing stability and safety and providing practically uniform performance even in turbulent weather conditions.

The year 2025 has been marked by innovations that have advanced propeller technology, not only for improved concrete boat performance but also for a more sustainable and responsive shipbuilding industry. These breakthroughs demonstrate how engineering precision meets ecological accountability, making a strong argument for continued investments in R&D for the future.

Reference Sources

- Propeller – Wikipedia

- Parts of a Boat From a Side View – Boat Ed

- Props 101: The Ultimate Guide to Boat Propellers – Wakemakers

- Propeller Terminology – AeroMarine Research

- Sailboat Propeller Terminology – Darglow

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What is the propulsion of a boat?

The propulsion of a boat is commonly referred to as a propeller. Within the propulsion system of a ship, it converts the rotational energy from an engine into thrust. It typically consists of blades that rotate in the water, producing a pressure difference that propels the boat forward. Some boats have the propellers situated at either the stern or transom. Therefore, an operator must consider the propellers and their impact on the boat’s performance and maneuverability.

⚙️ What sort of different propellers are used in boats?

Several types of propellers have been designed for boats, each crafted for a specific application. The most common type of propeller is a screw propeller. Screw propellers consist of blades that rotate around a central hub. Other kinds of propellers include variable-pitch propellers, which adjust the angle of the blades for optimal efficiency at different speeds, and jet propellers, which utilize jets of water to propel the boat. Vessel hull design, power source, and use, among other things, affect the choice of propeller– knowing all types enables a boat operator to pick out the most suitable one for his or her needs.

🔄 So, what exactly makes a boat’s propeller work?

The propeller works by generating rotation and thrust, which either move the boat forward or backward. In rotating after a displacement of water with the blades, a pressure differential is created, pushing the boat through the water. The angle of the blades, commonly referred to as the pitch, can significantly influence the propeller’s efficiency in propelling the boat. Moreover, the speed with which the propeller rotates is also critical; the faster the propeller spins, the more thrust it generates. But a vigilant boatman should be wary of cavitation, wherein the pressure on the backside of the blade becomes so low that it causes bubble formations and thereby affects performance.

🔧 What is the role of the propeller shaft?

The propeller shaft is the mainstay, running from the engine and transferring the engine’s turning power to the propeller, which pushes the boat forward. It generally passes through the hull, allowing the engine to drive the propeller situated at the stern or transom. This propeller shaft must take into consideration the torque generated by the engine, and any mounting is critical for a smooth operation. With any misalignment or damage, the misaligned propeller shaft will cause a power reduction or even lead to the failure of machinery. Keeping the propeller shaft in good repair through regular inspection will ensure excellent boating performance.

🚢 Does the hull design affect the propeller efficiency?

The shape of the hull fundamentally determines the propeller’s action. A hull that is appropriately designed will establish a correct position for the boat in the water, thereby reducing drag and enabling the propeller to work efficiently. For instance, a Deep V hull may perform better, as it allows the boat to slice through waves, whereas a flat-bottom hull would enhance stability, but its drawback would be increased drag. The interaction between the hull and propeller also affects how low the boat needs to be in the water to achieve efficient propulsion. When design is taken into account, the propeller efficiency could be used to optimize performance and fuel economy for the boat operator.

⚠️ What is cavitation, and how does it affect a propeller?

Cavitation is a phenomenon that occurs when the pressure behind the propeller blades drops below the vapor pressure of water, causing bubbles to form. When the bubbles implode, the shockwaves formed can cause damaging effects on the propeller blades, leading to a loss of effectiveness and decreased longevity. Traction is reduced while fuel consumption increases, as the engine now has to work harder to maintain speed. Boat operators should be aware of cavitation symptoms, such as unusual noises or vibrations, and take action to adjust either the pitch or depth of the propeller to minimize occurrences.

🛡️ What kind of protection does the propeller provide to the boat and its components?

Thus, a propeller helps shield the boat and its components by ensuring a smooth transfer of the ship through water, resulting in hull stability and prevention of extreme stresses. Any propeller that is not well-designed will increase drag and turbulence inside the water, potentially causing damage to the hull or engine components. Proper blade shapes and pitches always help reduce cavitation and promote good propulsion. Timely checks and maintenance of propellers and their corresponding parts, such as the propeller hub and shaft, are essential for maintaining the boat’s integrity and optimal operational performance.