The year 2025 marks another turning point in the development of propeller shafts, as never-before-seen advancements lead to a reevaluation of longevity and efficient design. Operators in the automotive, aerospace, and marine industries are demanding higher performance and sustainability. As a result, engineers and innovators are altering how propeller shafts are conceived, produced, and maintained. This article explores findings that set new standards in material strength, energy optimization, and lifecycle working hours. By examining present-day innovations, one realizes their ability to meet the highly demanding current requirements of industries and to pave the way for a future with machines that are increasingly resilient and energy-efficient. So sit tight as we chart the innovations germane to the next generation of propeller shafts with their rippling effects!

Understanding the Propeller Shaft: Basics and Functionality

What is a Propeller Shaft?

A propeller shaft-infamously called a driveshaft-is a mechanical component for transmission of torque and rotational motion from the source of power-generally an engine or a motor-to an end device such as a propeller or wheels. Propeller shafts are used in automobiles, marine vessels, and industrial machines as a primary link in the flow of energy, where they must withstand immense stress and strain.

🔧 Key Characteristics of Modern Propeller Shafts

- Made from high-strength steel, aluminum, or composites

- Designed to withstand axial and torsional loads

- Must resist bending and maintain alignment

- Enhanced with vibration-damping systems

Modern propeller shafts are made from high-strength steel, aluminum, or composites to ensure durability, perform well under axial and torsional loads, resist bending, and maintain alignment under various operational scenarios. For example, in an automobile, power is transmitted by the shaft from the transmission to the differential, putting “power to the wheels.” In a ship, the shaft connects the engine to the propeller, thereby converting power into thrust for steering.

To make them perform better, recent innovations include enhanced vibration-damping systems, lightweight configurations that reduce energy loss, and coatings for corrosion resistance. The shaft is designed to combine efficiency and reliability in the operation of motion in various industries.

Some of the Functions of the Drive Shaft

The drive shaft transmits torque from the source of power, like an engine or a motor, to the mechanisms of motion, such as the wheels or the propeller. It is essential for the efficient transfer of rotational energy to maintain balance and minimize vibration for smooth and steady operation.

Modern drive shafts are configured with advanced features to face the challenges of numerous applications. For instance, users favor high-strength alloys or composite materials so that these shafts can absorb increasing power outputs without excessive weight, which consequently aids energy efficiency. Another feature ensures proper alignment, thus reducing wear on connected components.

⚙️ Advanced Drive Shaft Features

CV (Constant Velocity) Joints: Building on these features, CV (constant velocity) joints allow the drive shaft some degree of flexibility, enabling it to operate under varying angles and providing even greater performance in vehicles and machinery.

Protective Coatings: Tougher coatings and treatments further protect against abrasion, corrosion, and extremes in temperature, giving a longer life to shafts working in harsh environments. The integration of these advanced technologies demonstrates how vital the drive shaft is in advancing the motion mechanics of industries.

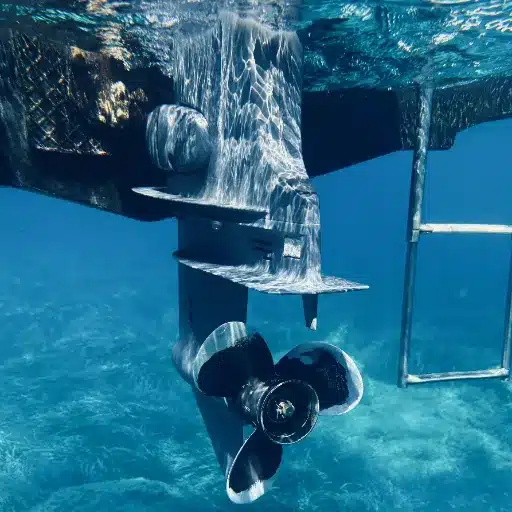

Differences Between Inboard and Outboard Propeller Shafts

Knowledge about the differences between inboard and outboard propeller shafts will provide the insight required for proper marine propulsion system selection. Put simply, inboard propeller shafts are located inside the hull, with the engine placed somewhat towards the center of the boat. The shaft goes through a sealed opening into the water and connects to a propeller down below through this window. Having this inboard balance, weight distribution, and all that stuff makes an inboard system well-suited for bigger boats or those built for long-distance cruising. Also, they can provide drag reduction because they have fewer external fittings, which can enhance efficiency in calm patch water.

Conversely, outboard propeller shafts are part of a self-contained propulsion unit located outside the stern of a boat. The engine, gearbox, shaft, and propeller are combined into one unit that can be taken off fairly easily and maintained. This characteristic provides more maneuverability, especially at slower speeds, thus making the outboard systems ideal for small to medium-sized boats. The advantage is that the outboard unit can be tilted out of the water while at rest, making it less subject to corrosion and maintenance requirements associated with marine high exposure.

| Feature | Inboard Propeller Shafts | Outboard Propeller Shafts |

|---|---|---|

| Location | Inside the hull, engine toward center | Self-contained unit outside stern |

| Best For | Bigger boats, long-distance cruising | Small to medium-sized boats |

| Maintenance | More complex, harder to access | Easier access for repairs |

| Horsepower | Higher degrees, commercial applications | Versatile, recreational boating |

| Corrosion Risk | Higher, constant water exposure | Lower, can be tilted out of water |

| Efficiency | Better drag reduction in calm water | Better maneuverability at low speeds |

Maintenance requirements are among the key aspects that differentiate the two. While inboard systems might offer a higher level of maintenance complexity and difficulty because of their location inside the vessel, outboard systems will generally be easier to access for minor repairs and replacements. Higher degrees of horsepower are typically provided by inboard systems, making them suitable for heavy work or commercial applications. At the same time, outboard engines are appreciated for their versatility and ease of use in recreational boating. Considering factors such as purpose, boat size, and the power needed, one should choose the system that best suits their needs.

Technological Innovations in Propeller Shaft Design

Materials Improving Durability

Contemporary inventions in the design of propeller shafts have opened avenues for employing innovative materials, which significantly advance durability and performance. Stainless steel is preferred over all other materials for its corrosion and wear resistance, especially in marine applications where corrosive elements like saltwater affect machinery. Titanium alloys are now being used increasingly for their very low weight and high strength, making them ideal for performance-focused efforts. Finally, the advanced composite materials, carbon fiber reinforced plastics, are also being used for their extreme toughness, very low weight, and fatigue resistance-all of which maximize the service life and hence, efficiency.

🔩 Stainless Steel

Preferred for corrosion and wear resistance, especially in marine applications exposed to saltwater elements.

⚡ Titanium Alloys

Very low weight and high strength, making them ideal for performance-focused applications.

💎 Carbon Fiber

Extreme toughness, very low weight, and fatigue resistance for maximized service life and efficiency.

These material innovations are alongside surface treatments and coatings that promote the lifespan of the propeller shaft. For instance, advanced anti-corrosion coatings and hardening processes improve wear-resistance on the shaft surface, thereby reducing maintenance requirements and allowing a longer duration of operational life. Through the use of these advanced materials and treatments, propeller shafts fulfill the reliability demands of the commercial and recreational marine industries while simultaneously offering reduced operating costs.

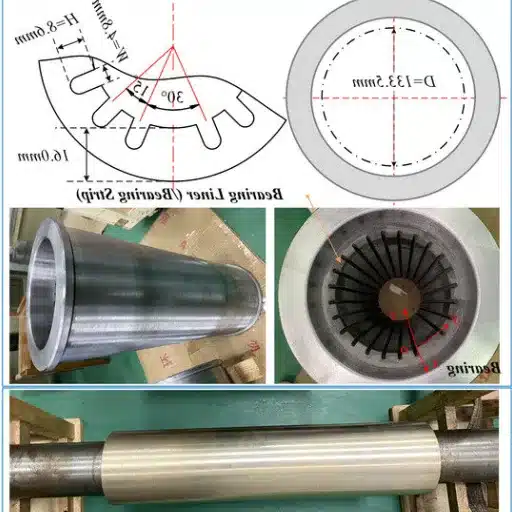

Shaft Geometry and Performance Improvements

Modern propeller shafts are optimized for performance, efficiency, and durability through proper geometry. Nowadays, engineers use computational modeling tools to analyze fluid dynamics and mechanical stresses, allowing shaft dimensions and contours to be accurately adjusted. For example, a tapered and hollow shaft can lose weight without losing strength, thus providing better fuel efficiency and greater vessel speed. Furthermore, manufacturing with high precision has helped reduce imbalances, leading to lower vibrations and noise levels and resulting in a very smooth and quiet operation. These developments will further increase propulsion efficiency while reducing environmental impact, which is an essential consideration on the sustainability agenda in the maritime industry.

📐 Geometric Optimization Benefits

- Computational modeling for fluid dynamics analysis

- Tapered and hollow designs reduce weight without sacrificing strength

- Precision manufacturing minimizes imbalances

- Lower vibrations and noise for smoother operation

- Enhanced propulsion efficiency with reduced environmental impact

Smart Sensors and Shaft Efficiency

Smart sensors have changed the way shaft efficiency is monitored and enhanced in the maritime domain. Information about torque, rotational speed, vibration, and other parameters needed for analyzing shaft performance is transmitted to the systems in real-time. Incorporating IoT technology allows these smart sensors to collect and send data to a centralized system, where advanced predictive analytics techniques can be applied to identify emerging problems, thereby preventing expensive failures.

🔬 Smart Sensor Applications

Vibration Monitoring: For example, vibration monitoring through smart sensors detects cases of misalignment and uneven wear, allowing for timely maintenance to prevent efficiency loss.

Torque Optimization: Another advantage is that torque sensors provide very accurate readings, enabling the optimization of fuel use by ensuring a propulsion system operates within its most efficient range. Increased efficiency through innovations, therefore, results in reduced costs due to less downtime and longer life for critical components.

Environmental Benefits: Through a plethora of data-intensive insights from smart sensors, maritime operators can optimize their empty activities toward decreased energy consumption and reduced emissions. This becomes increasingly relevant with the pace of international regulations toward greener shipping. Smart sensors thus become important performance drivers, cost savers, and enforcers of environmental conscientiousness to the industry.

Impact of 2025 Trends on Propeller Shaft Efficiency

Marine Engineering: Emerging Trends

Marine engineering continues to evolve through the amalgamation of technological advancements and sustainable innovation. One big trend is the use of Artificial Intelligence and machine learning technologies to improve vessel performance and maintenance. Predictive analytics systems are now capable of monitoring critical equipment, such as propeller shafts, in real-time to detect any problems before they affect general operational efficiency. This kind of proactive monitoring will reduce unscheduled downtime, thus greatly assisting operational resilience.

🚢 Key 2025 Marine Engineering Trends

- AI & Machine Learning: Real-time monitoring and predictive analytics for equipment performance

- Alternative Fuels: Biofuels, LNG, and hydrogen gaining momentum for emission reduction

- Hybrid Propulsion: Traditional engines combined with battery storage for efficiency

- Advanced Materials: Lightweight composites and carbon fiber for better fuel efficiency

- Digital Twins: Virtual representations providing real-time operational insights

- Autonomous Ships: Automated navigation and remote diagnostics for safety

Another key trend gaining traction is the use of alternative fuels and hybrid propulsion systems. With more stringent environmental regulations and the IMO 2025 emissions targets said to maximize effects, there is a growing focus on reducing carbon footprints. Alternative fuels and systems, such as biofuels, LNG, and hydrogen, are gaining momentum. Hybrid solutions that combine traditional engines with battery storage are becoming a cost-effective solution for improving fuel efficiency and reducing emissions.

Advanced materials are reshaping marine engineering, especially in the design of propeller shafts and hull structures. With lightweight composites benefiting hull structures, carbon-fiber production, durability, and corrosion resistance are granted, thereby enhancing fuel efficiency and reducing maintenance costs. Also, advancements in hydrodynamic modeling software provide marine architects with the opportunity to design more efficient shapes and streamline their ships, minimizing drag and maximizing propulsion performance.

This is another big disruption, as this essentially allows engineers to create a virtual representation of ship systems. These digital twins provide real-time operational insights and enhance decision-making based on an optimized performance model. It is essential to meet the performance benchmarks while remaining under sustainability regulations.

With further automation and the rise of autonomous ships, a mammoth advance in marine engineering is being realized. Automated navigation, collision avoidance systems, and remote diagnostics work to minimize human errors, thereby fostering safe, efficient shipping operations. With these emerging trends coupled with others, the maritime will be more efficient, sustainable, and technology-based, ensuring its long-standing adaptability to any global challenge.

Data-Driven Approaches to Shaft Performance

Modern approaches in shaft performance use data-driven technologies to optimize efficiency, reliability, and the choice of ultimate life. Integrating advanced systems of sensors and analytics, professionals in marine contexts continue to monitor parameters, including vibration, alignment, and torque. Predictive maintenance based on machine learning algorithms dramatically embraces the detection of potential problems before they grow big, along with the significant reduction in downtime and maintenance costs.

📊 Data-Driven Performance Optimization

Besides, currently, there is a paradigm where development emphasizes real-time data-enhanced operational decision-making. For example, by analyzing torque and power transmission data, marine operators can proactively modify the propulsion system in line with energy efficiency and environmental laws. Such innovations improve performance whilst targeting sustainability, which is well recognized in the marine industry today. Through integrating accurate data recording with sound decision-making, the sector is charting its course on a new, performance management strategy.

Challenges in Propeller Shaft Durability

Common Types of Failures and Causes

Several recurring failure modes challenge the durability of propeller shafts, each with operational and environmental causes. A widespread cause is corrosion resulting from long-term exposure to seawater, with minimal anti-corrosion measures considered. This tends to weaken the shaft material slowly, especially in vessels that sail in very saline waters or where the temperature fluctuates.

| Failure Type | Cause | Prevention |

|---|---|---|

| Corrosion | Long-term seawater exposure with minimal protection | Anti-corrosion measures and coatings |

| Fatigue Failure | Repeated stress cycles from fluctuating loads | Proper design tolerances and regular maintenance |

| Misalignment | Installation inaccuracies or hull deformation | Precise installation and alignment checks |

| Lubrication Failure | Insufficient or contaminated lubricants | Regular checks and lubrication schedules |

Another big problem is fatigue failure due to repeated stress cycles caused by fluctuating loads imposed during operations. Over time, these cyclical forces generate microscopic cracks in the shaft, which continue to propagate and can cause catastrophic failure if neglected. Factors that contribute to these include inappropriate design tolerances, lack of maintenance, and undue operational conditions.

From the general perspective of shaft parties, misalignment is another major contributor to wear and tear. The reasons may appear as installation inaccuracies or deformation of the hull structure. In a misaligned shaft, an uneven distribution of load is imposed, causing excessive stress on bearings and shaft parts.

And the last one: lubrication failure. Lubricants that are either insufficient or contaminated create extra friction and heat, which lead to accelerated wear of the bearing surfaces and other components. Regular checks and maintaining lubrication schedules will keep this situation under control.

By understanding and preventing these modes of failure, operators can drastically boost the operational life of propeller shafts and guarantee better reliability for the vessel.

Environmental Factors Affecting Shaft Longevity

Conditions in the environment certainly affect the life of propeller shafts. One major cause is known as saline water exposure, which acts as an accelerator for corrosion on metallic parts. A very high concentration of salt in water, especially in marine environments, can create pitting corrosion, which damages the shafts structurally over time. Standard preventative measures include regular application of protective coatings and corrosion inhibitors.

🌊 Environmental Factors to Consider

- Saline Water: Creates pitting corrosion on metallic components

- Temperature Variation: Thermal expansion/contraction causing material fatigue

- UV Radiation: Degrades non-metallic components like seals

- Underwater Debris: Abrasive particles causing mechanical wear

- Industrial Pollution: Intensifies shaft damage in sediment-rich areas

The effects of temperature variation on shaft longevity can also be observed. Extreme heat or cold causes thermal expansion or contraction, leading to material fatigue or cracking with repeated cycles of stress. In addition, extended exposure to sunlight or UV radiation in tropical circumstances may degrade non-metallic components, like seals or coatings, more frequently requiring maintenance.

Another important environmental factor to consider is worn underwater debris or abrasive particles that can induce mechanical wear and surface erosion. Shaft damage may be intensified by particle impingement in vessels operating in regions of increased sediments and industrial pollution. Hence, installing high-grade filtration systems and maintaining a strict maintenance schedule will be an effective remedial measure in this regard.

By addressing these environmental factors, ship operators can implement maintenance methods that protect the shafts from deterioration and enhance their life expectancy, even under strenuous operational conditions.

Cost vs. Quality: Making the Right Choices

💰 Balancing Investment and Returns

The decision-makers ought to weigh the immediate cost against its long-term returns while balancing cost and quality. Investment in component materials of the highest quality, especially those installed in ships exposed to harsh conditions, significantly reduces maintenance and, consequently, downtime. Shaft materials of premium grade may cost more initially, but they are resistant to wear and corrosion to such an extent that replacements are rarely necessary during an operational lifetime.

Afterward, advanced technologies, such as predictive maintenance systems, can improve operational efficiencies while extending asset life. These may incur a higher capital outlay at first, but they can pinpoint incipient fault conditions, thereby keeping these systems in working order and allowing far fewer costly interventions. Thus, with the quality-based approach, ship operators enhance their performance goals while achieving operationally viable cost savings.

Future Outlook: The Evolution of Propeller Shaft Technology

Imminent Innovations After 2025

Sustainable materials, intelligent systems, and data-driven performance optimization will undoubtedly influence the evolution of propeller shaft technology after 2025. A crucial trend includes the application of green composites with an emphasis on durability yet environmentally less discouraging. These materials are designed to minimize marine pollution and meet stringent international regulations that govern emissions and sustainability.

🌱 Green Composites

Application of sustainable materials designed to minimize marine pollution and meet international regulations.

🤖 Self-Monitoring Shafts

Sensors and AI capabilities providing real-time analytics and predictive maintenance algorithms.

⚡ Electrification

Redesigned shafts for hybrid and pure electric propulsion with optimized torque profiles.

The other big innovations would be the development of self-monitoring shafts with sensors and AI capabilities. Those intelligent systems would offer real-time performance analytics, detecting vibrations, misalignments, or wear that might turn into a critical failure before occurrence. Using predictive maintenance algorithms enables increased operational reliability and downtime prevention.

In addition, the move toward electrification will likely affect propeller shaft innovations. The increasing number of vessels using hybrid and pure electric propulsion will necessitate a shaft redesign to accommodate new torque profiles and energy transfer possibilities. Consequently, these shafts would need to be well-hydrodynamically optimized from the start to achieve better fuel efficiency and reduced energy consumption.

Collaborative efforts among these manufacturers, shipbuilders, and regulatory entities would become the true engine driving these innovations. By nurturing technological advancements in line with global sustainability and performance agreements, tomorrow’s propeller shaft research will not only be more functional but also gentler on the environment, meeting the demands of future maritime operations.

The Nature of Regulatory Changes that Impact Shaft Design

Regulatory changes in marine propeller shaft design appear to be increasingly influenced by a global focus on enhancing energy efficiency and reducing the environmental impact of maritime operations with ocean-going ships. One of the foremost changes is brought into force by the International Maritime Organization (IMO), especially under the Energy Efficiency Existing Ship Index (EEXI) and Carbon Intensity Indicator (CII) regimes. These rules aim to establish stricter energy-efficiency measures and establish a system to account for vessels’ emission performance. For propeller shafts, this means that the manufacturers, the shipbuilders, and the operators now have to design them to enhance the vessel’s energy efficiency by minimizing loss within the propeller system. Recent markets for the optimized propulsion systems are also in agreement with the regulatory requirements and consequently drive the demand for propeller shaft designs that utilize new materials and technologies.

📋 Key Regulatory Frameworks

- IMO EEXI: Energy Efficiency Existing Ship Index for stricter efficiency measures

- CII: Carbon Intensity Indicator for emission performance accounting

- Paris Agreement: Regional regulations for greenhouse gas reduction

- EALs: Environmentally Acceptable Lubricants to prevent ocean pollution

- Lifecycle Design: Full environmental impact consideration from production to disposal

Moreover, many regional and national regulatory bodies are adopting legislation to align with larger goals like the Paris Agreement to combat climate change. Such measures commonly emphasize reducing greenhouse gases (GHGs), and restrictions on shaft lubricants may be enacted to promote the usage of environmentally acceptable lubricants (EALs) to avert ocean pollution. Another important recent aspect is lifecycle design, where manufacturers are urged to consider the full environmental impact of the materials and processes used in producing shafts, from procurement to end-of-life disposal.

In general, emerging regulations drive innovation in the maritime industries, prompting a reevaluation of conventional design standards and the consideration of future, sustainable practices in the design and engineering of propeller shafts. If they stay abreast of developments and take the initiative, those involved can adapt to the changes and gain a winning advantage toward a greener and more efficient maritime scenario.

Integration with Renewable Energy Solutions

I envisage limitless opportunities in integrating renewable forms of energy into marine operations, with the potential for further innovations and technological efficiency gains. Propeller shaft systems, for example, synergise with renewable energy applications like wind-assisted propulsion and solar-powered auxiliary systems. By means of these technologies, vessels can drastically reduce greenhouse gas emissions and cut their fuel dependency, thereby making them more sustainable overall. Hybrid systems that use traditional propulsion alongside renewable energy sources, such as battery-assisted power storage, provide marine design flexibility and green solutions.

♻️ Renewable Energy Integration Opportunities

For integration to be effectively done, it starts with knowing how and when renewable energy technology fits into the operational profile of a ship. Rotor sails or kites harnessing wind power appear ideal for long-haul shipping routes, along which consistently good wind flows. Solar panels, conversely, would be suitable for auxiliary energy requirements during operations that last all day. When these technologies are combined with energy-efficient propeller shaft designs, they result in the optimal transfer of energy with minimal loss. Thus, this synergy greatly accentuates the advantages offered by the application of renewable energy.

Collaboration amongst various stakeholders is, in my opinion, key to the advancement of this integration. Manufacturers, engineers, and regulatory agencies must collaborate to set standardized criteria for ensuring that renewable technologies seamlessly integrate with traditional maritime systems. Therefore, by committing to research, development, and testing, the industry can work to harness opportunities in renewable energy solutions to further the transition toward clean and sustainable maritime industries.

Reference Sources

Durability, performance define new generation of propellers – AOPA

Marine Propeller Shaft Analysis 2025 and Forecasts 2033 – Archive Market Research

Automotive Propeller Shaft Strategic Roadmap – Archive Market Research

Boat Propeller Shafts Market Report | Global Forecast From 2025 – DataIntelo

Global Marine Propeller Shaft Market Size and Outlook 2025-31 – Infinity Market Research

Frequently Asked Questions (FAQs)

❓ What is a prop shaft, and how does it function?

The propeller shaft is a vital part of any machinery or vehicle as it transmits power generated by the engine to the propeller. It should be able to bear all the torque generated by the engine to maintain thrust. The propeller shaft varies in diameter depending on the application, and various types may be equipped with universal joints for flexibility of movement. In a marine environment, the propeller shaft connects the main engine to the propeller, transferring mechanical power in a thrusting manner. Proper lubrication and maintenance of shaft bearings extend to long-lasting performance.

❓ How does the drive shaft differ from a propeller shaft?

Drive shafts are generally considered the assemblies that transmit engine power through the drivetrain to the wheels, while a propeller shaft is restricted to connecting an engine to a propeller in marine applications. Both shafts serve similar purposes in transmitting power, but their design can vary widely depending on the machine’s requirements. Drive shafts are mainly used in rear-wheel and all-wheel-drive vehicles, where they link the transmission to the rear differential. Knowing the difference between the two can help decide which shaft is appropriate for the given application.

❓ What are often common materials used in manufacturing prop shafts?

Several materials go into making a prop shaft; stainless steel, aluminum, and Aqualoy all have their unique advantages. Stainless steel is widely used in marine operations because of its strength and corrosion resistance. Aqualoy, a steel-type material, is designed for aquatic environments to resist corrosion and maintain stability. The material choice might affect the shaft size, weight, and performance in power transmission. Another matter worth emphasizing is that precision-machined components are essential to achieve the tolerances needed for proper operation.

❓ What are the signs that a propeller shaft is failing?

What are the signs that suggest a propeller shaft might be on its last legs? Clunking noises, vibrations, and being stuck in propulsion!- If you hear a clunking noise during acceleration or deceleration, then your u-joints or bearings are possibly worn out. These will stop the power transmission from the engine to the propeller, affecting its performance. Regular inspection of the shaft and its components, such as the coupling and bearings, may assist in spotting potential faults before they fully develop into total failures. When vibrations become quite a nuisance, then it is time to look for an alignment fault or damage on the shaft.

❓ Does the size of the prop shaft really matter in performance?

The diameter and overall length of the prop shaft determine its performance capabilities. A shaft of larger diameter is required to transmit more torque in high-horsepower applications. But in the process of increasing the shaft size, the weight also increases, which may affect agility in both the vehicle and the vessel. On the other hand, a prop shaft with a smaller diameter reduces weight but restricts the amount of power that it can effectively transmit. Hence, the boat builders and engineers consider shaft size with respect to the desired performance and application requirements.

❓ What function do universal joints serve in a propeller shaft?

These are elements called universal joints or u-joints; they must be there so that some flexibility and movement between shafts actually exist in the propeller shaft. The power from the engine to the propeller is transmitted through these joints, while the angle and alignment slightly change due to drivetrain movement. This flexibility ensures smooth operation and reduces wear on other components like the gearbox and rear differential. U-joints should be well lubricated to ensure longevity and efficient operation. Everyday observations like clunking noises can be avoided through frequent checkups, which also maintain the power transfer at optimum levels.