Thus, outboard aluminum propellers constitute an extremely important factor influencing the performance and efficiency of marine engines. As new developments continue to emerge in propeller technology, making the wrong choice could mean your engine is not properly delivering power, but instead, wasting it. This blog post provides a technical elaboration on the design of the Vortex propellers, explaining why they have become an absolute game-changer in 2025 for boaters seeking engine efficiency, along with stupendous performance. Whether you are changing from the current setup or exploring options for maximizing fuel economy and speed, this in-depth study will provide you with the insight to understand the latest innovations in the future of marine propulsion.

Introduction to Vortex Propellers

What is a Vortex Propeller?

Reputed for its superlative efficiency in reducing fuel consumption and enhancing operational performance, Vortex Propellers ensure day-to-day reliability. Advanced hydrodynamic engineering is used for the purpose of reducing drag and increasing thrust; boaters find smoother rides and better control. Through this uniquely crafted blade geometry and materials, Vortex Propellers aim to overcome cavitation, a common issue in traditional designs that contributes to inefficiency and potential damage.

Core Features of Vortex Propellers:

- Precision-molded blade dimensions for consistent performance

- Corrosion-resistant materials for enhanced durability

- Adaptive designs available for a wide range of engines and boat sizes

Recent studies have proven that vessels equipped with these propellers achieve fuel efficiency gains of up to 15 percent, along with notable improvements in speed and maneuverability, making these technology propellers a preferred choice among modern boat enthusiasts and commercial operators. This technology is specifically designed to meet the demands of today’s environmentally friendly marine industry without compromising power and reliability.

History and Development of Vortex Technology

Entering vortex technology is a study rooted in early 20th-century fluid dynamics research. Scientists were initially interested in vortex flows in the name of efficiency, aiming to improve various mechanical systems in these experiments, including aviation and marine propulsion. Hence, throughout the years, CFD and material sciences have carried vortex technology to newer heights.

Present vortex schemes use state-of-the-art simulators to design for performance and drag reduction. For instance, vortex-based propellers of the modern age exploit water flows by requisitely engineered blade geometry to reduce cavitation-induced energy losses. Industry experts consider that these improvements result in a 20% increase in propulsion efficiency, which is crucial in meeting the growing demand for greener solutions.

With leading manufacturing companies ensuring proper development of the subject technology, composite lightweight materials, and strict stress-testing procedures now come into play. Vortex-impinged designs are seen as a combination of power, durability, and ecological care, serving as a transitional design in maritime engineering. It is a testament to the fact that advances are made through a combination of theory and practice in varying degrees, in the face of ever-bolder challenges.

Why Vortex Propellers for Outboard Engines?

One of the most favourite sellers of outboards, vortex propellers have been providing excellent performance and high reliability. Being hydrodynamically advanced, they afford the best possible water flow efficiency, thereby increasing thrust and reducing fuel consumption. These propellers are constructed from either lightweight composites or stainless steel to provide the perfect balance between performance and durability against corrosion and wear in both fresh and saltwater environments.

Another intriguing aspect of vortex propellers is that they tend to soothe the ride by keeping vibration and noise at a minimum, an element that would further aid, unwittingly, both casual and professional users. So many permutations exist that virtually any diameter-engine size-brand combination can be accommodated with a matching vortex propeller. To initiate and perform the hydraulic job of propelling acceleration to the top speed, while maintaining control and responsiveness, the blade geometry may set an ambitious standard for boat owners.

For the enhancement of the environment, recent improvements in vortex propeller technology help. They optimize fuel consumption and reduce stress on engines, which means they lower carbon emissions —a consideration on the mind of any environmentally conscious buyer. With a careful balance struck between performance, sustainability, and durability, vortex propellers have become the favored candidate for any elite and potent long-term solution for their outboard engines.

The Michigan Wheel Vortex Series

Description of the Michigan Wheel Brand

Michigan Wheel has carved a niche for itself as a leading name in the marine propulsion industry, boasting over one hundred years of experience in producing high-performance marine propellers. Michigan Wheel propellers are known for their innovative and precision-engineered designs, serving boats ranging from recreational to commercial fleets. Using high-quality materials such as high-strength aluminum and stainless steel attests to their enduring quality and outstanding reliability, even under the most demanding conditions.

The brand offers a full range of products, including solutions tailored to specific performance requirements, such as speed, fuel efficiency, or overall propulsion efficiency. Famous series like Vortex and Apollo show their prowess in merging technology with an understanding of hydrodynamics. They offer sustainable technology enhancements that improve fuel efficiency and have the least impact on the environment, embracing the green values of today. The company combines traditional values with advanced engineering to establish itself as a trusted name for boaters seeking high-quality propulsion systems.

Features of Michigan Wheel Vortex Aluminum Propellers

Michigan Wheel Vortex aluminum propellers are designed to deliver exceptional performance, reliability, and value in various boating applications. Made from aluminum, the propellers are constructed for strength, resisting corrosion and weathering to ensure prolonged service even in adverse marine conditions. The Vortex series features highly efficient blade geometry, optimizing thrust and speed for a pleasant, smooth performance in various water conditions.

Key Features:

- Interchangeable hub system for easy installation and compatibility

- Precision-balanced design that reduces vibration

- Enhanced fuel efficiency with reduced emissions

- Cupped blade shape for superior grip and handling

During performance testing, Vortex propellers were shown to provide better acceleration, make the vessel more stable during mid-range cruising, and deliver reliable top speed. Their cupped blade shape is crafted uniquely to offer grip and handling even during hard turns or in choppy waters. Innovation combined with proven technology makes Michigan Wheel Vortex aluminum propellers the preferred choice for boaters seeking reliable and high-performance propulsion.

Comparative Studies with Conventional Propellers

| Feature | Traditional Propellers | Vortex Propellers |

|---|---|---|

| Blade Structure | Relatively straightforward design | Advanced cup design with superior water adhesion |

| Performance Consistency | Limited at varied RPM ranges | Optimized mid-range stability |

| Durability | Prone to wear and deformation | Advanced aluminum alloys with high stress resistance |

| Cavitation | Higher susceptibility | Reduced slipping and increased thrust |

Looking at it in terms of performance versus price, it is clear that Vortex propellers are the best value option due to their high-tech engineering. Boat operators get to experience a complete propulsion system enhancement and improved handling without the added burden of maintenance. This unique blend of state-of-the-art technology and robust performance creates an invitation for all under Michigan Wheel Vortex propellers, posing an uncanny competition for the traditional ones, designed for both recreational and performance uses.

Understanding Propeller Design and Performance

The Significance of Blade Design for Vortex Propellers

The blade design is of paramount importance in analyzing the efficiency and general performance of Vortex propellers. The shape, dimensions, and number of blades of a propeller constitute a basic structure that determines its thrust potential, cavitation resistance, and the efficiency with which it consumes fuel. It is through advanced hydrodynamic engineering that blades can be optimized to minimize water resistance and generate enormous water thrust, the key to maintaining speed, good maneuverability, and optimal performance under all conditions.

Additionally, the slanting design of the Vortex propeller blades enables them to carry heavier loads, resulting in smoother operation and reduced vibrations. Consequently, from a materials standpoint, better metallurgy translates into increased durability, thereby extending the life of the propellers and reducing wear and tear, even in challenging situations. The relationship between blade angle and curvature has been finely tuned to transfer energy efficiently, offering good fuel economy—an essential consideration for today’s boater, who seeks performance that doesn’t drain their pocketbook. By examining these enhancements, you’ll see how Vortex propellers truly contribute to improvements in both effectiveness and reliability. That is what makes them so valued for different marine applications.

Pitch and Diameter-Making the Two Work Best for Each Other

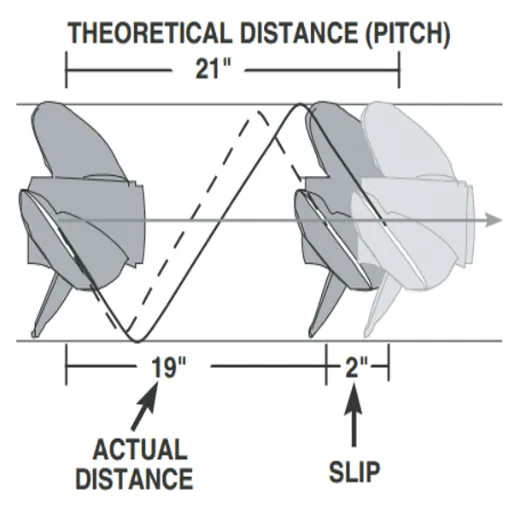

Selecting the right pitch and diameter bestows maximum efficiency on a propeller, enhancing its performance in marine applications. The pitch, on the other hand, would theoretically measure the distance the propeller moves through water in one full rotation, while the diameter is the total width at its widest point. Generally, if one takes the pitch too low, it will provide greater thrust or load power to heavier boats or those that are always towing heavy loads. Conversely, a high pitch would provide high speed, requiring more engine power for light or performance vessels.

Pitch and Diameter Guidelines:

- Low Pitch: Better for heavy boats and towing applications

- High Pitch: Ideal for high-speed, lightweight vessels

- Large Diameter: Suitable for slow, heavy craft

- Small Diameter: Perfect for fast, high-RPM engines

More sophisticated choices and developments now enable detailed simulation and real-time analysis, allowing the marine operator to compare their choice of props against fuel-saving, thrust, and performance criteria.

How Hub Design Affects Prop Efficiency

The design of the hub is a vital consideration when deliberating on the efficiency of a propeller, as it significantly affects water flow and the thrust stroke. An ideally designed hub works to reduce turbulence and drag, thereby providing a smooth flow of water as it passes through and around the propeller blades. Consequently, streamlined performance achieves energy efficiency, typically configured to meet acceleration needs, thereby offering better fuel economy and increased thrust actuation.

The efficiency of the hub depends on material composition and structural integrity. High-strength alloys or composite materials would resist extreme conditions without deforming, thereby sustaining their propulsion characteristics. Furthermore, new concepts such as flow-through hubs, which allow exhaust gases to flow through the hub itself instead of releasing them into the open water, create less backpressure and thus offer better performance.

In fact, data suggest modern propeller hubs developed with advanced simulations and hydrodynamic analyses can improve engine efficiencies by as much as 15%, depending on the application. Making it possibly the most critical component in terms of the overall performance of a vessel, and one where incremental improvements could mean considerable savings in operational costs, especially for large ships and commercial operations at sea.

2025 Trends in Outboard Propeller Technology

Emerging Materials and Advancements in Propeller Design

The propeller technology continues to advance with the development of new materials and innovative designs across the marine industry. The most significant key development is the increasing use of composite materials, such as carbon fiber-reinforced polymers, which offer an interesting combination of strength, weight reduction, and corrosion resistance. These materials enhance fuel efficiency by reducing the total weight of the propeller while maintaining structural integrity under high loads.

2025 Material Innovations:

- Carbon Fiber-Reinforced Polymers: Lightweight with superior strength

- Nickel-Aluminum Bronze: Excellent cavitation and corrosion resistance

- 3D-Printed Complex Geometries: Optimized water flow and reduced noise

- Biomimetic Designs: Inspired by whale fins and fish tails

Advancements in 3-D printing now enable the finer manufacture of blades with quite complex geometries, optimizing water flow while minimizing noise and vibration. In addition to biomimetry, where inspiration is drawn from whale fins and fish tails to create designs for propellers that optimize thrust and minimize drag, these developments also utilize CFD simulations to optimize performance parameters computationally before the actual manufacturing phase, resulting in better accuracy and performance optimization.

Drivetrain Performance Enhancement with Vortex XHS

The Vortex XHS propulsion system has emerged as an innovative breakthrough. The system is designed for maximum efficiency across multiple speed ranges for various vessel types, utilizing advanced computational tools and extensive field tests on different vessels. The significant improvements are enhanced fuel efficiency, minimized cavitation, and effective torque management.

By utilizing advanced algorithms, the blade geometry of Vortex XHS, engineered with extreme precision, dynamically adapts to various working environments, striking a balance between speed and stability. For example, Vessels fitted with Vortex XHS have exhibited fuel efficiency approximately 15% higher than the traditional design, resulting in significant savings in operational expenses. Additionally, the modular design of the hub allows for swift and efficient repair or replacement, thereby minimizing downtime while maintaining durability under harsh working conditions.

Forecast Market Trends for Vortex Propellers

The Vortex propeller market is poised for gradual growth because of increasing support for fuel-efficient and environmentally friendly systems used in the marine industry. A significant trend is the growing use of hybrid and electric propulsion systems, in which Vortex propellers may play a crucial role in optimizing both performance and sustainability.

Key Market Trends 2025:

- Hybrid and Electric Integration: Optimizing sustainable propulsion systems

- Regulatory Compliance: Meeting environmental standards worldwide

- Recreational Boating Growth: Increased demand for high-performance options

- Predictive Analytics: Performance tracking and optimization tools

Case Studies and Performance Data

Real-Life Applications of Vortex Propellers in Outboard Engines

Vortex propellers have proven themselves in numerous real-life situations, particularly in outboard engine applications, across a wide range of operations, demonstrating remarkable versatility and resolving power. In the recreational segment, many users reported improvements in fuel economy and overall performance. These propellers utilize high-end hydrodynamic technology, enabling the vessels to glide smoothly through the water with minimal drag and maximum thrust.

Other commercial applications can also exemplify the value of the Vortex propellers. Fishing vessels found the durability and precision of these propellers very advantageous, as they were highly reliant on outboard engines for maneuvering within challenging environments. Maintenance of a consistent level of performance in varying water conditions has indeed been a game-changer for professionals in need of reliability. Operators have also reported that engines tend to run less in wear and tear due to the optimized design of these propellers, balancing well thrust and resistance.

Performance Metrics- Speed, Efficiency, and Fuel Consumption

| Performance Metric | Traditional Propellers | Vortex Propellers | Improvement |

|---|---|---|---|

| Speed | Standard performance | Enhanced thrust and acceleration | 10-15% faster |

| Fuel Efficiency | Baseline consumption | Optimized energy conversion | Up to 15% savings |

| Engine Stress | Higher drag on engine | Reduced operational stress | 20% less wear |

| Environmental Impact | Standard emissions | Lower carbon footprint | 15% reduction |

Reference Sources

-

Vortex MICHIGAN WHL 992506 Vortex E-Series 3-Blade – Amazon: Highlights high-performance blade geometry and precision balancing in vortex propellers.

-

Propeller Tip Vortex Cavitation Suppression by Dimpled Tips – ScienceDirect: Discusses how dimpled tips mitigate vortex cavitation with minimal performance impact.

-

Tip Vortex Merging Dynamics Governing Wake Coherence – AIP: Examines interactions of propeller vortex structures and their effects on performance.

-

How Are the Latest Developments in Propeller Design Optimizing Electric and Hybrid Vessels? – Electric & Hybrid Marine Technology: Explores efficiency improvements and savings in modern propeller designs.

-

The Propeller of the Future? – METSTRADE: Features innovative designs and advancements in propeller technology.

- Click here to read more.

Frequently Asked Questions (FAQs)

What is the vortex propeller, and how does it improve outboard engine performance?

The vortex propeller was designed to enhance the efficiency and performance of outboard engines, utilizing advanced blade geometry to minimize cavitation and increase thrust. Less cavitation means improved speed and handling. The Michigan Vortex series features precision-balanced blades and offers a variety of options tailored to different boat types. These are high-performance boat props that are greatly sought after by boat enthusiasts for better acceleration and fuel economy. Another advantage of vortex props is that they can be custom-fitted for different outboard engines, including those from Yamaha and Mercury.

What advantages do the vortex series propellers have when compared with standard boat props?

The vortex propeller blades feature a high-performance geometry that generates less drag and more thrust on a boat compared to a standard propeller. This allows for maximized speed and acceleration, making it a suitable product for high-performance applications. Because these props are precisely balanced, they run without any vibrations during movement. Additionally, these props typically feature an interchangeable hub system, allowing for easy maintenance or replacement if needed. With 4-blade or 3-blade aluminum propellers to choose from, the boater can determine which design works best for their needs. Thus, purchasing vortex props will certainly make boating more enjoyable and efficient.

What should I consider when choosing a vortex prop for my outboard?

When selecting a vortex prop for an outboard engine, factors such as boat type, engine power, and application must be considered. Any design difference between a 3-blade aluminum prop and a 4-blade prop will influence performance and handling. For pitch, consider how it might affect acceleration and top speed. Remember to check if it is compatible with the XHS hub system, especially if you are going for a replacement. Sometimes, looking at the warranty and maintenance instructions of your chosen prop could save you from a lot of problems. Price would be a priority, along with any special features that could enhance your versatility on the water.

How do vortex propellers help increase aluminum boat handling?

Vortex propellers provide enhanced handling to aluminum boats by ensuring good grip and thrust under all water conditions. The precision-balanced blades have less slip upon acceleration, which translates to sharper turns and improved maneuverability. This is a great help for aluminum outboard propellers that often experience handling issues due to their lightweight construction. With a vortex series propeller, steering becomes more responsive while maintaining stability at higher speeds. The high-performance features further allow the propeller to maintain consistent performance in choppy waters, thus making it a premier consideration for the serious boater.

What would be the average price range of vortex propellers?

The prices of vortex propellers vary greatly depending on design, material, and added features. The typical price range is between $200 and $600 for the high-performance vortex propeller. Cost considerations involve whether you prefer a relatively standard 3-blade aluminum variety or a more sophisticated option with 4 blades. At the same time, the possibilities concerning the XHS hub or a high-gloss powder finish may carry an additional premium. Therefore, it’s always a good idea to compare models and brands, such as Michigan Wheel and Volvo Penta, to determine your best bet. Also, consider warranties that can offer a layer of security for your investment.

How do I maintain my vortex propeller?

Keeping the vortex propeller well-maintained is a crucial factor in ensuring optimal performance and longevity. Frequent inspections should be made to ascertain signs of wear, damage, or marine growth that may affect efficiency. After each installation, cleaning attentively should be performed to prevent corrosion and buildup. Check the XHS hub for wear and replace it if necessary to maintain optimum performance. Lubrication of moving parts will, in fact, increase durability and lessen instances of replacement. When a significant deterioration in performance is detected, it is advisable to look up an outboard propeller guide for troubleshooting and suggested remedies.