Choosing the right propeller for your boat can feel daunting, especially with the numerous options available in 2025. One of the most debated issues faced by boaters is deciding between choosing a three-blade prop or a four-blade. Each choice presents certain advantages depending on your boating nature, what you value in performance, and most importantly, your operating conditions. This guideline will outline the fundamental differences between these two more popular options, enabling one to make a well-informed choice and enrich their boating venture. Whether you prioritize speed, fuel economy, or handling, this article will provide the relevant perspectives to help you get on the right track. Let’s see the comparison of these two prop designs and, most importantly, which one should suit you for your needs.

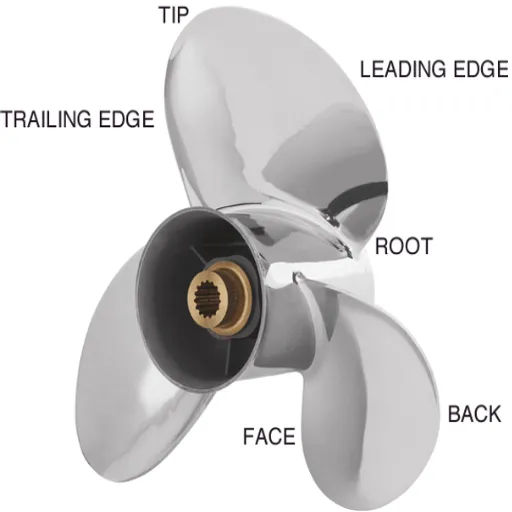

Understanding Propeller Basics

The Virtuous Function Operation of the 3-Blade Propeller

A 3-blade propeller is versatile and more favored for different boating requirements. Its geometry strikes a balance between speed, efficiency, and performance, making it suitable for both recreational and commercial usage. Since these propellers have fewer blades compared to other configurations, they also entail less drag, which, if ideal, means reaching a higher top speed and better fuel economy. These propellers are perfect for boats that demand quick maneuverability and acceleration, as less surface area means less resistance in water.

Key Advantages:

- Higher top speeds due to less drag

- Better fuel economy at high speeds

- Lighter weight and easier maintenance

- Lower cost compared to 4-blade alternatives

- Quick acceleration and responsiveness

Durability and lower price- the factors that increase the attraction towards 3-blade propellers. Their structure makes these props lighter and easier to maintain while still providing reliable thrust. Tests and analyses show that 3-blade propellers perform best with lighter boats equipped with high-power engines, where the main criterion considered is top speed. A downside could be that it offers less smoothness compared to its higher-end blade alternatives, especially in turbulent waters. When you have these small notes at your fingertips, you can be assured of selecting an exact propeller configuration that meets your needs in performance and efficiency!

Working of 4-Blade Propellers

Designed to strike a balance between power and smoothness, 4-blade propellers are suitable for a wide variety of marine applications. These are especially beneficial for acceleration and handling in rough seas or when a heavy load is present. It is usually better for grip with all maneuverability facilities in sharp angles or uneven conditions. They significantly reduce vibrations, thereby increasing comfort, particularly in recreational boats or fishing vessels.

Key Advantages:

- Superior handling in rough waters

- Reduced vibrations for smoother rides

- Better low-speed torque and acceleration

- Enhanced fuel efficiency at cruising speeds

- Improved grip and stability

Their design best supports fuel efficiency at mid-range speeds, a design feature that operators who prefer long-range cruising or steady travel would want to capitalize on, whereas pure speed is mostly considered. The evidence suggests that 4-blade propellers retain constant performance very well when it comes to larger-sized vessels or boats operating on high-torque engines. Understanding which characteristics align with your boating objectives can help you strike a balance between performance, efficiency, and durability.

VSThree-Blade And Four-Blade Propeller Key Differences

When considering a three-blade propeller versus a four-blade propeller, specific details must be examined regarding the inherent advantages each design offers and how they impact boat performance. Three blades are classically thought to be beneficial for achieving higher top speeds on a shaft line due to reduced resistance and drag. They tend to be chosen more for smaller boats that are built for speed and for existing applications where speed is a critical issue. They also come in higher-speed fuel efficiency, thereby suited to boaters who want good performance but are not concerned about fuel consumption. Three-blade type propellers are made lighter with fewer blades, thus expedient for speeding up and turning.

| Characteristic | 3-Blade Propeller | 4-Blade Propeller |

|---|---|---|

| Top Speed | Higher (5-10% advantage) | Moderate |

| Low-Speed Control | Good | Excellent (20% better) |

| Fuel Efficiency | High at cruising speed | 15% better at mid-range |

| Vibration | Moderate | Minimal |

| Rough Water Handling | Good | Superior |

| Load Capacity | Moderate | Excellent |

| Cost | Lower | Higher |

On the downside, four blades generally provide better control and stability than three blades, especially in choppy water conditions or during slow maneuvers. A four-blade prop is renowned for its smooth ride, resulting in reduced vibration and enhanced user comfort during longer excursions. Four-blade props also grip the water more effectively, thereby improving low-speed handling and making them great complements to towing work, especially for water skiing or hauling heavy loads. Moreover, four-blade props have more consistent torque and low-rpm power characteristics, which are valued by boats that require such traits, such as fishing boats or cruisers loaded with heavy gear.

💡 Key Insight:

Ultimately, the decision between a three-blade and four-blade propeller essentially boils down to understanding how each design aligns with your boating priorities, i.e., speed, fuel efficiency, or good control and balance in various conditions. After careful consideration of these factors, boat owners will be in a position to select the propeller that best facilitates their performance and the overall boating experience.

Performance Comparison of 3-Blade vs 4-Blade Props

⚡Speed and Efficiency Considerations

Three-blade propellers are considered the best in terms of speed, with less drag and a simpler design, which enables the boat to achieve a higher top-end speed. They are usually chosen where velocity has possibly been a price, either in water sports or racing applications. Of course, they could produce a loss of fuel efficiency, as three blades usually have to spin even faster RPM-wise to maintain their optimal performance.

Performance Data

Efficiency Insights

- 3-Blade: Optimal for high-speed applications

- 4-Blade: Better fuel economy at cruising speeds

- RPM Impact: 3-blades require higher RPM

- Load Factor: 4-blades excel under heavy loads

Typically, four-blade or pitch propellers are highly efficient in design; the extra blade moves a greater amount of water, providing more comfort and better mileage at cruising speed. This is especially beneficial to boaters who want to minimize fuel consumption on lengthy cruising or require consistent and reliable power under heavy load. They provide better control and speed consistency in choppy and rough water conditions.

📊 Performance Summary:

New data suggest that, at present, three-blade propellers can achieve a 5 to 10% increase in top speed over four-blade propellers, which, in turn, may result in as much as a 15% better fuel economy at cruising speeds. Bearing all that in mind with respect to their own operational setting and speed requirements, any boater will be able to make an informed decision that optimizes a compromise between speed, fuel conservation, and effectiveness.

🌊Handling and Maneuverability in Conditions

Emphasis is placed on selecting the appropriate propellers to achieve good handling and maneuverability in a suitable boat under varying environmental conditions. Four-blade propellers excel at maintaining stability and control in churned-up or turbulent waters. Meanwhile, the greater area holds that these transitions are slightly increased, more tinted, and smoother, particularly when turning sharply at low speeds or leaving the berth. Three-blade propellers, in contrast, offer rapid acceleration and greater responsiveness at high speeds, making them suitable for open waters and situations that require rapid directional changes.

Low-Speed Handling

Improvement with 4-blade propellers at lower speeds

High-Speed Agility

3-blade excels in rapid directional changes

Docking Precision

4-blade provides more predictability

Recent comparisons have revealed that four-blade propellers improve handling by 20% at lower speeds, offering more predictability and precision when docking or navigating through narrow channels. Meanwhile, three-blade models are best suited for water skiing or racing when agility and speed are the top priorities.

With currents, winds, and load distribution, other environmental factors come into play, affecting performance. Thus, the boat operator must consider these variables in addition to personal preferences and intended use cases. Once one understands the trade-offs between speed, stability, and maneuverability, they can consider selecting a propeller based on the specific prevailing conditions.

⛽Effect on Fuel Consumption and Range

Fuel consumption and range are important considerations when choosing a propeller, as they are operational parameters directly linked to efficiency and, consequently, to cost. Propeller dimensions and pitch are the critical parameters determining how efficiently an engine converts power into thrust. For instance, lower-pitch propellers may provide good acceleration but may lead to higher fuel consumption over time. Larger pitch propellers tend to consume less fuel while cruising, but require more power to generate thrust from standstill. Additionally, innovative designs, such as our stainless-steel series and variable-pitch system, help reduce fuel wastage.

Fuel Efficiency Optimization

Reduces operating costs and extends range significantly

According to real-world performance data, an optimized propeller setup increases fuel efficiency by about 10-15% and reduces running costs accordingly. Hence, the best efficiency and desired range set-up would depend on the engine performance characteristics for the vessel, as well as the average load condition and cruising speed considered typical for that vessel. Modern digital tools help fine-tune the selection procedure, thereby matching the propeller perfectly with the vessel’s intended use, resulting in a significant enhancement of fuel economy and operating range.

Trending Preferences in the Boating Community for 2025

📊Survey Results on Boater Preferences: 3-Blade vs 4-Blade

Based on the most recent surveys, boaters’ choice between propeller blade configurations versus each other seems balanced while still changing. The classic 3-blade remains popular for its versatility and efficiency at high speeds, as greater drag is reduced, and top-end performance is maximized. At a recreational or competitive level, be it for sport or a competitive sport, any enthusiast prefers this configuration just because it maximizes speed and responsiveness.

3-Blade Preferences

- Racing Enthusiasts: Speed and responsiveness priority

- Sport Boaters: Maximum performance focus

- Speed Seekers: Top-end velocity preference

- Light Boats: Efficiency with high-power engines

4-Blade Preferences

- Cruising Boaters: Comfort and stability focus

- Fishing Enthusiasts: Low-speed control needs

- Towing Activities: Heavy load requirements

- Rough Water: Superior handling demands

Conversely, 4-blade props are now being increasingly preferred as they offer somewhat better handling and more thrust at slow speeds, a configuration suited to the boater who tows or cruises for longer distances across rougher waters. Those boating for smooth acceleration and excellent fuel economy under heavy load conditions value this configuration.

Additionally, within the broader discourse in the boating community, more attention is being paid to how these configurations may impact the engine’s longevity and maintenance. Boaters increasingly tend to make these trade-offs, resulting in a theoretically more diverse yet less informed acceptance of the 3-blade versus 4-blade types. Once demands are accurately known, matching those demands with the right kind of propeller will always ensure the utmost satisfaction on the water.

🎯Expert Recommendations

In the view of marine experts, whether a propeller has 3 blades or 4 depends on the individual requirements of the vessel and its actual use. The experts advocate using 3-bladed propellers on boats that seek maximum top speed and fuel efficiency since they produce less drag and are lighter. They prepare scenarios in which high acceleration with low resistance is required, well, basically, recreational speedboats or vessels commonly seen in open waters.

Expert Insight: 3-Blade

Recommended for boats seeking maximum top speed and fuel efficiency. Ideal for recreational speedboats and open water vessels where high acceleration with low resistance is prioritized.

Expert Insight: 4-Blade

Preferred for enhanced control, stability, and smoother rides in rough conditions. Provides greater thrust at slower speeds with better water grip.

Performance Data

4-blade designs enhance handling by 10% in rough water, while 3-blade designs provide up to 5% better average speed performance.

Generally, 4-blade propellers have gained appreciation with boats that require enhanced control, stability, and smoother rides, particularly under rough or choppy conditions. They provide greater thrust at slower speeds, allow for a better hold in water, and enhance fuel efficiency under cruise conditions-therefore suitable for fishing boats, pontoons, or heavily loaded vessels. Technicians stress that when choosing, it is essential to consider pitch, diameter, and blade material, as these factors significantly impact performance.

🔧 Expert Advice:

Industry data emphasizes the need to align propeller choice with the operational profile of the boat. Tests have demonstrated that 4-blade designs can enhance handling by as much as 10% in rough water, while 3-blade designs can provide an average speed up to 5% better. Experts advise boat owners to conduct their own water trials and seek the guidance of propeller specialists to arrive at a balanced solution tailored to their particular boating needs.

🚀Emerging Technologies Influencing Prop Design

The introduction of advanced disciplines in materials science and engineering has primarily stimulated rapid evolution in propeller design. An important area of innovation lies in the entry of composite materials, which have a better strength-to-weight ratio than metals. This not only ensures strength but also creates better fuel efficiency by being lightweight. Additionally, various adaptive propeller systems, whose functioning depends on AI algorithms, are gaining immense popularity. These systems can adjust the pitch of the blade in real-time to enhance performance at various speeds and environmental conditions, thereby improving propulsion efficiency by up to 15 percent in some instances.

Composite Materials

Better strength-to-weight ratio than traditional metals

AI-Adaptive Systems

Real-time pitch adjustment for optimal performance

3D Printing

Custom propellers with unprecedented accuracy

CFD Simulation

High-performance computing for fluid dynamics

3D printing technologies allow the production of custom propellers with unprecedented accuracy and the ability to prototype alternative designs, one of such advancements. This allows for more radical blade geometries, which will result in smoother operations and thus quieter running. Further to the manufacturing process, hydrodynamic simulations have become critical tools for refinement. These simulations utilize high-performance computing to analyze fluid dynamics, enabling designers to predict and mitigate cavitation effects and optimize thrust efficiency.

🔮 Future Outlook:

These technologies, together, represent a future where propeller designs will be customized to individual needs, while offering sustainable and optimized performance in different marine environments. A boating enthusiast or an industry professional would surely look forward to these systems being redeveloped for the better.

Case Studies: Real-World Applications

🛥️Performance Evaluation of a 3-Blade Propeller in Different Kinds of Boats

The range of performance generated by 3-blade propellers varies significantly with the kind of boat and its intended function. To small pleasure boats, such as those used for runabout activities, the 3-blade configuration offers a compromise between speed and agility. This configuration enables fast acceleration, allowing these boats to plane quickly, while also providing decent fuel economy at cruising speeds. For such mid-sized fishing boats, the 3-blade remains the favorite configuration. Imparting thrust at moderate rpm checks stability, and the boat performs efficiently at long distances even when under load.

Small Pleasure Boats

- Optimal speed and agility balance

- Fast acceleration to plane

- Good fuel economy at cruise

Mid-Sized Fishing Boats

- Moderate RPM thrust delivery

- Stability under load

- Efficient long-distance performance

Pontoon Vessels

- Easy cruising capability

- Good maneuverability

- Reduced drag design

High-Performance Boats

- Maximum speed priority

- Sharp, high-rake blade design

- Efficient water cutting

However, as potential candidates for slow and easy cruising without a hitch in maneuverability, 3-blade propellers serve the pontoon-type vessels well. Hydrodynamically shaped, with improved materials, they shed drag in modern 3-blade configurations to enhance speed and conserve fuel, recent field tests have shown.

The 3-blade option for high-performance boats is designed to meet the end-user’s requirement for maximum speed while maintaining durability. Trials have indicated that for these boats, thin, sharply shaped blades with a high rake cut through the water more efficiently, allowing the boat owner to push their craft to top speed efficiently. Depending on the boat type, the success of the 3-blade propeller depends on the correct sizing, pitch, and design innovation tailored to the use case scenario. These factors work together to enable the propulsion system to be tailored to serve the needs of whichever boating category, thereby endorsing the use of the 3-blade concept.

🌊Four-Blade Prop in Challenging Waters

Usually selected for challenging water conditions, the four-blade propellers offer a combination of power, control, and efficiency. A design aspect ensures that these propellers have a higher grip and less slippage, which are vital characteristics in rough seas, strong currents, or situations requiring accuracy in handling. Key advantages of four-blade propellers include improved acceleration and enhanced speed-holding capabilities, particularly under heavy load or towing conditions.

Challenging Water Performance

The four-blade type propeller also minimizes vibration and enhances stability, making it a preferred choice among boat owners who seek comfort and a lower noise level. Recent progress in hydrodynamic engineering has enhanced blade geometry, enabling the achievement of improved performance while maintaining better fuel economy. Therefore, the correct combination of diameter and pitch must be selected for peak operation and exquisite handling in unpredictable maritime environments.

🏁Comparative Analysis of Propeller Options in Racing

Racing propellers stand as an essential requirement in the maritime competitive arena where performance, speed, and accuracy become the ultimate order. These types of racing propellers were rarely made of modern materials, such as stainless steel or composite alloys. Such materials promised extraordinary durability and the ability to resist corrosion during severe working conditions. The materials also allow for thinner, more streamlined blades, which reduce drag and facilitate faster acceleration.

| Propeller Type | Best Application | Key Characteristics |

|---|---|---|

| Cleaver Type | Light racing boats | Flat trailing edges, minimal lift, top-end speed focus |

| Chopper Type | Heavier racing boats | More bow lift, sharp turns, controlled acceleration |

| Variable-Pitch | Versatile racing conditions | Adaptive to water conditions, race-time adjustability |

Typical propellers in the racing business are cleaver and chopper types. Having flat trailing edges gives cleavers a leading edge of top-end speeds on light boats, where minimal lift is a requirement. Choppers provide more bow lift for the heavier racing boats that require sharp turns and controlled lifts in acceleration.

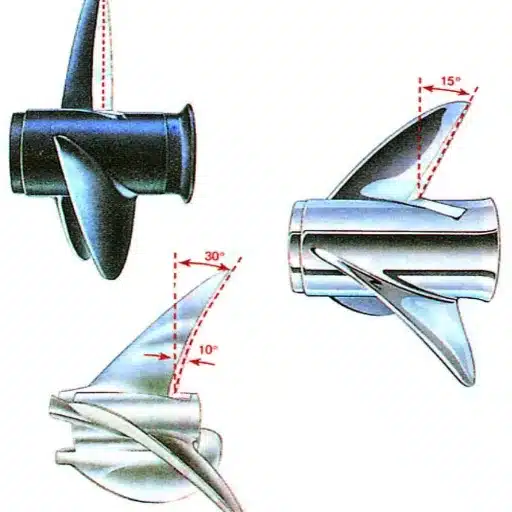

Performance Metrics

- Pitch Progression: Determines speed potential with available engine power

- Blade Surface Area: Affects grip and acceleration characteristics

- Rake Angle: Influences lift force and water displacement balance

Some of the main performance metrics to compare propellers are pitch progression, blade surface area, and rake angle. A high pitch can create a higher speed potential if enough engine power is available to rotate the propeller at the ideal RPM. Conversely, a steep rake angle will generate a greater lift force, but it must be correctly balanced to achieve an acceptable water displacement.

Variable-pitch racing propellers that vary according to water conditions have recently been introduced, making them very versatile during a race. Design processes have greatly benefited from the evolution of CFD modeling; pre-production testing of propeller shapes and angles has become very precise. Taking advantage of such developments, racing teams can maximize efficiency without compromising durability and consistency.

Choosing the Right Propeller for Your Boat

⚖️Factors to Weigh Amidst Selection of 3-Blade Versus 4-Blade

Several factors must be considered when selecting between a 3-blade and 4-blade propeller to ensure your boat achieves maximum performance. Each arrangement offers certain advantages that best fit the need, circumstance, or objective of boating being sought.

Speed and Efficiency

3-Blade: Higher top speeds due to lesser drag. Important for racing or fast vessels.

4-Blade: More fuel-efficient at lower speeds, pertinent to cruising and towing scenarios.

Handling and Stability

4-Blade: Smooth and stable operation, particularly in rough waters. Secure grip while turning.

3-Blade: Greater agility during high-speed maneuvering, but less stability in rough waters.

Acceleration and Load Capacity

4-Blade: More torque for heavy acceleration and load, better for pulling skiers or hauling gear.

3-Blade: Quick rush of speed, but may not provide enhancement under weight load.

Cavitation and Noise Reduction

4-Blade: Reduces cavitation force at high speeds, increasing thrust and minimizing engine wear.

Also quieter than 3-blade design, valued by boaters seeking calm waters.

Engine Match and Compatibility

3-Blade: Well-suited for engines operating at high revolutions, maximizing power output.

4-Blade: Used with engines operating smoothly through wide range of conditions.

🎯 Decision Framework:

It boils down to which priorities you put for your boat, whether speed, maneuverability, or efficiency, in the choice between a three-blade and four-blade propeller. Through recent improvements and working out how these factors apply to your application, you will find your own negotiating tool.

🚤Recommendations Based on Boat Size and Type

When choosing the ideal propeller for your boat, I believe size and type of vessel are the primary factors to consider. For light craft such as fishing boats and dinghies, a 3-blade propeller is often ideal. It is simply lightweight and presents minimal drag to achieve maximum speed and efficiency, especially in calm conditions. Meanwhile, 4-blade propellers typically perform better for larger boats, such as pontoons or cruisers, as load-bearing capacities come into play. The additional blade surface area provides greater thrust to the vessel, promoting smooth operation in adverse situations or when carrying heavier loads.

| Boat Type | Recommended Propeller | Primary Benefits |

|---|---|---|

| Small Fishing Boats | 3-Blade | Lightweight, minimal drag, maximum speed in calm conditions |

| Dinghies | 3-Blade | Efficiency and speed priority for lightweight craft |

| Pontoons | 4-Blade | Greater thrust, smooth operation with heavy loads |

| Cruisers | 4-Blade | Load-bearing capacity, smooth operation in adverse conditions |

| High-Performance Speedboats | 4-Blade | Better hole shot, maneuverability, good acceleration |

| Open Water Racing | 3-Blade | Top-end speed priority in unlimited open water |

A 4-blade propeller usually provides a better hole shot and maneuverability, along with good acceleration and handling, when dealing with high-performance speedboats or wakeboarding boats. On the other hand, unlimited open water is best suited for a standard 3-blade propeller when you are after top-end speed. Apart from that, I suggest that consideration be given not only to the characteristics of the boat but also to its intended use. This ensures that the propeller is geared to your unique performance and efficiency needs.

🔧 Professional Advice:

General guidelines are always a good starting point, but it never hurts to ask an expert. Additionally, all of this needs to be considered in relation to your engine. Once your specific performance needs are met with sound technical advice, the propeller for your boat may be refined to maximize its effectiveness in providing the overall boating experience.

🔧Maintenance Considerations for Both Prop Types

Maintenance-wise, with both aluminum and stainless steel, it’s always a matter I tend to stress when it comes to maintaining optimal condition. Inspections for damage, such as dings, bends, and cracks, should be a regular maintenance procedure for both types, as they may potentially lower performance and fuel efficiency. Hence, they must be addressed as soon as possible. Furthermore, depending on the area, fishing lines or debris may be wrapped around the prop hub, and potential damage to the internal engine parts or the lower unit should always be considered.

Stainless Steel Props

- Highly durable but prone to saltwater corrosion

- Rinse thoroughly with fresh water after use

- Apply protective anti-corrosion spray

- More expensive but longer lasting

Aluminum Props

- Lighter and less expensive option

- More prone to impact damage

- Keep spare propeller for emergencies

- Check paint for chips (oxidation protection)

🔧 Universal Maintenance Steps:

- Regular Removal: Remove prop occasionally to check for shaft wear or damage

- Spline Greasing: Grease the splines for easy operation

- Hardware Inspection: Check prop nut and cotter pin tightness

- Damage Assessment: Look for dings, bends, and cracks that affect performance

Sterling steel props are highly durable, so they are prone to corrosion in saltwater environments. I recommend rinsing thoroughly with fresh water after use. You may also go the extra mile and apply some protective anti-corrosion spray to maintain the condition of the prop. Aluminum props, being lighter and less expensive, are more prone to impact damage; therefore, an extra propeller should always be kept on hand for emergencies. Check the paint periodically for any chips or flakes; the paint acts as a barrier against oxidation and weakening of the prop over time.

Of course, any method applies to all. Likewise, consider removing the prop occasionally to check for wear or damage on the shaft while greasing the splines for easy operation. This is also a good time to inspect the prop hardware, such as the nut and cotter pin, to ensure everything is tightened up. Following these basic maintenance procedures will extend the life of your propeller, safeguard your engine, and provide a smooth cruising experience.

Reference Sources

-

3 Blade vs 4 Blade Prop: Which is Better? – Boats.net: Discusses surface area, performance, and efficiency differences between the two prop types.

-

3-Blade vs. 4-Blade Prop: What Are The Differences? – Reel Coquina Fishing: Explores drag, speed, and fuel mileage benefits of three-blade props.

-

Topic: 3 Blade vs 4 Blade Props – Bass Cat Forum: Highlights how four-blade props perform better for heavy boats and specific use cases.

-

Comparing Three-, Four-, and Five-Blade Propellers – Boating Magazine: Provides a detailed comparison of propeller types using Mercury propellers as examples.

-

3 Blade vs 4 Blade Prop: Which is Better? – Boats.net: Offers insights into how four-blade props help maintain a plane at lower RPMs.

- View for more details.

Frequently Asked Questions (FAQs)

?What distinguishes a 3-blade from a 4-blade propeller?

The chief distinction is one of performance: a 3-blade prop will generally reach higher top-end speeds due to less drag, whereas a 4-blade prop will provide better low-speed control and a better hole shot. This means a 4-blade prop will pull better for acceleration and low-speed control. A 3-blade prop will probably be the better one for high-speed, efficient performance applications. It’s mostly a matter of how the boat will be used and what hull it has.

?How does the number of blades affect prop performance?

To make a very generic statement, the propeller with more blades will probably perform a bit better than one with fewer blades because there is more surface area pushing, but it depends on how other characteristics of the 4 and 3-blade propellers trade off with each other, the specifics of blade geometry, and other details to be precise. However, generally speaking, a 4-blade prop will offer better low-speed acceleration and handling, allowing a skier to get up on plane more quickly under less-than-ideal conditions. Ultimately, however, the final choice rests on your boat setup and specific requirements.

?Are any 4-blade propellers good for fuel economy?

At lower speeds, a 4-blade propeller would offer some fuel economy, as it can generate more thrust without requiring a higher RPM. It is said an extra blade reduces cavitation and allows for smooth operation, somehow leading to lower fuel consumption. At the same time, at low speed, a 4-blade is a little inefficient and may actually create drag at higher RPMs, while a 3-blade will work the other way around before it hits drag. So, the fuel economy gains would be a function of the hull and how the boat is used.

?Why should you want to go for a 3-blade prop?

A 3-blade prop has a series of advantages, more so for fast boats. From a theoretical point of view, a 3-blade prop can achieve a higher top-end speed and be relatively more efficient due to its smaller blade area, which imparts less drag. This type of propulsion system is typically preferred for recreational speedboats that do not require low-speed handling, such as those with a 3-blade prop. Wide-open throttle performance also improves with a 3-blade propeller. For fast acceleration and low-speed manoeuvring, a 4-blade prop may have more advantages.

?How do I know which propeller is best for my boat?

Propeller Now goes as far as meeting with you to determine the right propeller, taking into consideration the hull, the fishing method, and maintenance characteristics. Testing various sets of props could help balance top-end and low-speed handling. Talk to a prop guy or a reputable dealer who can make the prop pitch or diameter recommendation based on his knowledge of your engine specifications and intended performance. For acceleration at low speeds, a 4-blade prop shall be preferable. For high-speed acceleration, though, a 3-blade prop may have the advantage.

?What about pitch effects on prop performance?

The pitch of a propeller is considered to be one of the most important factors affecting its performance. A high-pitch prop usually delivers a higher top speed while slowing acceleration. A low-pitch prop, on the other hand, allows a good hole shot and pleasant low-speed handling. When considering the pitch, one must also consider how it interacts with the number of blades. For example, a low-pitch 4-blade prop offers a great hole shot and actually achieves competitive speeds, making it perfect for water skiing.