This significantly impacts your boat’s performance, fuel efficiency, and handling. When so many are offered in 2025, it almost makes one feel overwhelmed in trying to find the perfect match. This guide aims to make the process easier by providing expert tips and tricks for selecting a propeller. Whether you are looking for improved acceleration, top-end speed, or durability, this article will guide you through the key considerations, update you on the latest thinking, and direct you to the newest blade developments for Yamaha outboard motors. Stay by us as we take the plunge into propeller selection so that your next prop can bring even more satisfaction to your boating adventures.

Understanding Yamaha Outboard Propellers

What Is an Outboard Propeller?

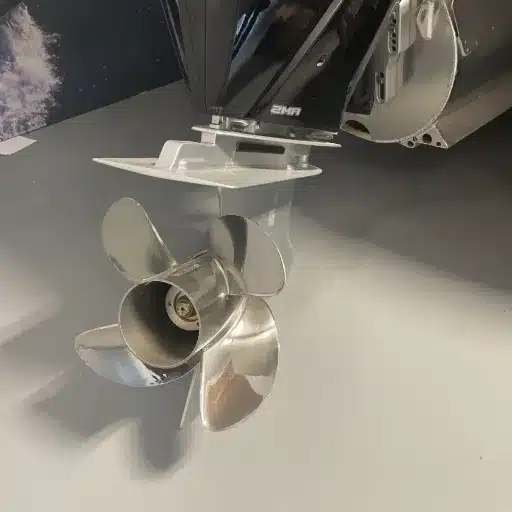

From the power imparted by the engine to its thrust for propelling the boat through water, the outboard propeller stands between these two forces. It comprises mainly blades mounted onto the hub that spins to create enough force for movement. The propeller’s design, size, pitch, and material greatly influence factors such as speed, fuel efficiency, and handling.

Newer models of Yamaha outboard propellers are made from superior materials, such as stainless steel and aluminum, which blend durability with cost considerations. The stainless steel types are stronger and more resistant to damage than the aluminum ones, and hence are favored where performance is of utmost concern. Noise and vibration are kept to a minimum, thanks to innovations such as the Shift Dampener System (SDS) by Yamaha, which improves the overall experience of being on a boat.

Choosing the right propeller for your boat depends on several factors, including the boat type, engine horsepower, the intended application (such as cruising, fishing, or casual watersports), and the average load weight. Proper selection and proper maintenance of an outboard propeller will, in turn, optimize engine performance and promote the smooth gliding of your craft.

Types of Yamaha Boat Props

Yamaha offers a range of propellers for boats, each designed to meet specific performance needs and enhance your overall boating experience. These props are engineered with the best technologies to provide efficiency, durability, and precision for all different types of boats and applications. The more common types are:

| Propeller Series | Key Features | Best Applications |

|---|---|---|

| Saltwater Series II | Stainless-steel corrosion-resistant bodies with more blade surface. Delivers superb thrust and fuel efficiency. | Big offshore boats, high-performance offshore fishing and cruising |

| Reliance Series | Lightweight design offering excellent acceleration and top-end speed with laser-precise handling. | Mid-range outboards, dual consoles, deep-V, and lightweight boats |

| Talon Pontoon Series | Features SDS (Shift Dampener System) technology. Ensures smooth and quiet operation with reduced vibration and noise. | Pontoon boats seeking peaceful and enjoyable boating experiences |

| Performance XT Series | Unique blade design with superior materials for ultimate performance. | Tournament bass fishing, heavy foul-weather recreation |

| VMAX SHO Series | Engineered for high-thrust applications with exceptional hole shots and high-speed performance. | Bass fishing, water sports where maneuverability and acceleration are priorities |

| Dual Thrust Series | Creates maximum forward and reverse thrust. Designed for steady performance in heavy operations. | Sailboats, pontoons, heavy loads requiring reliable maneuvering |

⚓ Technology Advantage: Yamaha propellers have advanced materials, precise engineering, and innovative developments such as the SDS. This guarantees quiet, smooth working performance with an extended life span. Hence, choosing a suitable propeller from the vast array offered by Yamaha contributes to making maneuvers easier, increasing speed, and ensuring fuel conservation; for that, the trip on the water comes with an added flair.

How Propeller Design Affects Performance

This simply means that the design of the propeller is a crucial factor in determining the overall performance, speed, fuel efficiency, and maneuverability of boats. Items such as blade form, diameter, pitch, and material all work together to determine how effectively a propeller can convert engine power into thrust. For example, a bigger diameter propeller suits heavier boats, providing more thrust at lower speeds, whereas a smaller diameter gives lighter boats the ability to move faster. The pitch also affects performance as it is the distance that a propeller moves ahead in one complete revolution. A high pitch means a higher top speed, but it reduces acceleration. Conversely, a low pitch enhances acceleration but limits top speed.

Furthermore, different blade counts and surface areas yield different outputs. Generally, three-blade propellers offer a good compromise between speed and efficiency, while four-blade propellers provide more holding capacity and smoother operation under load. Material choice determines performance and durability; for example, stainless steel propellers will generally be much tougher and can sustain more stress. By learning about these major design factors, the boat owner can select a propeller with the informed guarantee that it will perform optimally according to their requirements and the prevailing conditions of their boating.

Choosing the Right Yamaha Propeller

Factors to Consider: HP and Engine Compatibility

Choosing the right Yamaha propeller should never be done without first considering your boat’s engine horsepower (HP) and ensuring it aligns well with the propeller specifications. The propeller must complement the engine’s power output for smooth acceleration and optimal gas mileage. For example, high-performance engines typically work well with propellers that operate at higher RPMs, allowing for more precise control and speed through this water variation.

Another essential aspect to consider is the gear ratio of the engine, as it can affect the pitch and diameter of the propellers. Propellers with lower pitches are typically recommended for higher horsepower engines to achieve a good hole shot, allowing the boat to get up on plane quickly. On the other hand, lower-horsepower engines would require propellers with a higher pitch to conserve fuel and maintain cruising speed.

Thus, evaluating compatibility also means considering whether your engine setup involves two-stroke or four-stroke engines. In general, four-stroke engines require larger-diameter propellers due to their torque characteristics. If all those factors align, the propeller will be compatible with the engine, improving performance and handling while enhancing the life and strength of both, thereby making the entire boating experience more pleasurable and efficient.

Choosing Between Aluminum and Stainless Steel Propellers

This article describes the key differences between aluminum and stainless steel propellers, including their impact on speed, durability, and cost. Aluminum propellers are excellent for budget-conscious boaters or those working in shallow waters who are concerned about hitting underwater obstacles. These propellers tend to be lightweight and inexpensive and will bend somewhat when impacted, exposing them to greater damage than stainless steel ones, and with fewer performance capabilities or warranties.

In contrast, stainless steel propellers are perceived to be strong, resilient, and top performers in the propeller world. Due to their rigidity, they can be designed with thin blades to minimize drag and enhance efficiency. That, therefore, makes stainless steel propellers very suitable for high-speed applications or scenarios requiring precise handling or heavy loading. Even though they are expensive initially, the durability of their construction, which maintains their shape under heavy stress, can save the owner in the long run by limiting the need for frequent replacements.

Each option suits specific boating needs. For example, aluminum propellers typically work better for boats fishing in shallow water due to their lower cost and potential for local repair, whereas stainless steel is often better suited for performance or offshore boating. Engine horsepower, water conditions, and average speed are just a few of the factors that one should carefully consider when making their choice.

| Comparison Factor | Aluminum Propellers | Stainless Steel Propellers |

|---|---|---|

| Cost | Inexpensive, budget-friendly | Higher initial investment |

| Durability | Will bend when impacted, more prone to damage | Strong, resilient, maintains shape under heavy stress |

| Performance | Lower performance capabilities | Top performers, thin blades minimize drag |

| Weight | Lightweight | Heavier but more efficient |

| Best For | Shallow water fishing, budget-conscious boaters, lower-horsepower engines | High-speed applications, offshore boating, heavy loading, performance needs |

| Long-term Value | May require frequent replacements | Better long-term value due to durability |

Introduction to Translation: Its Effect on Speed and Torque

The pitch of a boat propeller is among the primary factors that affect speed and torque. As stated earlier, pitch is the theoretical distance that a propeller travels forward in one complete revolution. This means pitch affects the interaction of your boat with the water. The lower the pitch, the lower the speed it produces, but more torque is given, suitable for dragging or working in rough water. Conversely, the optimum pitch propeller provides more speed but less torque, making it ideal for boats that run faster in good conditions.

One-inch pitch propellers move a boat forward 19 inches by one complete revolution, effectively. Theoretically speaking, resistance such as slippage in the water may affect this concept. Achieving different grades of performance will require consideration of the engine power of the boat, its load-carrying ability, and typical operating conditions. Marine technological research indicates that matching the right pitch with these variables achieves maximum engine efficiency, lowest fuel consumption, improved propeller performance, and extended life.

Popular Yamaha Outboard Models and Their Recommended Props

Best Props for Yamaha F200 Outboard Motor

Being a versatile motor, it is also highly sought after for various purposes, ranging from fishing boats to pleasure craft. The propeller chosen for the F200, when correctly fitted, will allow it to operate at full capacity and hence yield the best performance from it. Typically, a prop falling in the 14-to-15-inch-pitch range is most suited from a performance viewpoint, because it equally favors speed and thrust. Therefore, considering the unprecedented durability and performance offered by stainless steel props in harsher marine environments, it would be wise to consider stainless steel props, such as the F200 Yamaha Reliance series or Saltwater series II, for this engine.

A higher pitch on a propeller sometimes increases the top speed of a lighter boat and can be significant if cruising economy is a consideration. On heavier boats, however, a slightly lower-pitch prop is suitable for acceleration and ensures smooth operation when under load. Inferior propeller designs, such as those with large blade surface areas, may not perform well in heavy-duty conditions when attempting to improve bite during turns.

One of the best things to do with the Yamaha F200 is to keep a keen eye on RPM at full throttle. Most experts maintain that a wide-open throttle should be employed in the range of 5,000 to 6,000 RPM to prevent shortening the engine’s life or straining it. Additionally, paying proper attention to prop inspection and maintenance ensures reliable and consistent performance in water.

F200 Recommended Specifications

- Optimal Pitch Range: 14-15 inches

- Recommended Series: Reliance Series, Saltwater Series II

- Material: Stainless steel for harsh marine environments

- WOT RPM Range: 5,000 – 6,000 RPM

Yamaha F150 Outboard Motor Top Choices

The Yamaha F150 outboard has been the one most discussed and contemplated each time it is praised for its outstanding balance between power, fuel efficiency, and durability, making it the ultimate choice for both recreational and professional boaters. Choosing the right propeller and accessories must therefore hold the key to drawing peak performance from this versatile engine. Some of the best candidates for F150 given below would, in turn, give their good handling and efficiency under different conditions:

1. Yamaha Reliance Propeller

It features enhanced performance capabilities with great acceleration and top-end speed. Because it is designed for mid-range outboards like the F150, it is the perfect fit for this motor. Constructed from lightweight, polished stainless steel for minimum drag and exceptional fuel economy, this would be an ideal choice in applications where speed and responsive handling are paramount.

2. Yamaha Saltwater Series II Propellers

Just as one who enjoys expeditions in saltwater environments, the Saltwater Series II offers a substantial amount of thrust and endurance. With its large diameter and progressive rake design, this propeller captures the water more effectively and transfers power more efficiently, even when heavily loaded or in rough waters. Being constructed with corrosion-resistant materials, it stands at the top in terms of durability and sustained performance in demanding marine environments.

3. PowerTech SCD4

The PowerTech SCD4 features a four-blade stainless steel propeller, which enhances handling and mid-range performance. It suits boats that require better control and acceleration, such as pontoons or ships operating in shallow water. By design, it reduces vibration, ensuring a smooth ride while also improving fuel economy.

4. Mercury Enertia Eco

Known all over for its revolutionary three-blade combination, the Enertia Eco provides speed, power, and fuel-saving for Yamaha F150. Thanks to the innovative geometry, hydro-drag is minimized and engine efficiency maximized. The advantages of this propeller can be enticing for those who cruise long distances and desire steady performance.

5. Yamaha Talon Pontoon Series SDS

This particular prop is engineered specifically for pontoon boats powered by the F150 outboard motor. The Talon SDS (Shift Dampener System) gives a smooth shifting experience and helps decrease noise for a quieter operation. Its design promotes the heavier loads that are typical of pontoon setups while offering good fuel economy and dependable performance at wide speeds.

The selection of the ideal propeller for the Yamaha F150 should consider the type of boat, typical load, and conditions. For instance, three-blade propellers generally provide higher top speeds and acceleration, whereas the four-blade version offers more stability and smooth handling under challenging conditions. Another factor is to regularly check the F150’s wide-open throttle (WOT) range, which should be between 5,000 and 6,000 RPM, for the engine’s survival and efficient time on the water.

Recommended 3 Blade and 4 Blade Options

When choosing the best propeller for your F-150, both 3-blade and 4-blade propellers offer benefits, and the selection should be made according to the boat’s specific needs. The high-speed performance, in terms of better fuel efficiency, is typically considered for propellers with three blades, particularly for lighter boats. Three blades reduce drag, thereby allowing for a higher top-end speed and quicker acceleration. The Yamaha Reliance SDS Series is a well-known option in this field, offering high strength, smooth shifting, and exemplary performance in various conditions. Another popular propeller is the Solas Rubex L3, featuring a high rake for a thin blade effect that maximizes efficiency and lift.

On the other hand, 4-blade propellers deliver exceptional performance for specific towage and water sport-related activities in choppy water or in rough conditions, offering higher-end control. These propellers produce higher thrust at low speeds and enhance stability, making them suitable for heavier boats or any activity requiring increased torque. One of the best recommendations is the PowerTech OFS4, which offers the best value in terms of performance, smooth handling, and low vibration. The Mercury Spitfire X7 also received commendations for being made of high-strength stainless steel and for maintaining excellent mid-range speed and fuel economy.

Somewhere between your boating priorities, usage patterns, and the desired style of performance will lie the choice between a 3-blade and a 4-blade prop. Regularly assessing your boat’s conditions, such as load, water environment, and engine specifications, will provide you with adequate insight into which propeller is best suited to optimize your F150’s performance and overall boating experience.

| Feature | 3-Blade Propellers | 4-Blade Propellers |

|---|---|---|

| Speed Performance | Higher top-end speed and quicker acceleration | Moderate speed with enhanced control |

| Fuel Efficiency | Better fuel efficiency | Good fuel economy |

| Drag | Reduced drag | Slightly higher drag |

| Thrust at Low Speeds | Standard thrust | Higher thrust at low speeds |

| Stability | Good stability | Enhanced stability |

| Best For | Lighter boats, high-speed applications | Heavier boats, water sports, choppy water, increased torque needs |

| Popular Options | Yamaha Reliance SDS Series, Solas Rubex L3 | PowerTech OFS4, Mercury Spitfire X7 |

Trends in Propeller Technology for 2025

Innovations in Propeller Materials

Modern times have witnessed a significant evolution in propeller materials, with a focus on enhancing efficiency, durability, and sustainability in marine technology. These modern propellers increasingly incorporate composite materials, which offer a lighter option than traditional metal materials, such as aluminum and stainless steel. Such composites indisputably reduce weight and enhance fuel efficiency, along with reducing the load on the engine. In the other direction, hybrid materials are said to be experiencing a resurgence, with metals being reinforced by state-of-the-art coating systems that ensure performance for extended periods, even under the most severe marine conditions.

The marine industry is further exploring 3D printing of propellers using reinforced polymers and metal powders. The new technology enables customized designs tailored to each special performance need, helping to minimize waste during manufacturing. Against this background, self-healing coatings have been developed through advances in nanotechnology. Such coatings help protect propellers from minor damage and corrosion, thereby prolonging their lifespan. These new-age material technologies will help future propellers offer more efficiency and adaptability in performance, all while remaining gentle on the environment.

Smart Propellers: The Future of Outboard Performance

The ability of smart propellers to adjust performance in response to changing real-time conditions has disrupted the maritime industry. Equipped with sensors and software that gather data on water currents, engine output, and vessel speed, these propellers make instantaneous adjustments. Any adjustments made are aimed at reducing drag and enhancing thrust to maximize efficiency, resulting in fuel savings and a lower carbon footprint.

Due to the innovative propeller systems installed in modern outboard motors, it is possible to adjust the blades at a suitable angle to suit the prevailing conditions, thereby achieving superior performance in both calm and turbulent waters. Additionally, these usually come integrated with connectivity features that furnish operator performance analysis data for better decision-making and maintenance. With ongoing developments, smart propellers will deliver higher levels of operational efficiency, thus cradling the growing sustainability concerns of the marine industry.

Case Studies for Successful Applications of Emerging Technologies

Autonomous Shipping Solutions in Practice

A major instance of innovative technology application is the integration of autonomous systems into commercial shipping. Mid-sized logistics companies have implemented fully automated navigation systems, whereby vessels navigate to their destinations with minimal interference. This technology uses AI algorithms that factor in real-time data from sensors, weather, and route-optimization modules. Within the first year of deployment, the company reported a 20% decrease in fuel consumption, accompanied by a 15% increase in delivery efficiency, attributed to optimized routes and steady vessel speeds. Additionally, safety incidents were also slashed by 30%, thanks to improved collision detection systems. These results suggest that autonomous technology leads to a significant increase in efficiency and safety.

Smart Propellers for Sustainability

One of the global shipping companies has embraced innovative propeller systems across its cargo vessels in a bid towards sustainability. These systems adjust the pitch dynamically in response to real-time indicators of water resistance and speed. During a six-month benchmark study period, the company observed an 18% reduction in fuel consumption compared to conventional propulsion technology. This also had a positive environmental impact, resulting in significantly reduced greenhouse gas emissions. Eventually, this saved the company on the operational side to the tune of $5 million every year. Further integration of performance analytics enabled the maintenance team to identify inefficient operations and take necessary steps to prevent breakdowns, thereby saving on heavy repair costs and extending the life of key components. This solidly indicates the market and economic viability of intelligent propulsion systems.

Renewable Energy Integration on Passenger Ferries

Passenger ferry operators are increasingly exploring renewable energy solutions to modernize their existing fleets. A Northern European operator retrofitted its vessels with hybrid systems that combine solar power with battery storage, further supported by energy-efficient hull designs. Post-implementation analysis revealed a 40% decrease in dependency on traditional fuel sources and a 25% reduction in noise levels, thereby significantly enhancing the passenger experience. Most impressively, CO2 emissions were significantly reduced during this transition, with the offset equivalent to the emissions of more than 1,200 cars taken off the road every year. Such a scenario demonstrates how renewable energy can transform logistics and, in turn, yield positive environmental outcomes, generating public goodwill toward its implementation and being well-received by regulatory bodies.

✓ Key Insight: The discussed case studies highlight new technologies that meet the sector’s demands with efficiency, sustainability, and profitability. Adapting to these innovations would empower a company to improve its performance while meeting modern challenges, such as environmental standards and cost-cutting requirements.

Maintenance Tips for Yamaha Outboard Propellers

Routine Checks to Ensure Peak Performance

When it comes to maintaining Yamaha-type outboard propellers, my top priority is always performing routine checks. The first thing I do is assess the condition of the propeller blades. A thorough inspection of the blades for dents, cracks, or even slight bending is necessary, as even the smallest imperfection can affect overall performance, reduce fuel efficiency, and potentially damage the engine. I ensure that the damaged prop is repaired or a new one is installed as soon as possible to avoid long-term complications. Any debris from the fishing line or seaweed wrapped around the propeller must be removed, as it can suddenly cause damage due to wear and tear.

The next step, in my opinion, is to inspect the propeller shaft and other associated equipment. Depending on the season of the year, this shaft and other structural parts of the boat are usually subject to corrosion. So, the shaft is duly greased in the process. Drying or wearing out of the shaft seals needs inspection because, if worn out, they will allow water to enter areas where it will further cause internal damage. Hence, when the seals show signs of deterioration, it is wise to replace them immediately to ensure the smooth operation of the outboard motor.

Finally, I check if the propeller is tightly attached to the shaft. The nut or pin holding the propeller can sometimes loosen over time, causing vibrations or even damage to the drivetrain. By tightening the fasteners and applying a light coating of marine grease to prevent rust, I ensure that everything runs smoothly and efficiently. These checks help improve the performance of my Yamaha outboard motor, prolong its life, and enhance its reliability on the water.

How to Clean and Maintain Your Yamaha Prop

Cleaning is the very first step of Yamaha prop maintenance. It prevents dirt and buildup that could hinder performance. To start, carefully remove the prop, ensuring the engine is off and the ignition key is safely stored. After detaching the propeller, dirt, algae, and marine contaminants are removed using warm water, mild detergent, and a soft-bristled brush. For tough grime and barnacles, marine-safe cleaner is applied to loosen the dirt without harming the propeller material. It is thoroughly rinsed with clean water and then left to dry before proceeding.

Inspection is paramount to ensure the propeller remains in pristine condition. After having the prop cleaned, I inspect it for any damage, including nicks, bends, or cracks, as these affect performance and fuel efficiency. If I find significant damage, I ensure that the propeller gets either replaced or repaired straightaway to prevent further erosion of the motor’s drivetrain. At the same time, I inspect the prop shaft to ensure it is not wrapped in fishing lines or debris. This removal helps prevent permanent damage to the seals and ensures the motor operates smoothly.

Finally, for maintenance, I apply a thin coat of marine grease to the prop shaft, then remount the prop. This avoids rusting and corrosion and, in fact, makes the next disassembly easier. The nut is then firmly tightened, and if necessary, the cotter pin is replaced, ensuring everything remains securely fastened. The regular cleaning, inspection, and greasing of the prop maximise its efficiency and longevity, guaranteeing that the Yamaha motor gives its best every time I go out on the water.

Maintenance Checklist

- Inspect propeller blades for dents, cracks, or bending

- Remove debris (fishing line, seaweed) from propeller

- Check propeller shaft for corrosion

- Inspect and replace worn shaft seals

- Verify propeller is tightly attached to shaft

- Clean propeller with warm water and mild detergent

- Apply marine grease to prop shaft

- Tighten fasteners and replace cotter pin if necessary

Signs of Wear: When to Replace Your Propeller

With years of engine maintenance experience under my belt, I understand the importance of recognizing signs of propeller wear to maintain optimal performance and prevent costly repairs. One glaring sign is actual physical damage, including cracks, chips, and bent blades. Even a slight imperfection would unbalance the propeller, causing vibrations to stress the engine and lessening fuel economy. I generally regard dents or deformations in the propeller as signs of time for replacement after an inspection.

Another key indicator is a drop in performance. If the boat won’t maintain its usual speed, if it takes longer than normal to get up on plane, or if the engine revs much higher than usual without producing proportional thrust, the propeller is probably not working efficiently. Inadequate functioning of the propeller due to blade wear or cavitation burns can compromise the consistency in boat performance, resulting in irregular speeds or unstable boating.

Lastly, any sign of excessive corrosion or pitting would catch my attention, particularly since my boat often operates in saltwater. Corrosion would undermine a propeller’s structural integrity, conceiving reliability issues and putting the propeller at risk of failure. With regular inspections for these problems plus an immediate replacement whenever a worn-out or damaged propeller is found, I keep the Yamaha motors dependable, efficient, and strong on the water.

| Warning Sign | Description | Action Required |

|---|---|---|

| Physical Damage | Cracks, chips, bent blades, dents, or deformations | Replace immediately after inspection |

| Performance Drop | Won’t maintain usual speed, takes longer to get on plane, high RPM without proportional thrust | Inspect for blade wear or cavitation burns; replace if inefficient |

| Excessive Corrosion | Corrosion or pitting undermining structural integrity | Replace to prevent failure, especially in saltwater operations |

| Vibrations | Unbalanced propeller causing engine stress | Inspect blades; replace if damaged |

| Irregular Speeds | Inconsistent boat performance or unstable boating | Check for blade wear; consider replacement |

Reference Sources

- How to Choose the Right Yamaha Outboard Motor Propeller – Yamaha Online Parts

This blog discusses factors like blade count, pitch, diameter, and material for Yamaha outboard propellers. - How to Choose the Right Yamaha Outboard Propeller – VIF Prop

A detailed guide covering material, diameter, pitch, and blade design for Yamaha outboard engines. - How to Choose the Right Yamaha Outboard Propeller – VIF Marine

This guide explains propeller materials, blade count, and diameter for Yamaha outboards. - Best Outboard Propellers – Top Picks for Performance – GetBoat Blog

A step-by-step guide to selecting the best outboard propellers, including performance evaluation tips. - How to Choose the Right Yamaha Outboard Motor Propeller – Yamaha Online Parts

This source highlights the benefits of various propeller types, including four-blade propellers, which are particularly suitable for watersports and heavier boats. - Find more info now.

Frequently Asked Questions (FAQs)

What kinds of propellers do Yamaha outboard engines have?

The types of propellers utilized for Yamaha outboard motors are aluminum and stainless steel. Aluminum propellers weigh very little and are known for their cheap price. They will suffice for a smaller or lower-horsepower Yamaha engine. Stainless steel propellers, being more durable and performing better, are usually fitted on high-horsepower Yamaha outboards. They are often more sophisticated than aluminum ones and can feature designs such as the SDS design, which promotes quiet shifting and fuel efficiency. You can opt for 3-blade designs or choose more advanced blade designs, depending on your specific needs for the boat.

How does one select the prop for a Yamaha outboard motor?

The right Yamaha propeller will depend on several factors, including your outboard motor’s horsepower and the type of boat involved. You should consider your owner’s manual or consult a Yamaha dealer for an exact recommendation. Propellers come in different pitches, with 16-pitch and 17-pitch being just two selections. A stainless steel ocean boat prop might be right for high-performance applications, whereas an aluminum prop will serve casual boating well. One should remember to consider their style of boating: either go fast, save fuel, or bear the load.

How do OEM and aftermarket Yamaha propellers differ?

A Yamaha OEM propeller is designed explicitly by Yamaha for its outboard engines and is therefore guaranteed to fit well and deliver excellent performance. On the other hand, aftermarket options, such as those from Solas or Michigan Wheel, may offer good performance but tend not to provide the exact specifications laid down by Yamaha for Honda outboard propellers. Besides being cheaper options that generally offer fair performance, aftermarket propellers may not be as reliable as genuine Yamaha props. It all depends on weighing the pros and cons of whichever choice suits you best regarding your particular needs and budget.

How does pitch affect the performance of a Yamaha outboard propeller?

Yamaha outboard propellers of different pitch classes vary in how much speed and acceleration you can expect in your boat. A higher pitch, for instance, slightly higher than, say, 17 pitch, will offer greater speeds with lower acceleration, which is not an ideal situation for a heavier load. On the other hand, a 16-pitch prop will give more acceleration but limit maximum speed. A balanced one should be found, depending on how you prefer your vessel, whether you go for speed or power. It is always beneficial to test the boat with a few different pitches to determine which one offers the best performance for your specific work.

Can I opt for a stainless steel prop on the Yamaha outboard boat?

Stainless steel propellers are pretty standard among owners seeking durability or performance advantages for their Yamaha outboard boat. With high-horsepower Yamaha engines, stainless steel props provide a greater thrust level with minimal ventilation. They are best known for high-speed performance or being used under adverse conditions. However, ensure that the stainless steel prop you select matches your Yamaha outboard model. Always check with your dealer or the owner’s manual for recommendations.

What kind of maintenance does a Yamaha outboard prop require?

Increasing the Yamaha outboards’ prop maintenance goes a long way toward achieving higher performance and durability. Propeller nicks and dents should be examined frequently, as these will lower efficiency and performance. After each use, the blades must be thoroughly cleaned, especially after exposure to saltwater, to prevent corrosion and deposits. Verify that the hardware is secure and that the propeller is firmly mounted to the outboard motor. For further maintenance work, check with your Yamaha retailer or perform maintenance per the guidelines detailed in the owner’s manual.