Selecting the prime propeller for a Yamaha outboard will bring in all the magic to your boating experience. From higher speed, or even fuel economy, to simply better handling, proper choice of the prop is a very important step in gaining top performance from one’s boat. With a large selection available and all sorts of technical specifications, finding just the right thing for your Yamaha outboard can be really frustrating. Hence, to make things easy for you, we have created this exhaustive guide for 2025 to help you with the entire gamut of knowledge needed on Yamaha outboard propeller replacement. From the things to look out for to pro tips on making the best choice, you will have all the knowledge to extract the most from your time on the water. Enjoy this boating experience upgrade!

Identifying the Need for Replacement

Visual Cues of Damage

A damaged propeller adversely affects a boat’s performance and efficiency. One of the more obvious types of damage is wear on the blades. Check for cracks, bends, or chips on the edges of the propeller. Even the tiniest imperfection will hinder proper water flow and will diminish propulsion force. Therefore, every time you collide with an invisible underwater obstacle or debris, make it a point to inspect the propeller.

In addition, during operation vibrations should be observed as an indicator. Excess vibration at cruising speeds can be due to props that are either imbalanced or deformed. It also puts added stress on the engine and drivetrain, and further problems may result if the repair is delayed.

Sometimes it feels as if the boat takes forever to reach its usual top speed or it plods along being just a wee bit slower and helplessly thirsty for fuel. It happens when some sort of damage is done to the propeller. In such cases, these performance issues become your best indicator that your propeller may require either fixing or replacing. Gathering such visual and operational clues will always make for smooth sailing and safe, fun times on the water.

Performance Changes Indicating Wear

Changes in boat performance are among the most prominent signs of propeller wear. When a boat is having difficulty maintaining speeds it normally has or is taking a longer time to get onto plane, it might be a sign that the propeller has been damaged or perhaps worn out. Likewise, soaring fuel consumption with no changes in boat usage can also be a major sign that something is wrong with the propeller.

The engine noise and vibrations vary when there is a culprit in the propeller. The vibrations indeed occur when the propeller blades are bent, chipped, or unbalanced. An unbalanced propeller is never good because it places stress on the engine and the drive train, leading to additional damage.

To avoid excessive wear, these inspections must be carried out. Look out for any visible damage such as nicks, cracks, or corrosion on the blades. These need to be promptly fixed. It is also important to pre-check for proper mounting of the propeller on the shaft. By taking proactive measures to check and maintain your propeller, its life will be further elongated; hence, increasing the general efficiency and safety of your boat.

Regular Maintenance Checks

Performing regular maintenance checks is paramount for maintaining a propeller in good condition. Start paying attention to the propellers before and after every outing. Observe any signs of physical damage such as dents, cracks, or bent blades, which can greatly reduce performance and efficiency. If any damage is detected, repair it immediately as neglect can create dire troubles during operation.

Next, make sure that the propellers are firmly fixed to the shaft. Loose or improperly seated propellers pose a risk to the engine and decrease your boat’s performance. In the interest of your maintenance program, with some degree of frequency, remove the propeller to check for fishing lines or debris that might be twisted about the shaft, as if left unattended, these could lead to corrosion and further problems.

Making it a regular task to clean the propeller prevents marine growth or debris from accumulating and obstructing the efficiency of your boat’s propulsion system. For optimum care, use either a non-abrasive scrub or a special cleaning solution. You may then coat the propeller surface with a period of protective film to hasten corrosion reduction and lengthen their lifespan. All one has to do is to adhere to these steps to enjoy safe and efficient boating while also extending their equipment’s service life.

Choosing the Best Replacement Propeller

Factors to Consider Based on Boat Type

When choosing the right replacement propeller for your boat, it is a point of consideration that the particularities of the vessel and the type of utilization it is put to be considered. Different boats have different requirements for performance, and a good propeller could mean that a boat performs efficiently versus being sluggish and awkward. Consider the following based on your boat type:

🚤 Recreational Boats

Recreational boats, basically taken for fun, must look for propellers that would balance speed and fuel consumption. Aluminium utilizations are commonly considered because of their cheapness and versatility, whereas the stainless steel ones offer superior performance and robustness when used more often.

🎣 Fishing Boats

Fishing boats often see a need for handling at slow speeds, with trolling the calm waters presenting such situations. A propeller with less pitch would do wonders as it facilitates control and makes more optimal use of engine power at low speeds.

⚡ Speedboats and High-Performance Vessels

Speedboats and high-performance vessels want the propellers to provide maximum speed and acceleration. Stainless steel props with increased pitch and special designs-that is, cleaver or chopper types-are suitable in attaining the best speed and performance under higher loads.

🛥️ Pontoon Boats

Propellers that support heavy loads and smooth, steady cruising are appropriate for pontoon boats. Aluminum three-blade props are commonly installed although stainless steel four-blade props provide better thrust and stability, useful when carrying additional passengers or gear.

⛵ Sailboats

In sailboats fitted with auxiliary engines, the need of propellers that give efficient thrust with minimum drag arises. Folding or feathering types are favored as these diminish resistance while the engine is shut off, allowing for better sailing performance.

In knowing all about the pitch, diameter, material, and number of blades in relation to your boat’s design and purpose, you will be able to make a fair and informed decision. Along with your newly found knowledge, you should also consider the engine specifications to be able to select a propeller fitting the particular requirements of your boat.

Understanding Engine Specifications

The most important thing in choosing the ideal propeller for your boat is to understand the engine specifications. These engine specifications like horsepower, RPM range, and gear ratio will go a long way to determining the kind of propeller that is going to provide the best results for your boat. For example, a high horsepower engine paired with a propeller with the wrong pitch is utterly ineffective-winning in overloading the engine or not using its full potential. Likewise, by matching the diameter and pitch of the propeller to the RPM range recommended by the manufacturer, you avoid over-stressing the engine, leading to smoother operation and longer engine lifespan.

The gear ratio of your boat engine is another important factor to be considered. Gear ratio is simply the number of revolutions made by the propeller to every revolution of the engine. Lower gear ratio propellers can accept larger diameters; such propellers usually seek thrust for towing or in rough waters. Higher gear ratio requirements go to a smaller diameter propeller to ensure greater boat speeds. By understanding the exact balance between engine power and propeller features, one can optimize fuel economy and performance tailored to boating needs.

In addition to the engine specifications, it is critical to consider the environment, water conditions, and usage for the boat. Depending on its use in salt versus fresh water, heavy versus light loads, or top speed versus maximum turning, some alterations in prop design may be necessary. Reading your engine manual, consulting with the manufacturer, and trying different options for the prop could give crucial information on whether they meet the engine needs well. Proper coordination means operation is smooth, wear is less, and you cherish the journey.

Intended Use and Performance Requirements

This is to say that your boat’s selection of the right propeller has got everything to do with the potential use and performance it expects to deliver. Whether you have a fine cruise, watersport, fishing, and commercial application on your mind, your propellers will strongly determine the efficiency and output of the vessel. Wakeboarding or water-skiing tow operations require possibly low pitch propellers for great acceleration, while cruising calls for high pitch propellers to maximize top speed and fuel economy.

In addition, the body of water where you operate-your salt or freshwater-body will affect propeller endurance and material selection, with stainless steel considered stronger and with higher resistance to corrosion, thus making it the best for saltwater environment. In favor of aluminum propellers, general-purpose use is cheap in freshwater application. Contemporary engineering of propellers embraces the application of modern hydrodynamics, so variable pitches can cater to all sorts of demand, maintaining the vessel to suit many conditions efficiently.

A mixture of relevant data, such as the engine specifications of the boat, weight, and horsepower on one side, and technical expertise on the other, makes much easier to obtain the best propeller match. Nowadays, advanced propeller calculators and other tools suggest options on the basis of load capacity, cruising speed, and vessel activities, among others. These devices eliminate guesswork, so you attain the targeted performance that could have been first undermined by a poorly matched propeller capable of straining the engine or otherwise leaving room for that frustrating boat experience.

Exploring Propeller Materials

Advantages and Disadvantages of Aluminum

✅ Advantages of Aluminum:

- ➤ Lightweight – Aluminum tends to be lightweight when stacked against other materials. Thus, it is simpler to work with; the load on the engine is much less.

- ➤ Affordable – Aluminum has been ranked among the cheapest materials for propellers, and it’s a brilliant buy for cash-conscious buyers.

- ➤ Corrosion Resistance – One of the good features is that it forms a native oxide layer, thereby offering a fair level of corrosion resistance, at least with fresh water.

- ➤ Flexibility – Aluminum propellers put in place provide slight flexing under heavy loads that could prevent an impact from damaging the drivetrain.

- ➤ Availability – Aluminum propellers are highly available, making them easy to source when one requires them for replacement.

❌ Disadvantages of Aluminum:

- ➤ Less Durable – Aluminum, in comparison with stainless steel, is less durable as it bends and chips easily.

- ➤ Slightly Less Efficient in Performance – Its lightness might tend to reduce somewhat the speed and load performance.

- ➤ Limited Corrosion Strength in Saltwater – Aluminum is resistant to freshwater corrosion but will not stand well in saltwater unless correctly coated.

- ➤ Shorter Lifespan – Aluminum propellers generally tend to get worn out much faster than those made out of sturdier materials like stainless steel.

- ➤ Heat Sensitivity – Aluminum melts at a much lower temperature and would be rendered useless by intense heat or friction.

Why Choose Stainless Steel?

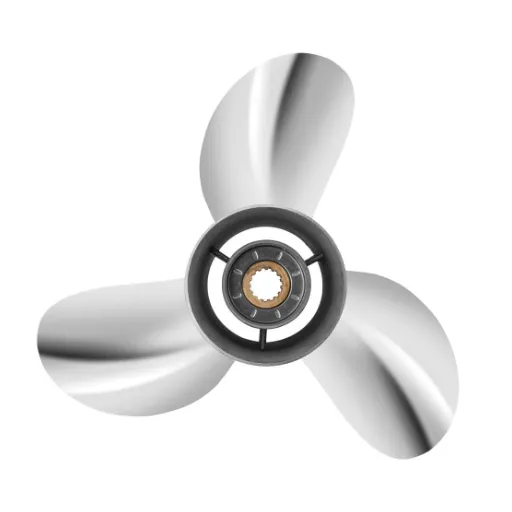

With its unprecedented durability and performance, stainless steel is often thought of as a boat propeller material. In stark contrast with aluminum, stainless steel is far stronger to resist high torque and might not bend under heavy loads, unlike weaker aluminum. This inherent strength and vigor provide for better performance, mainly at high speeds or rough waters. While stainless steel may present a higher initial cost, its greater resistance to impact damage and resultant longevity certainly make it one of the better investments.

Another advantage, maybe, offered by stainless steel is its excellent corrosion resistance, specifically when acting with saltwater. Aluminum ordinarily requires some protective coatings being applied to preserve it from saline conditions, whereas stainless steel remains in good condition due to its significant corrosion resistance brought about by the presence of chromium. In view of this, such a material can nicely meet marine applications where saltwater and adverse environmental conditions are constantly acting upon it. Moreover, stainless steel does not tarnish with time, thereby enabling the vessel to look good from day one.

From a performance point of view, stainless steel propellers are traditionally considered to have been made with absolute precision. Their body is rigid and does not bend even slightly when spinning through water, allowing better fuel efficiency and smoother navigation. Advances in manufacturing have made it feasible to create extremely complex blade shapes for greater acceleration, top speed, and handling in general. For reliability, durability, and maximum performance in marine activities, stainless steel is most often opted for-propellers going for great value in the harsher environment.

Composite Propeller Options

Composite propellers are fast becoming the preferred choice for those in the boating trade who desire a lightweight and inexpensive set of propellers. These types of propellers are built from advanced polymer materials and are expected to provide consistent performance while resisting corrosion and impact damage. They have an extremely lightweight construction, which reduces engine load and helps save fuel. Additionally, their flexibility gives them an impact absorption quality, so they are less likely to get damaged upon impact compared to metal propellers.

Composite propellers boast yet another advantage: their price. Composite propellers tend to be less expensive than their stainless steel or aluminum counterparts, making them an attractive option for recreational boaters wishing for reliable work without emptying their pockets. Lower cost does not suggest that composite propellers are brittle; they certainly boast decent durability to handle regular use, especially in freshwater settings wherein corrosion is less of a concern. Modular composite propeller systems are offered by many manufacturers wherein you can replace just one blade rather than the whole propeller, making these even more cost-efficient.

However, it is important to note that composites may not be the choice for extreme conditions or high-performance applications. While they are tough, composites generally lack the structural strength of stainless steel, which may be a drawback at high speeds or under heavy loads. A composite prop, on the other hand, provides a nice compromise in efficiency, ease of application, and pricing for the everyday casual boater. By comparing intended use and environmental conditions, the boater may decide whether composite is the propeller for them.

Step-by-Step Replacement Process

Tools and Equipment Needed

A boat propeller may be pretty daunting to replace; hence, below comes a list of tools and equipment for prep to safe and efficient handling:

| Tool/Equipment | Purpose |

|---|---|

| Propeller Wrench | A tool designed to fit snugly on the prop nut, avoiding damage to the nut with removal. |

| Rubber Mallet | To be used for loosening or slight adjustments to the components without harming them. |

| Prop Puller | Used for taking off a stuck propeller from the shaft. |

| New Propeller | Ensure this replacement fits the specs of your boat’s engine and the intended use. |

| Grease or Anti-Seize Compound | Helps keep the propeller shaft from corrosion and smears its easy removal later. |

| Cotter Pins | Percentage for the old ones used for holding the propeller nut. |

| Work Gloves | Keeps your hands protected from sharp edges or debris. |

| Clean Towels or Cloth | For inflicting dirt, grease, or water to keep the working environment clean. |

If purchased beforehand, these tools will ensure the smooth replacement process and will not turn into unexpected interruptions. Always cross-check these with the boat’s manual for specific compatibility and maintenance recommendations.

Removing the Old Propeller

- Position the Engine: Tilt the engine upward to facilitate better access to the propeller. Note that the boat must be safely docked, or the engine should be on dry land to avoid any undesired outcomes.

- Secure the Propeller: Pry one piece of wood, or something else, in between the propeller blades and the lower unit to keep the propeller from turning while being worked on.

- Remove the Cotter Pin: Straighten out the old cotter pin and pull it out well enough to keep it from holding the propeller nut in place. Needle-nose pliers come in handy for a step like this.

- Unscrew the Propeller Nut: With the appropriately sized wrench or socket in hand, loosen and remove the propeller nut. Keep it safe-you may need it for refitting.

- Slide Off the Propeller: Carefully pull the propeller off the shaft. If the propeller is stuck due to corrosion or dirt, gently wiggle it a bit, or apply some penetrating lubricant to free it up.

- Inspect the Shaft: After removing the propeller, look at the propeller shaft for any damages; check corrosion, and fishing line wrapped around the shaft. Remove those occurrences and clean that shaft well.

Following these steps, you can safely and efficiently remove the old propeller from the boat and pave the way for a new installation. For any specifications or troubleshooting tips, always refer to the manual for the boat to keep to proper maintenance techniques while working on it.

Installing the New Yamaha Boat Prop

Installing a new Yamaha boat propeller is a straightforward task that does much to upgrade the performance and efficiency of your boat. After applying some marine grease to the propeller shaft to aid installation and prevent corrosion, you would want to slide the propeller carefully onto the shaft, paying attention to the splines so they would not be damaged. After installing the washer and nut, tighten them with a wrench, following the torque value specified by the manufacturer. The correct torque value must be observed to avoid over- or under-tightening, which leads to a mechanical curse.

After securing the nut, place a new cotter pin in the shaft hole through the hole in the shaft and bend the ends to lock it in place. The cotter pin is an important safety part, as it keeps the propeller nut secure during working operations. At last, rotate the propeller with your hand to feel it is rotating freely with no wobbling and no interference. If any resistance or abnormal movement is felt, check the installation alignment again.

The best along any way is to support your new prop from time-to-time after installation itself and during regular maintenance. Both proper fitting and periodical checks would protect your investment and would keep your boat performing well in the water.

Maintenance Tips for Longevity

Regular Cleaning and Inspection

To engender durability and promote its optimal functioning, a cleaning and inspection schedule needs to be maintained for the propeller. Post- trip, any debris must be removed from the propeller-whatever that might be; seaweed, a fishing line, and so on. Cleaning is important: salt residue and grime could cause corrosion if left uncleaned, along with other buildup that would reduce the efficiency of the propeller over time. For this cleaning process, I use a soft brush and light detergent to avoid scratching or damaging the propeller.

While inspecting, I carefully check the blade surface treatments from wear to dents or cracks. Small dents can usually be repaired; however, if the blade is more severely damaged, it would probably have to be replaced in the interest of safety and to maintain the performance of the boat or prevent further harm to the engine of the boat. Furthermore, I check if the propellers are mounted securely and properly. It should not be loose and free, as in operational difficulties looms in the air.

In addition, I apply a light coat of marine-grade lubricant for rust prevention and smooth operation. Having this in my mind while on the water prevents arising of any sudden counter issues and extends the life of the propeller. Proper maintenance is a small but very important step that guarantees the enjoyment of my boating experience.

Using Anti-Fouling Coatings

Anti-fouling coatings thus play an important role therein the preventive maintenance of any vessel with respect to performances and longevity. These coatings are computed baiting adverse effects that could stick to the hull of the vessel from marine organisms-algae, barnacles, and mollusks. On the presence of fouling, a vessel would either look ugly or offer less efficiency by way of drag. More drag means more fuel is consumed and the vessel moves at slow speeds, leading to greater appreciation of the anti-fouling coating in the eye of any boat owner.

Modern anti-fouling techniques have thus developed to provide an array of choices according to needs and environments. Hard coatings would be suitable for vessels generally operating at very high speeds as they provide a durable and smooth surface. Ablative coatings, on the other hand, slowly release biocides to ensure protection against fouling. In more environmentally-conscious product lines, one has siloxane or fouling-release coatings that ease the removal of foulers without using harmful chemicals. The choice of anti-fouling coating will depend on the usage pattern of the boat, on its location, and environmental considerations so correct anti-fouling does have a bearing on the ultimate performance of the boat.

For antifouling paints to truly work effectively, they must be carefully applied and maintained on a regular basis. Typically, the procedure would include cleaning the hull of any fouling that may be present, sanding it down to smooth, and then applying at least a couple of coats of the paint. Many manufacturers suggest bearing the cost of application of one coat every one or two years for continued protection. Environmentally friendly compositions, from which a vessel can indeed be protected, are now being developed to reduce environmental iimpact as far as practicable. Given good upkeep and appropriate coating choice, antifouling methods can really save on costs, lift performance, and restore in some way marine ecology.

Ensuring Compatibility with Electric Propulsion

In the interregnum between conventional and electric propulsion for marine applications, one cannot put aside issues of compatibility with other current systems and technologies. In any case, in the modern context, electric propulsion systems have only really come to be considered for use in mercantile and recreational craft, as they offer compelling advantages such as pollution reduction, cheap operational costs, and the silent running feature. Nevertheless, integrating such systems needs analysis of vessel design and structure, weight distribution considerations, and onboard power requirements.

This is one important aspect to make compatibility function: choosing components that can interact smoothly with electric systems. For example, some hull design modifications on the electric boat may be required to complement the torque characteristics of the electric motor and hence optimize energy usage. Efficient energy management systems are also crucial as they control power allocation, monitor battery health, and maximize the charge-discharge cycles of advanced lithium-ion or solid-state batteries. A proper combination of renewable energy sources within the propulsion system will boost the energy efficiency of the boat even further and serve to decrease the dependency on shore-side charging infrastructure.

Lastly, regulatory compliance and environmental considerations have become important factors in the decision to adopt electric propulsion systems. Increasingly large markets are implementing stricter emissions testing in prompt support of electric or hybrid propulsion systems to induce shipbuilders and owners to invest in greener technologies. Ports and marinas are now being upgraded to provide charging facilities to match the increasing need for electric vessels. Thus, by addressing these technical, structural, and regulatory aspects, vessel operators guarantee a smooth and future-proofed transition to electric propulsion, marking a great step towards sustainable and eco-friendly marine operations.

References

- Yamaha Outboard Service Manual – Northwest Nazarene University

Provides detailed guidance on removing and installing a new propeller, along with other maintenance instructions. - Yamaha Outboard Service Manual – University of Iowa

Includes step-by-step instructions for propeller replacement and other essential maintenance tasks. - Yamaha Outboard Repair Manual – Yuin University

Covers routine care, including propeller replacement, oil changes, and spark plug maintenance. - Click here to read more.

Frequently Asked Questions (FAQ)

❓ Why is it important to change a Yamaha outboard propeller?

YAMAHA Outboard propeller replacement is important to maintain the best performance. A worn or damaged propeller causes the vessel to guzzle fuel, have crushed hole shot, and underperform. Propellers should be regularly inspected to keep your Yamaha engine running smooth and efficient.

❓ How to make sure that my new prop for my Yamaha outboard is properly loaded?

To be sure of proper loading, look at the pitch and diameter of the new prop. Use our outboard propeller guide to choose a prop that gives the right mixture of speed and power. If improperly loaded, the engine will strain and lose performance.

❓ What should I consider when selecting a new prop for my Yamaha engine?

Choosing a new prop for your Yamaha engine really depends on the boat type, the specific fishing, or cruising activities it will be engaged in, and also the performance characteristics that you desire such as hole shot and top speed. Furthermore, make sure the prop is applicable for your selected Yamaha outboard.

❓ How often should I change my Yamaha outboard propeller?

You should inspect your Yamaha outboard propeller at regular intervals, with emphasis on the occasions when extensive use has taken place or if you suspect it to be having performance troubles. Generally speaking, consider replacement if significant damage, wear, or performance below expectations is apparent.

❓ Can I put Michigan Wheel propellers on my Yamaha outboard?

Yes, provided the Michigan Wheel propeller is the correct one for your outboard model. In other words, verify that the prop size and design are suitable for optimum performance of your Yamaha engine.

❓ What are the benefits of using stainless steel propellers for Yamaha outboards?

Stainless steel propellers provide a number of advantages for Yamaha outboards, including better durability, performance, and efficiency. Because they resist corrosion better than aluminum or aluminum alloy, they help with better acceleration and increased top speeds. So, if you want a quality prop with that extra edge in performance, you may consider stainless steel.

Ready to upgrade your boating experience? Choose the right Yamaha propeller today and enjoy optimal performance on the water! 🚤