To ensure optimal performance and efficiency for your Yamaha 90 HP, it is crucial to select the correct propeller. This will affect your speed on the water, the amount of fuel you consume, the longevity of your engine, and ultimately, the enjoyment of boating along its myriad possibilities. However, considering the numerous propeller options that will be available by 2025, each with its cutting-edge design and state-of-the-art materials, selecting the right one can become a daunting task. This guide aims to make things easy by providing insight into the major deciding factors, such as size, pitch, material, and various usages. Depending on whether you want to go really fast, have smooth handling, or achieve excellent fuel economy, this guide provides expert knowledge to ensure your Yamaha 90 HP is up to the task. Keep reading to find out how the perfect propeller can work wonders for you on the water.

Understanding Yamaha 90 HP Outboard Engines

Overview of the Yamaha Outboard Models

Yamaha produces a large variety of outboard motors to suit every kind of boat requirement, from pleasure to serious marine applications. The 90 HP Yamaha outboard engine is a highly renowned engine, widely regarded as nearly ideal in terms of power, reliability, and fuel efficiency. A lightweight construction and refined engineering enable the 90 HP model to deliver exceptional performance without compromising durability.

Some of the key features of the motors include a four-stroke engine that is quiet and produces minimal emissions, while being environmentally friendly and pleasing to users. Also featured on the 90 HP is electronic fuel injection (EFI), which optimizes fuel use and ensures smooth acceleration, thereby combining the best technology with simple controls. The user will also appreciate the heavy-duty gear case, designed for durability, and an efficient cooling system that keeps the unit running, even in demanding conditions.

Since Yamaha outboard engines are designed for versatility, they can fit a wide range of boat types, including fishing boats, pontoons, and recreational boats. That is, if you have, for whatever reason, speed, cargo capacity, or economy, among others, in mind when displeased. Yamaha’s innovative designs make their 90 HP a versatile and adaptable option for a wide range of motor applications.

Differences Between 2-Stroke and 4-Stroke Yamaha Engines

Comparative analysis of 2-stroke and 4-stroke Yamaha engines reveals differences in operational characteristics, fuel efficiency, and application. A 2-stroke engine requires a power cycle in only two movements of the piston, whereas a 4-stroke engine involves only four in its process. This fundamental difference affects performance, fuel consumption, and maintenance.

2-Stroke Engines

- Ultralight architecture

- High power-to-weight ratio

- Quick acceleration

- Ideal for watersports

- Simpler to maintain

- Lower initial cost

4-Stroke Engines

- Smooth running

- Constant power delivery

- Better fuel efficiency

- Lower emissions

- Less frequent maintenance

- Ideal for cruising

Another factor that differentiates these engines is their fuel efficiency and pollution factors. Yamaha 4-strokes, utilizing state-of-the-art fuel-injection technology, are the best for fuel economy and emission control among the 2-stroke line. Being a 2-stroke engine is simpler to build and generally cheaper to buy, but it emits more than a 4-stroke engine because it burns oil mixed with fuel.

Maintenance in the engines varies again between these two types of engines. Two-stroke engines, having fewer components and hence simpler to maintain, employ oil for lubrication, which means they require more frequent maintenance. On the other hand, 4-stroke engines are more complex and heavier, but much less maintenance is needed for a given time, thus making it efficient for long-term use.

Making the distinction, Yamaha offers both 2-stroke and 4-stroke models to suit varied boating needs. The preference among the two is application-based, with 2-stroke engines favored for nimble high speed and 4-stroke engines for the good old reliable cruising.

Key Specifications of the Yamaha 90 HP Engine

The Yamaha 90HP outboard engine offers a balance of power, efficiency, and reliability, making it a truly versatile candidate for multiple marine applications. The following are its key specifications:

| Specification | Details |

|---|---|

| Engine Type | 4-stroke, in-line 4-cylinder design |

| Displacement | 1.8 liters (1832 cc) |

| Maximum RPM Range | 5,000–6,000 rpm |

| Fuel Delivery System | MPI (Multi-Point Injection) |

| Weight | Approximately 353 lbs (160 kg) |

| Gear Ratio | 2.15:1 |

| Fuel Type | Regular unleaded gasoline |

| Start System | Electronic start system |

| Alternator Output | 35 amps |

Built using Yamaha’s state-of-the-art technology and superior craftsmanship, the 90 HP engine features Variable Camshaft Timing (VCT) for quicker acceleration and enhanced fuel economy. Furthermore, due to its compact design, installation options are increased with no impact on durability or power output, ensuring a consistent performance for various boating requirements.

Choosing the Right Propeller for Your Yamaha 90 HP

Types of Propellers: Aluminum and Stainless Steel

Then, it becomes imperative that one is well-versed in the characteristics of aluminum and steel types of propellers when choosing a propeller for the Yamaha 90 HP engine. Aluminum propellers are less expensive and lighter, making them particularly suitable for recreational boating. Aluminum propellers are usually easier to repair and therefore cheaper than their stainless steel counterparts. However, they stand the chance of deterioration with time, especially in abrasive conditions or in frequent collisions with underwater hazards.

✈️ Aluminum Propellers

- Cost: Less expensive

- Weight: Lighter

- Repair: Easier and cheaper

- Best for: Recreational boating

- Drawback: May deteriorate over time

⚡ Stainless Steel Propellers

- Durability: Greater strength

- Performance: Better acceleration

- Efficiency: Improved fuel economy

- Best for: Heavy-use applications

- Investment: Higher initial cost

Conversely, stainless steel propellers are offered for greater strength and lasting value. Rigid and of modern design, these propellers perform exceptionally well under severe conditions, offering good acceleration, top speed, and fuel efficiency. This propeller costs a little more initially; however, with longer usage, its durability and performance consistency may outweigh the initial costs—the investment that heavy-use or frequent boaters can afford. Ultimately, the choice between aluminum and stainless steel would come down to your specific boating needs and conditions, as well as your expectations for performance and long-term maintenance.

Understanding Propeller Pitch and Its Importance

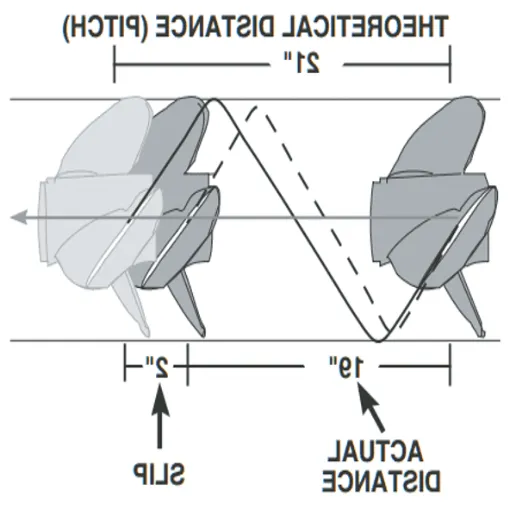

The type of propeller pitch is crucial for the boat to move and to attain efficiency. The propeller pitch is defined as the forward distance a propeller would theoretically move in one complete revolution without any slippage. A propeller with a 15-inch pitch will move forward by 15 inches with every rotation under ideal conditions. Hence, the right pitch should be selected, as it affects the speed, acceleration, and handling of the boat.

⚖️ Pitch Balance Guide

More thrust • Quick acceleration • Lower top speed

Less thrust • Slower acceleration • Higher top speed

Low-pitched propellers offer much thrust and quicker acceleration; therefore, they are an excellent choice for towing water skiers or having competitions on the shores of confined water bodies. Such propellers drastically reduce top speed due to the high engine RPM they generate. On the other hand, high-pitch propellers are designed for top-end speed but may compromise acceleration under heavy loads. A perfect pitch-engine RPM balance yields the best performance, stressing the motor the least, which reduces the chances of mechanical failure and increases fuel economy.

Choosing a propeller pitch requires consideration of the specific needs and performance of the boat. Factors include the size of the boat, engine type, and average load, ensuring the pitch is well matched for greater efficiency and a more enjoyable time on the water. Like other parts of the boat, the propeller should be maintained and assessed regularly to ensure it performs optimally.

Blade Configuration: 3-Blade vs 4-Blade Propeller

Choosing the proper blade type for a propeller depends largely on maximizing the performance and handling of your boat. The most commonly used propeller is the 3-blade design, as it maximizes speed and efficiency. However, it also achieves good top-end performance, which is very beneficial for high-speed activities such as water skiing or racing. Less drag with fewer blades helps to glide smoothly through open waters.

| Feature | 3-Blade Propeller | 4-Blade Propeller |

|---|---|---|

| Top Speed | ✅ Higher | ❌ Lower |

| Acceleration | ⚖️ Good | ✅ Better |

| Stability | ⚖️ Good | ✅ Excellent |

| Fuel Efficiency (Cruise) | ⚖️ Good | ✅ Better |

| Heavy Load Performance | ❌ Struggles | ✅ Excellent |

| Best For | Racing, Speed, Open Water | Fishing, Towing, Rough Water |

Then, 4-blade propellers provide thrust at lower speeds. This configuration works well for activities that demand stability and control, such as fishing, towing, or traversing rough waters. Besides, 4-blade propellers fare well for fuel efficiency at cruising speeds and grip in difficult conditions, such as heavy loads or rough waters.

According to data, 3-blade propellers produce top speeds, while 4-blade propellers have an edge in acceleration and smoother handling. You decide, depending on your boating priorities, if it is the highest speed you can get, the most stability, or somewhere between the two. Always ensure that the propeller type you choose is capable of operating the engine within the optimal range for the best results.

Factors Influencing Propeller Selection

Boat Type and Usage Considerations

The right choice of a propeller depends heavily on the type of boat and the purpose for which it is being used. Fishing boats require a propeller that provides better low-speed control and steady handling for precise maneuverability in tight spaces. Ski boats and wakeboard boats are all about propellers that can accelerate quickly and keep pulling power consistently for sustained sports towing. High-performance speedboats seek the highest top-end performance through a higher pitch, while pontoon boats prioritize thrust and load-bearing capacity for a smooth and steady ride.

🎣 Fishing Boats

Low-speed control

Steady handling

Precise maneuverability

🎿 Ski/Wakeboard

Quick acceleration

Consistent pull

Sustained towing power

🏎️ Speedboats

High-pitch propellers

Maximum top speed

Performance focus

🚤 Pontoon Boats

High thrust

Load-bearing capacity

Smooth & steady ride

Consider the weight, engine type, and typical water conditions in which the boat operates, as each factor can influence its efficiency and performance. However, current performance data suggest that prioritizing the uses for which the propellers are designed improves fuel economy and extends engine life by minimizing unnecessary stresses.

Boat Weight and Load Factors for the Best Performance

The weight distribution management and load capacity must be well understood to ensure the optimal performance of any type of boat. While interfering with handling and speed, additional weight may severely affect fuel efficiency. Studies have indicated that for every 100 pounds of added water to load, the average fuel consumption of a boat can increase by 2-5% while cruising at moderate to high speeds. Bad weight distribution can destabilize the ship, leading to loss of control and unnecessary pressure on the engine.

💡 Weight Impact on Performance

- +100 lbs = 2-5% more fuel consumption

- Poor weight distribution = loss of control

- Unbalanced load = unnecessary engine stress

- Heavy gear placement affects trim efficiency

To address these problems, the application of load balance control and adherence to the weight restriction recommended by manufacturers is required. Proper placement of heavier gear, such as batteries and equipment, helps achieve a trim that is hydrodynamically efficient and reduces drag. Additionally, using lighter-weight materials or improving gear storage would help achieve greater overall performance. Regularly reviewing load factors against the particular boat design and power setup will ensure better fuel efficiency and a safer, smoother ride on the water.

Environmental Conditions and Their Effects on Propeller Choice

Environmental factors play a crucial role in determining the most suitable propeller for a vessel, as varying conditions can significantly impact performance, efficiency, and durability. For example, boats cruising in shallow or debris-laden waters often feature stern propellers made of materials resistant to wear and impact, thereby reducing damage from obstacles such as rocks or underwater vegetation. High-altitude sites, where air density is lower, gradually affect engine performance; hence, pitch and diameter must be appropriately adjusted to maintain sufficient thrust and speed.

🌊 Water Conditions

- Shallow water: Impact-resistant materials

- Debris-laden: Wear-resistant propellers

- Cold water: Higher density = more resistance

- Saltwater: Corrosion-resistant materials needed

🌤️ Weather & Altitude

- High altitude: Lower air density affects performance

- Stormy weather: Need better grip & stability

- Turbulent seas: Enhanced design for control

- Wind conditions: Adjust for better handling

Other considerations include water temperature and salinity. Cold water with increased density will enhance resistance; therefore, configurators need to choose one that strikes the right balance between efficiency and power. On the other hand, the presence of saltwater requires materials with high corrosion resistance, such as stainless steel alloys, which can withstand long-term exposure to saline environments. Lastly, if any stormy weather setting with high winds or turbulent seas arises, alterations in the propeller design would allow for better hold and stability. This would enable safer navigation and improved fuel economy. Consideration of these factors would enable an operator to make a propeller-appropriate selection based on environmental needs, performance, quality, and lifespan.

Installing and Maintaining Your Yamaha Propeller

Step-by-Step Guide to Installing Your Outboard Propeller

Typically, the entire process of installing an outboard propeller can be daunting. However, when broken down into steps, it becomes easier and more manageable. Proper installation guarantees peak performance and longer propeller life. The following steps will help you install your Yamaha outboard propeller correctly:

- Prepare Tools and Workplace: Ensure you have at least a wrench, marine grease, and a block of wood to hold and stabilize the propeller. Have your boat in a safe and secure area, and turn off the engine. Always remove the key to prevent an accidental start.

- Removing the Existing Propeller: Begin by positioning the block of wood between one of the propeller blades and the anti-ventilation plate so that the propeller cannot rotate while loosening the nut. Loosen the propeller nut using a wrench, then slide off the nut, washer, and any other hardware carefully. Inspect them for wear or damage; if any are damaged, replace them.

- Inspect the Propeller Shaft: With the old propeller removed, inspect the propeller shaft for corrosion and debris. Clean it thoroughly with a cloth, and if desired, apply a thin coat of marine grease to protect it from corrosion and facilitate the smooth installation of the prop.

- Slide the New Propeller Onto the Shaft: The splines of the new propeller need to be lined up with those on the shaft, and then the propeller can be slid into place. Great care needs to be taken when doing so, to avoid damaging the rubber hub or causing the splines to go out of alignment, as neither of these would be disastrous during operation.

- Reinstall the Hardware: Place the washer and prop nut back onto the shaft, then tighten the nut to the torque specifications provided by your manufacturer. Using a torque wrench at this point ensures that the nut is tightened correctly, preventing both over-tightening and under-tightening.

- Lock the Propeller: Lock the propeller nut with a cotter pin or a tab washer (again, depending on your model). Ensure it is properly bent or locked so that the nut cannot come loose during operation.

- Performing a Last Check: Grab hold of one propeller blade and spin it around, forcing it with your hands if need be, and watch for any hindrances to free movement. Test again to ensure everything is installed and secured according to the directions. Any strange resistance or noise might be a sign. The issue that should be resolved before going into first use.

⚠️ Safety Reminder

By implementing these procedures and performing regular maintenance work, your Yamaha outboard propeller will be adequately maintained, providing you with fine, breakdown-free performance and efficiency that can be adjusted to suit your exact boating needs. Always refer to the manual for your specific engine model for model-specific instructions and recommendations.

How to Maintain Your Propeller For Longevity

Only consistent upkeep will ensure the longevity and good performance of Yamaha outboard propellers. Look for any wear, such as chipped blades or corrosion, as these can affect efficiency and have adverse implications for fuel consumption. Cleaning the propeller after every use, particularly after exposure to saltwater, helps prevent dust accumulation and marine growth.

🔧 Essential Maintenance Checklist

- Inspect for chipped blades

- Check for corrosion signs

- Clean after each use

- Apply manufacturer grease

- Remove fishing line tangles

- Check hardware tightness

- Verify proper alignment

- Consider stainless steel upgrade

Apply grease, recommended by the manufacturer, to the propeller shaft to prevent unnecessary friction and damage. Also, check whether any fishing lines or other foreign matter are tangled around the shaft, as these may eventually damage the seals. Periodic checks on the propeller hardware, including securing the nut with a cotter pin, are necessary to maintain tightness and proper alignment while in operation.

Last but not least, a stainless steel prop can be upgraded if the boat is used frequently in heavy conditions, as these can withstand more, are tougher, and offer a slight increase in efficiency over aluminum. Thus, by observing the propellers closely and implementing the suggested care procedures, an owner can enjoy the benefits of a long-lasting propeller that will deliver optimum performance in various marine activities.

Troubleshooting Common Propeller Problems

With proper maintenance, most propeller problems can be avoided; however, issues may arise due to wear, damage, or improper usage. Here are some common propeller problems and how to recognize and fix them.

⚡ Cavitation

Problem: Air bubbles form around propeller blades, reducing efficiency and potentially causing surface damage.

Causes: Damaged blades, improper pitch, or obstructions around the propeller.

Solution: Inspect for physical damage, adjust pitch if needed, and clear debris or marine growth around propeller housing.

🌀 Unusual Vibration

Problem: Abnormal vibrations during operation indicate bent or unbalanced blades.

Impact: Reduced performance and increased stress on the drivetrain.

Solution: Have a qualified technician repair or balance the propeller, or replace if necessary.

📉 Reduced Speed and Performance

Problem: Normal engine RPMs but poor boat performance indicates worn or damaged propeller.

Signs: Excessive wear on leading edges or missing blade material.

Solution: Replace the propeller to restore optimal performance.

🌡️ Engine Overheating

Problem: Propeller too large or excessive pitch for the marine engine.

Impact: Unnecessary strain on the engine from wrong propeller selection.

Solution: Check manufacturer specifications and select appropriate propeller for engine power output.

🦠 Corrosion or Pitting

Problem: Metal propellers show corrosion or pitting from saltwater operations and inadequate maintenance.

Prevention: Apply anti-fouling coatings regularly and inspect surrounding anodes.

Solution: Replace corroded propellers beyond repair to avoid sudden failure.

🔍 Professional Help

Taking prompt action on these causes and conducting periodic inspections can help keep the propeller and engine damage-free in the long term. For persistent issues, always seek the advice of a professional marine technician.

2025 Trends in Outboard Propeller Technology

Innovations in Propeller Design and Materials

The outboard propeller industry, which requires innovations for improved performance, fuel efficiency, and durability, is now at the forefront of design and material advancements. One clear trend is the increasing use of composite materials in conjunction with metals, such as aluminum and stainless steel. Most modern composites are very light, which leads to increased speed and maneuverability, while also being corrosion-resistant —a must in long-term use in both salt and freshwater environments.

🧪 Advanced Materials

- Composite materials with metals

- Lightweight construction

- Enhanced corrosion resistance

- Suitable for salt & fresh water

🌊 Hydrodynamic Design

- CFD modeling optimization

- Minimized drag

- Maximized thrust

- Variable-pitch cupped blades

📡 Smart Technology

- Real-time monitoring sensors

- Water pressure tracking

- Speed and torque analysis

- Data-driven optimization

Propeller efficiency gained further ground as the hydrodynamic design progressed through its developmental stages. CFD modeling has been instrumental in the development of blade shapes that minimize drag and maximize thrust. In contrast, variable-pitch, cupped-blade designs are becoming more common, allowing for a better grip of the water and improved handling at various speeds. These modifications also reduce cavitation, improve the life of the propeller, and enhance its smooth operation.

Also, a new trend comprises integrating innovative technology into propeller systems. Smart boats feature sensors that continuously monitor water pressure, speed, and torque in real-time. This data-driven approach enables precise adjustments that optimize performance and reduce wear on associated parts, such as the engine.

Propeller innovation has also focused on sustainability. Manufacturers are considering recyclable materials and eco-friendly coatings to lessen the environmental impact of producing and operating marine equipment. Along with these, some innovations are setting new standards in performance, durability, and environmental sustainability as of 2025 and beyond.

The Effect of Technology on Fuel Economy and Performance

Witnessing such significant changes has been truly rewarding. From the propulsion angle, we now have much better hydrodynamic propeller designs and real-time monitoring applications that, based on operational aspects, control fuel consumption. By integrating data analytics and machine learning, operational parameters can be dynamically adjusted to minimize energy losses and enhance performance. Fuel reduction is the first objective of these tools, but they also ensure that an optimal level of efficiency is maintained throughout the period.

🚀 Technology Impact on Marine Operations

Engine health tracking

Fuel consumption analysis

Dynamic adjustments

Proactive measures

LNG integration

Biofuel compatibility

Smart sensors and automation are among the most cutting-edge technologies I have encountered. Real-time engine health monitoring and fuel consumption tracking enable us to take proactive measures to increase performance and reduce emissions. In addition, advancements in hybrid propulsion systems and alternative fuels, such as LNG and biofuels, are crucial for achieving efficiency and are also necessary to address environmental concerns. These sustainable ways are paving the way for a more environmentally conscious and resourceful future in maritime transport.

Almost everything about marine technology has redefined what was previously considered efficient and fuel-efficient in terms of performance. They are points of operational excellence and sustainability simultaneously. With more innovation in practice and tools, we will be able to put the industry’s aspirations on a track of environmental friendliness, ensuring a bright future for marine operations.

Case Studies: Successful Propeller Upgrades for Yamaha 90 HP

When I think about successful propeller changes for the Yamaha 90 HP, a few prime examples immediately come to mind. There was one owner of a fishing vessel who wished for improvement in speed and fuel economy. Given the specifications of the vessel and its performance requirements, I recommended opting for a high-performance stainless steel propeller instead of the factory-installed aluminum one, with only a slight pitch adjustment. The results were phenomenal—as the boat could now accelerate better, consume lesser fuel, and offer smoother handling in rough waters. The customer enjoyed his boat more, operating it less expensively, which showed that a customized upgrade is worthwhile.

📊 Case Study 1: Fishing Vessel

🏖️ Case Study 2: Recreational Boater

The other case involved a recreational boater carrying heavier loads due to family outings and gear. That stock prop was struggling to deliver optimum performance under those conditions. Hence, by installing a 4-blade prop with improved thrust capabilities, followed by a pitch rebalance, the boat’s ability to plane quickly was enhanced, even with the added weight. The change in props resulted in a marked improvement in performance at mid-range speeds, and the torque was significantly improved for low RPMs, thereby eliminating concerns for the operator, regardless of the changing load situation.

These illustrations highlight the fact that proper propeller matching to an operator’s needs can truly unlock the potential of a Yamaha 90 HP motor. In addition, having a prop that suits the running conditions means not only the highest efficiency but also everlasting happy operators.

Reference Sources

-

Yamaha Prop Selector – A tool to help you test and select the best propeller for your Yamaha 90 HP outboard based on your specific needs.

-

How to Choose the Right Yamaha Outboard Propeller – A comprehensive guide covering engine specs, shaft splines, and other critical factors.

-

Selecting the Yamaha Propeller That’s Best for You – Discusses key considerations like pitch, diameter, material, and blade number.

-

Genuine Yamaha Outboard Propellers – Offers insights into choosing the right propeller tailored to your Yamaha outboard engine.

-

Propellers for Medium & Small Boats – Features propeller options designed for high-horsepower outboards, including Yamaha models.

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What is the top-rated Yamaha propeller for a 90 hp outboard motor?

Selecting the best Yamaha Propeller for a 90 hp outboard generally depends on the needs of the bosuns. A 3-blade aluminum propeller with a pitch of 13 X 19 is the most recommended one for general use. It gives just enough speed and acceleration for cruising or fishing. For enhanced performance, one might consider opting for stainless steel ones due to their durability and efficiency. The weight of the boat and the type of water should be considered when selecting the most suitable one.

❓ Pitch spoken of in the performance of the Yamaha outboard prop?

When it comes to Yamaha outboard propellers, the pitch plays a significant role in the propeller’s performance. A higher pitch, like 17, will boost its top speed at the cost of acceleration and hole shot. On the contrary, a lower pitch will provide more acceleration. The low-pitch propellers are ideal for heavy stocking loads or water sports. Find the right balance for the motor so that the return rpms come within a recommended range. Usually, this means selecting a pitch that can make the motor hit WOT while attaining low, but never exceeding, max rpms.

❓ What are some advantages of using a stainless steel propeller on the Yamaha 90 hp?

What advantages does the stainless steel propeller offer a Yamaha 90 hp outboard? Stainless steel props last longer and resist corrosion better than aluminum, providing better overall performance and efficiency at higher speeds, which results in improved handling and fuel economy. Additionally, a stainless steel prop will withstand more torque and is therefore better suited for heavier boats or rough conditions. Nonetheless, while they are expensive, their benefits for the serious boater ultimately outweigh the cost.

❓ What splines count as standard grit for Yamaha 90 hp outboard props?

Usually, it is 15 spline that is standard for Yamaha 90 hp outboard props. This is necessary to ensure that the propeller fits alongside the drive shaft of the outboard engine. Hence, when purchasing a new prop, checking the spline count is of utmost importance to avoid a fitting issue. Also, many aftermarket prop manufacturers will offer outboard props with the same spline counts, giving you a multitude of choices for performance upgrades. Check your outboard engine manual for requirements pertinent to your motor.

❓ Which prop would be ideal while fishing with a Yamaha 90 hp outboard?

What about a lower-pitch aluminum prop of 13 x 17 for fishing with a Yamaha 90 hp outboard? This allows for quicker handling and acceleration, making it crucial to maneuver to your favorite fishing spots quickly. In addition, a 3-blade balancing system allows speed with control so it can be maneuvered through small places. Factors such as the weight of the boat and the typical load should be considered when selecting a prop that suits your fishing style.

❓ How can I make my Yamaha 90 hp outboard accelerate faster?

More speedy propellers with lower pitch will work to your advantage in terms of acceleration—a 13-pitch propeller yields quicker hole shot acceleration and generally better acceleration than most higher-pitch alternatives. One thing to check is whether your outboard engine has undergone proper maintenance, including periodic inspection of the lower unit and engine mounting. Another effective method to optimize acceleration is to adjust the trim so that drag is minimized. Should problems persist, a marine dealer may offer a proper solution that considers your boat and motor setup.