Choosing the right outboard propeller can mean anything to your boating: to achieve greater speed, less fuel consumption, or enhanced performance. Technology rapidly evolves, presenting us with an incredible array of propellers in 2025, differentiated by type, material, and design, each designed for a particular advantage. This guide aims to simplify the decision-making process by briefly explaining the most popular types of outboard propellers and how to make a choice that fits your boat as closely as possible. The factors governing propeller performance will be introduced here, and in the end, you will be able to make choices neatly suited to your own specification so that you will be opened up to your boat’s potential.

Understanding Propeller Basics

What Is A Boat Propeller?

It is a mechanical device made of blades that spin to provide thrust and propel a boat through water. It works by applying fluid mechanics principles to convert the rotational power of the engine into forward or backward motion. Most of the time, the propeller has two or more blades connected to a center piece, which mounts onto the driving shaft of the boat. As the blades spin in water, their curvature creates a pressure difference that pulls the ship forward.

The propeller efficiency depends on several factors, including diameter, pitch, number of blades, and the materials used. For example, a larger diameter would push more water and hence be used on heavier boats, while the pitch would determine how far the boat would travel with one rotation of the propeller. The materials used for propellers, such as aluminum, stainless steel, or composite materials, greatly determine not only the performance but also the life of the propeller. Proper selection of a propeller is crucial because it will lead to the most fuel-efficient, fastest boat, and smoothest running in various conditions.

How the Type of Propeller Can Affect Boat Performance

Boat speed, fuel efficiency, and maneuverability are performance parameters that are influenced by propeller types. For instance, three-bladed propellers are generally capable of higher speeds. They would be favored for lighter, faster boats. In contrast, a four-blade propeller would provide slightly less speed but considerably more thrust and smooth operation —an ideal choice for a heavier boat or one that requires better handling capability in choppy waters.

Considering the effect of pitch is also important. A propeller with low pitch gives better acceleration; hence, it finds great application in towing. That of a higher pitch provides for better speed on the higher end. The diameter of the propeller also accounts for the amount of water displaced. The larger the diameter, the better it does for heavy loads, transferring power efficiently. Rose-styled propellers with cupped blades or adjustable pitch would make a significant difference, as they would enhance performance by effectively fine-tuning a propeller’s ability to handle specific operating conditions.

Modern studies emphasize materials as well. For instance, stainless steel propellers have been praised for their durability and ability to continue performing under high stress. At the same time, those made of aluminum are light and cheap and therefore better suited for a casual boater. Owners can hence maximize performance by carefully selecting the right type and size of propeller according to the boat’s size, weight, and intended use, ensuring the ship remains efficient and smooth in operation across various operating conditions.

The Key Ingredients of Propeller Design

In design, there are several critical elements that affect how a boat performs and how efficiently and maneuverably it will operate. By considering blade materials as a primary factor, stainless steel offers excellent strength and corrosion resistance. In contrast, aluminum lacks the mechanical strength to sustain heavy loads, but it is lightweight and more cost-effective.

Number of Blades

Fewer blades offer higher speed and efficiency but create more vibrations. More blades provide smoother operation and better thrust but may limit top speed.

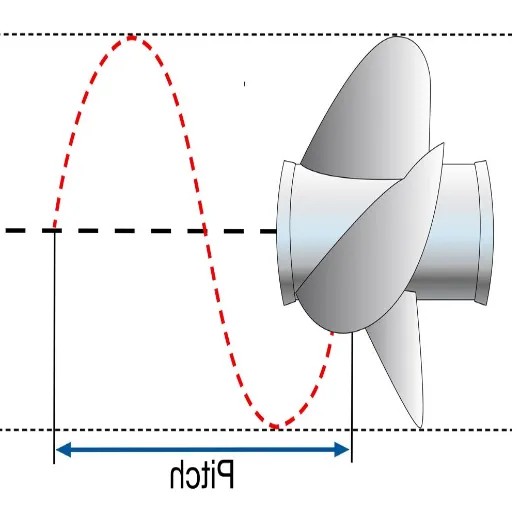

Pitch Angle

The theoretical distance covered in one revolution. Higher pitch = greater velocity; lower pitch = better acceleration and towing power.

Diameter

Higher diameter suits heavy boats with more thrust; narrower diameter generates less thrust for light, high-speed boats.

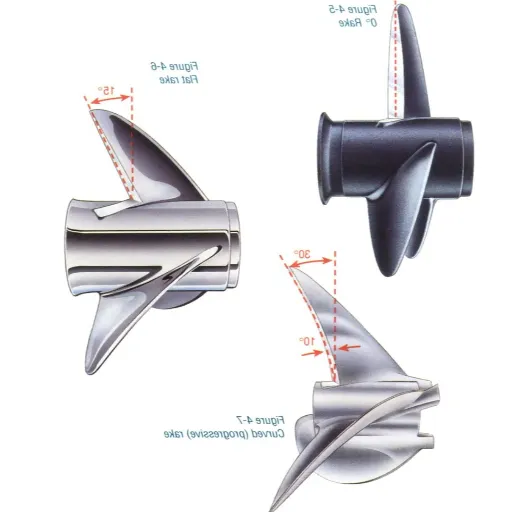

Rake Angle

Affects water flow and vessel handling. Higher rakes perform better in rough waters; lower rakes are intended for smooth waters.

Key Insight: By studying these key parameters and optimizing them further, propeller operators can fine-tune their vessel’s performance to meet their specific maritime needs.

Different Types of Boat Propellers

Aluminum Propellers: Advantages and Disadvantages

Aluminum propellers are one of the most common propeller types out in the boating world, mainly because of their relatively cheap price and versatility. In general, they are lightweight and can be easily repaired at a low cost, which is of interest to recreational boat owners or operators of light-duty craft. These propellers are typically cast, which allows designers to create fairly complex geometries that strike a balance between performance and efficiency.

✓ Pros

- Economical: Aluminum propellers stand far better in the price range against the stainless steel possibilities and hence make an irresistible option for any other budget-conscious boater.

- Ease of Repair: Simple, minor fixes can often resolve damage caused by dings or bends, making replacement of the old propeller unnecessary.

- Very Lightweight: This minimizes the load on the engine, making these props a good fit for lighter boats in moderate-speed applications.

- Availability: Aluminum propellers are among the most commonly used types; hence, they are available in a wide array of sizes and designs.

✗ Cons

- Durability: Being softer than materials such as stainless steel, aluminum propellers are more prone to dents, chipping, or blade deformities in rocky or debris-laden waters.

- Performance under Stress: An aluminum propeller will flex under higher torque and heavy use, compromising its performance and efficiency.

- Lifespan: While aluminum propellers are inexpensive to purchase, in the long run, they may not prove to be more affordable if frequent repairs or replacements are required in areas with heavy use.

💡 Recommendation: Aluminum propellers are ideal for general-purpose boaters seeking cost savings and convenience, but a closer examination of their limitations may help a user determine whether they are a good fit for their specific boating needs. For more heavy-duty performance and longer life, stainless steel alternatives may be worth considering.

Stainless Steel Propellers: Why Choose Them?

The stainless steel propellers are renowned for their durability, strength, and performance, making them a desirable proposition for boaters seeking longevity. Stainless steel is resistant to bending or warping, even when subjected to heavy stress or high speeds during operation. The ability to maintain integrity in shape translates to greater fuel efficiency and handling compared to the aluminum propellers.

Their superior hydrodynamics, combined with the blade geometry featuring thin blades, favor a stainless steel propeller, improving acceleration and enabling it to reach higher top speeds due to reduced drag. Stainless steel propellers do cost more upfront; however, they are economically viable because they wear down less frequently and require replacement less often. Hence, stainless steel propellers are an extremely reliable and functionally superior alternative for those working in harsher conditions or for those who require precision performance.

Specialty Propellers: Surface-Piercing, Folding, and Feathering Models

Specialty propellers are, in effect, performance instruments that address a particular implementation of a general need for performance and give the owner and operator a selection of options for his or her specific vessel and requirements. For example, surface-piercing propellers will be considered in high-speed applications where, at times, a portion of the propeller is above the waterline. That way, the drag is reduced, and the propeller becomes more efficient, making it well-suited for racing boats or vessels that require extreme speed capability.

| Propeller Type | Primary Application | Key Benefits |

|---|---|---|

| Surface-Piercing | High-speed racing boats | Reduced drag, extreme speed capability |

| Folding | Sailboats | Blades fold back to minimize drag when engine is off |

| Feathering | Competitive sailing | Variable blade angle for optimal propulsion and reduced drag |

Folding propellers have blades that fold backward when not in operation to minimize drag. They are used chiefly for sailing, to enhance sailing performance by reducing resistance when the engine is off. Feathering bends the idea further, allowing the blade angle to vary dynamically to provide the least drag when sailing and optimal propulsion when under power. In numerous ways, these two mechanisms are considered a boon for competitive sailing and green-leaning boat owners.

The various new-life technologies for propellers had a profound impact on the upgrading of durability, adjustability, and material composition of these specialty varieties. These are made of strong alloys with utmost precision engineering, so modern-day specialty propellers perform well under high stresses while maintaining long-term reliable operational capability in line with the marine world’s current trends of sustainability and efficiency demands.

Choosing the Right Boat Propeller

Assessing Your Type of Boat

Choosing the proper propeller starts by identifying the type of boat and its intended purpose. For instance, smaller recreational boats may focus more on speed and acceleration, whereas larger boats, such as those used for fishing or cruising, consider power and fuel efficiency more. For sailboats, there must be specially made propellers that produce minimum drag when the sails are set. Some of the key factors include the hull shape, the boat’s weight, and engine specifications, all of which affect the desired propeller performance. Whether it’s a pontoon, bass boat, or offshore powerboat, understanding these parameters will make it easier to select a propeller that complements the boat’s design and enhances its overall efficiency.

Understanding Propeller Pitch and Its Impact

What is Propeller Pitch?

The pitch of the propellers is the theoretical distance a propeller could move ahead in one complete rotation if we were to consider zero slippage through water. From here, this factor is key to measuring the performance of a boat, together with its speed and its fuel efficiency. A lower pitch tries to generate higher thrust; it is ideal for heavier boats that require high pulling power to take water skiers or haul a load. Conversely, a higher-pitch propeller provides good speed but needs more engine power, making it well-suited for much lighter and faster boats.

A good match of propeller shall be a compromise between optimal engine speed (RPM) and efficient operation. Let us suppose that an uncommonly high pitch is selected for the propeller; therefore, the engine would run galaxies away from its recommended operating RPM, hence a reduction of performance and possible straining of the engine. Conversely, with a propeller having too low a pitch, the engine may exert pressures that will cause damage due to excess pressure impingement. Testing, checks, and consulting manuals for your engine do yield an optimal match between the engine and propeller pitch for your boat’s particular needs. Hence, testing and understanding the selection process will serve you well in maximising performance, lessening fuel consumption, and wear.

Number of Blades-Which Works Best for You?

The number of blades on a propeller will be crucial for managing speed against power and efficiency; this is the primary consideration in the construction of your boat. Typically, 3-blade and 4-blade propeller configurations are available, each offering a distinct set of benefits tailored to your specific boating requirements.

3-Blade Propellers

Used primarily on recreational boating due to the higher speeds they offer. Better suited for applications where the focus is maximized on velocity. Lightweight and nimble, making them the favored choice for boats operating in open waters at high speeds.

4-Blade Propellers

Characterized by increased stability, smoother operation, and better fuel efficiency at mid-range speeds. Helpful for heavy towing, such as waterskiers or fishing gear, or in rough waters under low-speed maneuvering where maximum control is needed.

⚖️ The Bottom Line: The number of blades that works best for your propeller is determined by your particular boating activities and expectations for performance. Assessing the weight of your boat and the water conditions it commonly plies, along with the objectives you want to hit, would surely make your choice all the more transparent and possibly maximize your power versus efficiency trade-off.

Propeller Materials and Their Benefits

Aluminum vs. Stainless Steel

Aluminum and stainless steel are two popular materials used for propellers, a term that conveys different connotations depending on the context in which it is used. Aluminum propellers are less expensive and lighter, and so most recreational boaters are interested in these. They are great for moderate-speed applications and work well for most casual boating activities. Aluminum propellers, however, are more prone to damage from impact because of the softer nature of the material. Consequently, in rough waters or environments with debris, they would lead to poor performance.

Stainless steel propellers, conversely, are deemed superior in strength and durability. Hence, they are apt in high-speed or high-performance water applications, being less vulnerable to damage and deformation. Thin blades offered by stainless steel propellers decrease water resistance; hence, they produce better acceleration, fuel economy, and top-end speed. The price is also high, but the longevity and performance justify that initial cost for the serious boating enthusiast or challenger in rough water conditions. Hence, choosing the right material depends on what your boat needs, how often you use it, and budgetary constraints.

| Comparison Factor | Aluminum | Stainless Steel |

|---|---|---|

| Cost | Lower ✓ | Higher ✗ |

| Durability | Lower ✗ | Higher ✓ |

| Weight | Lighter ✓ | Heavier ✗ |

| Performance | Moderate | Superior ✓ |

| Repairability | Easy ✓ | Difficult ✗ |

Innovative Materials in 2025 Propeller Design

🚀 2025 Innovation Spotlight

In 2025, the world is witnessing phenomenal developments in composite propeller materials, characterized by unprecedented strength-to-weight ratios. Advanced composites are commonly made of high-performance fibers such as carbon or glass set in durable resin matrices. Such a combination affords better resistance to corrosion, the very property that enables their primary application in saltwater environments. The other properties of this lightweight material include reduced drag, which leads to improved fuel efficiency and less engine wear. In contrast to aluminum propellers, recent testing has revealed that composite propellers yield about 15% better load distribution and better efficiency. As players in the field continue to innovate, composite designs are increasingly combining performance and sustainable manufacturing to chart a greener route for marine propulsion.

Durability vs. Performance: Making the Right Choice

When selecting a propeller to meet specific operational requirements, a delicate balance must be struck between strength and performance. Composite propellers, being lighter in structure and corrosion-resistant, are preferable to traditional materials in terms of withstanding chemical exposure and saltwater damage. On the other hand, aluminum and stainless steel propellers are better suited to resist high mechanical stress under extreme conditions. They are therefore more suitable for applications where longevity and resistance to mechanical wear are necessary factors. For instance, a composite blade may flex under load to achieve better efficiency, whereas stainless steel blades remain rigid and provide better acceleration and higher speed. Advancements in materials-processing technology, like the inclusion of carbon fiber reinforcements, have increasingly eroded the central distinctions in performance that have traditionally divided propellers. Through an understanding of the application’s specific demands—load, operating conditions, efficiency—users should be able to make an informed choice that effectively tailors marine propulsion systems for their own particular needs.

Trends in Outboard Propeller Technology for 2025

Emerging Trends in Propeller Design

Examining emerging trends in propeller design reveals innovations driven by a focus on greater efficiency, sustainability, and performance. The most notable advancement is an increased use of the 3D printing technique to create propeller forms. This method enables designs that are highly customized for optimal performance and minimal material loss. The 3D-printed prototypes would allow manufacturers to test various designs for propeller blades in a significantly shorter timeframe, often resulting in designs that reduce drag and improve fuel efficiency in both commercial and recreational marine operations.

🖨️ 3D Printing Technology

Enables highly customized designs for optimal performance and minimal material waste. Allows rapid prototyping and testing of various blade designs for improved fuel efficiency.

📊 Smart Monitoring Systems

Incorporates sensors that record performance parameters like torque, vibration, and efficiency in real-time, enabling better maintenance and system optimization.

⚡ Electric & Hybrid Integration

Development of propellers specifically designed for hybrid and electric propulsion systems, focusing on lighter materials and quieter operations.

🔧 Modular Systems

Arrangements allow blades to be easily removed, replaced, or upgraded, reducing downtime and offering maximum flexibility for changing conditions.

Another exciting trend is the incorporation of innovative technologies in propeller systems. For example, some of today’s designs incorporate sensors that record performance parameters, such as torque, vibration, and efficiency, in real-time under various conditions. This information enables users to adjust and maintain their systems more effectively, thereby avoiding undue stress and ensuring the maximum lifespan of the system. Meanwhile, with the parallel development of hybrid and electric propulsion systems, significant changes are wrought in the very design of propellers. Manufacturers are seeking lighter materials that will facilitate quieter operations, aligning with today’s sustainability thrust that is ever focused on reducing environmental impact.

Finally, there is a renewed interest in modular propeller systems. These arrangements allow, for example, blades to be easily taken out, replaced, or improved, thereby reducing downtime and offering the best flexibility. The very idea fits into and promotes lifecycle management and flexibility amid ever-changing regulatory, environmental, and market demands on marine operations. In tandem, these innovations are carving out a new path for propeller technology, promising an environmentally friendly and efficient future for marine propulsion systems.

Data-Driven Insights: What Boaters Are Choosing

By the look of it, unless factors such as fuel efficiency and eco-friendliness are taken into consideration, a boater cannot choose any other option in marine propulsion systems. This demand for sustainable solutions must reflect, on one hand, the change in environmental regulations, and on the other, the growing awareness of boater activities that affect nature. Electric and hybrid drives have been trending, with many operators selecting these options because they generate lower emissions and pay for themselves in cost savings from the first use. A lesser reliance on fossil fuels, combined with their quiet operation, offers prime appeal to boaters conscious of the environment and those operating in areas sensitive to environmental concerns.

Customizable, modular propeller designs indeed form a prominent trend. Customers are demanding systems that are sufficiently versatile to respond to shifting needs and conditions. Variations, for example, in water environments enhance the performance of their boat; over the years, upgrades to specific parts can be attempted. They value being able to increase the efficiency and durability of their equipment via replacement parts or design changes. Another point to note is the increasing use of innovative marine technologies, which feature advanced monitoring systems. Such systems are capable of delivering real-time data to the boaters concerning the propulsion efficiency and fuel consumption as well as maintenance needs, thereby empowering the boaters to take informed decisions while carrying out operations.

Over the years, with increased sustainability based on the natural agility of a very tiny flex hydro or similar technology, designers are now employing flex hydro as a propulsion system and testing it with different modes of efficiency measurement to apply the best design and technology acceptable to them. Environmental-related technologies remain in demand. Combining this new technology with practical methods provides an answer to the demand and shapes a future in which efficient design and responsible care are balanced.

Future-Proofing Your Boat Performance

🔮 Strategy for Long-Term Success

To future-proof a boat’s performance, I focus on technologies and procedures that ensure productivity, adaptability, and sustainability. One of the significant steps is installing advanced propulsion equipment, such as electric or hybrid engines. Such systems have lower emissions, better fuel consumption, and improved maintenance. The latest battery technologies, for example, lithium-ion batteries, offer an advantage in that these vessels can be powered by cleaner energy alternatives, which drastically reduces my carbon footprint while simultaneously improving performance.

Staying abreast of innovative marine technology is equally crucial. Integrating tools such as GPS navigation systems, IoT-enabled monitoring devices, and automation systems enhances boat operations. These provide for real-time tracking of fuel consumption, weather changes, and the vessel’s overall performance, thereby helping me make informed decisions regarding safety and efficiency. On the other hand, as connectivity matures, it offers benefits such as remote diagnostics and software updates to the boat over the air in the latest patch releases.

Lastly, I emphasized installing systems that require minimal maintenance and are made of durable materials. Corrosion-proof components and environmentally friendly coatings maximize the planking’s lifespan, allowing me to avoid constant glazing or repairs while adhering to passing environmental regulations. By integrating maintenance with foresight, I thought I would prepare the investments so that, conversely, my boat stands confidently ahead of tomorrow’s demand while contributing to a sustainable marine environment.

Reference Sources

-

Understanding the Different Types of Boat Propellers – Explains various propeller types, including three-blade and four-blade options.

-

How to Choose Outboard Propellers – Offers tips on selecting the best propeller based on material and performance.

-

How to Choose the Right Mercury Outboard Propeller – A 2025 guide focusing on Mercury outboard propellers and their features.

-

An Introductory Guide to the Different Types of Boat Propellers – Covers materials like stainless steel and aluminum, along with engine compatibility.

-

How to Choose the Right Yamaha Outboard Propeller – Breaks down propeller materials, blade count, and other key factors for Yamaha outboards.

- Click here to read more.

Frequently Asked Questions (FAQs)

What are the different types of boat propellers?

Various types of propellers include specific performance characteristics. The most common types are three- and four-blade propellers. Three blades are set between the choice of boaters who generally like acceleration and top speed; four blades offer more plane stability and good handling. Surface-piercing types of propellers can be used on high-performance boats to get the best speed out of them. Depending on your boat’s engine and intended use, picking the correct propeller is always a significant feat.

How do I choose the right prop for my boat?

Choosing the right propeller for your boat is a process that involves several key considerations, including the type of engine installed and the performance objectives you envision. You need to know whether the ship requires aluminum or stainless steel props since these metals differ in durability and performance benefits. The pitch of the propeller makes a remarkable difference in fuel economy and acceleration. Consider also the number of blades; for example, a three-blade propeller may increase top speed, while a four-blade propeller may increase fuel economy and stability.

What are some of the materials outboard propellers are made from?

Most outboard propellers are usually made of aluminum or stainless steel. Aluminum is the most common material due to its affordability and lightweight nature; these traits render it suitable for smaller boats. Stainless steel-driven propellers, however, are much more resistant to wear and corrosion, making them perfect for use in high-performance boats or boats operating in adverse marine conditions. When choosing the material for your propeller, it will also determine how well your boat performs and how long it lasts. Therefore, making the right material choice should be based on how you intend to use the boat.

How does propeller pitch affect boat performance?

Folding pitch refers to the distance the propeller travels with one complete revolution. It is a significant factor in influencing a boat’s performance. The highest pitch could indicate top speeds; the lowest is typically associated with acceleration and lower RPM. The lowest pitch provides the best acceleration and handling, making it suitable for use in small boats or for towing. When choosing the appropriate propeller, it is common to compromise on pitch to achieve the best performance expected from the propeller.

What are folding and feathering propellers?

Folding and feathering propellers are specialized types designed for specific boating applications. Folding propellers would retract when not in use, thereby preventing drag and improving fuel economy, making them a suitable choice for sailboats. Feathering propellers, however, change their blade angle during sailing to provide better performance and efficiency in the water. Both can significantly enhance the performance of a boat. Most importantly, this relates to fuel economy and acceleration.

What would be the outcome of a change in blade number on propulsive performance?

A propeller’s performance characteristics can be greatly affected by the number of blades it has. Typically, three-blade propellers are selected for speed and efficiency, while four-blade propellers are chosen for stability and load-carrying capabilities. More blades mean more blade area to provide thrust at lower speeds; large boats benefit from this. Conversely, drag increases with the number of blades; therefore, it is advisable to strike a balance according to your requirements.