The correct propeller selection is of utmost importance for the Yamaha 25 HP outboard motor to perform at its best. Aspects like speed, fuel consumption, and handling are all dependent on the propeller, which, therefore, is an important factor in your boating experience. However, the variety of available props can make the choice for your Yamaha F25 model look confusing. Aiming at the proper speed, smooth operation, or economical fuel consumption, we are here to help you through this offer, i.e. giving the proper decision making that will maximize your motor’s capability. This guide will strip away the uncertainty and enable you to know the propeller selection process so that you can choose wisely.

The Importance of Selecting the Correct Propeller

Understanding Propeller Basics

The Performance of Your Yamaha F25 Motor Is Directly Influenced by the Propellers, Which Are a Critical Part of Your Boat. To put it simply, the propellers are the ones that take the engine’s power and turn it into thrust, moving your boat through the water. Choosing the right propeller means your engine will function at its best, giving you the well-blended combination of speed, good use of fuel and apparent handling.

Pitch and diameter are the two factors which must be understood when one is going to choose a propeller. Pitch indicates the distance that the propeller moves the boat forward in one complete turn, whereas diameter signifies the length of the circle that the rotating propeller blades form. A higher pitch leads to a higher top speed but may slow down the acceleration, on the other hand, a lower pitch gives the opposite effect of speed versus acceleration. Balancing these factors correctly is very important for getting the best performance.

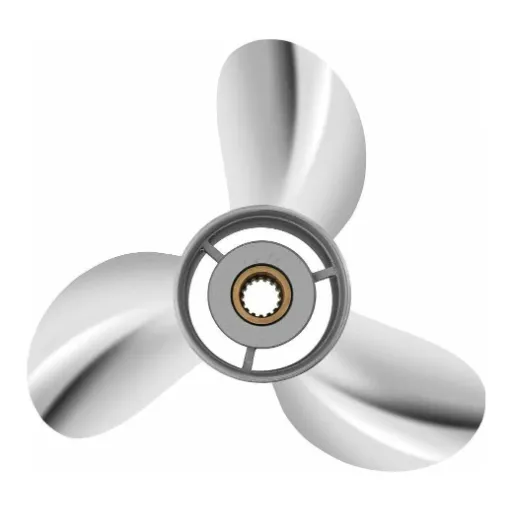

Moreover, you should think about the number of blades and the propeller’s material. Generally, more blades would result in better stability and smoother operation, thus making them suitable for heavier loads or slower speeds. On the contrary, stainless steel propellers grant long life and high performance, while aluminum propellers have the advantage of being cheaper and more adaptable to various conditions. Knowing these basics, you will be able to pick a propeller that corresponds with your boating needs and utilizes your motor’s potential to the fullest.

Impact of Propeller Choice on Performance

The propeller selection has a really big impact on the performance, efficiency, and handling of a boat. Going for the correct propeller not only maximizes engine efficiency but also cuts down on the amount of fuel consumed and finally the entire boating quality is improved. Listed below are the five major factors that show the impact of propeller choice on performance:

- Speed and Acceleration

The characteristics of the propeller like the number of blades, pitch, and diameter basically set the limit for the boat’s acceleration and speed. For instance, a propeller with a smaller pitch gives a boost to acceleration while a larger one supports higher top speeds. - Fuel Efficiency

Getting the right propeller for the boat’s engine helps not only to save fuel but also to reduce costs in the long run. An incorrectly sized propeller can result in overloaded engines, thus consuming more fuel than necessary. - Handling and Maneuverability

Propeller design affects boat stability and responsiveness. More blades on the propeller mean smoother operation and better handling; especially during rough waters or when making sharp turns. - Load Carrying Performance

For boats that are meant to carry heavy loads, the right propeller gives the thrust necessary for smooth operation. A propeller with high torque characteristics will increase the performance in moving heavy loads and passengers. - Durability and Lifespan

The material from which a propeller is made, e.g., stainless steel or aluminum, determines the propeller’s resistance in different aquatic areas. Stainless steel propellers, for example, have a longer lifespan and are more appropriate for high-performance vessels, while aluminum is cheaper, more flexible, and perfect for standard use.

Recognizing these factors can help boat owners with making the decision regarding their boat’s operation and the performance to which the specific needs and the conditions are adjusted.

Common Misconceptions About Prop Selection

One of the biggest myths regarding propeller selection holds that there is a single “perfect” propeller that can be used for multiple applications with any boat. The truth, however, is that there is no universal solution when it comes to propellers. The performance of every boat gets affected by multiple aspects such as for instance engine power, hull characteristics and its intended use that can be cruising, towing to racing. Pitch and diameter being the only criteria for propeller choice and overlooking other factors will lead to less than the best performance.

⚠️ Warning: It is also a misconception that a higher pitch always results in a faster boat. Although a high pitch propeller can actually result in a higher speed if the engine power is enough, it can also cause newer engines to run at their peak but with slow acceleration and thus requiring, inefficiently, a lot of fuel.

So, too, relying solely or mainly on the material’s advantages – say for instance that stainless steel is always better than aluminum – without having in mind the specific needs and financial flows of the user can lead to extra costs or wrong performance.

In addition, there are some folks who come to the conclusion that once the propeller is mounted, it is no longer a matter of concern. It is true that regular maintenance and sometimes even adjustment are required, such as using polish, or performing repairs, to keep the efficiency and the lifespan of the propeller. Overlooking these aspects may mean a drop in performance and even damage to the engine for a longer period of time. Boat owners who are aware of these myths can take the right steps guided by data to improve their boating joy.

Comparing Propeller Materials: Aluminum vs. Stainless Steel

| Feature | Aluminum | Stainless Steel |

|---|---|---|

| Cost | Lower price point | Higher initial investment |

| Weight | Lightweight design | Heavier but stronger |

| Durability | Moderate durability | Superior strength and longevity |

| Repairability | Easier and cheaper to repair | More difficult to repair |

| Performance | Good for moderate needs | Excellent high-speed performance |

| Best For | Recreational boating, freshwater | Saltwater, high-performance applications |

Advantages of Aluminum Propellers

- ✓ Cost-Effective

Aluminum propellers come at a much lower price than the stainless steel ones. This is a reason why they are preferred for such boaters who are either very conscious about their budget or for such people who are just starting and want a propeller that is affordable. - ✓ Lightweight Design

Aluminum propellers, because of their light material, take away a part of the weight from the engine, which sometimes results in better fuel consumption. This is a great advantage for the smaller boats and the recreational watercrafts. - ✓ Easier Repairs

Aluminum propellers offering repair at easier level compared to stainless steel. The minor damage like dents or dings can usually be repaired at a lower cost, which means convenience and also the cutting down of long-term expenses. - ✓ Widely Available

Aluminum propellers are so well-known that there are no difficulties for the boaters to find a model that suits their needs, as they would have many options available in different sizes and designs in the market. - ✓ Ideal for Moderate Performance Needs

Aluminum propellers are good enough to perform in calm or moderately difficult environments. Their combined features of being functional and low-priced make them appealing to most of the recreational boats and the boating enthusiasts.

Benefits of Stainless Steel Propellers

- ★ Superior Strength and Durability

Stainless steel props are way stronger than aluminum ones and hence are more damage-resistant and do not give in easily to impacts or debris. Difficult marine conditions won’t affect the durability, thus being the propeller’s most important factor to longevity. - ★ Enhanced Fuel Efficiency

The thickness-less and more accurate stainless-steel blades create less drag and provide more fuel-efficient operation, which represents significant cost savings in the long run especially in long-distance voyages. - ★ Superior Performance

Stainless steel propellers possess the ability to keep perfect contours even under pressure which leads to better acceleration and high-speed performance. The design helps to have a quieter and more reliable operation across the various conditions of the sea. - ★ Corrosion Resistance

As the exposure to saltwater and other corrosive elements is a daily routine for them, stainless-steel propellers experience no rusting and deterioration which makes them suitable for both freshwater and saltwater use. - ★ Wide Range of Design Options

Stainless steel props come in various designs optimized for specific performance needs, from high-speed applications to heavy-load situations. This variety ensures boat owners can select a propeller tailored to their exact requirements. Additionally, these designs often offer enhanced handling and smoother rides.

Choosing the Right Material for Your Needs

The boat propeller material selection is based on the specific usage conditions. In case of saltwater applications, I prefer stainless steel because it is durable and performing-wise excellent. The combination of corrosion resistance and high strength makes it very suitable for demanding environments, e.g., saltwater. Its longer life usually compensates for the higher initial cost and thus I do not need to deal with frequent replacements.

In situations where less intensity or a tighter budget is the case, I often recommend aluminum propellers. They are light, inexpensive, and easy to get making them a practical choice for common boating activities. I particularly like them when working in freshwater or where potential collisions with underwater obstacles are concerned because they are cheaper and easier to repair than stainless steel.

In the end, my decision is based on my sailing habits, the environment, and my budget. If I always choose power, performance, and long-term cost savings, stainless steel is the winner without a doubt. Yet, for hobby or recreational purposes, aluminum is a reliable and cost-effective option that fulfills my basic needs.

Understanding Blade Designs and Their Impact

Different Blade Shapes and Their Functions

The shapes of propeller blades are of utmost importance in dictating the performance aspects of a boat, as well as its efficiency on the water. The three main blade types—round ear, cleaver, and cupped—are each different from one another in terms of their physical characteristics as well as the functions they perform.

Round Ear Blades

Round ear blades have applications in quite a number of areas, which explains their widespread use in general-purpose boating. Their edges are rounded, which leads to the performance being evened out and being accepted in many conditions, thus they are the choice for boats that are involved in the recreational industry. They are particularly good for achieving good acceleration and mid-range speed.

Cleaver Blades

Cleaver blades are low-profile and made to be very effective at good speeds. Their flat edges eliminate drag, so they’re best suited for sports or racing boats. The way they are shaped helps to cut down resistance in water and hence boats with these blades can attain higher speeds while keeping control.

Cupped Blades

Cupped blades are those that have a minor curvature or cup at the trailing edge. The design not only allows for better water ‘holding’ but also sets the water ‘holding’ better to be faster than the water drag. Hence, such boats during the outfitting with cupped blades would be less affected by ventilation and would be able to perform better during high altitudes or in heavy water conditions. They are also preferred for activities like ‘water-skiing’ or ‘wakeboarding’ where the power of the towing ski boat is a factor.

Being aware of the distinctive features of each blade shape, the boaters would be able to make wise decisions that would be suitable for their personal needs. The taking into account of elements like the desired speed, the water quality, and the application would make sure that the prop design chosen would provide performance as well as reliability.

How Blade Count Affects Performance

A propeller’s blade count significantly influences its performance and efficiency as a whole. In general, propellers with fewer blades, such as two or three blades, experience less drag and therefore are more suitable for getting a higher maximum speed. Such designs are mostly installed on small, light-weight boats or applications where speed is the only selecting criterion. Yet, sometimes, the low number of blades could lead to heavy vibration and decreased smoothness in operation.

| Blade Count | Characteristics |

| 2-3 Blades | Less drag, higher maximum speed, more vibration, suitable for lightweight boats |

| 4+ Blades | Better smoothness, improved water grip, enhanced acceleration, ideal for rough water and heavy loads |

Conversely, a four-blade plus propeller is characterized by its excellent smoothness and water grip, making it the desired choice for rough water and heavy load conditions. More blades mean a bigger surface area which can result in more acceleration and better handling at lower speeds. This is why they are popular for towing boats, for instance, during wakeboarding or water skiing, and also for the vessels working in the rough seas.

Moreover, it is imperative to keep in mind that, blade count increase, in many cases can lead to torque improvement and cavitation reduction, on the downside this may also result in slightly lower peak speed because of the drag that has been added. Therefore, balancing blade count with other parameters like blade shape, material and pitch is a must for the selection of a propeller that is optimized for the specific needs of the boaters. In short, a good understanding of the trade-offs involved, boaters will be in a position to get the perfect combination of speed, power and durability in the performance of their watercraft.

Choosing the Right Blade Design for Your Setup

The process of choosing the best propeller blade design requires you to know every detail about your boat such as its peculiar needs, type of engine, and use. Blade design includes many important factors, such as the number of blades, their profile, and their pitch. Usually, by reducing the number of blades, higher speeds are attained because of less drag, but on the other hand, the higher the number of blades, the more torque, less cavitation, and thus, the more efficient the system. For example, a 3-blade propeller is commonly used on lighter boats for high speed applications, while a 4- or 5-blade design would be more appropriate for a heavy vessel where smooth handling and increased thrust are the goals.

Another important aspect that should not be overlooked is the blade profile, which is a distinguishing factor that may lead to a significant alteration in the performance. Using varieties of design, the rounded blades are usually, though not always, dedicated to the delivery of maximum thrust and control in the water, thus, causing them to become the best option of choice for the hard towing or slow cruising situations. On the other hand, pointed or swept-back blades give a lesser resistance in water which is suitable for activities with high speed such as racing or water skiing.

Moreover, the tilt of the blade towards the hub, also known as the rake angle, is significant in generating lift and also controlling the boat hull. Blades that have high rake can give lift to boats that are stern-heavy because of the placement of the weight; whereas blades that have low rake give priority to stability.

Consideration of material is another aspect which has to be answered in a proper way when the decision about blades is to be made. Stainless steel blades, despite their higher cost, outperform aluminum in terms of durability and sharpness providing superior performance at high speed. On the other hand aluminum blades, which are popular for recreational boating, are lighter and cheaper but may get worn out faster under stress. By knowing your specific water conditions as well as the priorities in boating, you will be able to select the optimal blade design, taking into account the pros and cons of the different materials. The synthesis of these factors with the latest developments, such as propeller coatings or hybrid materials, will enable the modern boaters to gain peak performance without the hassle of routine maintenance.

Optimizing On-Water Performance and Efficiency

Propeller Pitch and Its Effects

Pitch of the propeller has a very great impact on the performance, efficiency, and handling of the vessel on water. Simply put, the pitch is the distance a propeller would travel theoretically in one full clockwise rotation, specified in inches. A propeller with a higher pitch can complete the distance faster and thus is good for speeds but at the same time may cause stress on the engine when it is operating at low RPMs. On the contrary, a lower pitch propeller would give the best grip when starting and also be able to pull heavier loads thus being ideal for such activities like towing but might cost you a little on the overall speed.

Pitch Selection Guide

| Activity Type | Recommended Pitch | Benefits |

|---|---|---|

| Water Sports (Wakeboarding, Tubing) | Lower Pitch | Quick acceleration, better torque |

| High-Speed Cruising | Higher Pitch | Maximum speed, fuel efficiency |

| Heavy Load Hauling | Lower Pitch | Enhanced pulling power, better grip |

To illustrate, a boat set for water sports like wakeboarding or tubing would almost always have a lower pitch propeller. This kind of propeller gives the required torque for quick acceleration. Conversely, high-performance speedboats or vessels mainly doing long distances often prefer a higher pitch to reap the benefits of speed and fuel efficiency. The trick is to set the propeller pitch to the recommended range of engine operation (RPMs), as the wrong pitch can lead to poor performance, excessive fuel burn, or even engine damage in the long run.

💡 Pro Tip: New technologies have brought to life the adjustable pitch propellers which can change the pitch dynamically depending on the operating conditions thus, bringing about more versatility and efficiency on various rivers and lakes. With the knowledge of propeller pitch and advancements in propeller engineering, boaters can set up their rigs for perfect performance that is right for their specific needs. The data that manufacturers have also shows a great reduction in fuel consumption and an increase in engine life when the propeller pitch is accurately matched hence making it a vital factor in the sustainability of both performance on the water and operations.

Tuning Your Propeller for Maximum Efficiency

To get the most out of your propeller, it is necessary to apply a variety of adjustments, take into account different factors, and perform regular checks. First, make the evaluation of your boat’s standard load and the operating conditions since these aspects will help to identify the best fitting pitch and diameter of the propeller. An incorrect propeller size can lead to either over-revving or in-revving the engine, thus ruining the performance and consuming more fuel than necessary.

📊 Performance Testing Checklist

- Rely on performance data such as RPM (revolutions per minute) and speed readings obtained during sea trials

- Ensure your engine operates within the manufacturer-specified RPM range at wide-open throttle (WOT)

- Reduce pitch to increase RPM or increase pitch to reduce it if needed

- Consider blade count and material compatibility

- Use GPS-based speed tracking for accurate measurements

Also, take into account factors such as blade count and material. For instance, stainless steel propellers, although they are more durable, may be less tolerant than aluminum ones in certain impacts.

The technological progress has made it possible to employ GPS-based speed tracking and onboard computer diagnostics, which automatically provide you with the data necessary to fine-tune your setup with great accuracy. Regular maintenance of the propeller—such as checking for cracks, dents, or excessive wear—will contribute to the longevity of the optimal performance. By putting emphasis on these factors, you will be able to reduce the amount of fuel used, improve the engine’s condition, and have a more pleasant boating experience.

Real-World Performance Tips for Yamaha Outboards

1. Choose the Right Prop

It is essential to select the right propeller if you want to get the maximum performance from your Yamaha outboard. Take into account factors like the weight of the boat, the engine’s RPM range, and the water conditions where you usually operate your boat. For example, stainless steel props are not only strong but also allow for better performance at higher speeds whereas aluminum props are a more economical option and suitable for occasional use only.

2. Regular Engine Maintenance

Proper maintenance is one of the most crucial factors that contribute to the longevity and reliability of your Yamaha outboard. Do not neglect the regular changing of the oil and oil filter, checking the spark plugs, and maintaining the cleanliness of the fuel filters to prevent clogging. In addition, constantly check for the presence of corrosion on metal parts, especially if you often work in saltwater.

3. Monitor Fuel Quality

The use of high-quality, ethanol-free fuel will not only keep your Yamaha outboard running smoothly but will also prevent common problems like vapor lock or clogged injectors from occurring. Keep a record of your fuel consumption during each trip so that you can monitor the usage efficiently and also spot the potential performance problems which need to be attended to.

4. Clean Cooling System

Preventing engine overheating is one of the major functions of the cooling system. Check the condition of the water pump and impeller and replace them if necessary. Besides, make it a habit to run fresh water through your system after every use, especially after operating in saltwater, to prevent the formation of debris and deposits.

5. Leverage Integrated Features

Yamaha’s built-in digital systems like Command Link Plus or Helm Master EX are great for control and monitoring. These technologies not only give you access to real-time information about engine performance, fuel flow, and system diagnostics but also let you adjust your outboard and operate it with more accuracy.

You can keep your outboard at its best for years if you follow these simple tips along with knowing your engine specs.

Maintenance Tips to Extend Propeller Life

Routine Inspection and Care

The right propeller maintenance plan includes a series of inspections that help to detect the physical damage or wear and tear that may affect the performance of the propeller. Start by doing a visual inspection of the propeller looking for dents, cracks, and any changes in shape. Just the tiniest imperfection can already cause vibration, inefficient use of power, or put extra load on the engine. In case you find out that the propeller is damaged, do not hesitate to perform repairs or replacements to avoid further complications. Additionally, inspecting for fishing lines or other debris around the propeller shaft is a good practice to prevent seal damage which may lead to water entering the gearcase.

🔧 Essential Maintenance Steps

- Regular Cleaning: The drag created by the build-up of marine life such as barnacles and dirt can be so much that it will cause the thrust’s efficiency to drop. A soft brush and mild detergent can be used to very carefully clean the blades.

- Check Fittings: During the cleaning, check that the nuts and washers holding the propeller are tight but not too tight, as loose fittings can cause accidents while over-tightened pieces run the risk of stripping the thread.

- Protective Coating: The propeller can be protected with the application of a coating, especially if it is going to be the case that the seawater environments are saltwater. Among the types of paints, anti-fouling paint is great for the prevention marine growth while a thin layer of grease on the propeller shaft keeps it from rusting and makes it easy to remove during servicing.

If you use these routine care practices in combination with the observance of the latest standards and tools, you will have a propeller that is durable with consistent performance.

Common Issues and How to Fix Them

Even with adequate upkeep, propellers are still susceptible to some typical problems that result from wear and tear and the influence of the environment. One of the usual problems is propeller destruction caused by foreign matter or underwater collisions, which can result in blades being bent or edges being chipped. The aforementioned damages are usually accompanied by a decrease in thrust efficiency, a rise in vibrations and a change in performance. Therefore, it is advisable to check the propeller condition regularly for obvious signs of damage as part of the maintenance routine. Sometimes, small nicks or bends can be repaired by smoothing or straightening with the proper tools; however, in the case of severe damage, it may be wiser and safer to opt for a replacement.

| Problem | Causes | Solutions |

|---|---|---|

| Physical Damage | Foreign matter, underwater collisions | Smooth minor nicks, replace if severe |

| Cavitation | Incorrect pitch, blade damage, improper design | Adjust pitch, replace with proper propeller |

| Corrosion | Saltwater exposure, lack of protection | Apply anti-corrosive coatings, use sacrificial anode |

Cavitation is another prevalent problem, which refers to the formation and bursting of bubbles around the propeller blades due to fluctuations in pressure, thus causing erosion and loss of efficiency. Typically, cavitation is triggered by incorrect pitch, blade damage, or propeller design not suited to the boat being used. Basically, the solution to cavitation lies in doing the following: the propeller is accurately positioned, its pitch is correctly made, and it fulfills the requirements of the vessel. A worn or ill-fitting propeller should be replaced with one that is tailor-made for your engine’s specifications and operating conditions. The likelihood of cavitation will be sharply reduced.

Moreover, as far as propellers are concerned, corrosion, more so in saltwater, is a big problem that happens all the time. The metal would eventually be weakened and performance affected. One of the most important things to do is to apply suitable anti-corrosive coatings, for example, using anti-fouling paint or a protective metal spray. Besides that, putting a sacrificial anode on the propeller shaft will also help as it pulls corrosive forces away from the propeller. By keeping the propeller clean and inspecting it regularly, you will be able to detect any corrosion at an early stage and take the necessary action so that the propeller will last longer. If you deal with these common problems in advance, you will not only avoid unexpected breakdowns, but also keep the performance at a high level.

When to Consider Replacing Your Propeller

In my opinion, a propeller should be changed when its effectiveness goes down considerably or if there is any damage that can be seen. For example, during an inspection, if I see chips, cracks, or bent blades, I know these problems can cause the propeller’s balance and efficiency to be disrupted leading, eventually, to more fuel being consumed and less performance, in general, being delivered. Repairing of slight damage may be an option but in most cases, if the problem is serious or happens repeatedly, it would be better to replace it.

Diminishing speed or being less responsive is another sign for me. If my boat finds it difficult to get to its normal speed or if it feels like it is moving slowly even though the engine is in good condition, this could be due to the propeller suffering from problems such as excessive wear or wrong pitch. A new propeller can not only bring back the boat’s performance but also make the operation on water a lot smoother and more enjoyable.

Moreover, I will think about upgrading my propeller if there is a change in my boating requirements. For instance, if I start pulling water skiers or carrying heavier loads, I may need a propeller with different material or pitch to meet these needs. In the end, the main point is that being aware of the propeller’s state and modulating it according to the usage is the best way to guarantee boater’s reliability and efficiency.

References

-

Keragaan Mesin Penggerak Perahu Motor Tempel

This document provides technical details about outboard motors, including propeller specifications and performance analysis. -

Ski-Dogs, Pol-Cats, and the Mechanization of Winter

While focused on propulsion systems, this source discusses the mechanics and reliability of propellers, which can provide insights into their design and application. -

Small Scale Marine Fisheries: An Extension Training Manual

This manual includes information on small-scale marine operations, which may cover the use of outboard motors and propellers in artisanal fishing. - Click here to read more.

Frequently Asked Questions (FAQ)

Q: Which main characteristics are advisable for a yamaha 25 hp outboard propeller?

A: In the process of choosing yamaha 25 hp outboard propeller consider blade material (aluminum or stainless steel), diameter and pitch that correspond to your engine power and hull type, the number of blades (3 or 4/four), and compatibility with yamaha 20-30 series engines. A propeller tuned for the yamaha 25 hp outboard propeller will enhance acceleration, top speed, and fuel economy while avoiding engine overloading.

Q: How do I select the right pitch and diameter for a yamaha 25 hp outboard propeller?

A: Determine pitch and diameter from boat weight, usual load, and performance. A yamaha 25 hp outboard propeller attracts a lot of users who start with the factory recommendations for yamaha 20-30 and adjust: lower pitch (smaller number) for getting off the plane and heavier loads, higher pitch for getting maximum speed. Discuss with a prop shop for testing and consider the propeller options in ranges like 10-20 pitch increments to get the best balance for your 20-30 hp setup.

Q: Is it possible to interchange a yamaha 20-30 propeller with a yamaha 25 hp outboard propeller?

A: Yes, most of the yamaha 20-30 propellers are made to work with the same mid-range leg and spline patterns, so a yamaha 25 hp outboard propeller from the yamaha 20-30 family will almost always fit. Just make sure the number of splines and the hub compatibility is the same as for your 25 hp 2 stroke or 4-stroke model. When in doubt, take your lower unit information to a prop shop for guidance.

Q: What is the best number of blades for a yamaha 25 hp outboard propeller: 3 or 4?

A: The decision between 3 and 4 blades is based on your needs. A 3-blade yamaha 25 hp outboard propeller usually allows for higher top speed and efficiency, whereas a 4/four-blade prop gives better acceleration, heavier unit handling, and improved hole-shot. In cases where you tow or you run heavy loads, a 4-blade propeller can be a good choice even on a 25 horsepower engine.

Q: What is the required maintenance for a yamaha 25 hp outboard propeller to keep it in good condition?

A: It is important to inspect for dings, bends, and corrosion regularly. Occasionally remove the prop to inspect the spline and hub, check the cotter pin and nut torque, and replace damaged hubs or blades. If you operate in shallow water or get debris in the water, have a prop shop check the yamaha 25 hp outboard propeller and repair or replace it to avoid vibration and gear damage.

Q: Is it possible to use a yamaha 25 hp outboard propeller on a 30hp 2 stroke or a 30hp 2-stroke engine?

A: A yamaha 25 hp outboard propeller may be usable on a 30hp 2 stroke in some cases depending on hub compatibility and the pitch that is required for your performance, but the performance may not be as good. The 30hp 2 stroke usually requires a different pitch or blade count to match its rpm and horsepower. For optimal results and to prevent overloading or overspeeding the engine, refer to manufacturer specs or a prop shop before switching between 25 and 30hp units.

Q: How is the choice of propeller affecting tachometer RPM and general engine performance for yamaha 25 hp outboard propeller?

A: The pitch of the propeller influences the tachometer RPM directly. A lower pitch causes an increase in RPM (better acceleration), while a higher pitch results in a decrease in RPM (higher top speed). With a yamaha 25 hp outboard propeller, it is important that the engine achieves the recommended wide-open throttle RPM range for that particular model. If the RPMs are too high or too low at WOT, then the pitch needs to be changed so that the engine runs efficiently without overstressing the 25 horsepower unit.