Choosing the right aircraft is a crucial decision for both aviation professionals and enthusiasts. Technology established demands for efficient fuel consumption and proven performance, and the old debate shifted to shift drives versus turboprops. This article will examine the nuances of both power plants, including their efficiency, operating costs, and capabilities in today’s aviation sector. Whether you’re an operations manager, pilot, or a passionate aviation enthusiast, this article will help you understand the fundamental differences and decide which is better suited to the needs of modern-day aviation. This will enable you to compare the performances and practicality of these aircraft in 2025.

Understanding Aircraft Engines

Overview of Types of Aircraft Engines

There are basically four sorts of aircraft engines: piston, turboprop, turbojet, and turbofan. All of these clearly vary in characteristics, performance, and operation, and therefore suit the various features of the aviation performance spectrum.

Piston Engines

Generally found on smaller aircraft in general aviation. They operate much like car engines with a set of cylinders in which fuel is combusted. Such engines are pretty simple, inexpensive, and easy to maintain, making them ideal for short-range flights at lower altitudes.

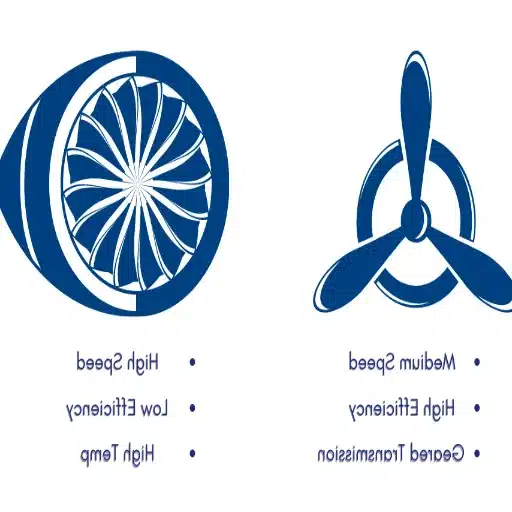

Turboprop Engines

A cross between a propeller and a turbine engine. These engines are preferred for regional and commuter aircraft due to the tremendous fuel efficiency they offer for short to medium distances. Turboprops, generally, perform efficiently at speeds of less than 500 mph at an altitude of below 25,000 feet.

Turbojet Engines

Designed for high-speed performance and are commonly found in older or military aircraft. The jets run on a relatively simple propulsion mechanism; they provide powerful thrust, sometimes at the cost of greater fuel consumption than the more modern engines.

Turbofan Engines

Dominate the current commercial aviation environment. Equipped with typical fan-and-jet propulsion, turbofans offer a balance of powerful thrust and fuel efficiency, making them the preferred choice of engines for long-haul flights. Being able to do so quietly and working well under a variety of conditions indeed guarantees the preference of turbofans for almost all modern airliner types.

Understanding the role and capabilities of each engine type allows for more informed decisions regarding balancing efficiencies, cost-effectiveness, and mission requirements.

Key Differences: Piston Engines vs. Turboprop Engines

On the other hand, two completely different philosophies come into play for piston and turboprop engines, in terms of design, operation, and application, which cater to differing aviation demands. Piston engines are those typically found in smaller general aviation aircraft. They work through an internal combustion process using reciprocating motion, which rotates the propeller. Known for their simplicity, they are also lightweight and inexpensive. Hence, they have a strong appeal for short-haul flights and training. But ensure that it is highly efficient at higher altitudes and speeds.

Turboprop engines, in contrast, integrate a gas turbine engine with a propeller, giving the engine higher performance capabilities. Compared to piston engines, these engines are better at medium-range flights, have superior fuel consumption, and have power at higher altitudes. For short-runway airports and small cargo aircraft, especially under different conditions, turboprops are preferred. They are advantageous for medium speeds and over longer ranges.

Ultimately, the choice between two engine types would depend on good considerations like the distance of flight, operational cost, efficiency at given levels, and other such factors with which the aircraft is being put to service. Recognizing these significant differences will enable operators to select the type of engine that best aligns with their specific mission requirements.

The Role of Jet Engines in Modern Aviation

A jet engine has revolutionized modern aviation since it enables travel to become faster, more efficient, and further away. The engines pressurize the ambient air, mix it with fuel, ignite the mixture to produce a high-velocity exhaust stream, and get thrust in return. Over the years, the advancement of jet engines has significantly improved fuel efficiency, reduced emissions, and enhanced overall performance.

Today, turbofan engines are engineered to strike a balance between speed and fuel efficiency, making them an optimal choice for commercial airliners. Lightweight materials and design changes, such as the incorporation of high bypass ratios, are said to contribute to these improvements while also reducing environmental impact. Parallel research into alternative fuels and hybrid-electric propulsion systems aims to transform the industry, tackling relevant sustainability challenges without compromising reliability. It is this evolution that keeps jet engines at the forefront of aviation progress.

Performance Comparison: Turboprop vs Jet

Efficiency Parameters of Turboprop Aircraft

Applications of turboprops on short- and medium-haul routes have been rightly termed fuel-efficient choices. These aircraft operate at slower speeds and altitudes because the turboprop engines do not consume as much fuel as a jet engine. For example, on comparable routes, turboprops will consume 25-40% less fuel, making them ideally suited for regional travel. The reason for such efficiency is that turboprops can convert engine power to thrust more efficiently at lower speeds and are relatively lighter-weight aircraft.

They provide excellent takeoff and landing performances, especially on shorter runways. Due to their relatively slow approach speeds, brakes and tires experience less wear and tear, thereby reducing operational costs. Modern turboprop aircraft utilize advanced materials and aerodynamics to achieve increased efficiency and reduced environmental impact. All of these aspects combined make a strong case in favor of turboprop aircraft, balancing cost-effectiveness with performance reliability.

Speed and Range: Turboprops vs Jets

| Parameter | Turboprops | Jets |

|---|---|---|

| Cruising Speed | 300-400 mph | 500+ mph |

| Range | ~1,500 miles | 3,000-8,000 miles |

| Best Use | Regional operations, short routes | Long-haul, intercontinental |

| Fuel Efficiency | Superior on short routes | Efficient on long routes |

Once were to compare turboprops with jets, huge differences become apparent when focusing on speed and range-the very things that affect the suitability for a type of operation. They fly at an average cruising speed of 300 -400 mph, whereas turboprops operate at slower speeds; hence, they are suited for shorter regional operations or flights to airfields with marginal infrastructure. Their ranges are further limited to approximately 1500 miles with relative efficiency.

The jet is a synonym for speed and long-distance travel. With cruising speeds usually above 500 mph, jets easily cover intercontinental distances, having a range falling anywhere between 3,000 and 8,000 miles depending on the model and configuration. Jets, thus, are an excellent choice for business or airline work where time and range are critical.

On the other hand, turboprops have proven to be more fuel-efficient on short-haul routes, thus being a more cost-effective and environmentally friendly option. Operators wanting to balance speed, range, and cost of operations need to contemplate all these factors for choosing the right aircraft for their specific mission profile.

Cost Analysis: Operating Turboprop vs Jet Engines

When studying the operational costs of turboprop and jet engines, several factors come into consideration, like fuel consumption, maintenance, and overall operating efficiency. As a general rule of thumb, turboprop engines convert fuel most efficiently on short-haul routes in that they consume less fuel per mile than do jet engines. With environmental issues now becoming paramount concerns, fuel-friendly processes are a bonus.

Maintenance costs also vary. Turboprops are typically designed with fairly simple mechanical concepts, so they usually cost less to maintain over a more extended period. On the jet side, fast speeds enable operators to complete long routes more quickly, which can result in higher revenue potential, even with marginally higher maintenance and fuel consumption costs.

Without a doubt, this capacity for operational flexibility is another consideration. Turboprops excel at relatively low altitudes and short runways, making them an excellent choice for regional and remote operations. Jets, on the other hand, are designed to be fast and to cover longer distances, and such features may justify their higher operational costs on intercontinental routes.

All in all, choosing between turboprops and jets involves weighing the above cost considerations in line with the particular mission at hand, i.e., the required range, speed, and passenger load. Familiarity with such trade-offs would enable an operator to provide the most effective and least costly fleet performance.

2025 Trends in Aviation Engines

Emerging Technologies in Turboprop Designs

- Composite Materials: Recent advancements in turboprop engine technologies are driving improvements in efficiency, performance, and sustainability. Today’s turboprops increasingly utilize composite lightweight materials to reduce engine weight and improve fuel economy.

- Advanced Propeller Design: Greater effort in making propellers through advanced aerodynamic designs, such as scimitar blades, developed to maximize thrust while reducing noise and vibration.

- Hybrid-Electric Systems: Hybrid-electric propulsion systems constitute another area of innovation, where these systems combine electric motors with conventional turboprop engines to achieve improved fuel efficiency and lower emissions.

- Digital Twin Technology: Digital twin technology has found widespread applications in the design and service of turboprop engines. By creating a virtual model of the engine, manufacturers and operators can now predict performance, analyze potential failures, and schedule maintenance more effectively.

These developments are shaping the future, where turboprop-powered aircraft will be more competitive, greener, and cheaper than ever before.

Impact of Sustainability on Engine Choices

Sustainability has emerged as a crucial factor in the selection and development of engines, including turboprop engines. With the worldwide efforts to cut carbon emissions and lessen the environmental impact, green technology adoption is highly being pressured on the industry. The desire for fuel-efficient turboprop engines is increasing, as these engines parallel jet engines in terms of consumption, but less so in terms of CO2 emissions produced. Put simply, their efficiency makes them flagship candidates for regional travel and short-distance routes, where environmental concerns are increasingly considered.

The development of sustainable aviation fuels (SAFs) further refines the green attribute of turboprops. Renewable-derived SAFs, when blended with standard jet fuel, offer the possibility of significant reductions in lifecycle emissions. Newer engine designs, combined with SAF compatibility, take the definition of green aviation even further. The search for lightweight composite materials for the engine components takes it even further in improving efficiency and fuel burn. Such developments demonstrate a shift in the industry toward aligning performance with sustainability, enabling technology available to operators to meet new environmental criteria while remaining reliable and cost-effective.

Future of Turboprop and Jet Engine Efficiency

Development concerning turboprop and jet engine efficiency includes innovations in aerodynamics in materials science, and the integration of alternative energy. One of the key research areas contains advanced materials like ceramic matrix composites that possess lower density and higher heat resistance as compared to metals and allow engines to operate at higher temperatures with greater thermal efficiency. Further design considerations for the fan blades and compressor systems now utilize computational fluid dynamics to reduce drag and maximize airflow, thereby contributing to increased efficiency.

The reduction of emissions and fuel consumption for short-haul flights has sparked interest in the use of hybrid-electric propulsion systems, which combine conventional engines with electric motors. In addition to working to achieve carbon reduction for turboprop and jet engines, the use of sustainable aviation fuels (SAFs) derived from renewable sources, such as plant-based feedstocks or waste, is expected to play a key role. Real-world testing and certification have begun, so large-scale implementation seems somewhat inevitable.

Additionally, innovations in digital technology enable increased efficiency. Real-time engine performance, life, and disruption analysis and prediction based on artificial intelligence and machine learning techniques are kept at an optimal level. From now on, these advances will be leveraged increasingly to assist aviation in complying with new and evolving environmental regulations while maintaining safety and performance. With these technologies on the horizon, turboprop and jet engines are poised for unprecedented efficiency in the years to come.

Case Studies: Turboprops in Action

Turboprop Aircraft That We Can Consider Successful

ATR 72

A turboprop regional aircraft, widely regarded as one of the most prominent for short-haul operations that require efficiency and reliability. An ATR 72 may seat up to 78 passengers and is known for its fuel efficiency and low operational costs. The newer aerodynamics and lightweight materials contribute to low noise and emission levels; thus, regional operators are choosing an eco-friendly option worldwide.

Bombardier Dash-8 (Q400)

Considered more or less a classic in regional aviation, the Bombardier Dash 8-Q400 is known for its speed and performance. Able to carry up to 90 passengers, the Q400 is notable for its high cruise speeds, which are tailored very closely to those of small jet aircraft while preserving the economic advantage of a turboprop engine.

Pilatus PC-12

A single-engine turboprop considered by many to be exceptionally versatile and adaptable to operate in a myriad of commercial, cargo, and medical evacuation flights. It can carry up to nine passengers, with the PC-12 famed for long range, fuel efficiency, and short unpaved runway operations.

De Havilland Canada DHC-6 Twin Otter

Being rugged and sturdy by design, the DHC-6 specializes for operations in very extreme and unconventional environments. Their twin turboprop engines can allow them to take off and land on short airstrips, water, snow, and even ice, thus behaving as the lifeline for services in far-flung regions.

Each of these turboprops serves as a testament to the engineering developments and innovations that continually characterize the regional and customized aviation industry. Their uniqueness serves to answer divergent operational needs while defining the efficiency and performance of modern turboprop technology.

Real-World Applications of Turboprop Engines

Regional Aviation: Turboprop engines are a significant component of modern aviation industries and find applications in various sectors. One major area of regional aviation is travel; regional airports servicing remote regions are connected by turboprop aircraft, such as the Bombardier Dash 8 and the ATR 72. They can operate from shorter runways and consume less fuel than jet engines. Reduced fuel consumption offsets operating costs more on regional routes.

Military and Government Operations: Turboprop engines find almost equal use in military and government operations. Aircraft such as the Lockheed C-130 Hercules are used throughout various tactical airlift operations, including personnel transport, equipment delivery, and airdrop. Moreover, turboprop engines are also widely used for maritime patrol, surveillance, and training purposes, owing to their reliability and operational flexibility.

Humanitarian and Freight Services: Humanitarian and freight deliveries require the use of turboprop aircraft to operate effectively in remote and challenging terrain. With relatively good takeoff and landing performance from unimproved runways, aircraft such as the Pilatus PC-12 provide essential goods, medical assistance, and emergency support services to out-of-the-way communities. With the dawn of cheaper maintenance, turboprop engines stand undaunted as the solution to problems posed by the real world.

Conclusion: Choosing the Right Engine for Your Needs

Performance and Efficiency Evaluation

When evaluating performance and efficiency, I tend to focus on the most critical parameters: speed, fuel consumption, and operational flexibility. Turboprop engines are best suited for shorter routes at lower speeds, exemplifying the concept of regional travel where fuel economy and cost savings are significant factors. As jet engines operate at higher speeds for longer distances, the premiums are primarily for intercontinental routes or situations that require a swift time.

Payload capacity and operational cost are two other factors that tend to influence my decision-making. Such aircraft are generally turboprops, which are cheaper to operate and carry smaller payloads over shorter routes, especially those that require short takeoff and landing instructions. Jets, on the other hand, have a larger payload capacity. In contrast, their efficiency shines in longer, high-demand routes, as they are faster cruising aircraft that compensate for higher fuel consumption.

Ultimately, my decision comes down to mission-related issues. Balancing all the factors ensures that the chosen aircraft engine meets operational requirements and achieves the best balance between cost-effectiveness and performance. Considering these factors enables me to select the best option in terms of the importance of speed, efficiency, and versatility in aviation operations.

Factors Affecting Aircraft Engine Selection

Fuel Efficiency: Fuel efficiency plays a crucial role in determining the cost-effectiveness of aircraft and addressing environmental concerns. Engines are, therefore, built with the latest techniques at their disposal, including a high-bypass ratio design, to consume the least amount of fuel to produce thrust.- 2

Performance Requirements: The mission needs dictate engine selection. The cruise speed, altitude performance, and payload determine whether the mission requires a high-thrust turbofan, a lightweight turboprop, or another type of engine. - 3

Maintenance and Durability: Constraints on reliability and maintenance are crucial for the vessel’s continued operation. These include longer intervals of maintenance, lesser downtime, and proven durability so that operational costs would be kept on the lowest level throughout the working life of the engine. - 4

Weight/Size Constraints: The weight and size of an engine are factors that influence the aircraft design and thus its performance. Smaller, lighter engines may be preferred for small aircraft or in those cases where every pound saved goes toward either efficiency or maneuvering ability. - 5

Environmental Compliance: Stringent international regulations on emissions and noise dictate the engine design and its selection. Growing environmental restrictions insist on engines that emit less carbon dioxide and noise while being sustainable with other additives.

The Future of Aviation: Turboprops VS Jets

In my view, the future of aviation will likely be a nuanced balance between turboprops and jets, rather than an absolute replacement of one over the other. Turboprops are fetching their relevance yet in this industry for short-haul and regional-flight operations. In fact, at lower speeds, turboprops would be more fuel-efficient and thus appropriate for shorter distances or areas lacking proper infrastructure. In other words, these planes appeal to the airlines that wish to remain profitable while considering environmental upkeep, bearing in mind their lower operational costs. I thus foresee some development in turboprop designs toward noise abatement and performance enhancement, making them more suitable for the needs of modern aviation.

Jet aircraft have a significant advantage in terms of speed, range, and passenger capacity, which are vital factors driving their use on long-haul and transcontinental routes. The aerospace industry’s attempt at innovation has seen cleaner, more efficient jet engines take center stage—and the trend is bound to continue. With hybrid-electric and electric propulsion systems, as well as sustainable aviation fuel (SAF), jets could arguably grow to meet stricter environmental regulations without shedding their performance-based benefits. My reasoning for this is that I believe jets will remain in the limelight in the corridors of global air travel, especially amongst major cities.

Sustainability and efficiency, ultimately, will define the future of aviation, with turboprops and jets being integral components of that effort. Ideally, there will be a more blended approach, whereby aircraft for every route fit the requirements economically and environmentally.

Reference Sources

-

2025 FLYING Buyers Guide: Turboprops – Flying Magazine: Discusses the growing popularity and features of turboprop aircraft like the Piper M500 and M600 SLS.

-

Propeller vs Turboprop: Understanding Aircraft Engines – Captain Propeller: Explains the efficiency and performance differences between propeller and turboprop engines, focusing on fuel usage and range.

-

Turboprop Aircraft Propeller System Market Insights 2025 – HDIN Research: Provides insights into turboprop systems, highlighting their fuel efficiency, noise reduction, and performance at lower altitudes.

- Find more info now.

Frequently Asked Questions (FAQs)

What sets a turboprop apart from a jet engine?

A turboprop engine features a turbine engine that drives a propeller to generate thrust, making it suitable for smaller-class aircraft that require thrust during takeoff and landing. On the contrary, jet engines, whether turbojet or turbofan, produce thrust through high-speed exhaust gas flow, which is limited to operating at high speeds and altitudes. Turboprops are more fuel-efficient at low speeds compared to jets, making them more suitable for regional flights. However, jets perform well at cruising speeds, often exceeding supersonic speeds. This decision primarily depends on the type of airplane and the mission it will undertake.

How do turboprop engines work?

Turboprop engines function using a gas turbine engine that takes the air, compresses it, mixes it with jet fuel, and ignites it inside the combustion chamber. The resulting high-pressure exhaust gas drives a turbine, which is connected to the propeller and powers it. This enables turboprops to generate more thrust from the propeller while remaining highly efficient in terms of fuel consumption, especially on short runway operations. The 1940s witnessed the invention of the first turboprop engine, which gave rise to concepts for several other types of aircraft, including military transport aircraft and regional jets. Turboprops are better suited for shorter haul flights, where speed means less than efficiency.

Are turboprop engines more fuel-efficient than piston engines?

For the most part, turboprop engines consume less fuel than piston engines, especially when operating at higher altitudes or over longer distances. When piston-engine aircraft do smaller operations at low speeds, turboprops shine in fuel consumption and efficiency for medium-range and regional operational flights. Turboprops, having considered that they compress and make use of a greater volume of air in their operation as compared to reciprocating engines, have efficiency and performance enhancements. As such, turboprops often become the first choice for many charter companies, as well as light aircraft operations, where operational costs heavily influence decision-making.

What are the primary uses of the turboprop engines in aircraft?

Turboprop engines power regional airliners, military transport aircraft, and light aircraft. The well-known Cessna Caravan and Beechcraft King Air are examples of turboprops valued for their reliability and efficiency. These aircraft can use short runways, which makes them perfect for locations where larger jets cannot go. Hence, turboprop aircraft can carry heavier payloads for their size, enabling them to be used for both cargo and passenger transport in various forms of aviation.

Can these turboprops and jets run on the same runway?

Turboprops and jets can use the same runway, but there are considerations for runway length and performance. Generally, turboprops are types of aircraft that require shorter runways for takeoffs and landings, while larger jets typically need longer distances for takeoff due to their greater takeoff speed. In the event of an engine failure, pilots of both types must follow predetermined procedures to operate the aircraft safely. Airports supporting operations of both turboprops and jets have facilities to handle all kinds of aircraft design, thereby ensuring easy connections between different types of aviation.

What kind of advantages do turboprops provide?

Cost-efficient and fuel-efficient, it flies off shorter runways and operates at lower costs than jets, offering turboprop advantages. With turboprops being of lower speed, these make ideal aircraft for regional and shorter flights, thus reducing fuel consumption. Turboprops also generate lower maintenance costs; however, depending on the operation, they may be more reliable than jets in some cases. Furthermore, larger-diameter blades of turboprop propellers generate higher thrust at low speeds, enabling turboprops to operate effectively in diverse aviation environments. They are turboprop-efficient and multi-purpose, making them the preferred choices in the aviation sector today.