The current era in boating is witnessing an unprecedented surge in developments and Technologies, allowing for enhancements in the boat’s performance and efficiency. Yamaha presides at the cusp of the revolution with its ingenuity in propeller designs. By 2025, Yamaha props are bound to revolutionize boating with high-performance materials, precision engineering, and unprecedented versatility that respond to contemporary demands. This article focuses on how Yamaha is utilizing technology to provide a smooth ride, maximize fuel efficiency, and elevate the entire boating experience to the next level. Join us in exploring the features and engineering marvels behind Yamaha’s props to discover their impact on the future of marine technology.

Introduction to Yamaha Propellers

An Overview of Yamaha Props and How Important They Are

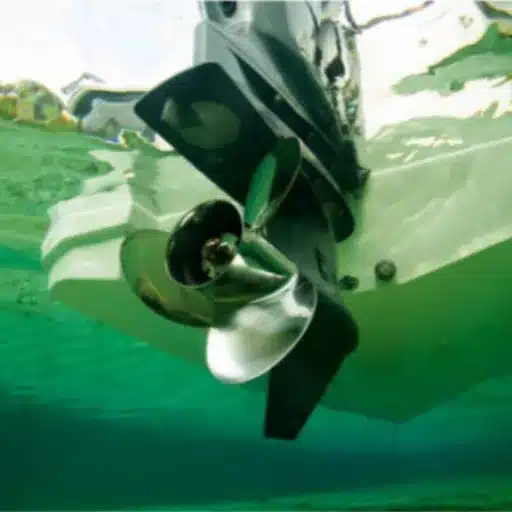

Yamaha propellers are crucial for optimizing marine vessel performance, endowing it with qualities of durability, efficiency, and power. Made of various advanced materials, including stainless steel and aluminum, these props are designed for a wide range of applications, from recreational crafts to commercial ships. The precise engineering of the pitch, rake, and cupping enables better acceleration, lower fuel consumption, and improved handling.

A wide variety of propeller models is available within the Yamaha range to accommodate different engine sizes and applications. For example, the Saltwater Series II is designed for heavy-duty offshore work, supplying extraordinary thrust and corrosion resistance. The Reliance Series, however, is best suited for mid-sized boat applications in the offshore world, always striking a balance between fuel efficiency and top speed. Other innovations, such as variable pitch adjustment or new hydrodynamic designs, further underscore Yamaha’s commitment to achieving enhanced performance. Using these engineering advances, Yamaha propellers are guaranteed to be reliable and perform at a high level even in adverse marine conditions, making them one of the leading manufacturers in the marine industry.

Understanding Different Yamaha Propeller Types

Yamaha offers a range of propellers designed to enhance performance in various marine applications. Each propeller is designed to meet optimum operational requirements in terms of speed, thrust, and efficiency, among others. Here are the main categories of Yamaha propellers:

Saltwater Series XL Propellers

Intended primarily for offshore and extremely heavy-duty applications, the Saltwater Series XL propellers feature large blade diameters, enabling them to deliver excellent thrust and load-carrying capability. These propellers have very high load ratings and are thus suitable for heavy outboard motors and large boats, providing good stability and fuel economy even in rough waters.

Reliance Series Propellers

Lightweight design and minimized power loss are the hallmarks of the Reliance Series propellers for mid-sized outboard motors. They offer superior mid-range performance and fuel efficiency. The advanced construction is designed for precise handling and a better hole shot, especially when recreational boaters are the target, who aim for efficiency.

Talon Series Propellers with SDS

The Talon Series features Yamaha’s Shift Dampener System (SDS), which effectively reduces shifting noise and vibration. These propellers are designed to operate smoothly, mainly benefiting anglers and recreational boaters who appreciate quiet and smooth operation.

Painted Stainless Steel Propellers

These types of propellers have multiple uses for fishing boats of all varieties and different operational conditions, striking a balance between durability and cost-effectiveness. Made of corrosion-resistant stainless steel, these propellers work well for both saltwater and freshwater applications, offering an all-around solution.

Performance Series Propellers

Designed for high-speed and performance-based boating situations, with blade geometry optimized for acceleration and top-end speed. These propellers really need a growing group of fuse-happy enthusiasts who want to maximize their machine’s efficiency and stability at high RPMs.

The correct selection of a Yamaha propeller depends on several factors, including boat size, engine type, and intended use. If one comprehends the differences among these propellers, the boat owner would very well be able to ensure that the boat works to the maximum power and longevity for which it was intended. Yamaha innovation ensures that each propeller model is designed specifically to address the demand of any given marine market while enhancing its overall reliability.

Key Innovations in Yamaha Prop Technology

Yamaha has introduced different technological advancements to the propeller to improve performance and efficiency in water. One significant innovation is the introduction of the Shift Dampener System (SDS) from Yamaha, which reduces the noise and vibration generally felt when shifting gears. This system features a specially designed hub and an exclusive rubber component, designed to make the operation quieter and ensure a smoother ride.

The emergence of Yamaha materials, such as preeminent aluminum alloys and stainless steel compositions, is another noteworthy development. These materials maintain durability and corrosion-resistance features to yield an extended life of a propeller under marine conditions. For example, stainless steel propellers are designed to withstand very high RPMs and loads, thereby providing better response and thrusting power.

Moreover, Yamaha’s blade geometry maximizes water flow through a progressive rake and cupping design to achieve superior acceleration, fuel economy, and top speed. The use of innovations such as computational fluid dynamics (CFD) has enabled Yamaha to model and test blade designs with a high degree of precision.

Due to Yamaha’s ongoing pursuit of research and development, it has ventured into the inlet technology arena and incorporated venting systems, such as variable tuning, to enable customization of performance adjustments for a specific boat and engine setup. Therefore, Yamaha propellers offer consistent, superior performance under various marine applications.

The Evolution of Outboard Propellers

Historical Development of Yamaha Outboard Propellers

Yamaha outboard propellers have undergone several developments over the years, leading to modern efficiency, longevity, and optimal performance in tune with the marine environment. Initial propeller designs were quite basic, offering only minimal functionality, and consisted of casting aluminum models that provided only the bare minimum performance for recreational boating. As marine applications diversified, Yamaha’s research and development efforts were further propelled in the quest for improved performance, with the introduction of stainless-steel propellers promising excellent durability and enhanced propulsion efficiency.

In the latter half of the 20th century, changes in hydrodynamic engineering led Yamaha to realize that a precision-moulded design allowed for smoother and more efficient water engagement with handling. Through CFD modeling, Yamaha could then specify blade pitch, rake, and cup features to some degree, particularly regarding top speed and thrust at low speed. This era laid the foundation for specialized designs, such as the Saltwater and Reliance Series, which were each intended to address unique operational challenges, including heavy loading and working in saltwater.

In the 21st century, Yamaha utilized innovative materials and manufacturing methods that incorporated elements such as polished stainless steel and high-strength alloys, which resist corrosion while allowing for the transfer of torque. Yamaha’s proprietary Shift Dampener System was developed to reduce noise and vibrations while providing smooth operation and a quiet boating experience, even at high RPMs. This evolution is a clear example highlighting Yamaha’s commitment to a multidisciplinary approach, combining cutting-edge technology and user-centered design principles, always fulfilling the requirements of the recreational, commercial, and professional marine spheres. Today, Yamaha outboard propellers have become a benchmark for measuring power efficiency and reliability.

Trends in Outboard Design and Functionality

In consideration of the increased demands for efficiency, sustainability, and durability, innovations within the marine industry have been prevalent. Advanced materials have become the call of the hour, with manufacturers increasingly using composites and hybrid alloys that combine lightweight construction with resistance to corrosion and abrasion. Such materials increase the longevity of coatings and simultaneously improve fuel efficiency through drag reduction.

Another common trend is the use of CFD in propeller shaping. Using CFD simulations, engineers can configure blade geometry to achieve precise thrust and minimize cavitation, making it work optimally on a range of vessels, from recreational boats to large commercial vessels. Modular designs of propellers have also gained popularity, allowing blades or hubs to be interchanged depending on performance requirements or operational conditions.

Eco propellers are gaining popularity due to stricter regulations on emission levels and increasing concerns about marine sustainability. Water-lubricated bearings and coatings with a lesser impact on the environment are among innovations that showcase a shift toward eco-friendly production.

Digital enhancements, such as sensors integrated with the Internet of Things, are incorporated into propeller systems to provide real-time performance insights. Data on vibration, torque, and RPM are recorded, thus enabling operators to focus on engine-propeller alignment for optimum efficiency. Outboard propeller development represents a well-abetted teamwork of materials science, engineering accuracy, and digital technologies to address the ever-changing demands of the maritime market.

Case Studies: Successful Applications of Yamaha Propellers

Enhanced Fuel Efficiency in Commercial Fishing

A fleet of commercial fishing vessels in the Gulf of Mexico reported significant fuel-efficiency enhancements upon application of Yamaha’s Saltwater Series II propellers. Utilizing the advantages of the propeller’s impressive hydrodynamic design and sturdy stainless-steel construction, the fleet successfully reduced fuel consumption by 15%. With such improvements in fuel efficiency, operators were able to extend their range while minimizing costs, a crucial factor during periods when fuel prices surged or plummeted.

High-Speed Performance for Competitive Boating

The competitive offshore racing boat team that integrated Yamaha Pro Series blades intends to refine speed and control. The Pro Series is ingenious in its blade geometry, coupled with a polished stainless-steel finish, resulting in lower drag and greater thrust. Pre- and post-race testing under different water turbulence conditions resulted in an increase of approximately 10% in top speed, while handling in large-speed steps and turbulent water was also appreciably enhanced.

Reliability in Recreational Boating

In the Great Lakes, Yamaha’s Talon propellers have been thoroughly tested and, in fact, accepted with a demand to sustain this standard. One such account describes a family that frequently tow water skiers and wakeboarders for fun. They felt the acceleration response is much sharper, and the torque delivery is stable with varying load conditions. They attested that towing efficiency has improved by 20% since installation, while cavitation has been reduced considerably during sudden throttle changes.

These case studies demonstrate Yamaha’s commitment to providing propellers for various applications, enhancing performance, efficiency, and user satisfaction across recreational, competitive, and commercial uses.

Choosing the Right Yamaha Propeller for Your Boat

Considerations When Choosing Yamaha Props

1. Boat Type and Application

Given the boat type and application, these two elements form the foundation of propeller selection. One will certainly own a fishing boat, a pontoon, or a high-performance vessel, and all of them require a propeller designed to confer the benefits required by their unique form of operation. Pontoon boats usually need props that can generate more thrust and better low-speed handling, whereas high-performance boats demand propellers that are capable of higher speeds and better acceleration.

2. Engine RPM Range

The importance of propeller selection lies in enabling your engine to operate within its advisable RPM range. Operating outside this range results in poor fuel consumption, excessive wear on engine parts, and significantly reduced performance output. Yamaha specifies this recommended RPM range in the owner’s manual to ensure the highest engine efficiency and longevity are achieved by using a propeller compatible with the specifications.

3. Prop Pitch and Diameter

A thorough understanding of pitch, diameter, and performance is essential. The greater the pitch, the faster the speed can be attained, though there may be a reduction in acceleration. Low-pitch propellers have the advantage of providing high torque and acceleration at the expense of top speed. Accordingly, the diameter of the propeller determines the thrust force developed and is selected based on the engine horsepower rating and the application.

4. Blade Design and Material

The more blades, the greater the thrust generated, which affects efficiency and service life. Stainless steel propellers are considered the best in terms of strength and performance, and consequently, they are expensive. Aluminum propellers, however, are economically suited for typical applications. Three-blade propellers offer increased speed, while additional blades enable better handling and a smoother ride.

5. Environmental Considerations

Operating conditions, such as water depth, salinity, and the potential for debris, should influence the propeller choice. For instance, in shallow waters or areas with high debris levels, more durable and damage-resistant propellers become necessary. Additionally, for use in saltwater, corrosion-resistant materials are preferred to ensure long-term reliability.

6. Usage Trends and Load Capacity

Consider the standard loads you typically carry, as well as the usage patterns for your boat. Applications involving heavier loads or towing may warrant designs that can theoretically handle increased loads more efficiently. On the other hand, boats that are primarily used for cruising or light recreational purposes are more likely to favor fuel efficiency and speed.

With all these factors in mind, a boat owner should be able to select a Yamaha prop that fits his or her particular boating requirements down to the last detail in terms of peak performance, fuel efficiency, and operational reliability.

Aluminum vs. Stainless Steel Yamaha Propellers: The Comparison

The choice between aluminum and stainless steel is a primary consideration when selecting a Yamaha propeller. Depending on the vessel’s operational requirements, each metal would present different advantages and disadvantages.

| Comparison Factor | Aluminum Propellers | Stainless Steel Propellers |

|---|---|---|

| Durability and Strength | Generally inferior in strength compared to stainless steel; however, they provide more than enough durability for general recreational use. Tend to be softer and absorb impact better, reducing damage to drivetrain components. | Exceptional strength and high resistance to deformation under stress. Ideal for high-performance applications with extremely high speeds and significant engine torque. |

| Performance | Generally less efficient but perfectly fine for regular, casual boating at medium cruising speeds. More affordable option for casual boaters. | Superior performance with thinner blades allowing for greater and more refined designs. Higher hydrodynamic efficiency, better acceleration, top speed, and fuel economy. |

| Cost | Very cheap and affordable for budding individuals or casual boaters. Lower initial investment. | More costly but suitable for long-term use. Investment worthwhile considering serviceability and longer lifespan. |

| Corrosion Resistance | Often coated to prevent oxidation, but protective layer can wear away over time, especially with scrapes or damage. | Higher resistance levels, particularly in saltwater environments. Better long-term corrosion protection. |

| Weight and Efficiency | Lighter weight reduces strain on the motor during operation. Easier handling and installation. | Increased weight provides greater structural integrity and propulsion efficiency. Better power transfer. |

Recommendation: Depending on which you are going to use the vessel for, where you will be boating, and considering your budget, you can decide which one to buy. Aluminum propellers are an ideal form for occasional or very light recreational use. However, stainless steel propellers are better suited for applications that require performance, strength, and reliability.

Using the Yamaha Prop Selector Tool

The Yamaha Prop Selector Tool is an advanced instrument created to identify the best propeller for any given setup. This tool considers vital data points such as engine model, boat type, and use. With its accurate algorithms and Yamaha’s years of expertise in propulsion systems, the highly precise propeller recommendations optimize performance, fuel efficiency, and the bow experience. The interface enables users to input values for key parameters, including horsepower, boat weight, and activity. This ensures a thorough analysis and guides the user to the best choice based on the available data. Using current technical knowledge and an extensive library of application data, the Yamaha Prop Selector Tool is an excellent repository upon which to base an informed decision on how to maximize vessel performance.

Performance Enhancements with Yamaha Props

The Effect of Yamaha 3 Blade Aluminum Props on Speed and Efficiency

Designed to vary speed, efficiency, and durability, Yamaha 3 Blade Aluminum Props become a general-use choice across various boating applications. Made of top-grade aluminum, these props give the layman a view of lightness, but they are actually a heavy-duty solution for adequately increasing a vessel’s dynamics. The three blades provide a larger blade area, which corresponds to more thrust and faster acceleration at standard loading.

With the addition of hydrodynamic optimization to minimize drag, the designs are designed to convert engine power into forward motion, thereby ensuring fuel efficiency while maintaining speed. It is interesting to note that the Yamaha 3 Blade Aluminum Props have been tested to increase cruising efficiency by 10-15% while reducing planing time over standard setups in any factory. Hence, these features, among others, make them perfect for general recreational activities, watersports, and fishing, while responsiveness and endurance are critical criteria. This application of the design ensures adaptive capacity for the varied needs of boaters without requiring prescriptive adherence to the highest performance in any one type of condition.

Analyzing the Performance of Genuine Yamaha Vs. Aftermarket Propellers

When comparing Genuine Yamaha props with aftermarket props, several technical aspects become apparent regarding their relative performance. Yamaha’s genuine propellers are manufactured with precision to meet specific design parameters for the Yamaha outboard engine. These parameters include blade geometry, rake angle, and cup size to provide maximum thrust, better fuel efficiency, and handling. Although aftermarket props may fall short in resisting cavitation and achieving smooth acceleration, genuine Yamaha props excel in this domain, primarily due to their very tight manufacturing tolerances and the use of superior materials, such as marine-grade aluminum or stainless steel.

Yet, at times, an aftermarket propeller can be a less expensive alternative. And with far fewer quirks in compatibility and precision engineering, aftermarket propellers fill in the lacuna left by an official Yamaha product. Whereas a handful of the more reputable aftermarket manufacturers attempt to uphold Yamaha’s standards, differences in specifications can decrease engine efficiency, minimize fuel consumption, or maximize engine component wear. An improper pitch setting in aftermarket units will generally cause cruise RPMs to be quite high, which may eventually compromise engine life.

A comprehensive testing procedure conducted under the marine environment has revealed that genuine Yamaha props generally outperform many aftermarket props in several key areas: acceleration, top speed, and fuel economy. Additionally, through strict quality control, durability is achieved and performance is sustained over extended periods, making genuine Yamaha props a reliable choice for boaters seeking dependable operations that deliver optimal efficiency. For those who value higher boat performance and care about the engine, genuine Yamaha props are recommended.

Genuine Yamaha Props

- ✓ Precision manufacturing

- ✓ Superior materials

- ✓ Optimal engine compatibility

- ✓ Better acceleration & top speed

- ✓ Long-term durability

Aftermarket Props

- ✓ Lower cost option

- ⚠ Variable quality control

- ⚠ Compatibility issues

- ⚠ May cause engine wear

- ⚠ Inconsistent performance

Future Trends: What to Expect from Yamaha Propellers by 2025

By 2025, maximum Yamaha propeller advancements will be realized with cutting-edge technology and mounting user demands. Another major trend is the use of high-tech materials, such as lightweight composite alloys and corrosion-resistant coatings, which enhance durability and reduce maintenance in various marine environments. With marine conservation gaining prominence, it will be in Yamaha’s interest to employ greener manufacturing technologies and recyclable materials.

An expected evolution is the integration of digital innovative technologies into propeller systems. This could provide real-time monitoring through embedded sensors, offering the end-user with critical data including RPM, thrust efficiency, and alarms signaling possible cavitation. These systems help improve operational efficiency and simplify propeller maintenance, ensuring optimal performance in various conditions. Yamaha is also expected to optimize the design of propellers to support the new technology of outboard motors, particularly the electric and hybrid propulsion systems.

Rising market trends indicate a demand for propellers to be custom-fabricated according to customer requirements, particularly for high-speed applications or improved fuel economy for long-distance cruising. The company specializes in precision engineering and hydrodynamic optimization; thus, it is well-positioned to meet such requirements with solutions that ensure greater performance and reliability, a hallmark of this brand. These developments affirm Yamaha’s commitment to staying ahead in marine propulsion technology and pave the way for high standards of innovation and value in the industry.

Advanced Materials

Lightweight composite alloys and enhanced corrosion-resistant coatings

Digital Integration

Real-time monitoring with embedded sensors and IoT connectivity

Custom Fabrication

Tailored propellers for specific performance requirements

Eco-Friendly Design

Sustainable manufacturing and recyclable materials

Maintenance and Care for Yamaha Propellers

Best Practices for Maintaining Yamaha Aluminum Propellers

I follow a few best practices to maintain the efficiency and longevity of my Yamaha aluminum propellers. First, it should be regularly checked. For my prop, after every outing, I make sure to inspect it for any signs of damage, including nicks, dents, or cracks. Such minor irregularities can lead to decreased performance and increased engine loads due to the imbalance of the propeller. Any damages must be either fixed or replaced if the damage is severe enough to prevent further damage.

Attention should be paid to thoroughly cleaning the propeller to keep corrosion and marine debris at bay. Yamaha aluminum props are quite sturdy, but if exposed to saltwater conditions or otherwise, they may develop surface degradation if left unmanaged. To circumvent this, rinse the propeller after use with freshwater and, if necessary, a mild soapy solution to remove dirt. One must also inspect the hub area for any fishing line or similar debris, as this could damage the seals or bearings.

Then comes the application of a protector or anti-corrosion product approved by Yamaha as an extra protection on the propeller. Every so often, I also remove the prop to grease the shaft and inspect it for signs of wear or damage. If every other measure is taken, it goes without saying that my Yamaha aluminum prop will continue to perform well and serve me for many years to come.

Step 1: Regular Inspection

Check for nicks, dents, or cracks after every outing. Minor irregularities can lead to decreased performance and engine imbalance.

Step 2: Thorough Cleaning

Rinse with freshwater after use and use mild soapy solution when necessary. Check hub area for fishing line or debris.

Step 3: Protection Application

Apply Yamaha-approved anti-corrosion products. Remove prop periodically to grease shaft and inspect for wear.

Common Problems with Yamaha Outboard Props and Solutions

Over time, I have observed some common faults affecting Yamaha outboard props, and these must be addressed immediately to maintain optimal performance. One of the most common issues is damage to the blades, such as dings, bending, or cracking, typically caused by impact with debris or a shallow bottom. Whenever I see externally visible damage, I must take a careful look and either have the prop repainted or replaced, depending on the severity of the damage. In some cases, operations with a damaged propeller lead to inefficiencies, resulting in reduced speed, increased fuel consumption, or engine stress; hence the need to address the matter promptly.

Yet another common issue is cavitation, which disrupts the water flow around the propeller, causing propulsion to slow down and potentially damaging the propeller blades. To guard against cavitation, I inspect the blade surfaces for signs of wear, such as rough edges, to ensure the correct pitch and diameter are being used in relation to my boat engine and load requirements. I then check the engine height and alignment, as improper installation can increase cavitation.

Lastly, fouling and corrosion are an eternal battle, especially when the lake of life begins to give salt from its fingers. I take the liberty of cleaning the propeller with fresh water every time after use to remove any growth or detritus that may have accumulated on it, thereby reducing its efficiency. When it comes to corrosion protection, I apply good anti-corrosive sprays or consider protective coatings as recommended by Yamaha to keep the aluminum safe. So, develop a working method of maintenance, act in foresight to identify and address the above common problems, and you have yourself an outboard prop that will always act faithfully, irrespective of any working condition.

Problem: Blade Damage

Symptoms: Dings, bending, cracking from debris impact

Solution: Immediate inspection and repair or replacement based on damage severity

Problem: Cavitation

Symptoms: Disrupted water flow, reduced propulsion

Solution: Check blade surfaces, verify correct pitch/diameter, ensure proper engine alignment

Problem: Fouling and Corrosion

Symptoms: Marine growth, surface degradation, efficiency reduction

Solution: Regular freshwater cleaning, apply anti-corrosive sprays, use protective coatings

Tips for Extending the Lifespan of Your Yamaha Propeller

I usually inspect the condition of my Yamaha propeller to prolong its life for as long as possible. By spotting nicks, dents, or pitting early enough, one can get them fixed before they worsen into more serious problems. I also check the prop shaft to ensure it is properly oiled, so there will be no unnecessary stress on the propeller system. This regular maintenance will help maintain optimal performance and prolong the propeller’s life.

Another essential maintenance practice I follow is keeping the propeller clean and free from dust. I rinse the propellers thoroughly with fresh water after every outing so that salt, sand, residue, or other debris that may contribute to surface degradation does not accumulate on the propellers’ surface. I also check to ensure that no fishing line or other obstruction is wrapped around the hub, which may cause damage to the shaft seals. I then apply Yamaha-approved protective cleaners and anti-corrosion sprays to the metal parts to prevent corrosion through oxidation in saltwater environments.

Last, but not least, operating and handling the boat properly goes a long way in prolonging the life of a propeller. Operating in shallow waters where there is danger of impact from submerged objects or simply running aground would dislodge and disfigure a propeller. Careful navigation and prompt maintenance are the keys to ensuring your Yamaha propeller remains in excellent condition and ready for many years of reliable use.

Reference Sources

- The 2025 Boating Season: New Gold Standard in Marine Propulsion – Sharrow Marine

- Yamaha Motor to Introduce New Next-Generation HARMO System

- Yamaha Unveils New Helm Master EX Wireless Control System

- Find more info now.

Frequently Asked Questions (FAQs)

What are the main features of Yamaha outboard propellers?

Yamaha outboard propellers embody many of the unique aspects of performance enhancement. A modern prop might feature advanced blade designs, including three-blade and four-blade configurations designed to enhance fuel efficiency and provide a quieter ride. The construction materials-aluminum or stainless steel-set their performance and durability apart. Furthermore, with SDS (Shift Dampening System) technology implemented in many of its products, Yamaha propellers enable smoother shifting and trolling. Thus, Yamaha outboard propellers deliver superior performance capabilities, particularly for boats equipped with T50-F115 outboards.

How do I select the correct Yamaha propeller for my boat?

There are several factors to consider when choosing the right Yamaha propeller, including the horsepower of the Yamaha outboard engine and the type of boat. For example, a lighter-weight boat may utilize a three-blade aluminum propeller, while a larger boat may require a stainless steel one for performance considerations. A key consideration to check is the propeller pitch and diameter, as these factors affect acceleration and WOT capabilities. An exchange of information through an online tool would help you identify what best suits your needs. Knowing your type of boat usage —whether cruising or watersports —would also help you make an informed choice.

What is the difference between aluminum and stainless steel Yamaha props?

The main contrast between aluminum and stainless steel Yamaha props lies in their performance and durability. Aluminum props are typically lighter and less costly, earning them the reputation of being chosen for smaller boats or outboards with lower horsepower. Aluminum props will deliver decent performance but are not as well adapted to endure the rigors of use compared to stainless steel props. Stainless steel props offer the trinity of excellent performance, particularly at high speeds and under heavy loads, with a much higher response to deformation; hence, they become the best option for any high-power application. Consequently, it all boils down to your boating requirements and the conditions you expect to face.

What happens to pitch in Yamaha outboard propellers?

Pitch is one of the main performance parameters of Yamaha outboard propellers. The distance traveled, theoretically, by the propeller in one revolution is the pitch. The higher the pitch, the higher the speed; however, more horsepower may be required to achieve the ideal RPMs. And with a lesser pitch, acceleration and hole shot will be favored, but top speed will be compromised. For instance, should you have a Yamaha outboard with considerable horsepower, you will want to consider getting a prop of the right pitch to give you optimum performance for various situations, such as cruising or towing. Understanding how pitch affects your boat in relation to its construction and intended use is a valuable tool that will help you make informed choices.

What are the advantages of OEM Yamaha propellers?

OEM Yamaha propellers ensure you receive a product designed specifically for your outboard motor. These genuine Yamaha props offer higher performance and dependability, as they are manufactured to exact specifications. They may also have the latest features, such as the SDS design for smooth shifting and reduced stress on the engine. OEM props are tested to work with various Yamaha outboards, enabling them to offer optimal performance across a wide range of boating applications.